Patents

Literature

43results about How to "Avoid stitching errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

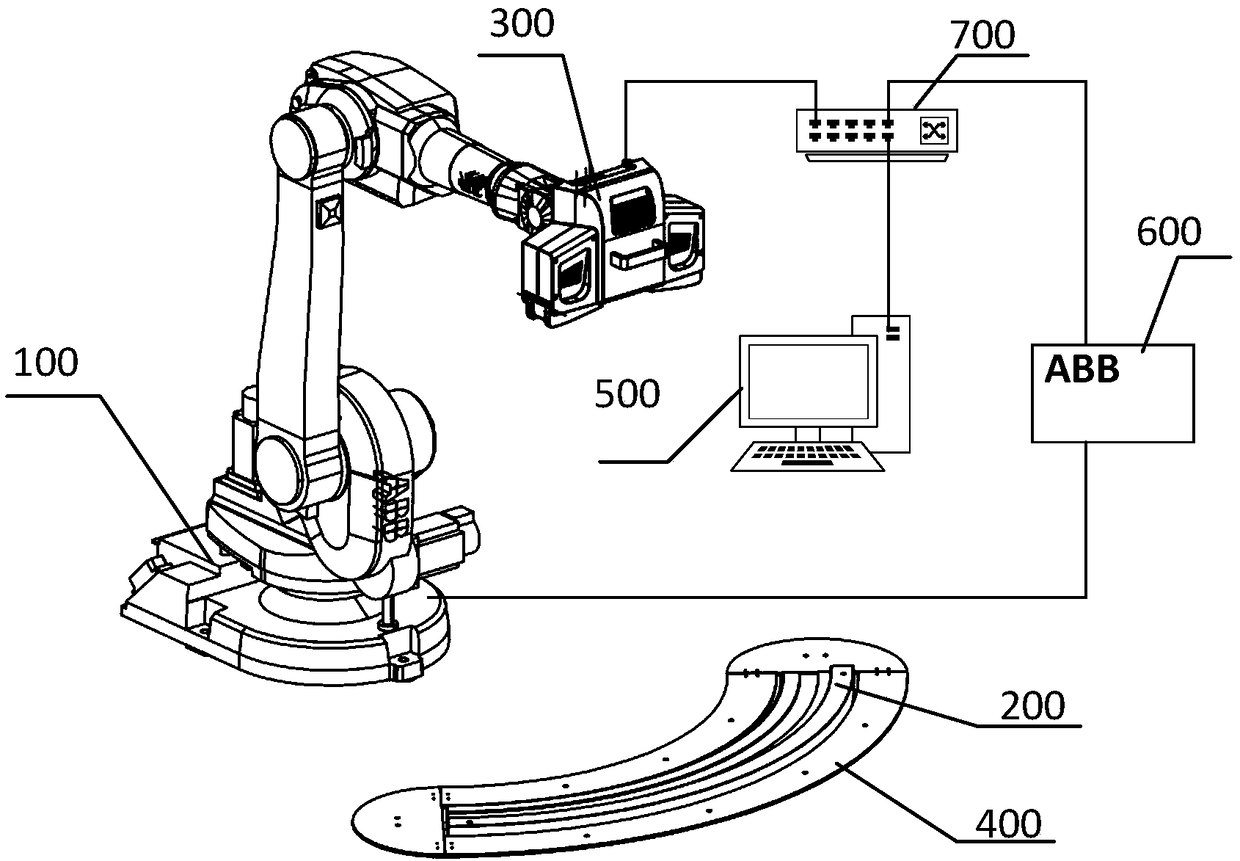

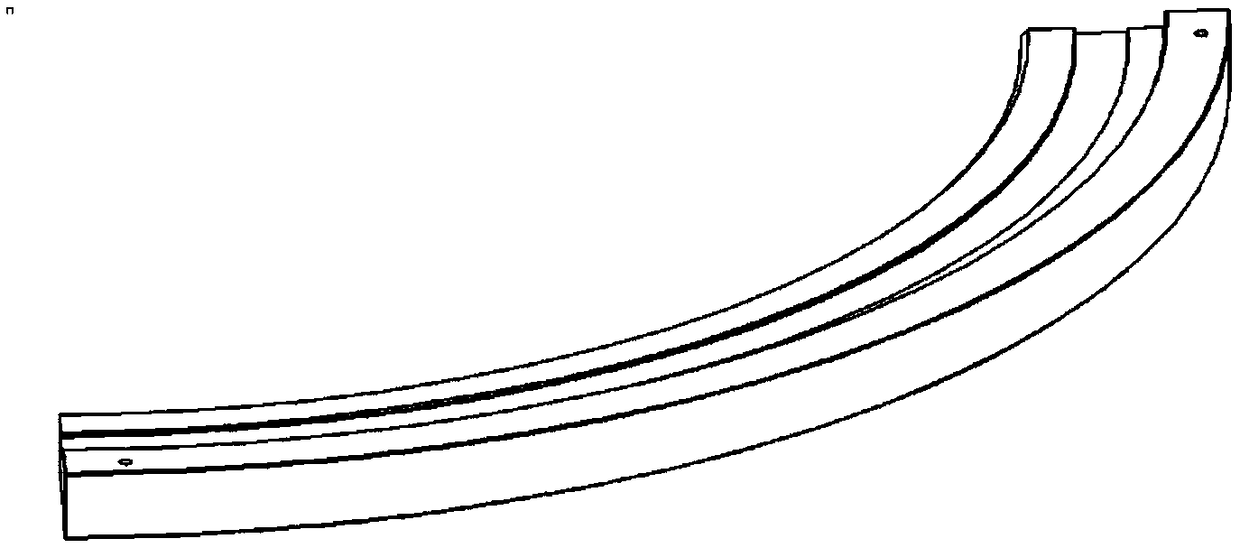

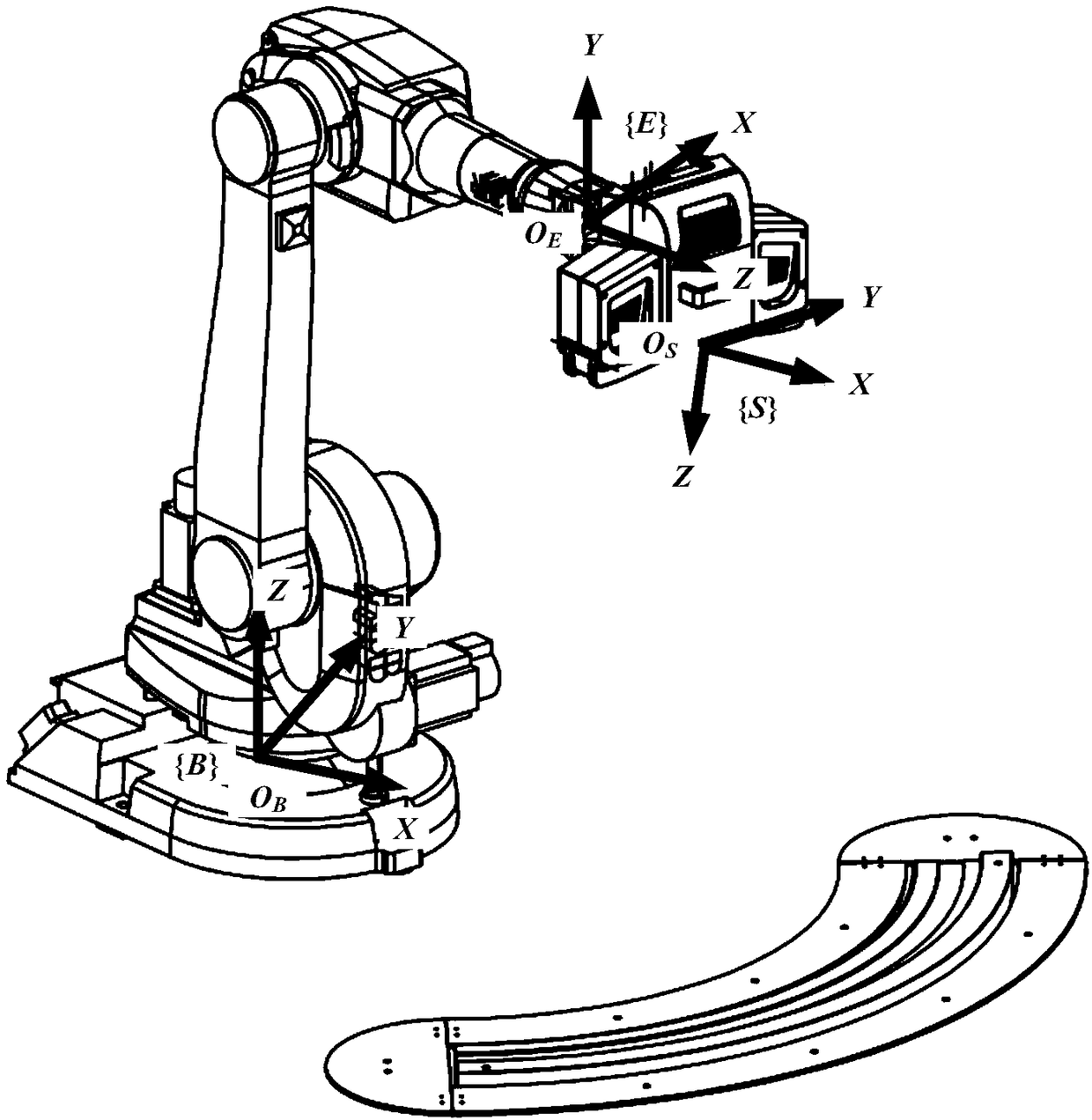

Complex part pose estimation system and method based on three-dimensional measuring point cloud

ActiveCN109373898AAccurate measurementWide measurement rangeUsing optical meansPoint cloudMeasurement point

