Method for manufacturing optical micro-nano pattern on surface of lithium niobate film

A technology of surface fabrication and lithium niobate, which is applied in the direction of optics, photographic process of pattern surface, photolithographic process exposure device, etc., can solve the problems of affecting electron beam deflection, large optical mode field size, and reducing the performance of optical devices, etc. , to achieve the effect of precise and controllable pattern size, large refractive index contrast, and improved performance of optical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0046] The electron beam exposure machine used in this embodiment is produced by UK Nanobeam Co., Ltd., and the model is NB5.

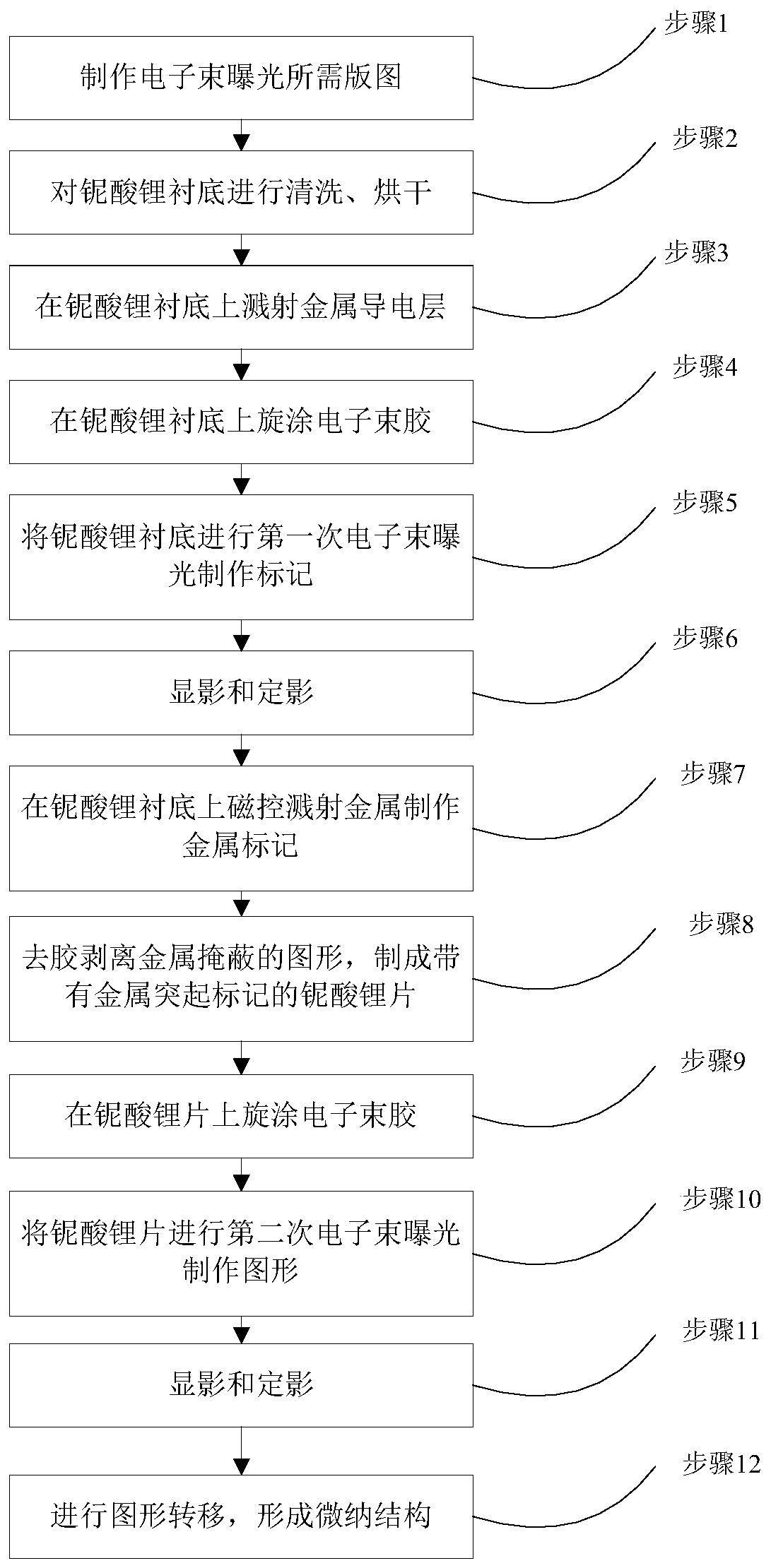

[0047] A method for making optical micro-nano patterns on the surface of a lithium niobate thin film, such as figure 1 shown, including the following steps:

[0048]Step 1, making a layout required for electron beam exposure in drawing software (such as AutoCAD or Ledit, etc.), and the layout includes first-layer marks and second-layer graphics. The first layer is marked as a square with a side length greater than 4 μm, or a cross with a width greater than 4 μm, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com