Prefabricated double-column vase bridge pier and assembling construction method thereof

A technology of prefabricated assembly and construction method, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of difficult construction, long construction time, loud noise and dust pollution, etc. Bit difficulty, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

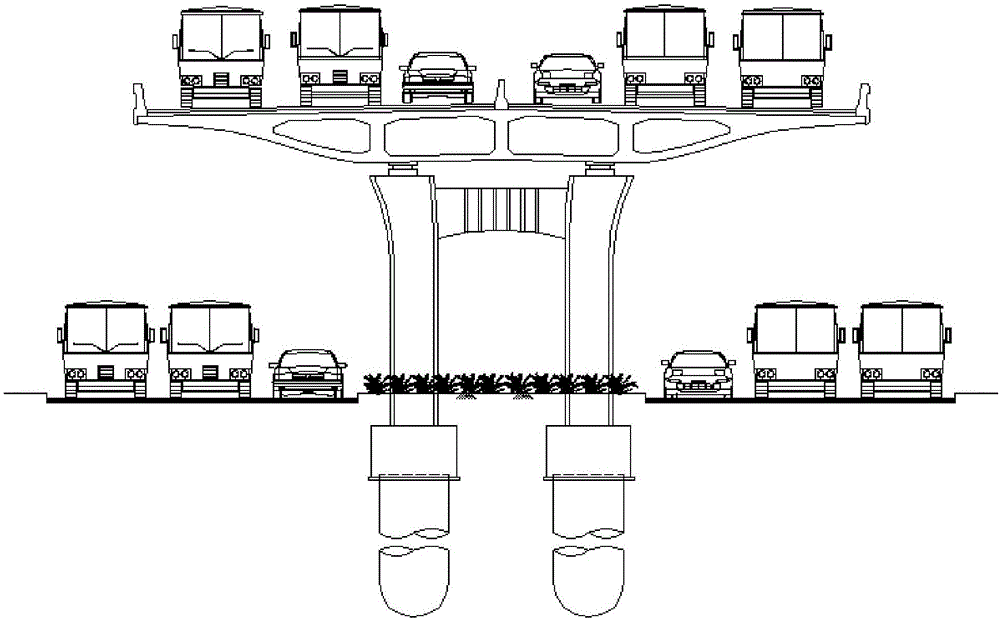

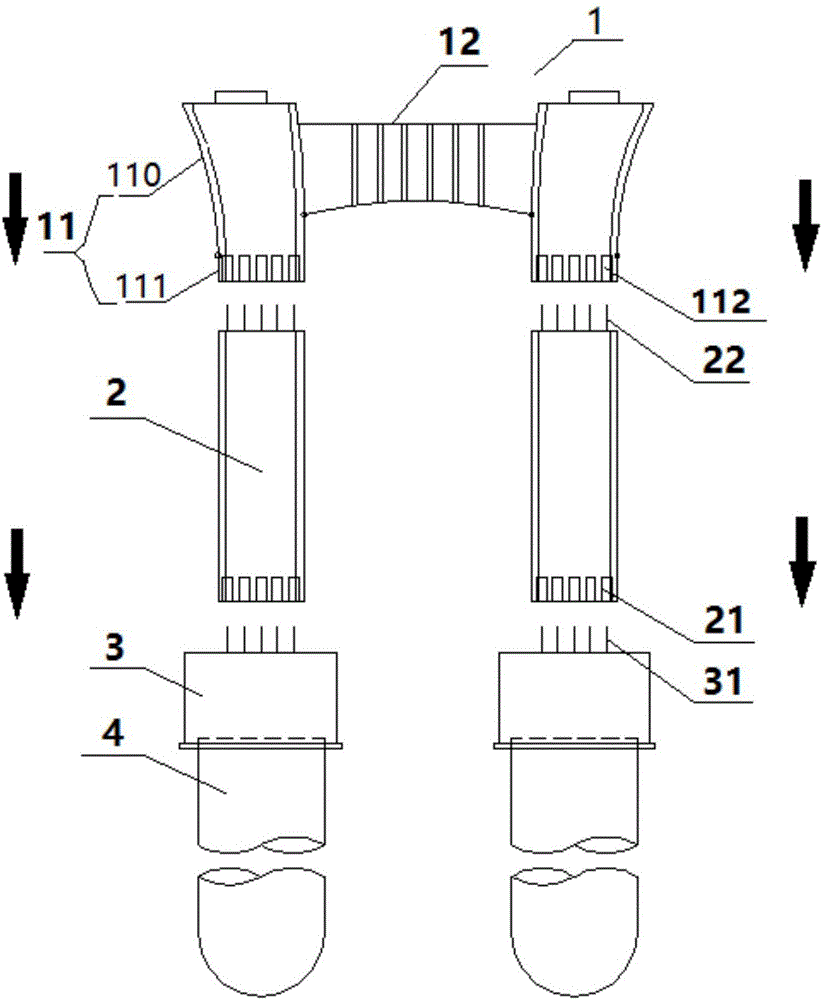

[0030] Such as figure 2 As shown, a specific embodiment of the present invention includes two pier body segments 2 and a pier cap segment 1, the pier body segment 2 is the main straight section of the pier, and the pier cap segment 1 is the straight-curved transition between two pier piers The junction of section 11 and a tie beam 12, two pier straight-curved transition sections 11 are respectively located at both ends of tie beam 12; the upper part of pier straight-curve transition section 11 is pier curved section 110, and pier curved section 110 gradually transitions downward It is the end section 111 of the straight line of the bridge pier.

[0031] The bottom end of the pier body segment 2 is provided with a built-in embedded sleeve 21 , and the stressed steel bars of the pier body segment protrude from the top of the pier body segment to form a pier body steel bar joint 22 .