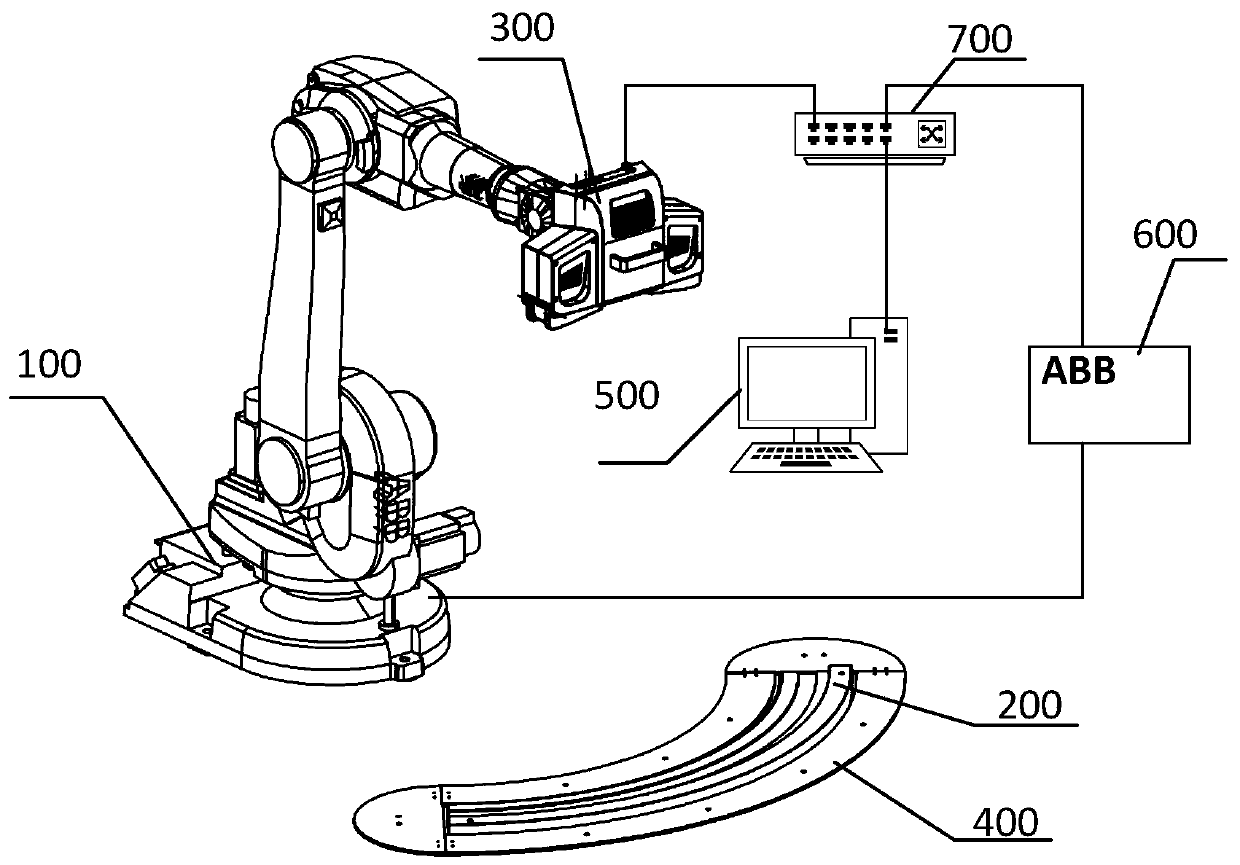

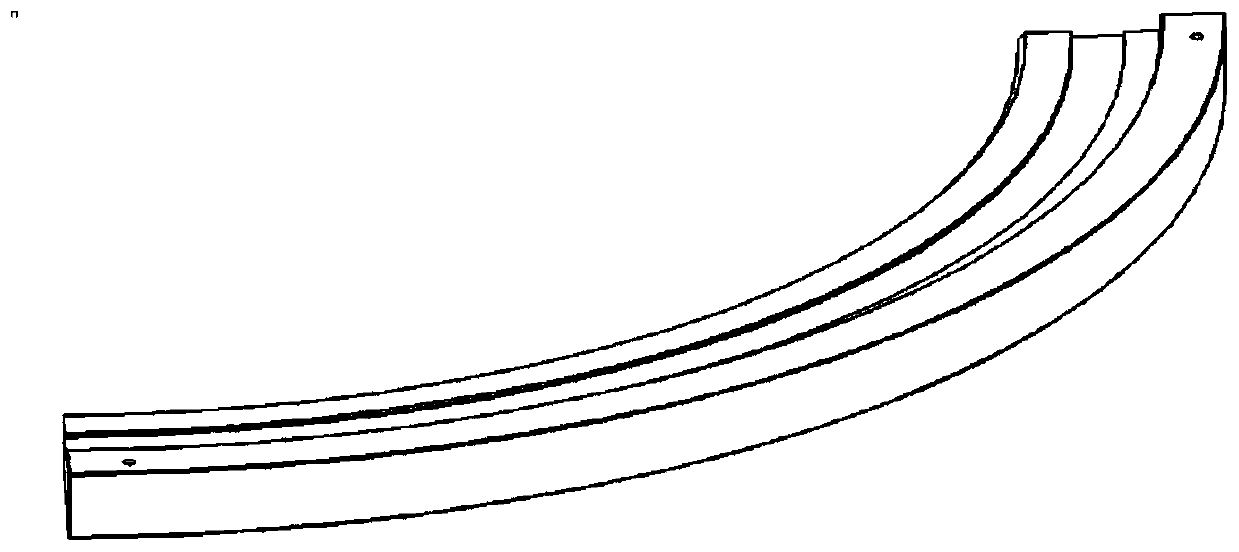

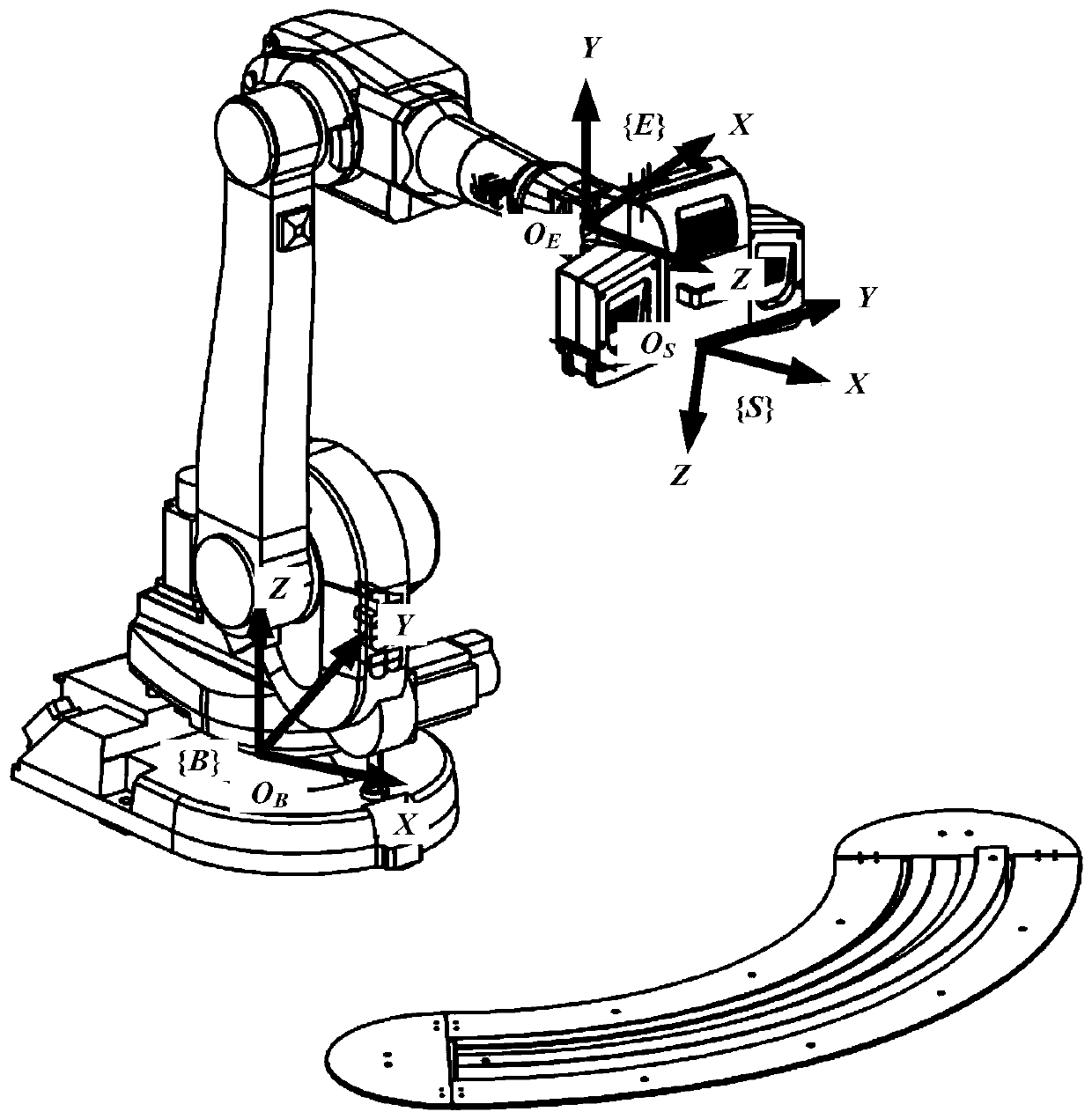

The invention belongs to the field of automatic measurement and specifically discloses a complex part pose estimation system and method based on three-dimensional measuring point cloud. The method forestimating a complex part pose comprises a step of calibrating a conversion matrix between a six-degree-of-freedom industrial robot end flange and a grating area array scanner measurement coordinatesystem, a step of driving a grating area array scanner to move through the six-degree-of-freedom industrial robot to scan a measured workpiece and obtaining three-dimensional point cloud data of the measured workpiece, a step of converting the three-dimensional point cloud data of the measured workpiece to a robot base coordinate system to obtain converted three-dimensional point cloud data, and astep of matching the converted three-dimensional point cloud data with a three-dimensional design model of the measured workpiece to obtain the pose of the measured workpiece relative to the robot soas to complete the estimation of the pose of a complex part. The invention has a wide measurement range, the accurate measurement of multiple regions and complete topography of the measured workpiececan be achieved, and the pose of the measured workpiece can be accurately obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

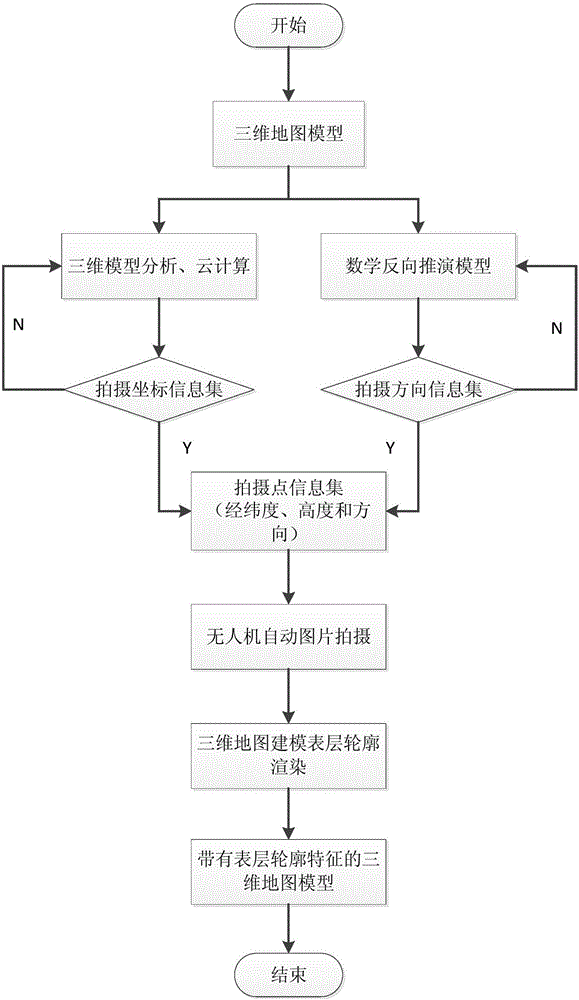

3D map modeling surface contour fast linkage rendering method

ActiveCN106408640AImprove work efficiencyLow cost3D-image rendering3D modellingCloud computingMaterial resources

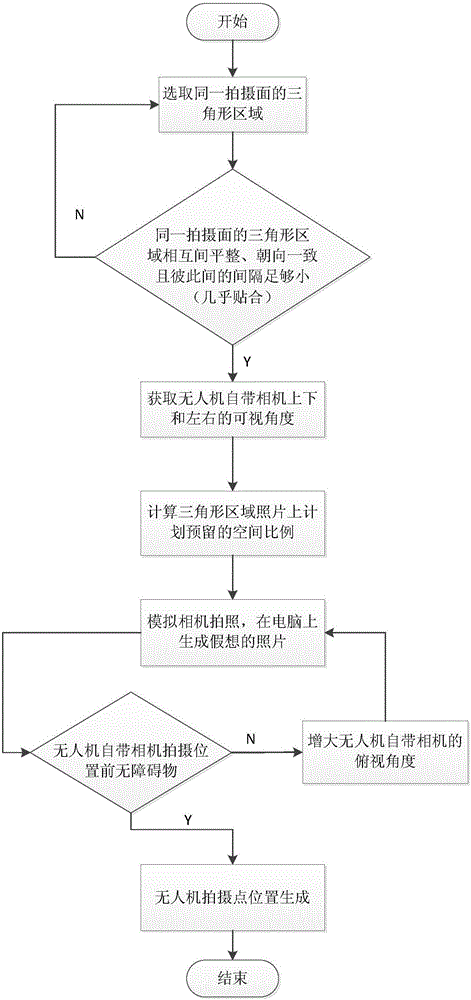

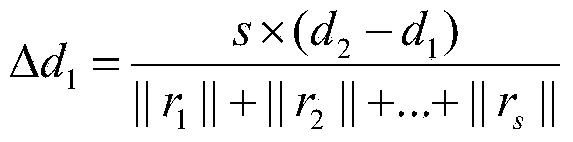

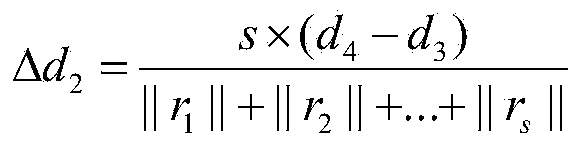

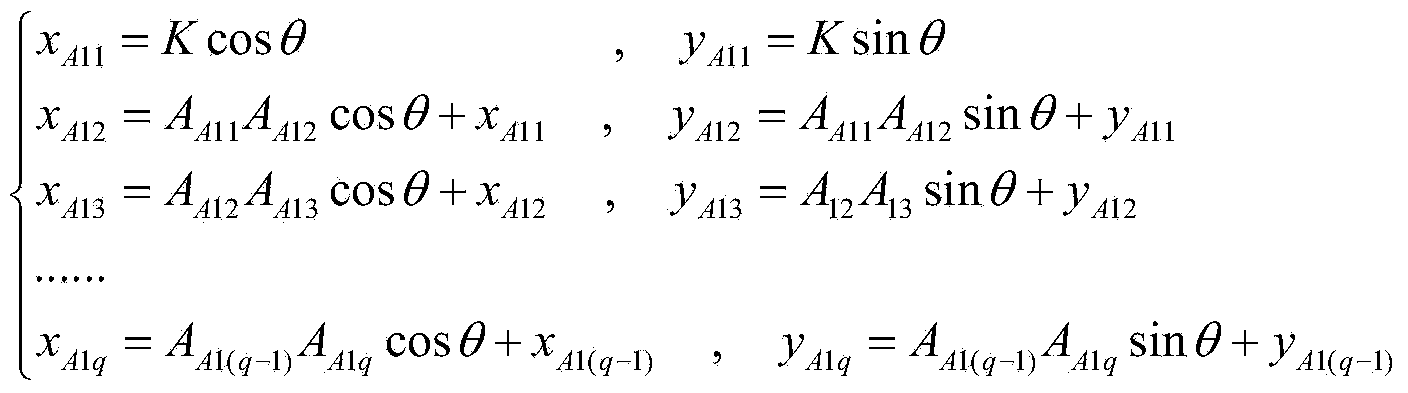

The invention relates to the technical field of 3D map, and provides a 3D map modeling surface contour fast linkage rendering method. The method comprises the following steps: (1) acquiring the coordinate information of a building, and building a 3D map model; (2) analyzing the characteristics of a surface mounting area, and determining the space coordinates of shooting points of an unmanned aerial vehicle in batches according to a mathematical reverse deduction model; (3) storing the space coordinates of the shooting points; inputting the space coordinates of the shooting points of the unmanned aerial vehicle to the unmanned aerial vehicle to realize automatic shooting by the unmanned aerial vehicle; and (5) automatically screening a shot image to match the surface mounting area according to the feature point information of the surface mounting area, and performing surface mounting. The beneficial effects are as follows: with the help of 3D map modeling, cloud computing, a mathematical reverse deduction model, an unmanned aerial vehicle and a smart surface mounting technology, efficient linked 3D modeling surface rendering is realized, and the surface texture characteristics of a 3D map are presented truly; the shooting points of an unmanned aerial vehicle are automatically generated in batches, position deviation caused by artificial selection is avoided, the work continuity is improved while the quality of rendered images is guaranteed, and manpower and material resources are saved.

Owner:上海网罗电子科技有限公司

Two-dimensional image splicing method based on optical grating positioning in automatic visual inspection

The invention belongs to the field of image automatic inspection and particularly discloses a two-dimensional image splicing method based on optical grating positioning in automatic visual inspection. The splicing method includes the steps of modifying the coordinate values of sub-images in a large image according to the coordinate included angle parameter of a shooting platform and a camera, calculating the position coordinates of four corners of each sub-image, obtaining the size of the large image through the actual physical distances corresponding to all pixels, calculating the pixel gray levels in sub pixel coordinate positions of the sub-images through bilinear interpolations to obtain the spliced large image, conducting modification to eliminate errors caused by inconformity of shooting coordinates through the coordinate included angle parameter of the shooting platform and the camera, and directly conducting calculation through the coordinate positions of the sub-images in the splicing process at the same time. Therefore, splicing errors caused by a splicing method where image features are used for inspect splicing are avoided, meanwhile, sub pixel accuracy is adopted for all the calculated coordinates, and the quality of the spliced image is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

