Automatic exposure machine for flexible printed circuit board

A technology of automatic exposure and soft board, which is applied in the direction of photomechanical equipment, microlithography exposure equipment, photoplate making process exposure device, etc., to achieve the effects of good stability, accelerated development process, and high exposure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

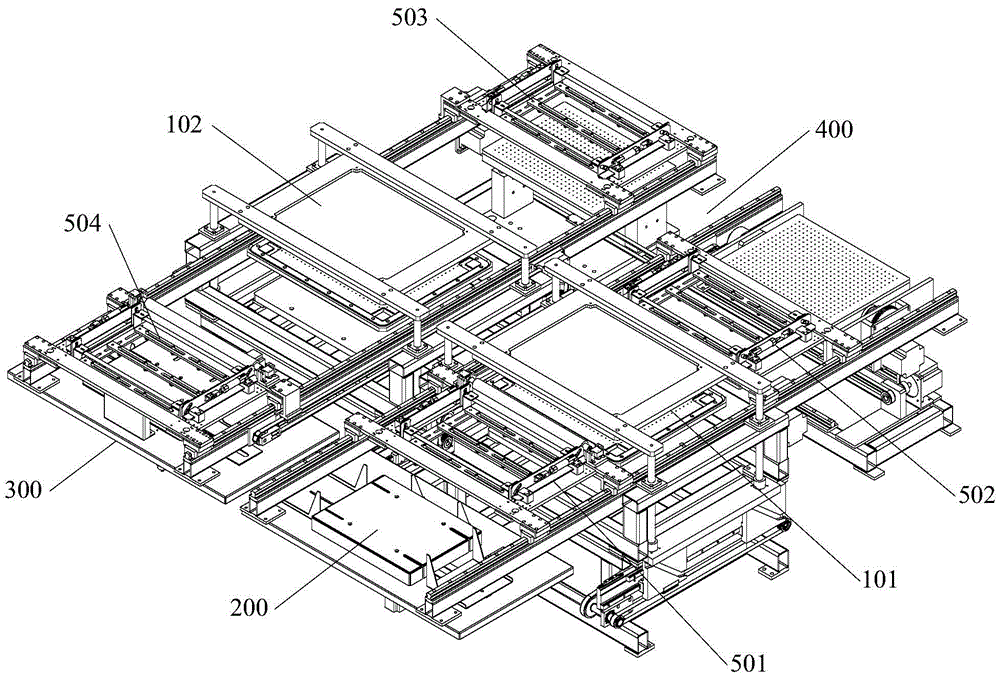

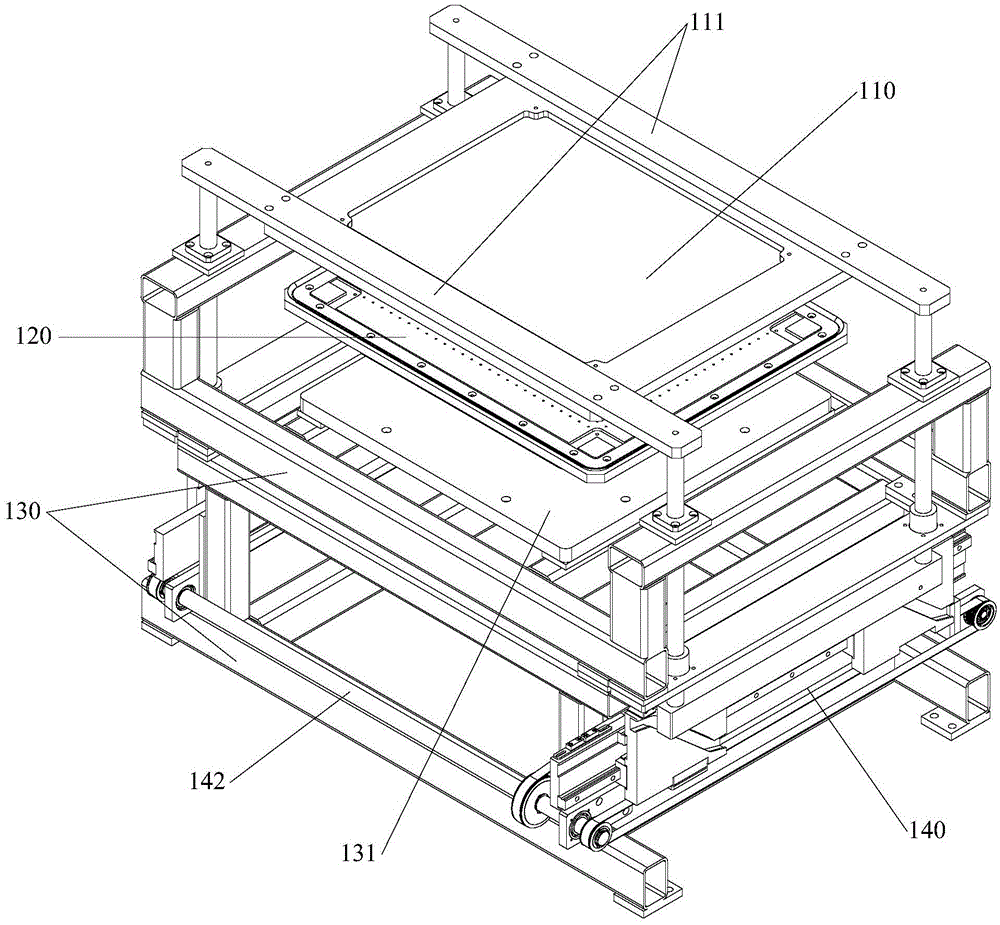

