Optical-fiber type laser wavemeter

A laser wavelength meter and fiber optic technology, applied in the field of wavelength meters, can solve the problems of increasing the difficulty of optical tuning and alignment, increasing energy loss and device complexity, reducing the accuracy of wavelength calibration, etc., to avoid maintenance and debugging, Improved energy transmission efficiency, high accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

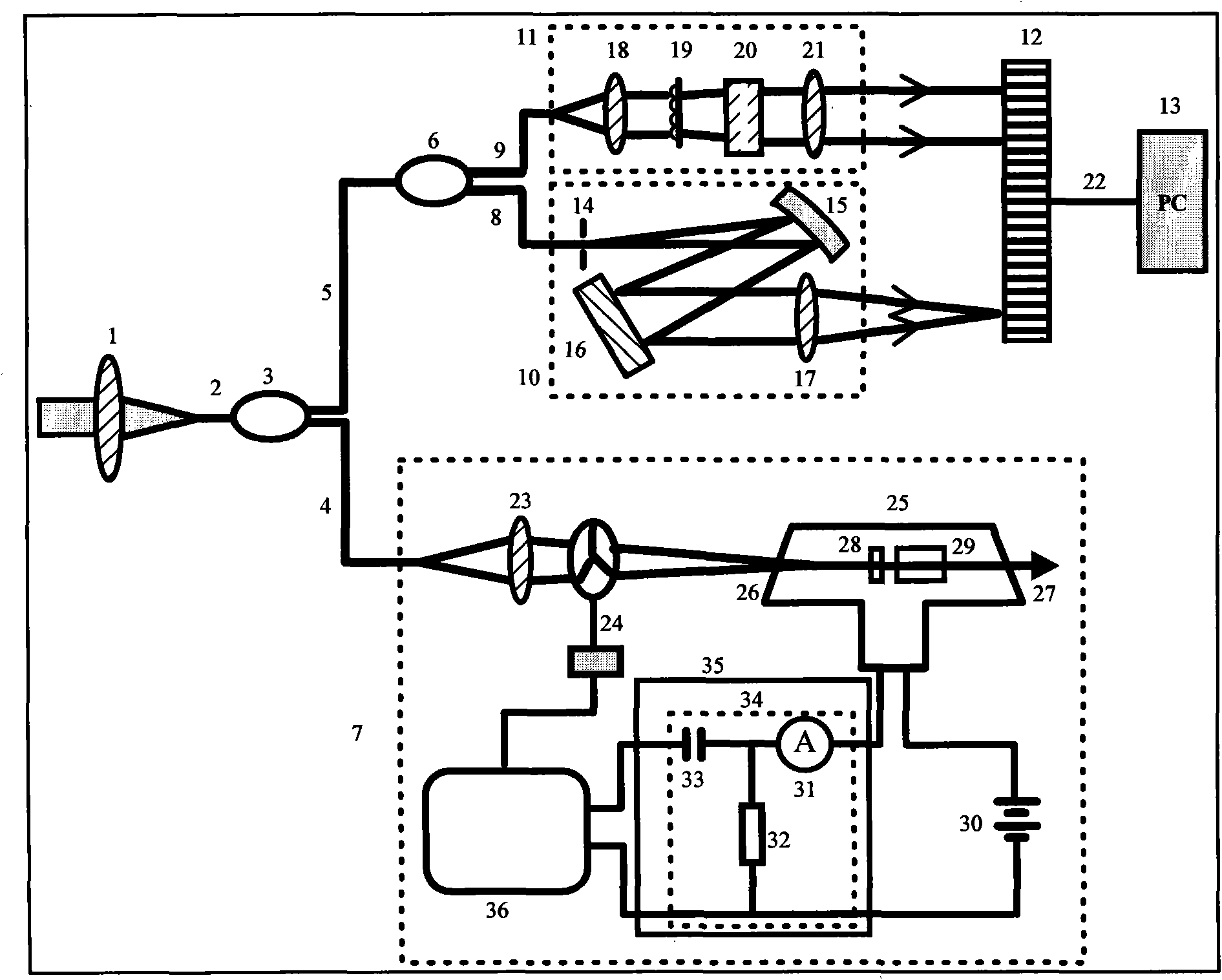

[0034] see figure 1 , figure 1 It is a schematic diagram of the structure of the fiber optic wavelength meter of the present invention. As can be seen from the figure, the optical fiber laser wavelength meter of the present invention consists of a focusing lens 1, a first fused silica optical fiber 2, a second fused silica optical fiber 4, a third fused silica optical fiber 5, a fourth fused silica optical fiber 8, and a fifth fused silica optical fiber 9. The first fiber coupler 3, the second fiber coupler 6, wavelength calibration device 7, grating monochromator 10, wavelength precision measurement device 11, linear CCD 12, signal processor 13 and data line 22, the above-mentioned parts The positional relationship is as follows:

[0035] The laser to be measured is coupled to the first fused silica fiber 2 through the focusing lens 1 and transmitted to the first fiber coupler 3 with a high beam splitting ratio for beam splitting. The stronger beam split by the first fiber co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com