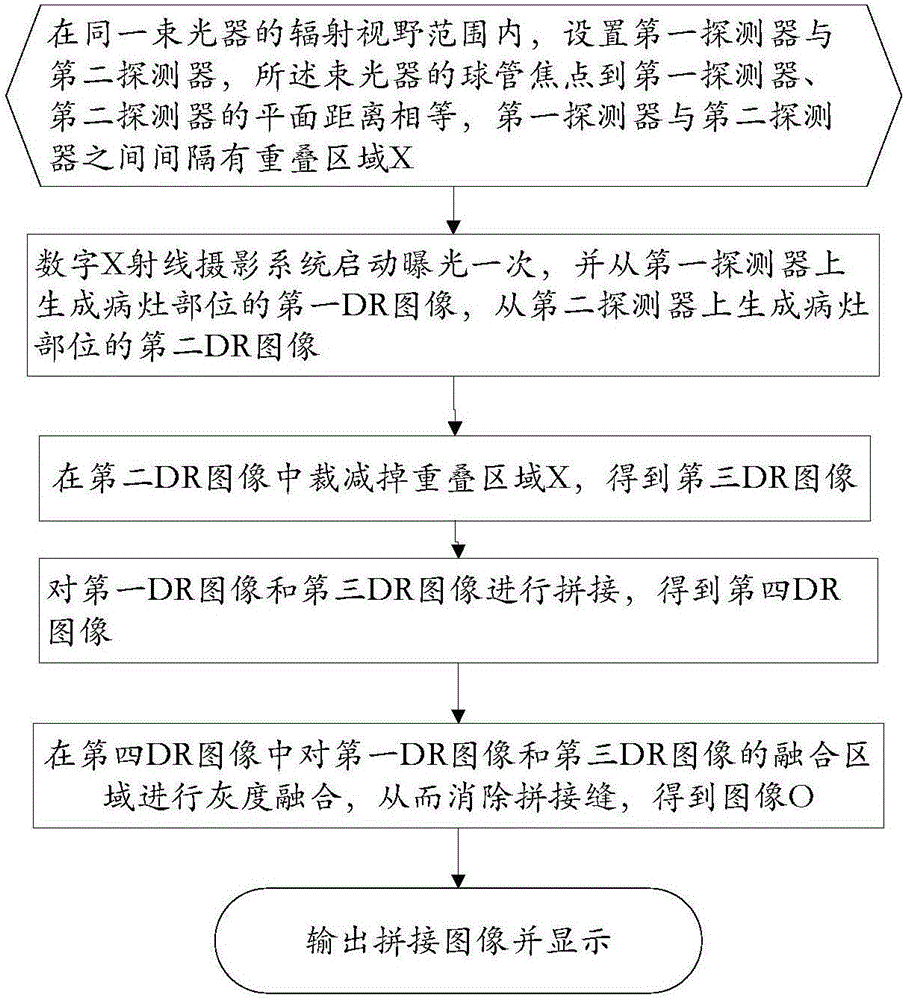

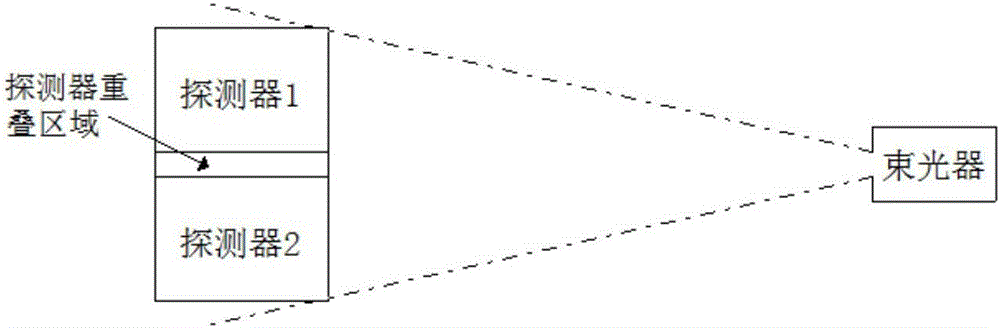

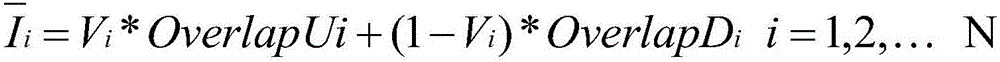

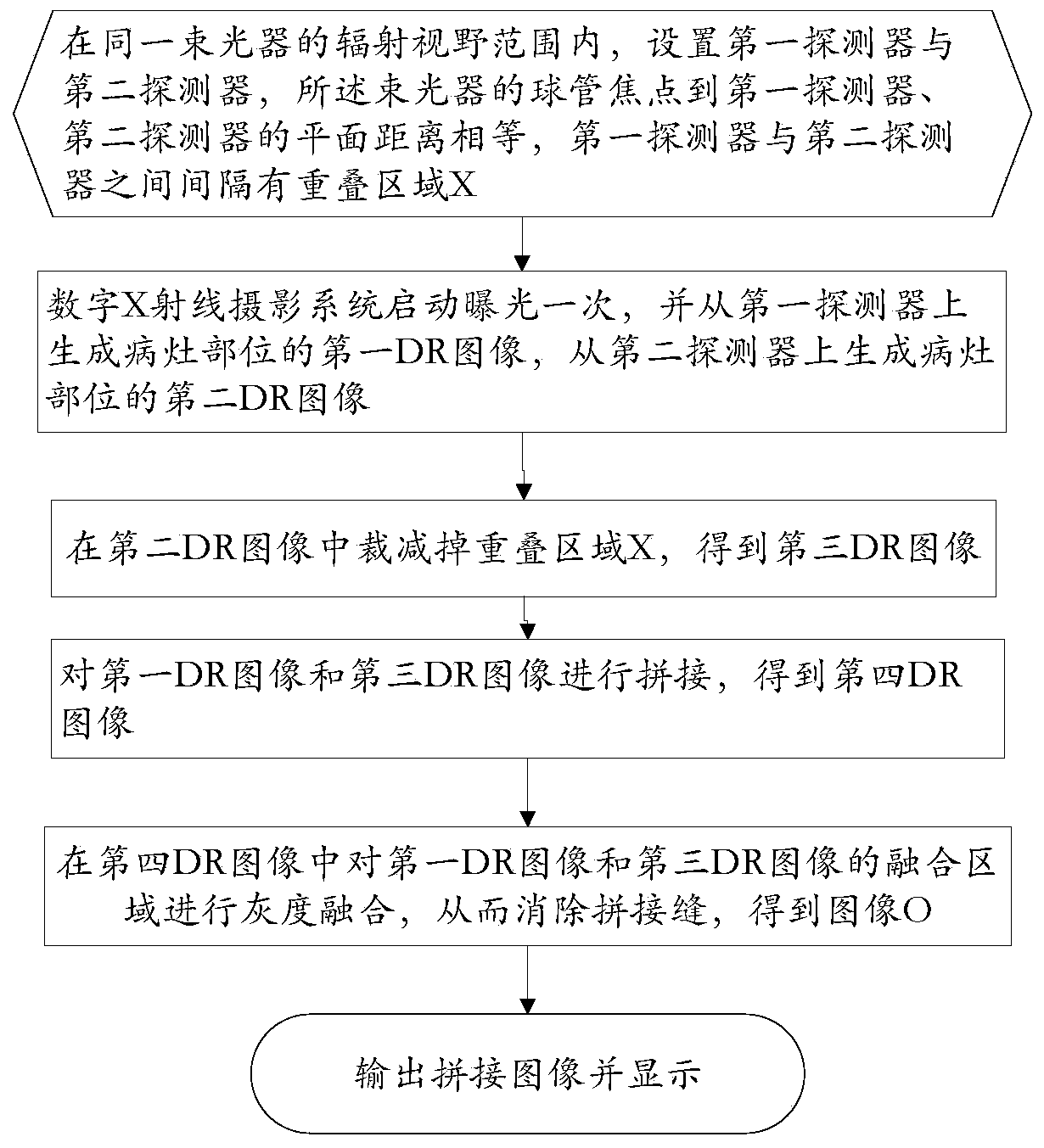

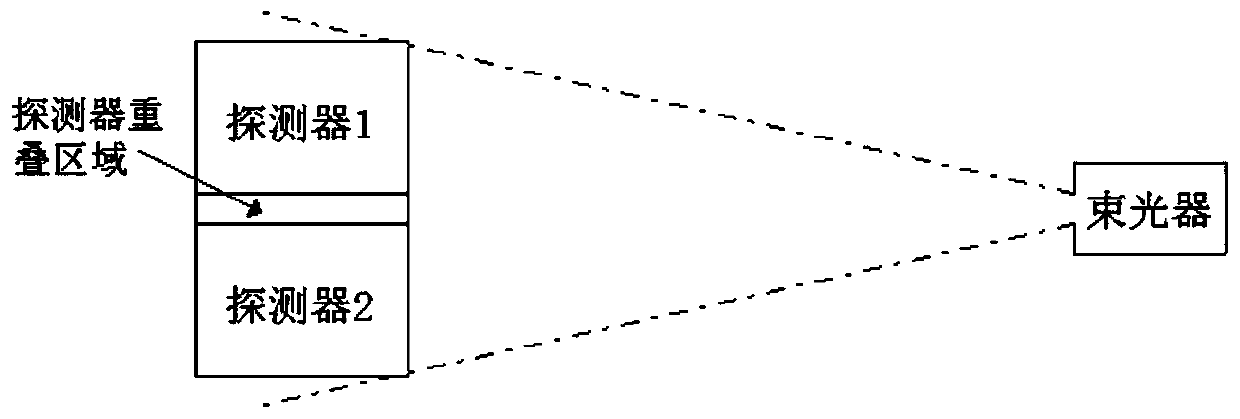

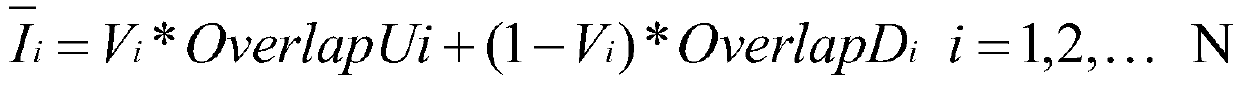

Digital X-ray image splicing method and system

ActiveCN106651771AReduce setup timeEliminate seamsImage enhancementImage analysisSingle exposureX-ray

The invention discloses a digital X-ray image splicing method and system. The digital X-ray image splicing method comprises steps that a first detector and a second detector are arranged in a radiation vision field scope of a same beamer, plane distances from a bulb focus of the beamer to the first detector and the second detector are identical, an overlapping region X is arranged between the first detector and the second detector with intervals; a digital X-ray shooting system starts for exposure for one time, a first DR image of a focus portion is generated on the first detector, and a second DR image of the focus portion is generated on the second detector; the overlapping region X is cut from the second DR image to acquire a third DR image; the first DR image and the third DR image are spliced to acquire a fourth DR image; gray fusion for the splicing region is carried out to eliminate a splicing seam to acquire an image O; the image O is displayed. The method is advantaged in that the spliced image can be acquired through one-time exposure, and thereby a radiation dose and the patient positioning time can be greatly reduced.

Owner:深圳蓝影医学科技股份有限公司

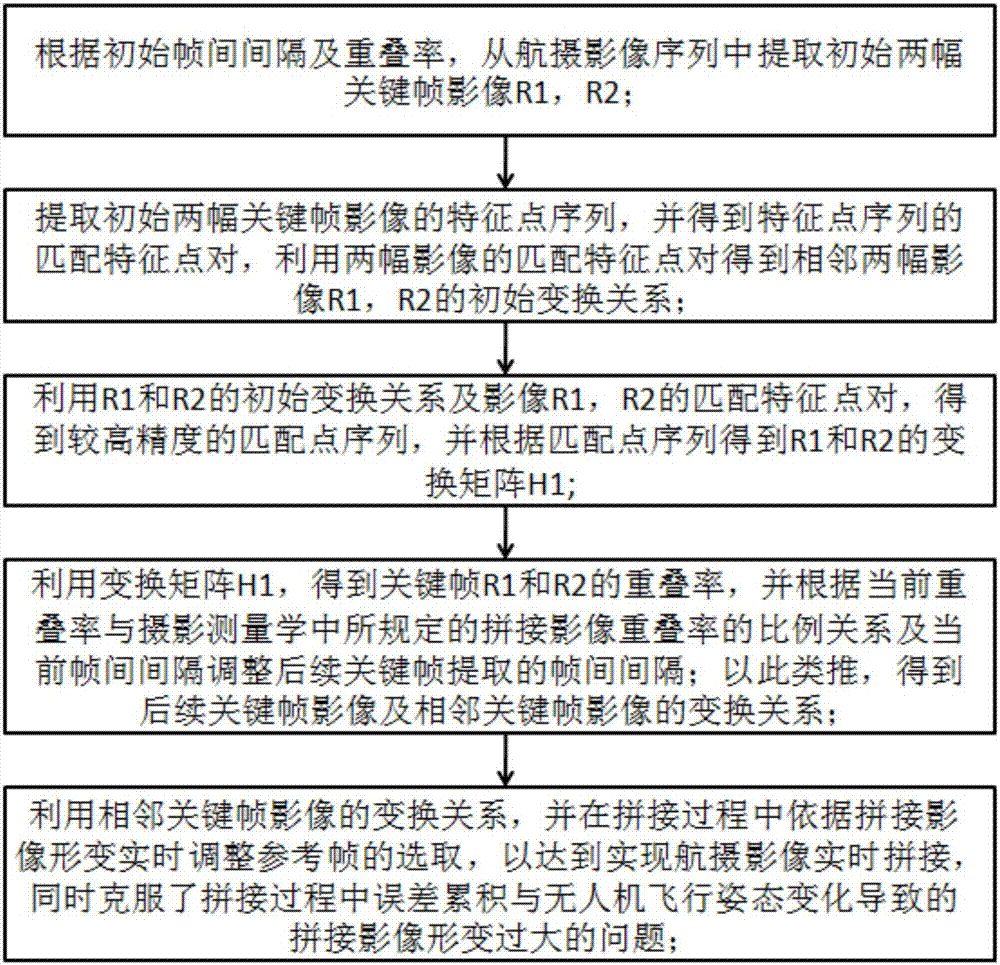

Real-time splicing method for unmanned aerial vehicle aerial stereo images

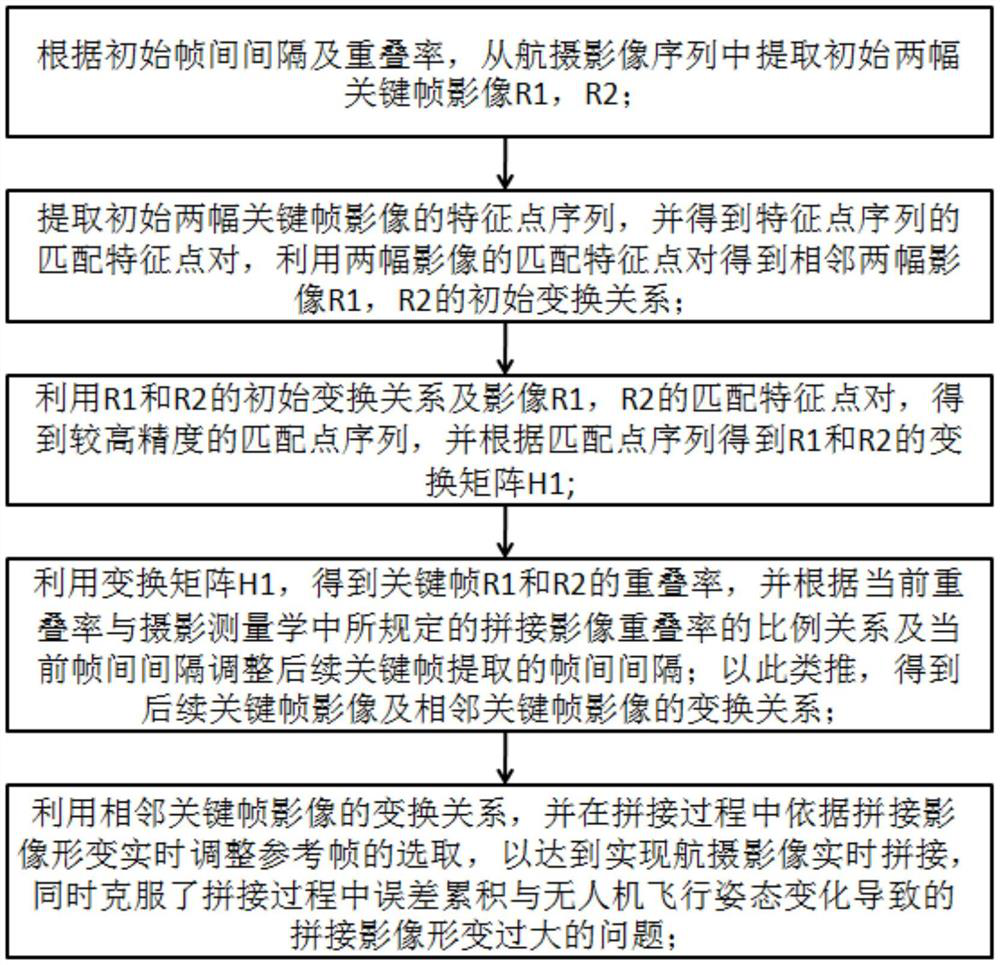

ActiveCN107507132AIncrease overlapImprove efficiencyImage enhancementImage analysisImaging processingReference image

The invention relates to the field of image processing, in particular to a real-time splicing method for unmanned aerial vehicle aerial stereo images. According to the splicing method for the unmanned aerial vehicle aerial stereo images, an inter-frame interval of key aerial stereo images is adjusted and extracted in real time according to the overlapping ratio of adjacent to-be-spliced aerial stereo images; a transformation matrix of every two adjacent frames is obtained according to a matching relation between homonymy points of every two adjacent frames, and the serial aerial stereo images are transformed to a coordinate system of reference images; and reference frames are adjusted in real time according to set reference frame adjustment judgment conditions, so that accumulative errors generated in the process that the aerial stereo images are transformed to a coordinate system of the reference frames are dispersed to all frames of images, and the situation that serious distortion of subsequent images is caused by error accumulation is avoided.