[0032] Built-in embedded sleeves 112 are provided in the two pier straight end sections 111 a...

Embodiment 2

[0035] Such as figure 2 As shown, the direction of the arrow in the figure indicates the installation direction. The assembly construction method of the prefabricated double-column vase pier includes the following steps:

[0036] First, when the cast-in-place cap 3 is cast-in-place on the foundation of the cast-in-place pile 4 and the cast-in-place bridge cap 3, the reinforced steel bar reserved for the cap extends out of the top of the cap to form a cap reinforcement joint 31;

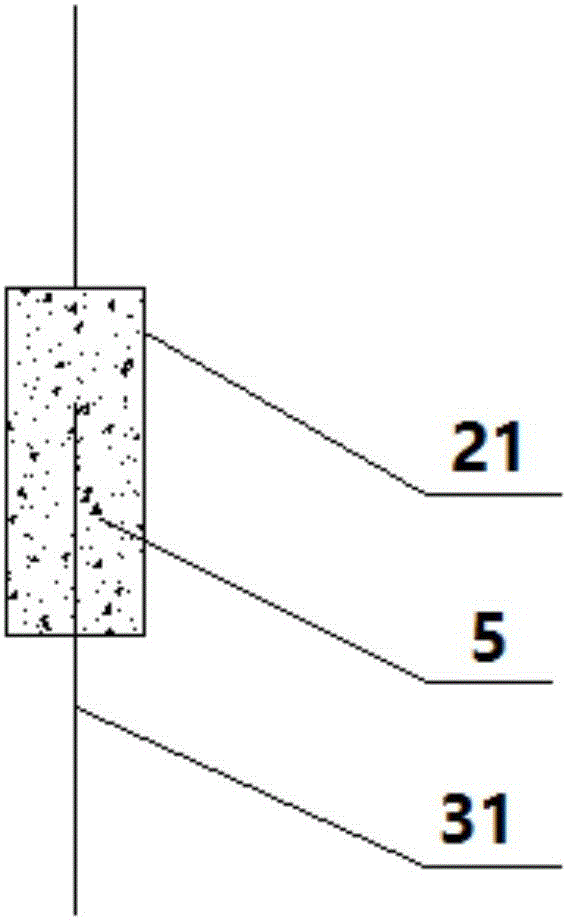

[0037] Secondly, the pier body segment 2 and the cap 3 are assembled and connected; the specific method is: after the pier body segment 2 and the cap 3 are closely fitted, the cap rebar joint 31 is inserted into the built-in embedded sleeve at the bottom of the pier body segment Inside the barrel 21; then, if image 3 As shown, the high-strength grouting material 5 is poured into the gap between the steel bar joint 31 of the cap and the built-in embedded sleeve 21 at the bottom of the pier body seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com