Quartz tailings heat-insulating building block and preparation method thereof

A technology of quartz tailings and thermal insulation blocks, applied in the field of quartz tailings used in building materials, can solve the problems of long production cycle, high production cost, easy shrinkage, etc., to ensure hollowness and heat preservation degree, improve heat preservation effect, Reduce the effect of radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

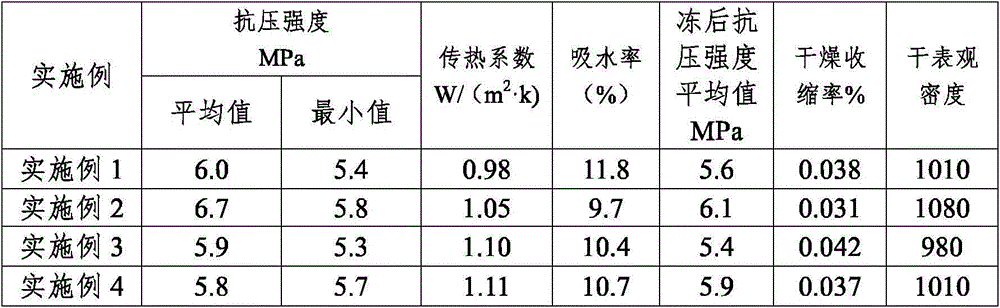

Embodiment 1

[0029] A quartz tailing thermal insulation block, the thermal insulation block is composed of a hollow block and a filling material, wherein both the hollow block and the filling material include quartz tailings powder, and the quartz tailings powder is ground by quartz tailings The fineness of the resulting fine powder is sieved by a square hole sieve with an aperture size of 45um, and the sieve residue is 10%; and the content of silicon dioxide in the quartz tailings powder is 70%.

[0030] The raw material components of the hollow block are 60 kg of quartz tailings, 10 kg of quartz tailings powder, 20 kg of sand, 8 kg of cement, and 4 kg of quicklime on a dry basis.

[0031] The raw material composition of the filling material is 80kg of quartz tailings powder, 12kg of quicklime and 0.05kg of aluminum powder in terms of dry weight.

[0032] The additive is sodium hydroxide.

[0033] The preparation method of the described quartz tailing insulation block comprises the follo...

Embodiment 2

[0038] A quartz tailing thermal insulation block, the thermal insulation block is composed of a hollow block and a filling material, wherein both the hollow block and the filling material include quartz tailings powder, and the quartz tailings powder is ground by quartz tailings The fineness of the resulting fine powder is sieved by a square hole sieve with a pore size of 45um, and the sieve residue is 9%; and the content of silicon dioxide in the quartz tailings powder is 90%.

[0039] Said hollow block, its raw material components are 70kg of quartz tailings, 20kg of quartz tailings powder, 30kg of sand, 10kg of cement, 7kg of quicklime and 0.5kg of admixture on a dry basis.

[0040] The raw material of the filling material is 85kg of quartz tailings powder, 20kg of quicklime and 0.15kg of aluminum powder on a dry basis.

[0041] Described quicklime, its fineness is the square hole sieve of 0.08mm aperture and the sieve residue after sieving treatment is 10%, and the mass pe...

Embodiment 3

[0048] A quartz tailing thermal insulation block, the thermal insulation block is composed of a hollow block and a filling material, wherein both the hollow block and the filling material include quartz tailings powder, and the quartz tailings powder is ground by quartz tailings The fineness of the resulting fine powder is sieved by a square hole sieve with a pore size of 45um, and the sieve residue is 7%; and the content of silicon dioxide in the quartz tailings powder is 80%.

[0049] Said hollow block, its raw material components are 65kg of quartz tailings, 15kg of quartz tailings powder, 25kg of sand, 9kg of cement, 5kg of quicklime and 0.3kg of admixture in terms of dry weight.

[0050] The raw material of the filling material is 83kg of quartz tailings powder, 17kg of quicklime and 0.1kg of aluminum powder on a dry basis.

[0051] Described quicklime, its fineness is that the square hole sieve of 0.08mm aperture is sieved after the sieve treatment is 7%, and the mass pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com