Owner:CHENGDU JOUAV AUTOMATION TECH

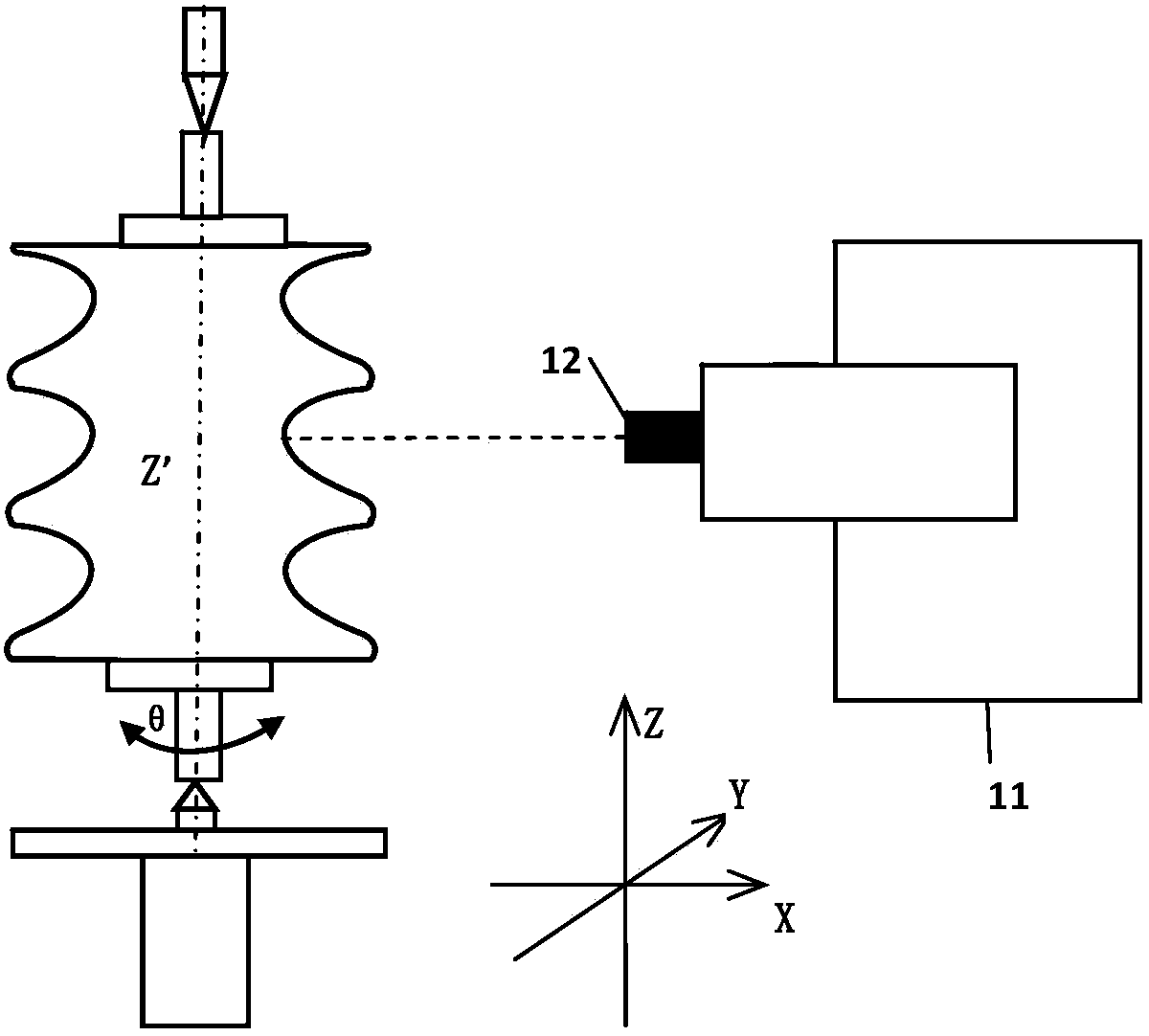

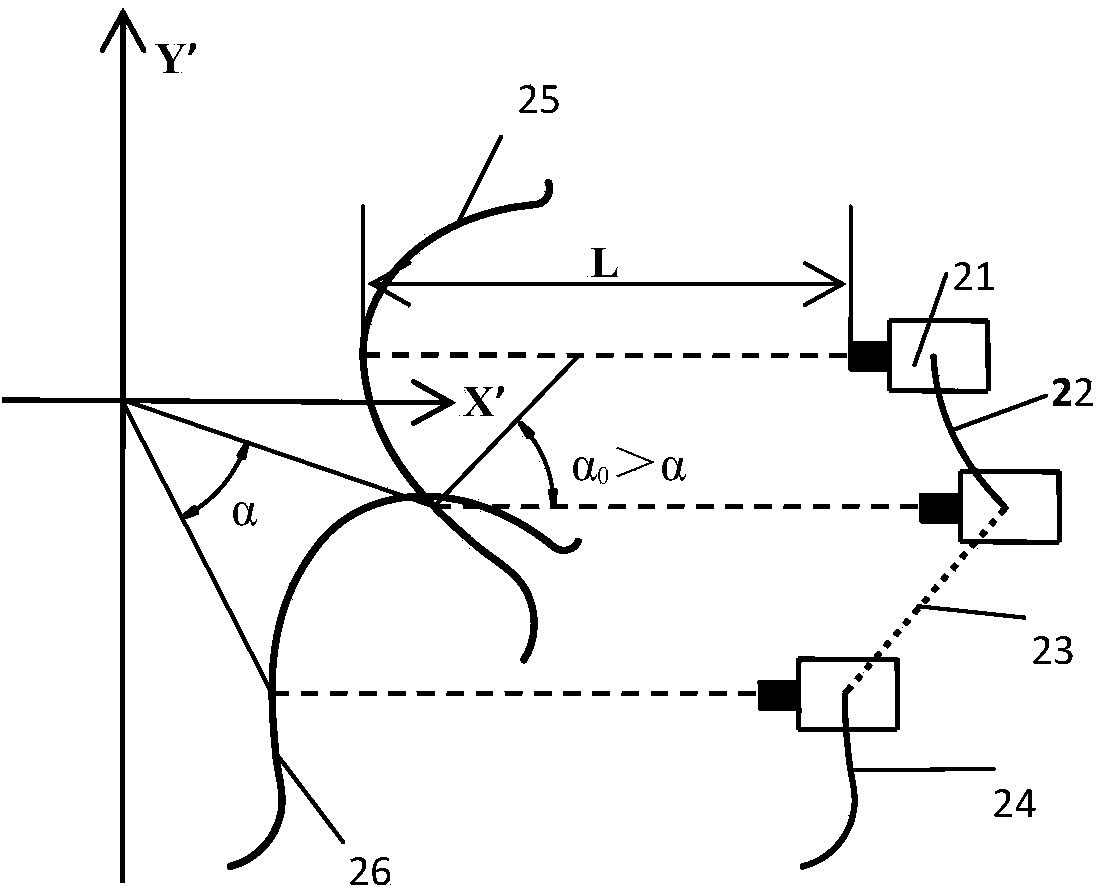

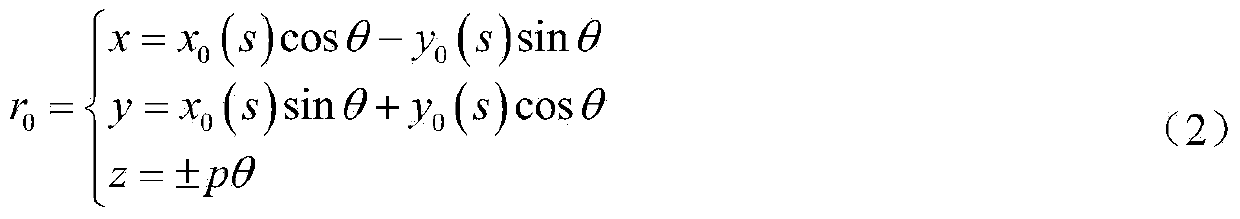

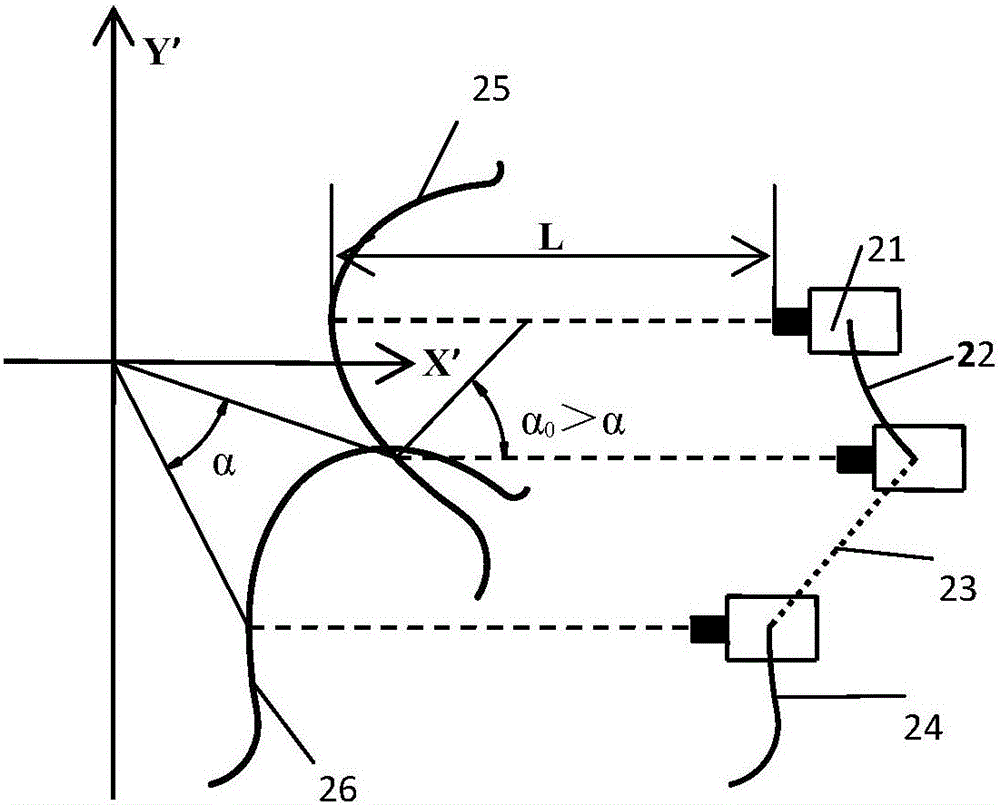

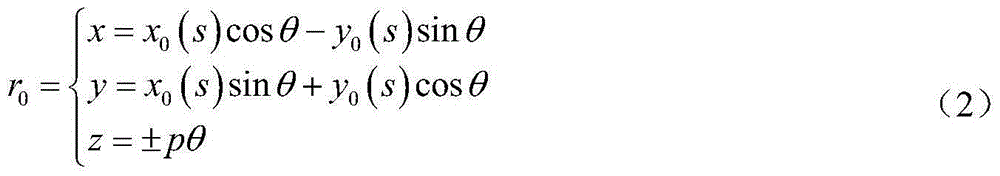

Method for laser detection of screw rotor end sectional shape

InactiveCN103438828AExtend your lifeImprove detection accuracyUsing optical meansInterference phenomenonEngineering

The invention discloses a method for laser detection of a screw rotor end sectional shape, and relates to detection of screw rotors. The measurement advantages of high precision, non-contact type and long service life of a laser displacement sensor are utilized, and the laser displacement sensor moves along the rotor theoretical end sectional shape to keep equidistance measurement. A kinematic relation between a screw rotor rotating coordinate system and a coordinate system where a movable platform of the laser displacement sensor is located is established, a normal vector of each data point of the rotor end sectional shape is calculated, by the rotation of the screw rotors, the interference phenomenon that a measured point is sheltered by other contours in the measurement process is avoided, and the problem that the included angle between the normal vector of the measured point and the laser emergent direction exceeds the angle range, which can be accurately measured, of the laser displacement sensor is solved. The detection accuracy can be effectively improved, the high-precision detection of the screw rotor end sectional shape is obtained, and the method is also applied to measurement of end sectional shapes of the screw rotors with wide helicoids.

Owner:XIAMEN UNIV +1

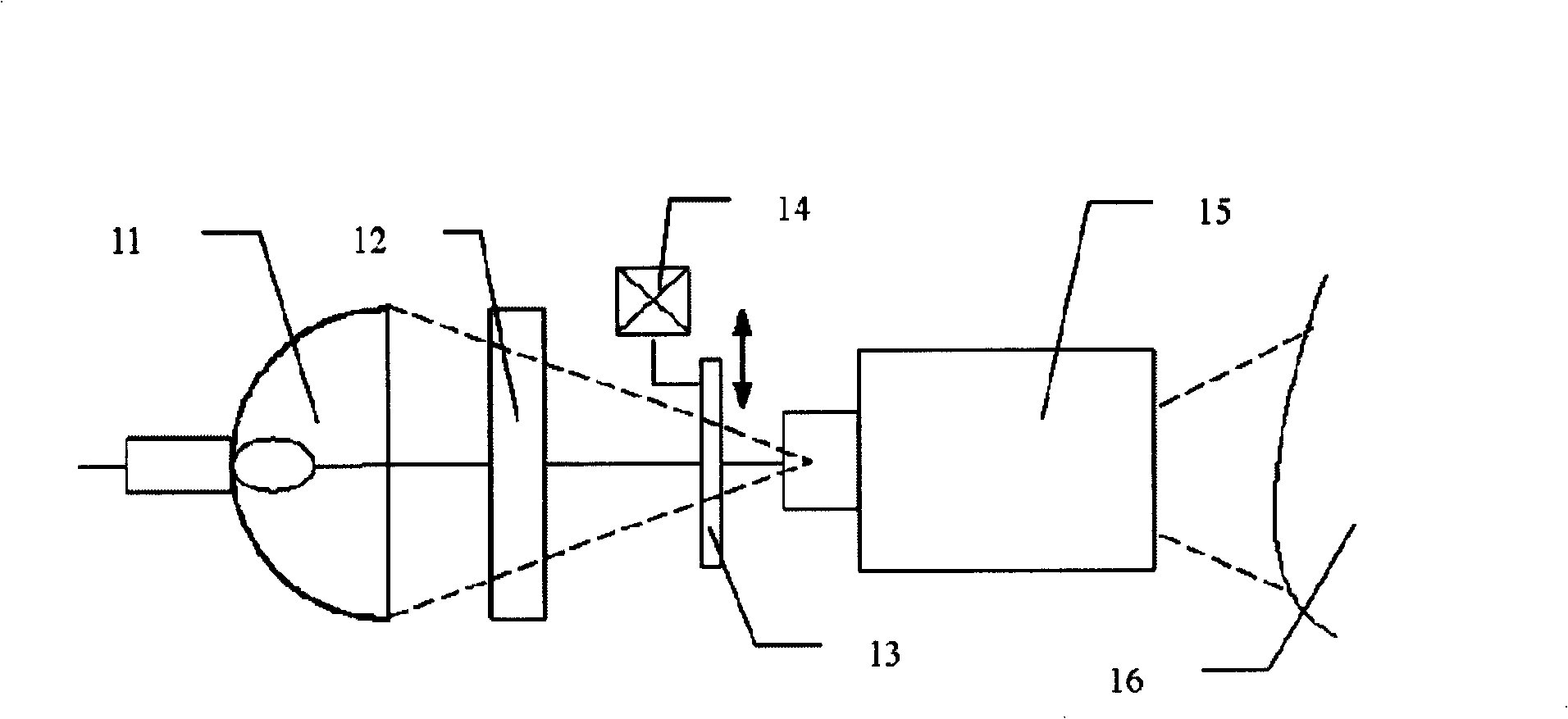

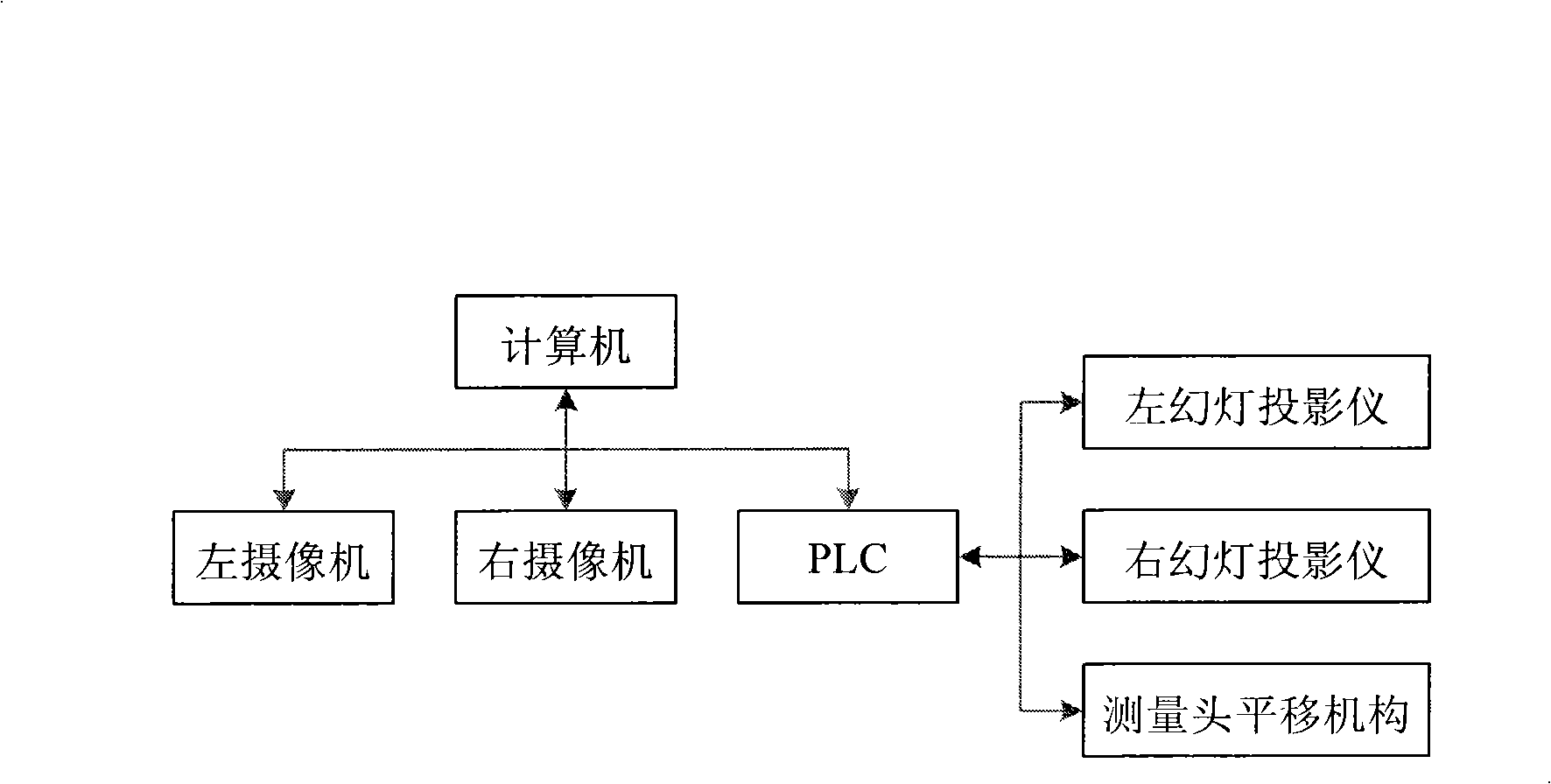

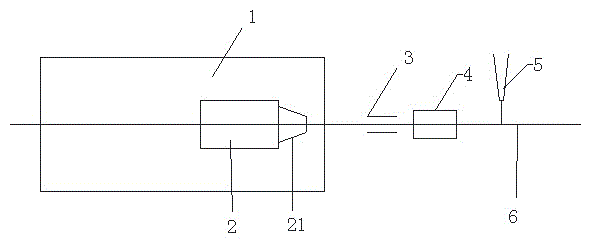

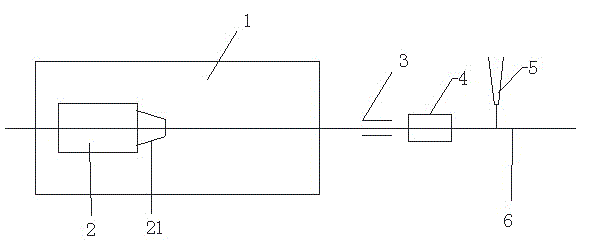

Double/single ocular white light three-dimensional measuring system for repairing defects of patient face

InactiveCN101301199AAvoid stitching errorsIncrease contrastDiagnostic recording/measuringSensorsHuman bodyParenchyma

A double-monocular white light three-dimensional measurement system used for restoring face defect of patients belongs to fields of optical measurement, mechanical engineering and medical engineering. The measurement system includes a left monocular measurement head, a right monocular measurement head, a measurement head support, a measurement head translation mechanism, a control cabinet and a computer. Based on structure optical projection three-dimensional vision measurement technique, the measurement system employs double-monocular measurement structure, white light sources which are safe for human body are employed in a left magic lantern projector and a right magic lantern projector for rear projection of physical coding grating, Gray codes and phase shift coding stripes are projected on left and right faces of patients, after a left camera and a right camera take a view of deformed gating images, measurement of complete three-dimensional face appearance of patients is realized by image decoding, triangle principle and double-eye measurement data combination. The measurement system can realize accurate data collection of natural state parenchyma of patient faces under non-contact condition and provide credible three-dimensional appearance original data of patient faces for clinic appearance defect restoring therapy.

