Liquid crystal display and method for manufacturing same

A liquid crystal display, a square technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as static electricity and particle pollution, damage to liquid crystal elements, etc., and achieve the effects of wide viewing angle, increased area, and improved blue light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A liquid crystal display comprising:

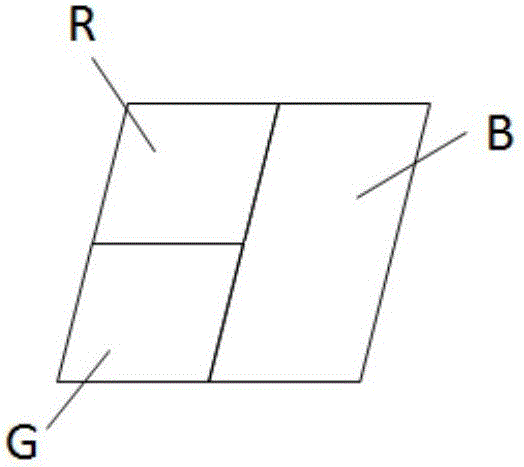

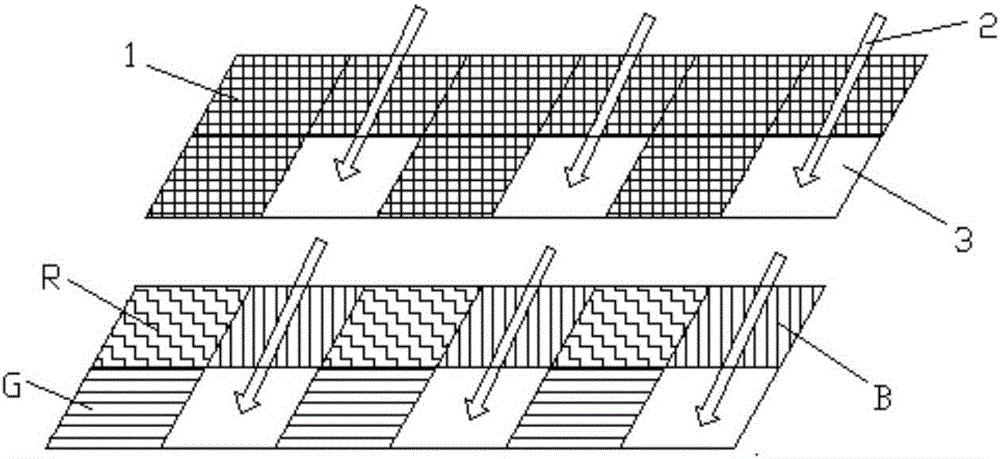

[0031] Multiple square pixel structures, each square pixel structure is composed of red sub-pixels, green sub-pixels and blue sub-pixels, each square pixel structure is divided into four square sub-regions of equal size, the blue sub-pixels A pixel occupies two adjacent sub-regions, and the area of the blue sub-pixel is twice that of the red or green sub-pixel. Among them, the blue sub-pixels rely on the backlight to emit light, and the square pixel structure is arranged in an array.

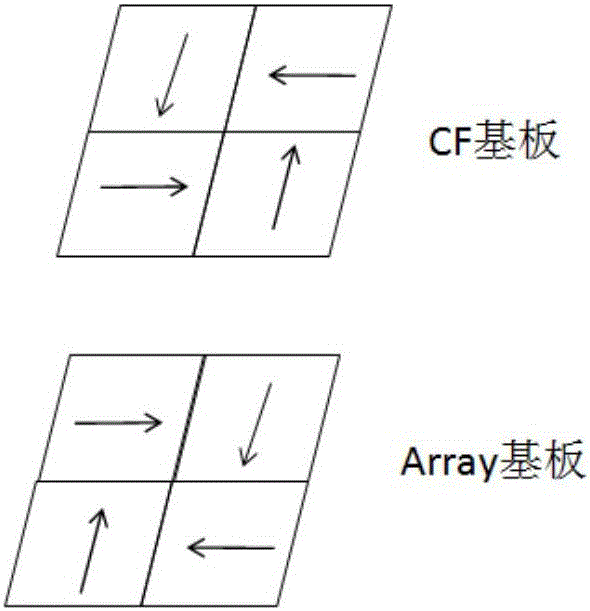

[0032] The preparation method of the liquid crystal display is as follows: according to the commonly used TFT-LCD manufacturing process, the color filter and the array substrate are prepared and surface treated respectively;

[0033] Among them, before the color filter substrate is coated with the alignment layer, the RGB color film is prepared by materials doped with quantum dots. The transparent photoresist material of quantum dots, the doping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com