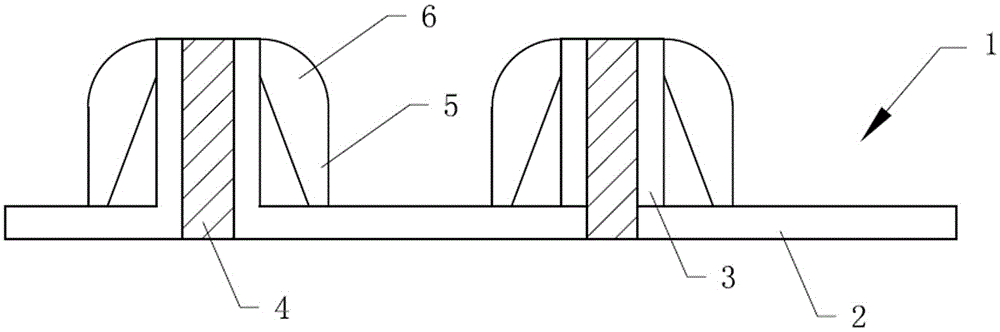

PP high-modulus twining structural wall corrugated pipe and manufacturing method thereof

A structural wall, high modulus technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of pipe deformation and insufficient rigidity, and achieve the effect of enhanced strength, best performance, and firm welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The manufacturing method of the bellows includes the following steps:

[0032] a. Extruding shaped strips: extruding continuous shaped strip units through the first extruder;

[0033] b. Shaping of special-shaped strips: the special-shaped strip unit is cooled and shaped at 55°C under the conditions of wind blowing and air pressure spray by moving the forming mold; after cooling and forming, preheating and drying are carried out;

[0034] c. Winding special-shaped strips: spirally wind two special-shaped belt units side by side on the forming drum, and form a gap of 100mm between the flanges on adjacent special-shaped belt units;

[0035] d. Welding: Continuously extrude molten plastic melt into the gap through the second extruder;

[0036] e. Pressing: apply opposite pressure on the outer side of the flange on the adjacent special-shaped belt unit through the pressure roller, so that the flange on the adjacent special-shaped belt unit and the plastic melt in the gap a...

Embodiment 2

[0041] The manufacturing method of the bellows includes the following steps:

[0042] a. Extruding shaped strips: extruding continuous shaped strip units through the first extruder;

[0043] b. Shaping of special-shaped strips: the special-shaped strip unit is cooled and shaped at 60°C under the conditions of wind blowing and air pressure spray by moving the forming mold; after cooling and forming, preheating and drying are carried out;

[0044] c. Winding special-shaped strips: spirally wind two special-shaped belt units side by side on the forming drum, and form a gap of 120mm between the flanges on adjacent special-shaped belt units;

[0045] d. Welding: Continuously extrude molten plastic melt into the gap through the second extruder;

[0046] e. Pressing: apply opposite pressure on the outer side of the flange on the adjacent special-shaped belt unit through the pressure roller, so that the flange on the adjacent special-shaped belt unit and the plastic melt in the gap a...

Embodiment 3

[0051] The manufacturing method of the bellows includes the following steps:

[0052] a. Extruding shaped strips: extruding continuous shaped strip units through the first extruder;

[0053] b. Shaping of special-shaped strips: the special-shaped strip unit is cooled and shaped at 58°C under the conditions of wind blowing and air pressure spray by moving the forming mold; after cooling and forming, it is then preheated and dried;

[0054] c. Winding special-shaped strips: spirally wind two special-shaped belt units side by side on the forming drum, and form a gap of 110mm between the flanges on adjacent special-shaped belt units;

[0055]d. Welding: Continuously extrude molten plastic melt into the gap through the second extruder;

[0056] e. Pressing: apply opposite pressure to the outside of the flange on the adjacent special-shaped belt unit through the pressure roller, so that the flange on the adjacent special-shaped belt unit and the plastic melt in the gap are fused in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com