Owner:SHANGHAI JIAO TONG UNIV

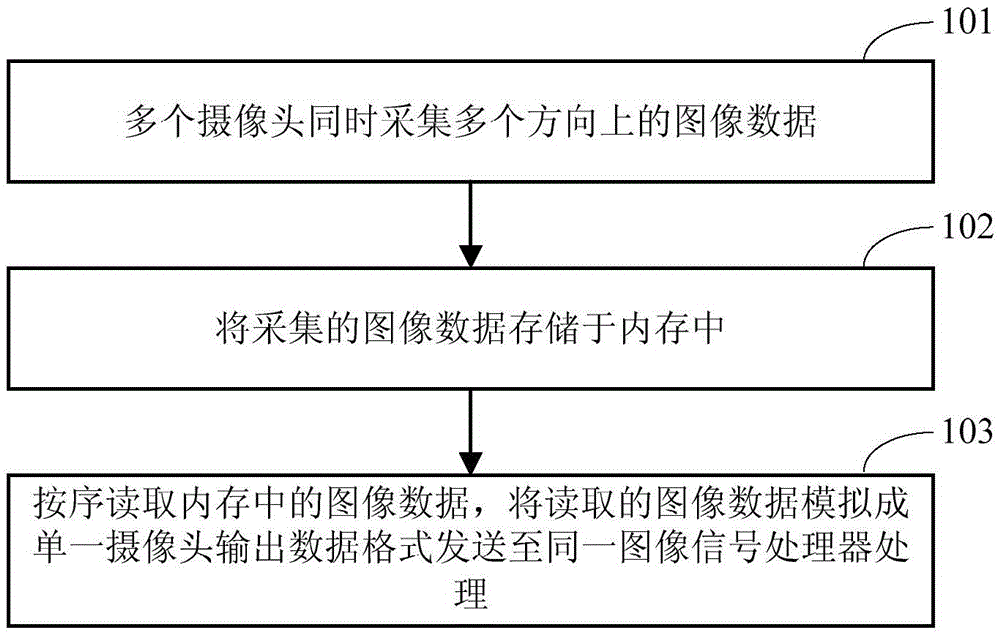

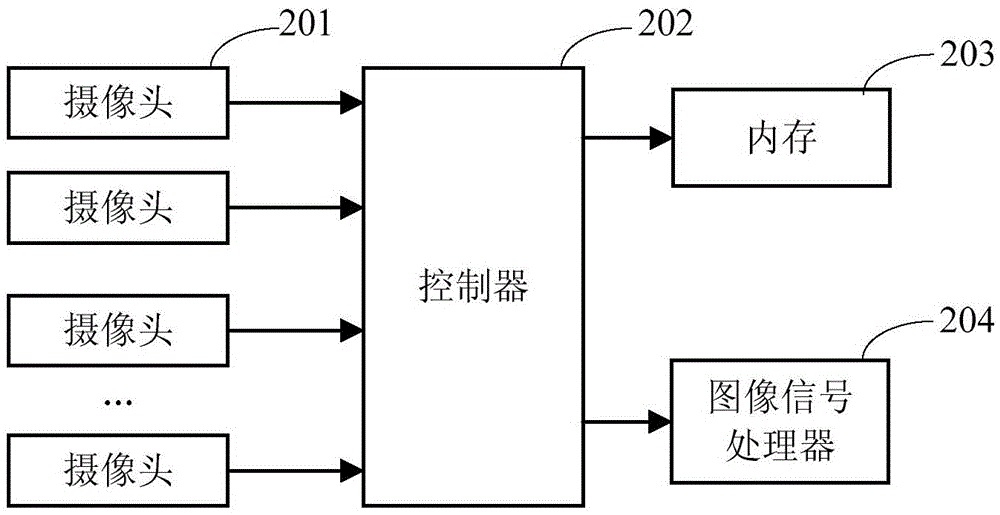

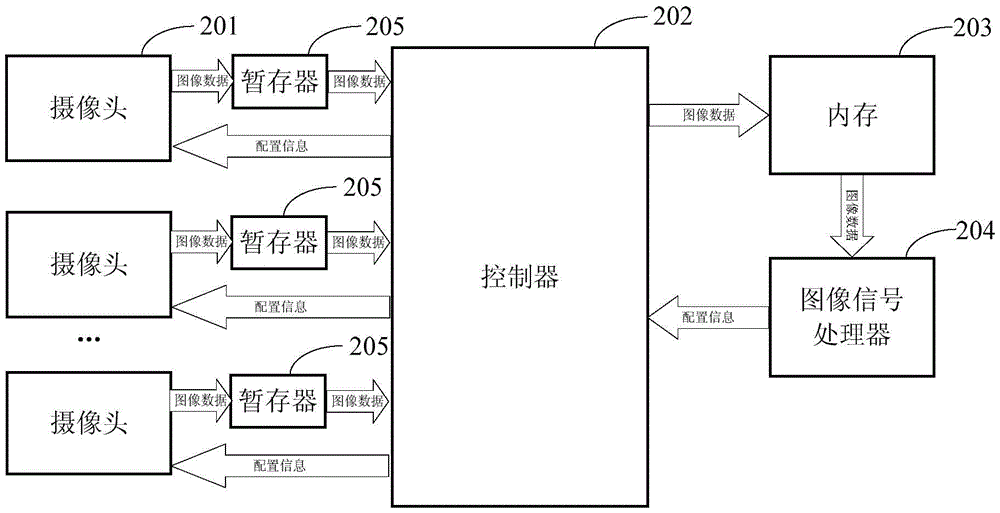

Method for realizing multiple-camera simultaneous photographing of panorama camera and panorama camera

InactiveCN105611177AReduce clock frequency requirementsAvoid stitching errorsTelevision system detailsColor television detailsImage signalData format

The invention provides a method for realizing multiple-camera simultaneous photographing of a panorama camera and the panorama camera, belonging to the field of the panorama camera; the method comprises the following steps: simultaneously collecting image data on multiple directions by multiple cameras; storing the collected image data to a memory; and reading the image data in the memory in sequence, simulating the read image data as a single camera output data format and sending to a same image signal processor for processing. According to the method for realizing the multiple-camera simultaneous photographing of the camera and the panorama camera disclosed by the invention, the problems of high requirements on hardware, multiple required hardware and high cost can be solved in the prior art when the panorama camera realizes the multiple-camera simultaneous photographing.

Owner:BEIJING PANOTHINK TECH CO LTD

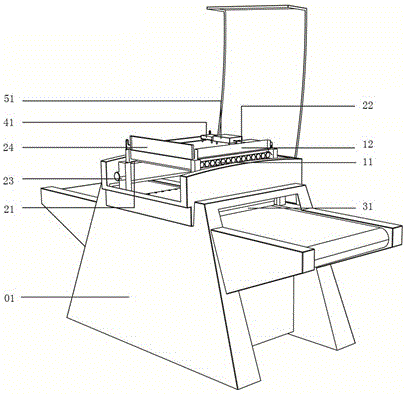

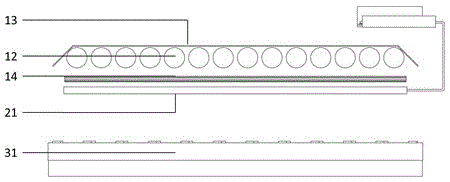

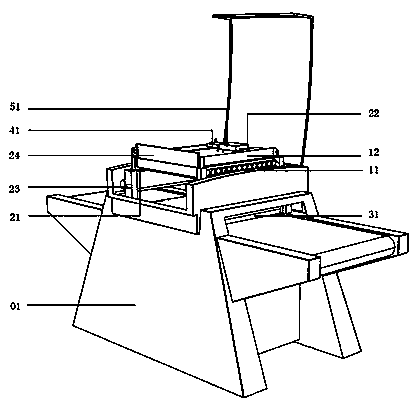

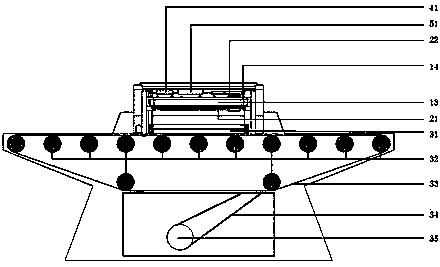

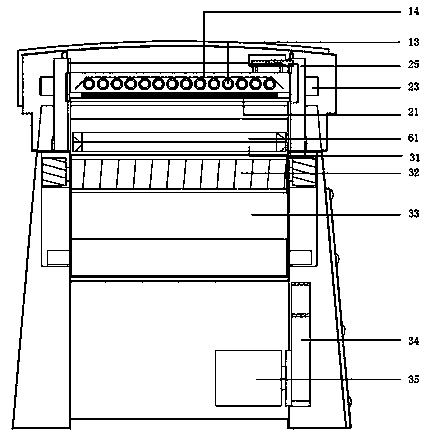

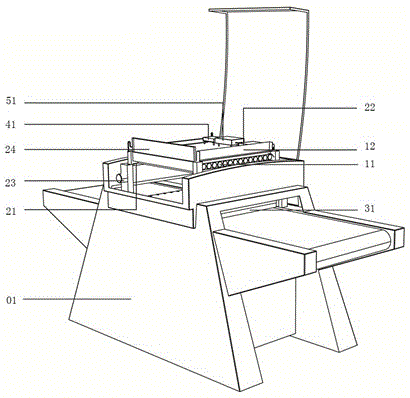

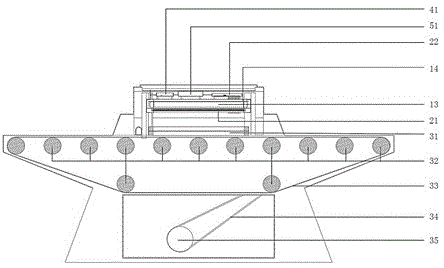

Computer imaging type direct plate making equipment and plate making method

ActiveCN103955112AQuality improvementReduce usagePhotomechanical apparatusForme preparationLight guideSheet film

The invention provides computer imaging type direct plate making equipment and a plate making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, so as to mask the light from the exposure light source, and thus a corresponding exposure image is formed on the printing plate; to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Due to the introduction of a light homogenizing layer, dependence on a light source is further reduced, and in particular, good plate making precision can be obtained by combination of light sources with different specifications, light sources or spot light sources with different surface luminescence uniformity and line light sources. A plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:青岛斯博锐意电子技术有限公司

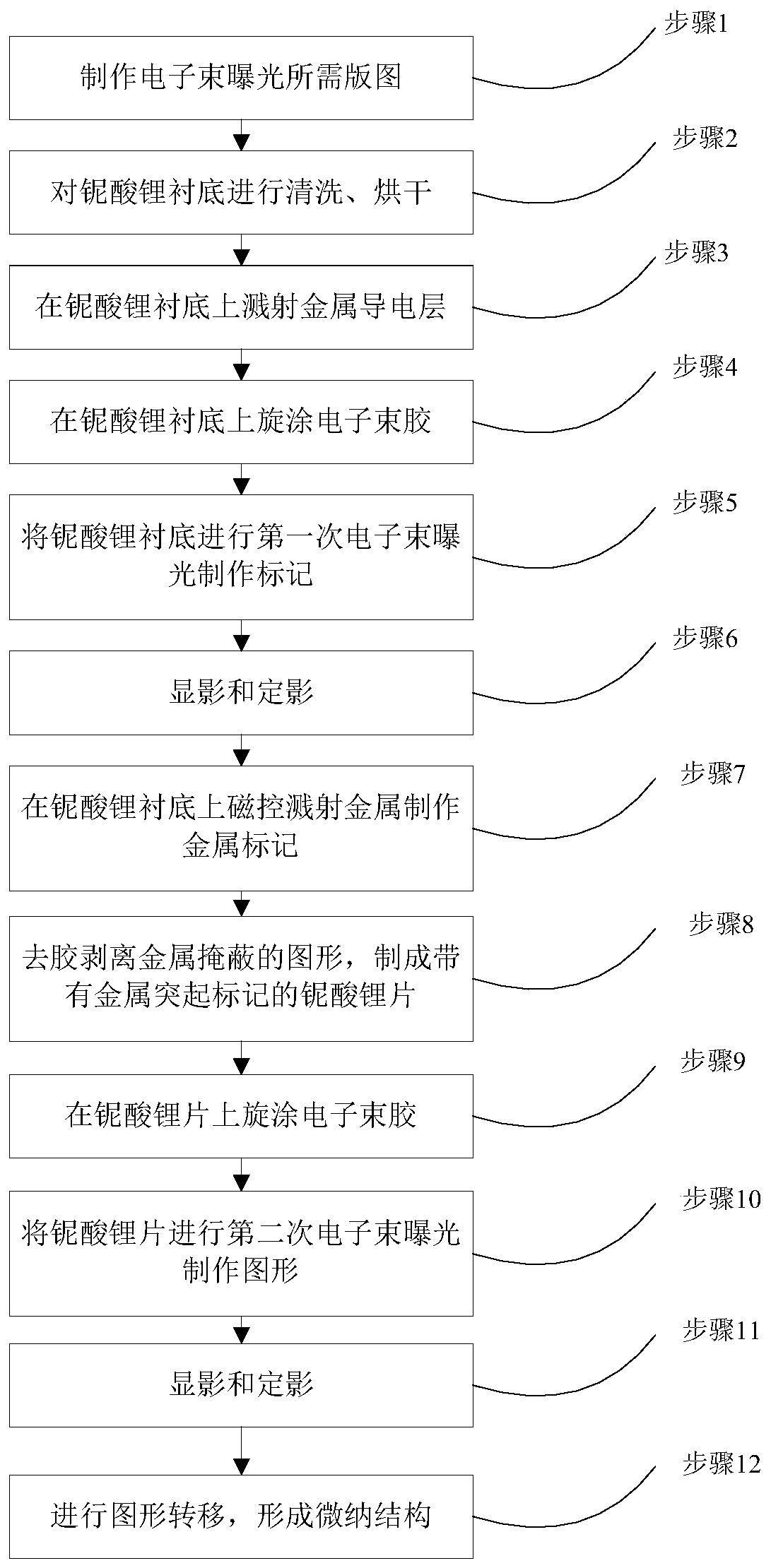

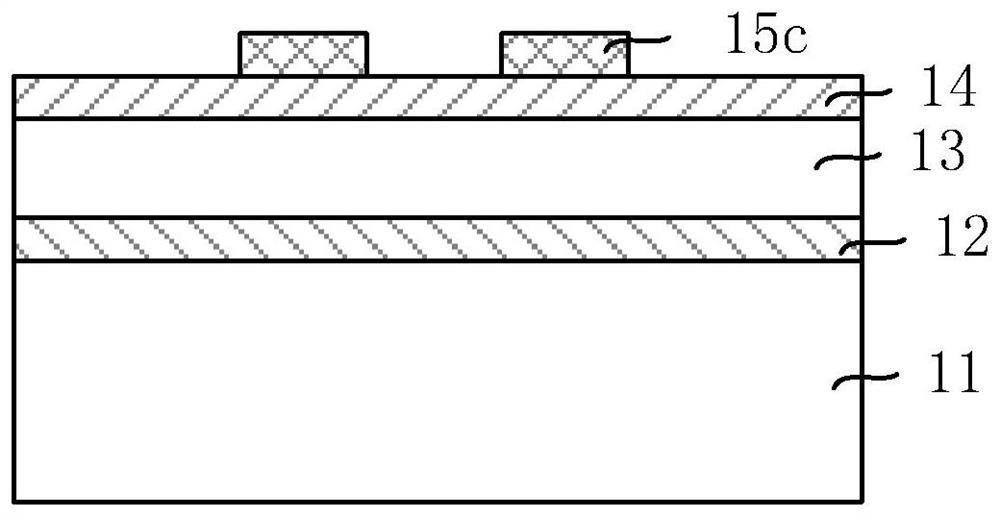

Method for manufacturing optical micro-nano pattern on surface of lithium niobate film

ActiveCN110850688AImprove Exposure AccuracyReliable technical solutions for exposing HSQPhotomechanical exposure apparatusMicrolithography exposure apparatusSputteringNano structuring

The invention relates to a method for manufacturing an optical micro-nano pattern on the surface of a lithium niobate film, which belongs to the technical field of micro-nano processing. The method comprises the following steps: manufacturing a layout required by electron beam exposure; cleaning and drying a lithium niobate substrate; sputtering a metal conductive layer on the lithium niobate substrate; spin-coating the lithium niobate substrate with electron beam glue; carrying out first electron beam exposure on the lithium niobate substrate to manufacture a mark; carrying out developing andfixing; carrying out magnetron sputtering of metal on the lithium niobate substrate to manufacture a metal mark; removing the photoresist and stripping a metal-masked pattern to prepare a lithium niobate sheet with a metal bulge mark; spin-coating the lithium niobate sheet with electron beam glue; carrying out second electron beam exposure on the lithium niobate sheet to manufacture a pattern; carrying out developing and fixing; and carrying out pattern transfer to form a micro-nano structure. By means of the method, a pattern with a steep side wall can be manufactured on a non-conductive lithium niobate material, a micro-nano pattern with the size smaller than 900nm can be manufactured, the manufactured optical waveguide is large in refractive index contrast ratio, the size of an opticaldevice can be reduced, and the performance of the optical device can be improved.

