Anti-shearing self-recovery voltage-withstanding cable

A self-restoring and anti-shearing technology, applied in the field of power cables, can solve problems such as poor buffering and compression resistance, low practicability, and core wire damage, and achieve the effects of buffering extrusion, comprehensive protection, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

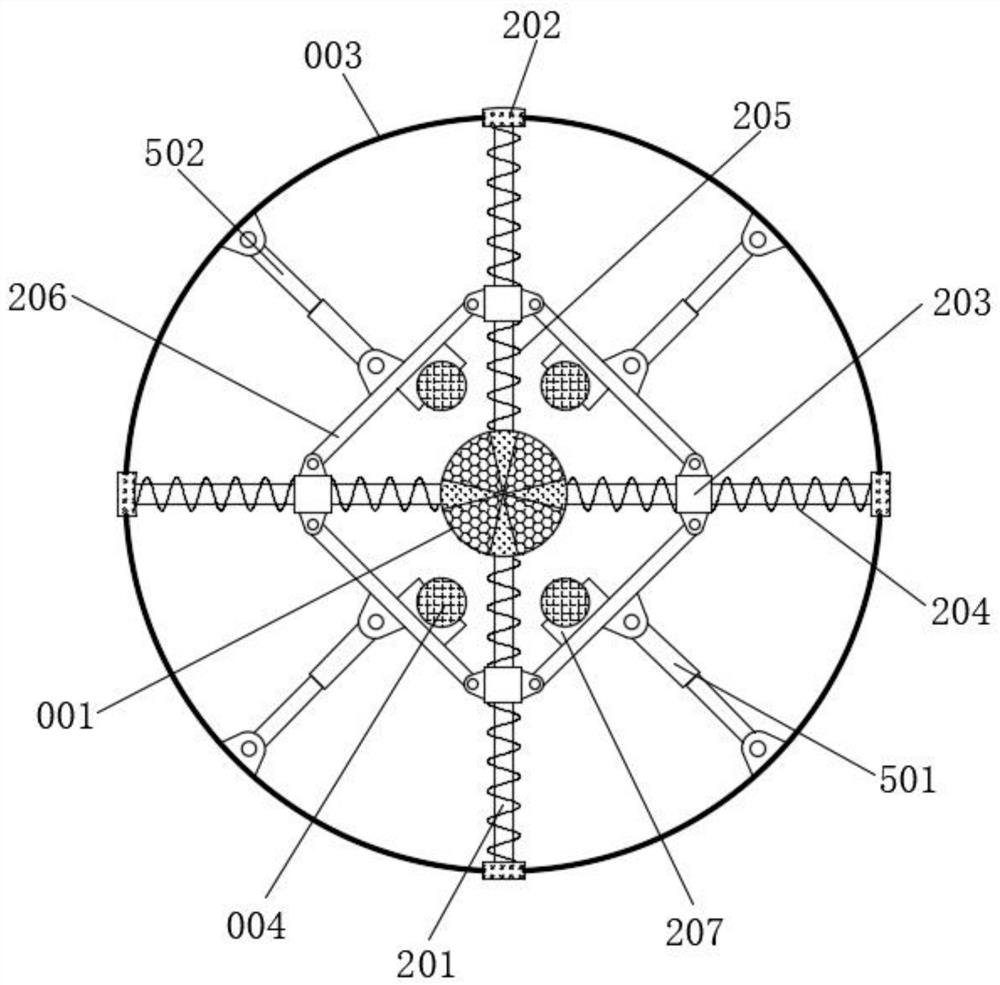

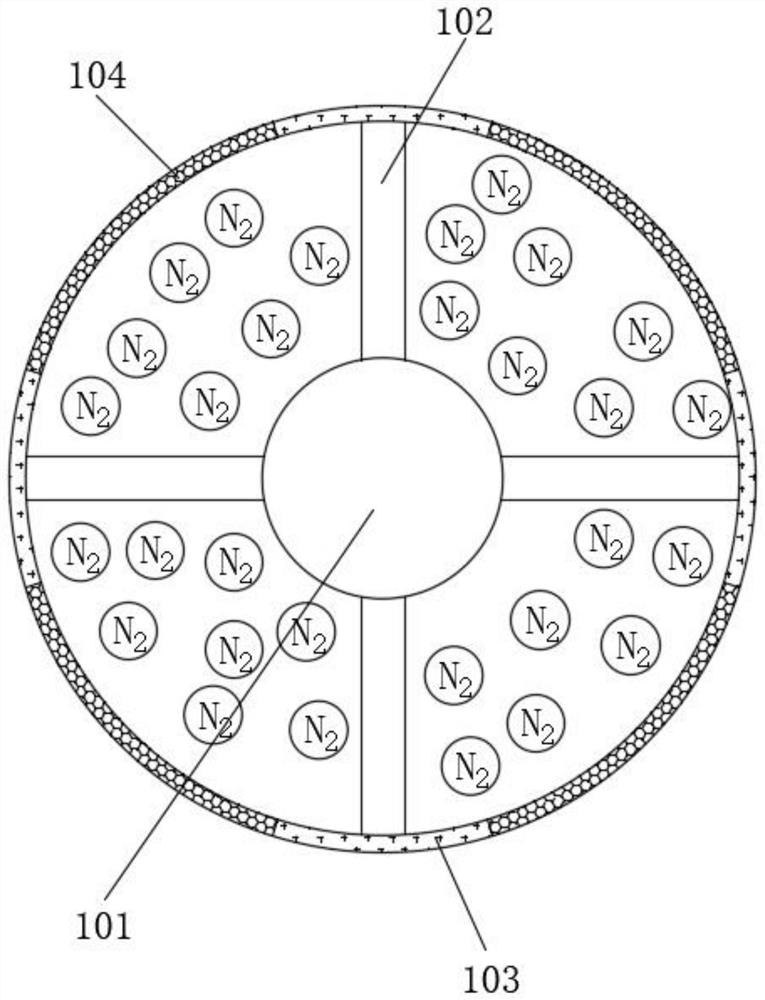

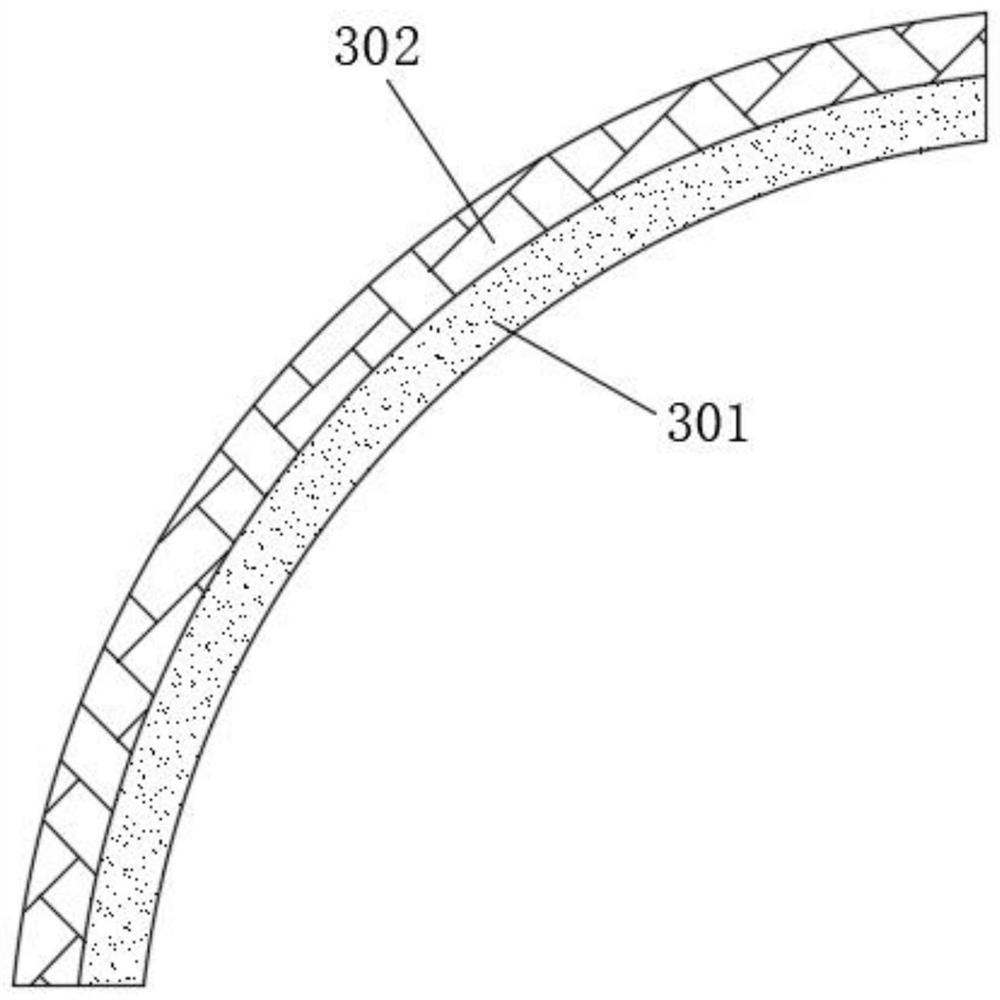

[0039] see figure 1 and image 3 , a shear-resistant and self-restoring pressure-resistant cable, including a central support ball 001, a support and compression frame is arranged on the outside of the center support ball 001, and the support and compression frame includes four ring-shaped and uniformly distributed fixing rods 201, fixed The end of the rod 201 far away from the center support ball 001 is fixedly connected with a connection block 202, and a protection pressure piece 003 is fixedly connected between two adjacent connection blocks 202, and the protection pressure piece 003 is set as a circle centered on the center support ball 001 Arc-shaped, the protective pressure piece 003 includes an elastic inner layer 301 and a protective outer layer 302. The elastic inner layer 301 is made of elastic metal sheet material, and the protective pressure piece 003 is used as the force contact surface of the cable. When the cable is under pressure, The pressure point will be lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com