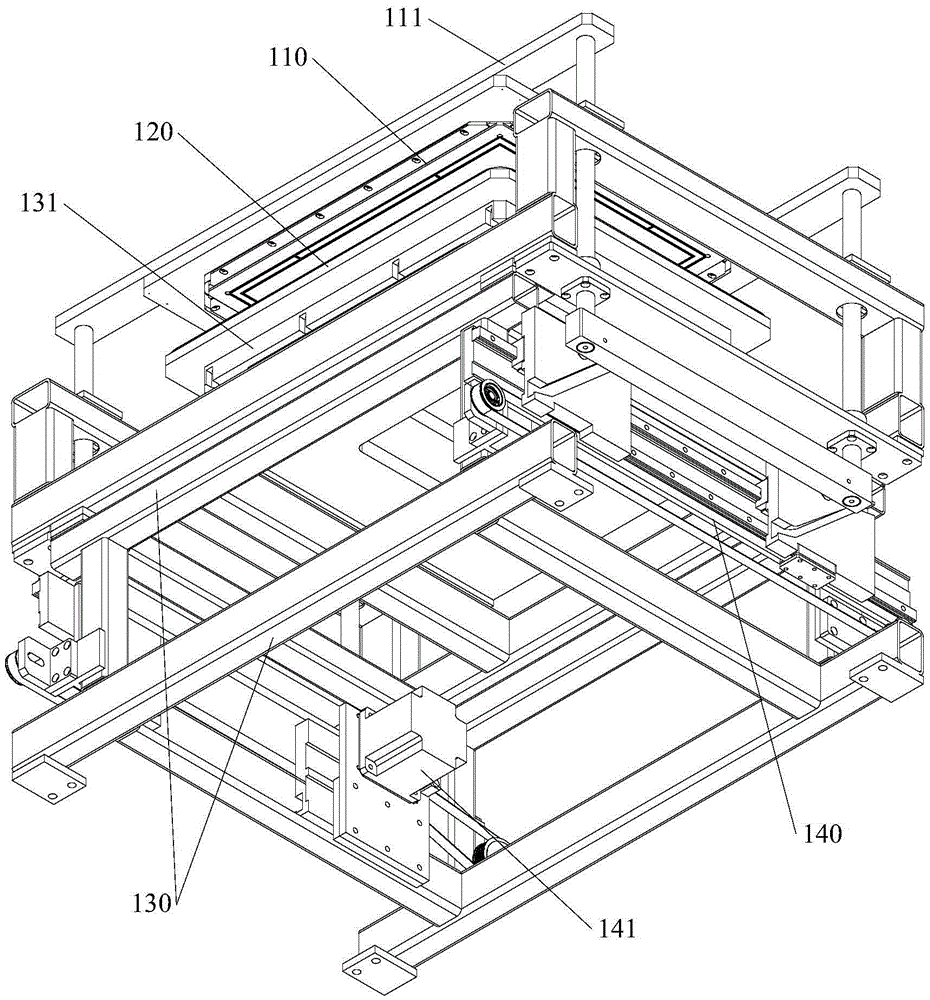

[0035] See figure 1 , an automatic exposure machine for flexible boards designed in a preferred embodiment of the present invention, which mainly includes: two exposure mechanisms, a material feeding and stacking mechanism 200, a material receiving and stacking mechanism 300, a plate turning mechanism 400 and four A suction cup assembly, the first and second exposure mechanisms are arranged side by side, and the feeding and stacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com