Owner:TSINGHUA UNIV +1

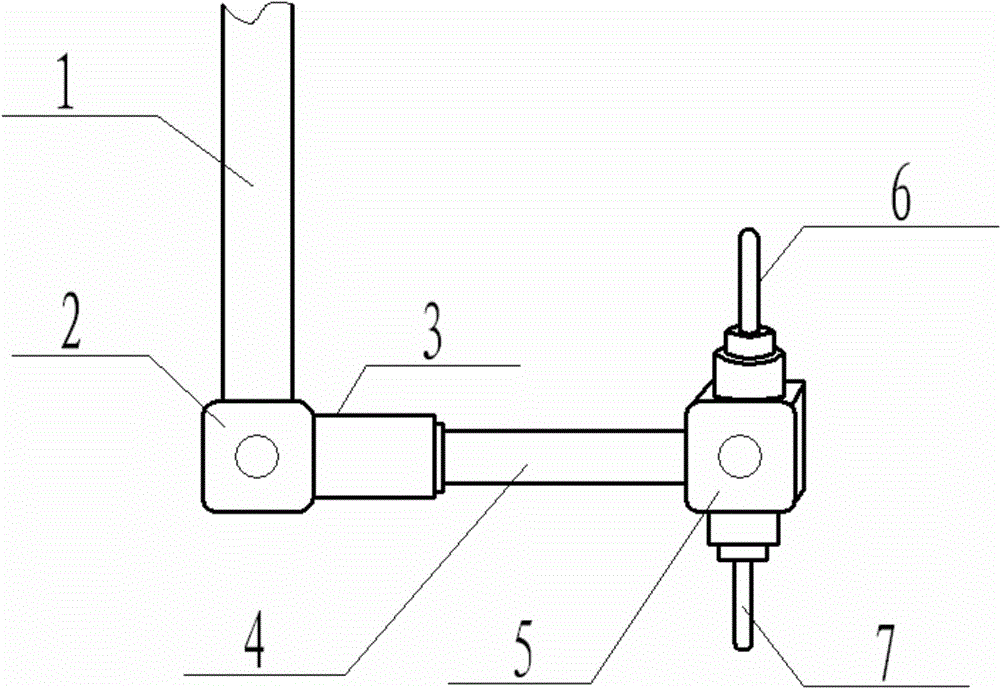

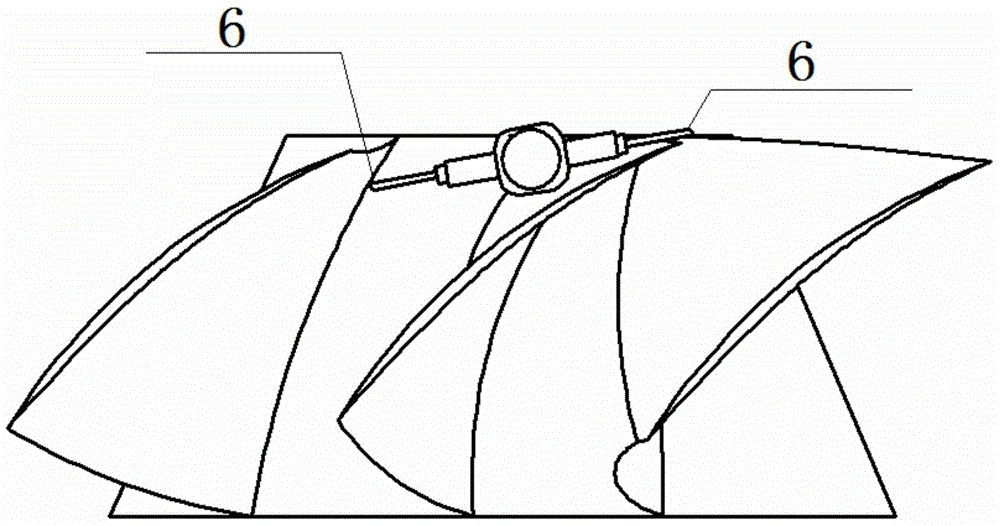

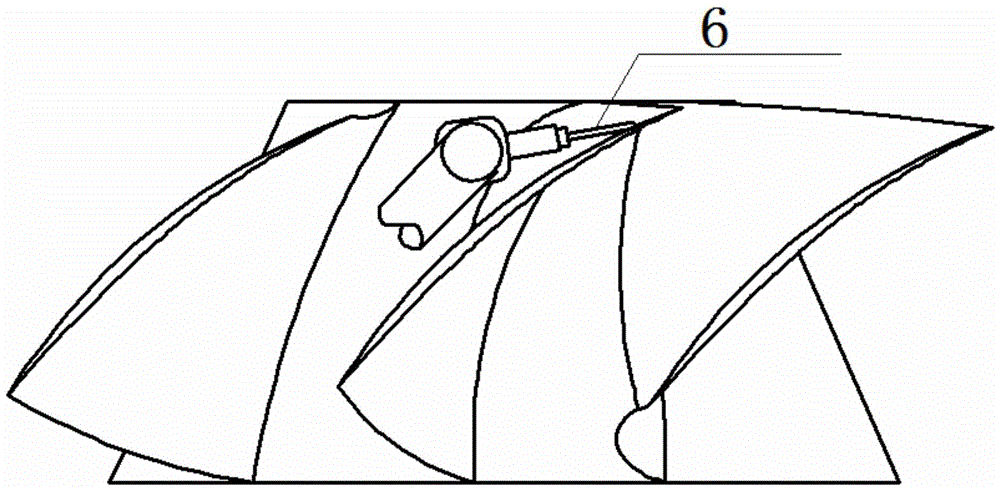

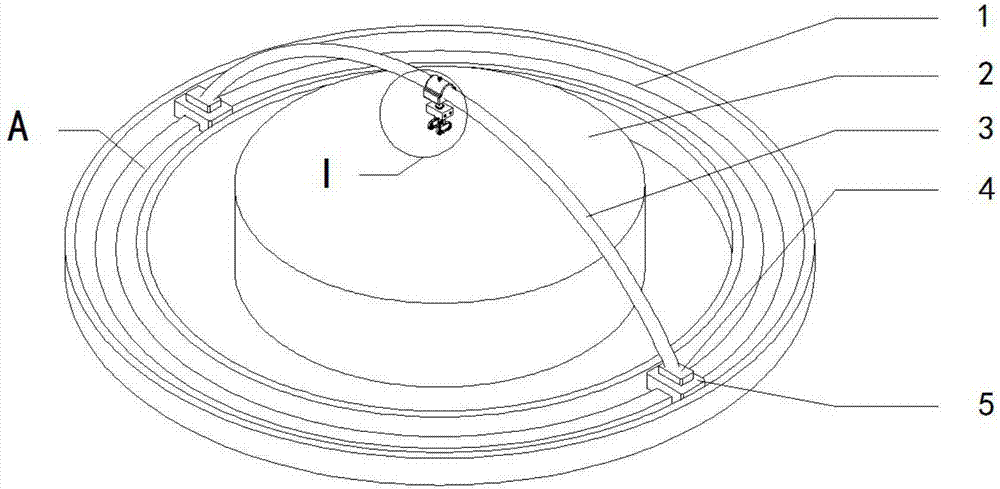

Cylindrical probe and method for measuring and scanning blade profile of blisk

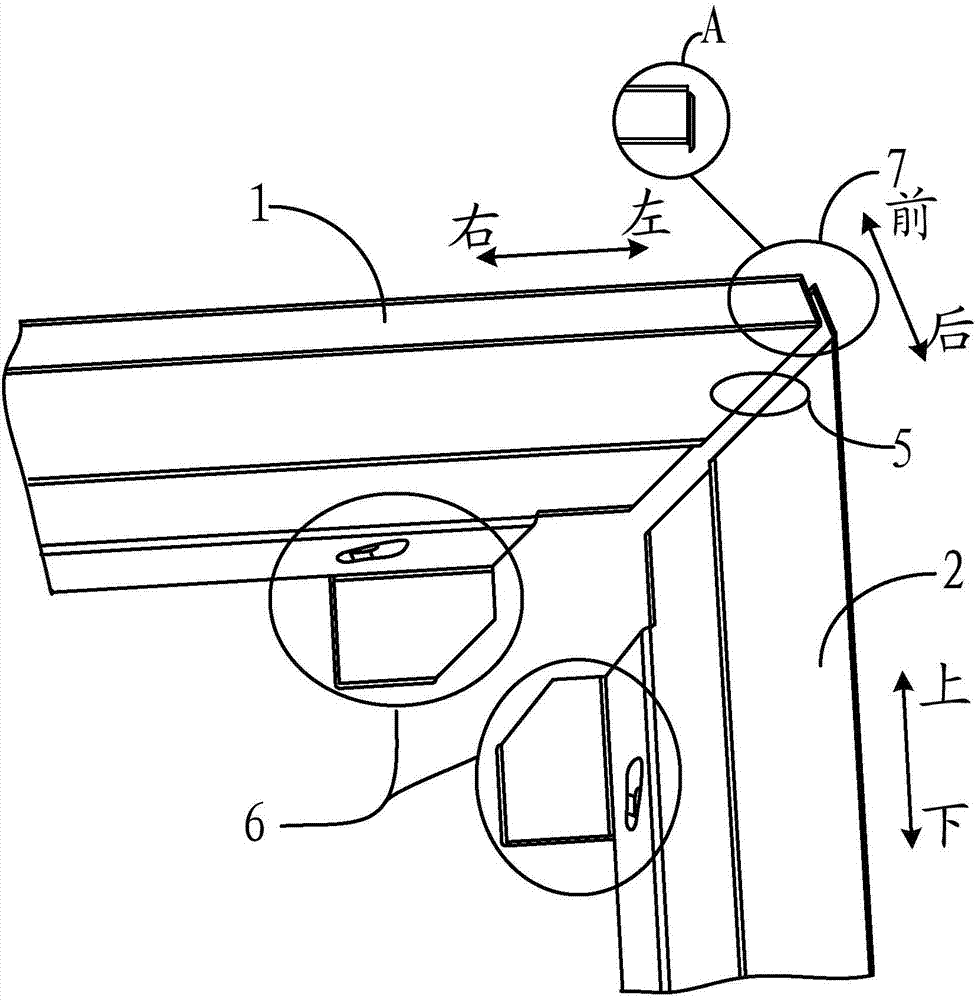

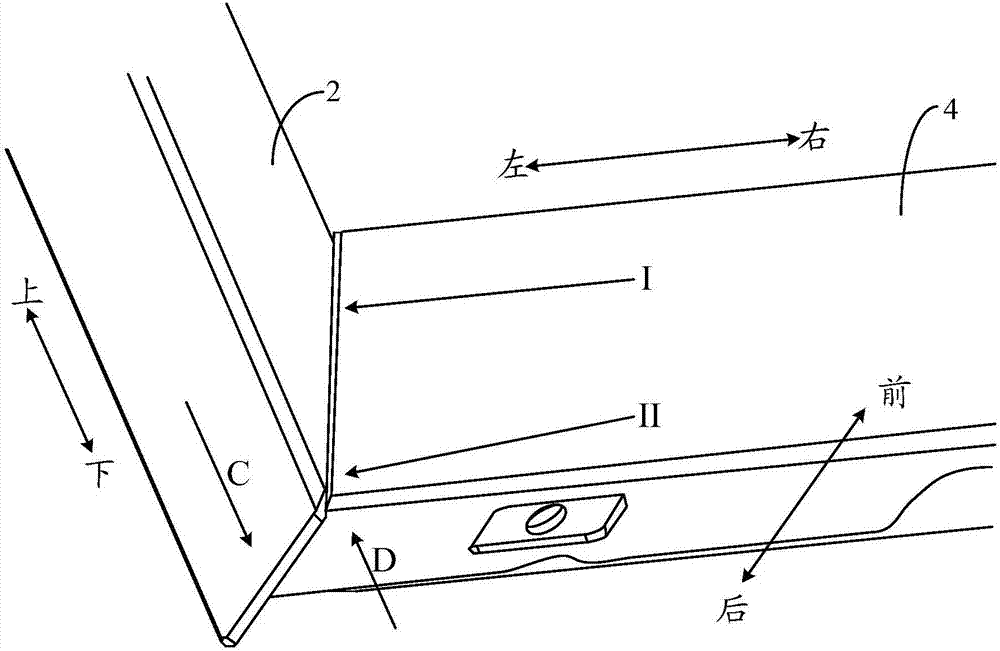

InactiveCN105651234AAvoid stitching errorsRealize high-efficiency and high-precision measurementMeasurement devicesObservational errorContinuous scanning

Disclosed are a cylindrical probe and a method for measuring and scanning the blade profile of a blisk. The cylindrical probe is composed of an extension bar I (1), a five-dimension adapter I (2), a universal joint (3), an extension rod II (4), a five-dimension adapter II (5) and a cylindrical probe I (6). One end of the extension rod II (4) is connected with the extension bar I (1) through the five-dimension adapter I (2) and the universal joint (3). The problems of data discontinuity and large measurement error are solved, data splicing error is avoided, and the efficiency of measurement is improved. With the cylindrical probe and the method for measuring and scanning the blade profile of a blisk, continuous scanning measurement of the blade profile of a blisk can be completed at one attempt. Data is continuous and complete, there is no data missed, and there is no cohesion error. The measurement precision and speed are high, and the stability is good. High-efficiency and high-precision measurement of blisks is realized. The cylindrical probe and the method satisfy the aero-engine blisk quality control requirements, and adapt to the progress demand of batch production on the production site for measurement.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

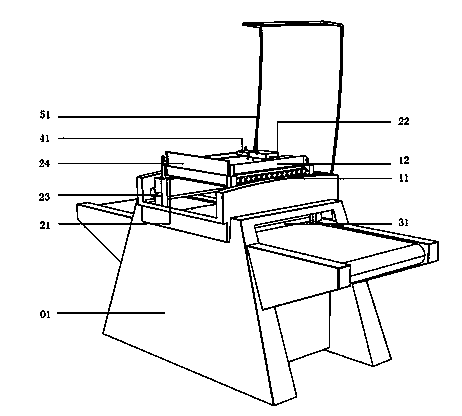

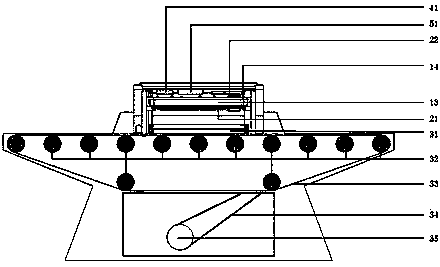

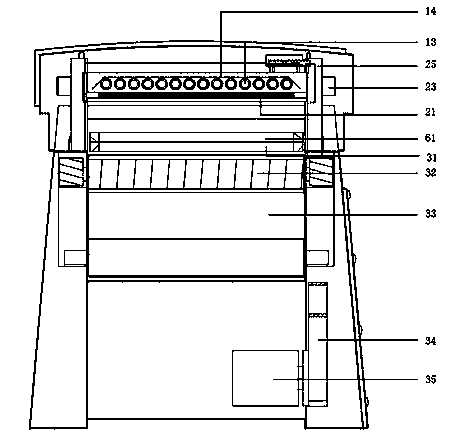

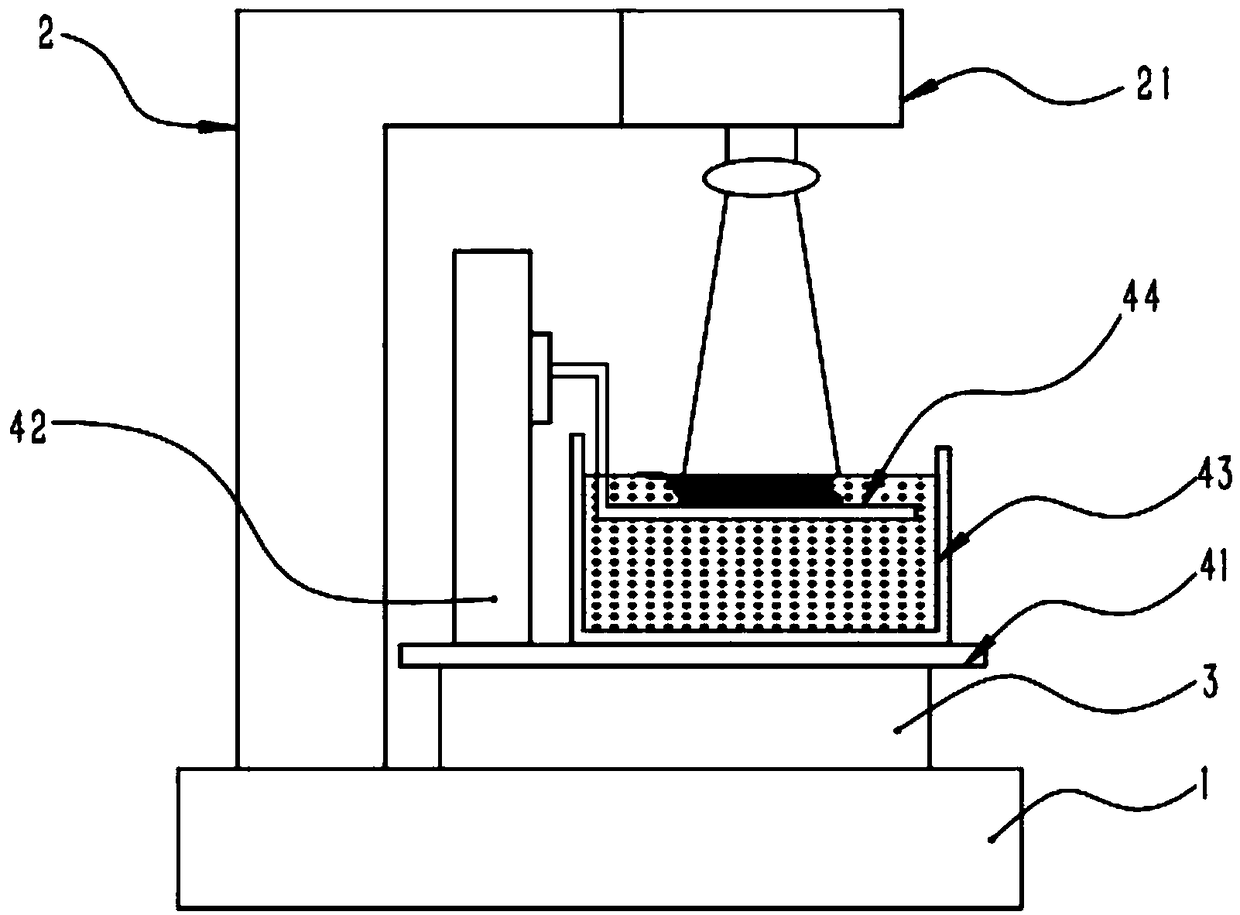

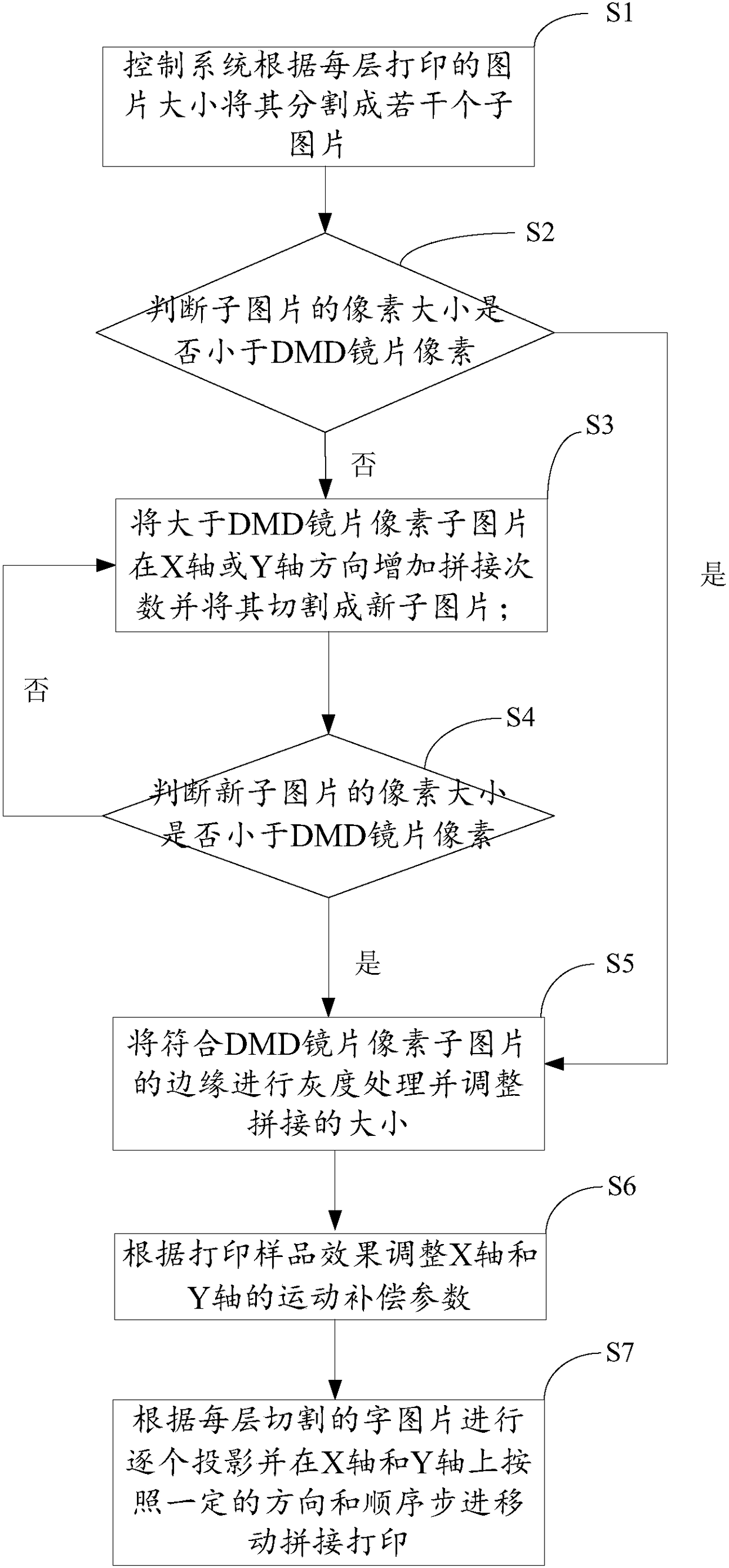

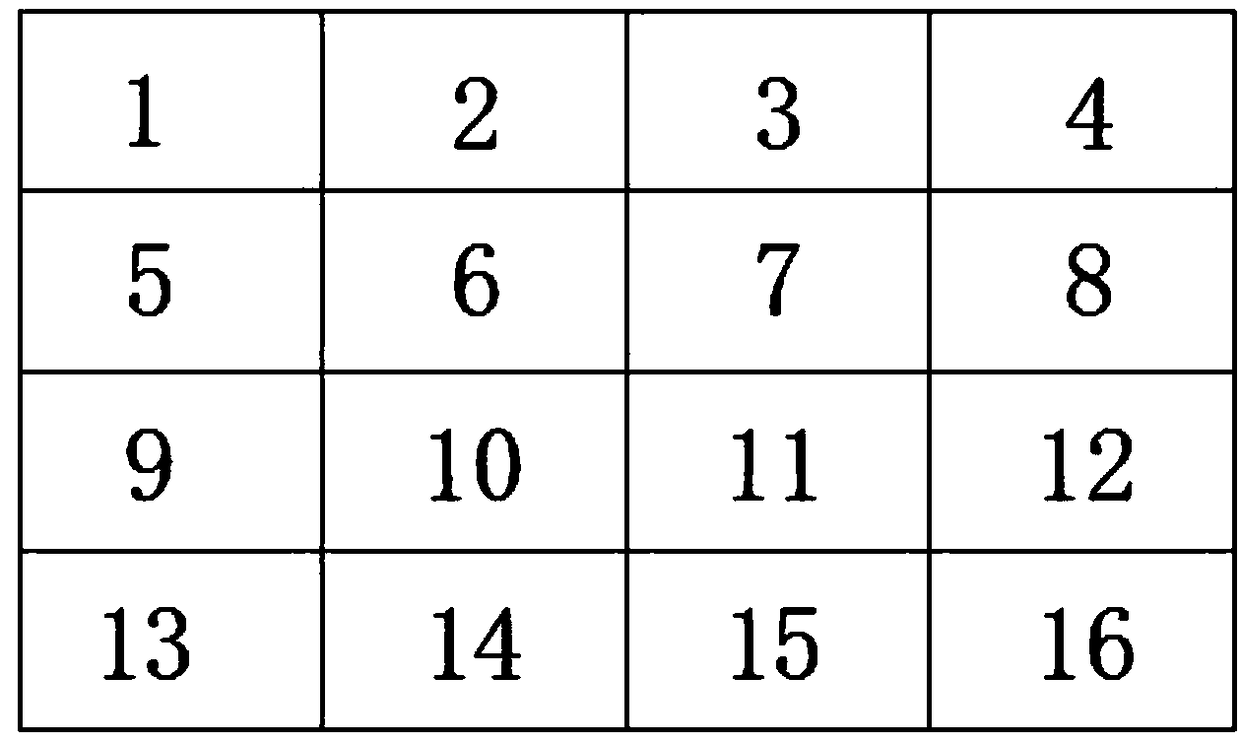

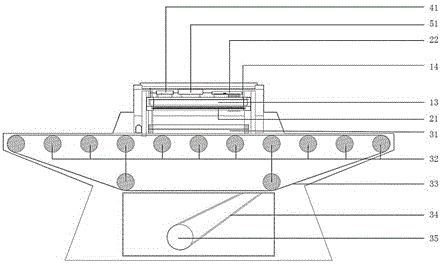

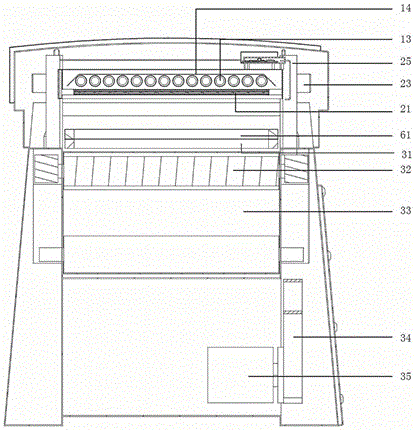

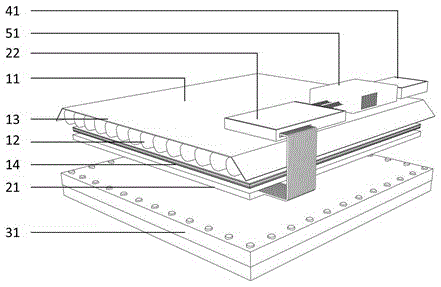

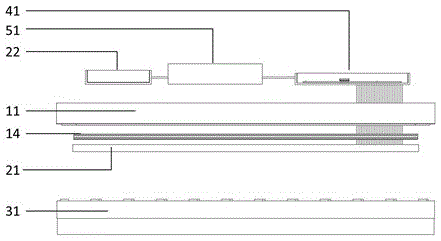

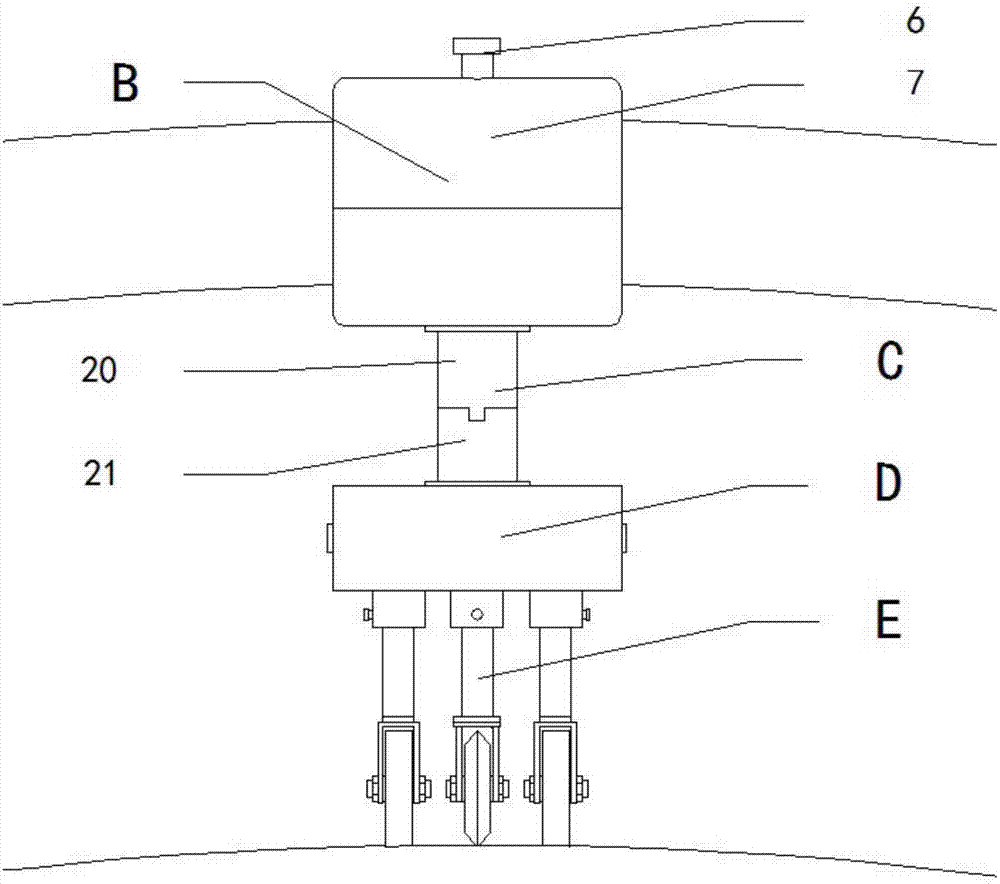

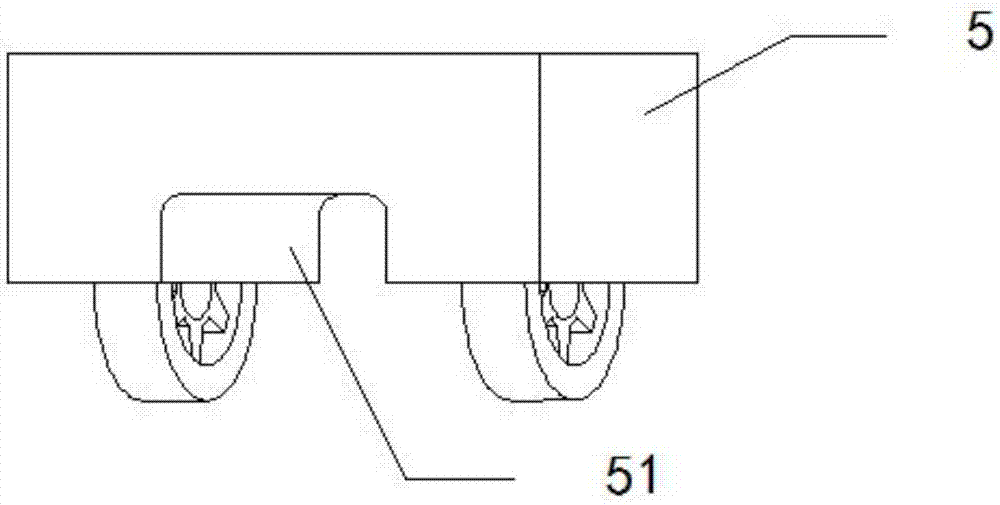

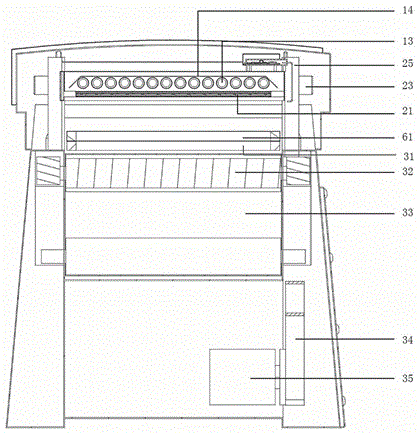

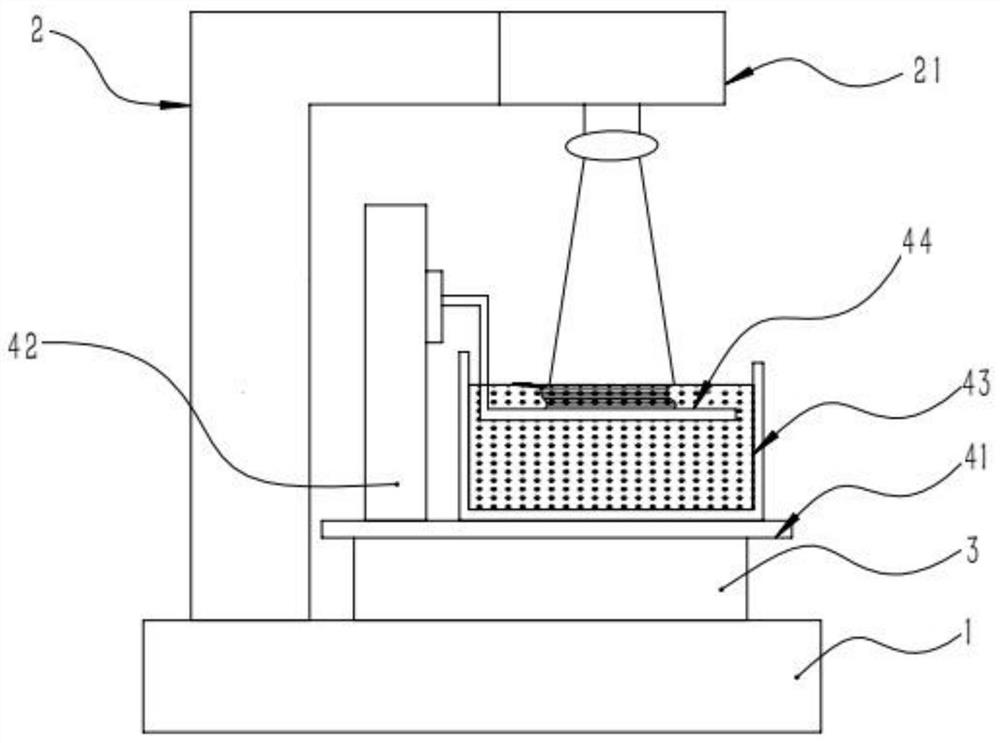

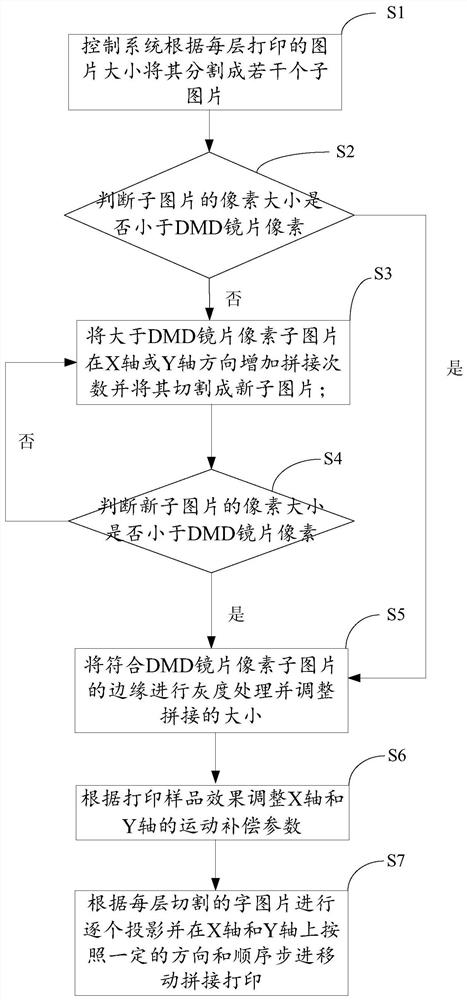

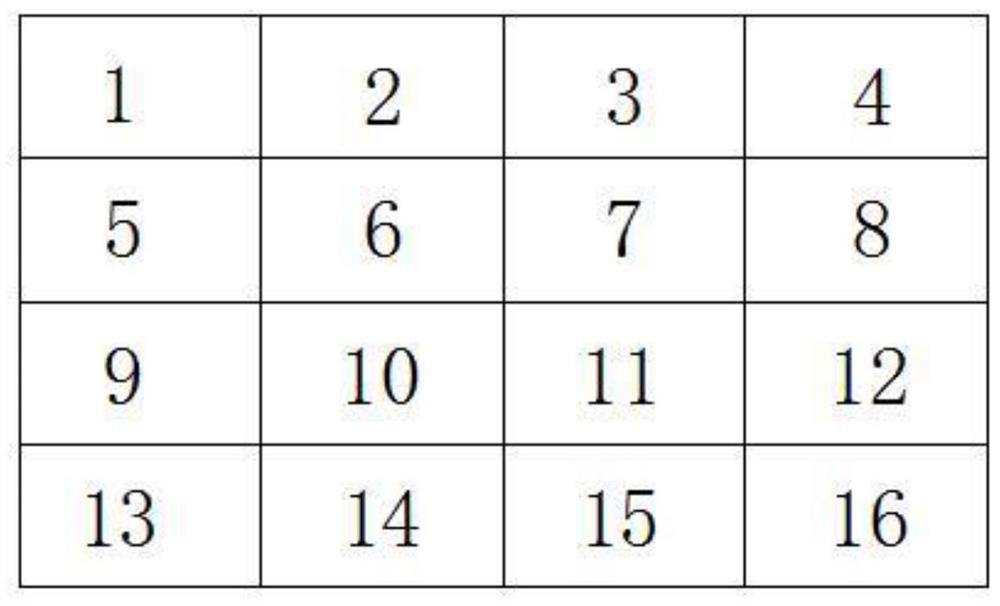

Stepping splicing type 3D printing system and printing method

ActiveCN108274745AImprove printing accuracyAvoid stitching errorsManufacturing platforms/substrates3D object support structuresControl systemAgricultural engineering

The invention provides a stepping splicing type 3D printing system and a printing method. The system comprises a control system and a 3D printer, wherein the control system is in communication connection with the 3D printer, the 3D printer comprises a fixing platform, a lens fixing column and a printing mechanism, the lens fixing column and the printing mechanism are arranged at the upper end of the fixing platform, the lens fixing column is provided with a photoetching lens corresponding to the printing mechanism in position, an XY-axis movement platform is arranged between the printing mechanism and the fixing platform, and the XY-axis movement platform comprises an X-axis movement mechanism and a Y-axis movement mechanism. The XY-axis movement platform is arranged, so that high printingprecision can be guaranteed, meanwhile, the printing breadth can be increased in a stepping splicing mode, and the splicing error in the splicing process can be effectively avoided.

Owner:BMF NANO MATERIAL TECH CO LTD

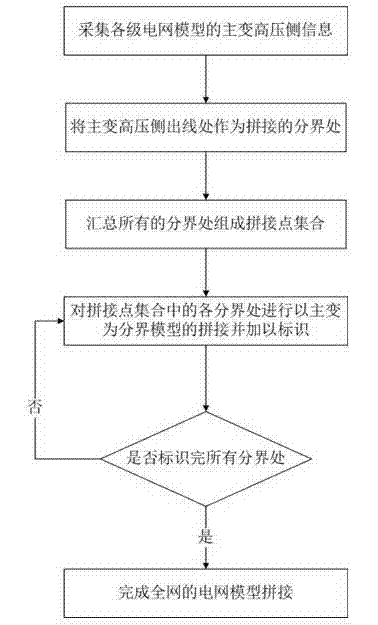

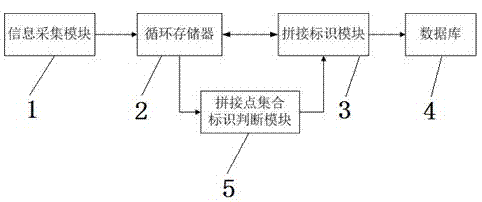

Power grid model splicing method for relay protection multistage setting calculation and system thereof

InactiveCN103532144ALower Consistency RequirementsReduce splitSpecial data processing applicationsAc network circuit arrangementsTransformerPower grid

The invention provides a power grid model splicing method for relay protection multistage setting calculation and a system thereof, and according to the method, the power grid model splicing for whole network with the high-voltage side outlet wire of a main transformer is used as a boundary model. The invention further provides a power grid model splicing system for the relay protection multistage setting calculation. The high-voltage side outlet wire of the main transformer is used as the splicing boundary place, so that the demand to the model consistency is reduced, the splicing error due to different modeling of buses in superior and subordinate power grids is avoided, the model splitting and splicing operation quantity is largely decreased, and the smooth splicing is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER CO LTD +1

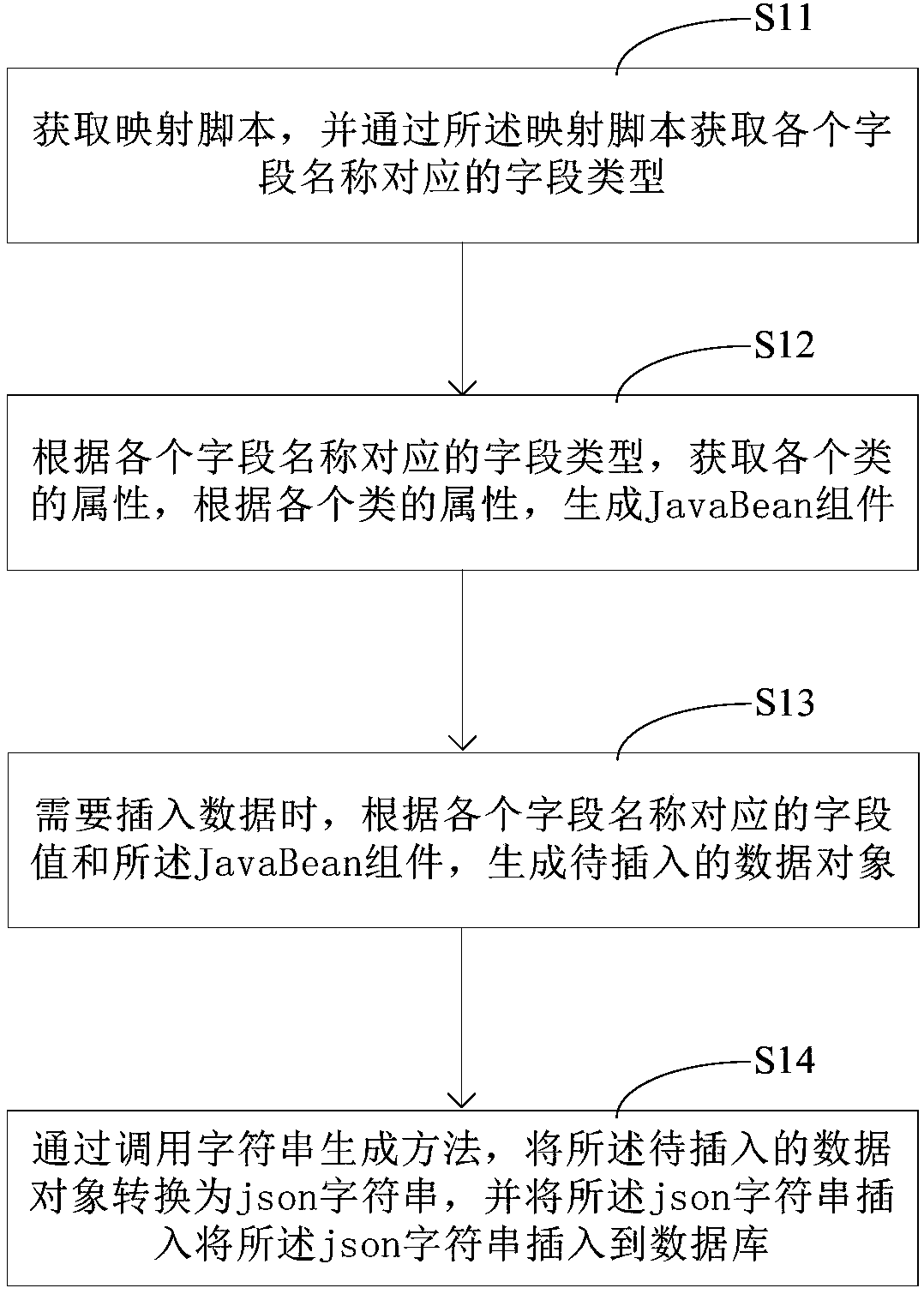

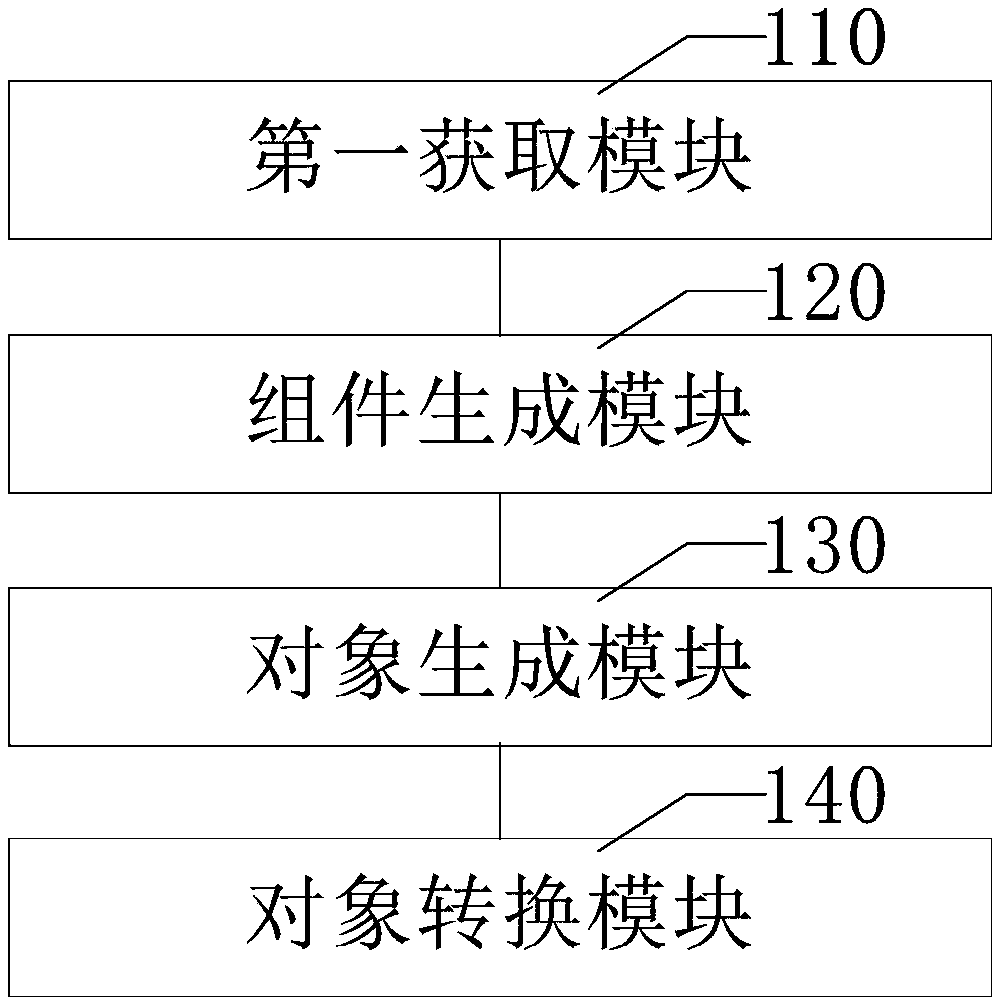

Data insertion method and apparatus

ActiveCN108241705AAvoid stitchingAvoid stitching errorsSpecial data processing applicationsJSONData objects

The invention discloses a data insertion method and apparatus. The method comprises the steps of obtaining a mapping script, and through the mapping script, obtaining field types corresponding to field names; then according to the field types corresponding to the field names, obtaining attributes of classes; according to the attributes of the classes, generating a JavaBean component; according tofield values corresponding to the field names and the JavaBean component, generating a to-be-inserted data object; through calling a character string generation method, converting the to-be-inserted data object to a json character string; and inserting the json character string into a database. Through the scheme disclosed by the method, data can be inserted in ElasticSearch; the method avoids splicing of the field names and the field values, so that the problem of splicing errors is avoided; and compared with the prior art, the data insertion accuracy is improved.

Owner:ULTRAPOWER SOFTWARE

A method of laser detecting screw rotor end truncation

InactiveCN103438828BEffective and accurate machining precisionEffectively and accurately obtain machining precisionUsing optical meansInterference phenomenonEngineering

The invention discloses a method for laser detection of a screw rotor end sectional shape, and relates to detection of screw rotors. The measurement advantages of high precision, non-contact type and long service life of a laser displacement sensor are utilized, and the laser displacement sensor moves along the rotor theoretical end sectional shape to keep equidistance measurement. A kinematic relation between a screw rotor rotating coordinate system and a coordinate system where a movable platform of the laser displacement sensor is located is established, a normal vector of each data point of the rotor end sectional shape is calculated, by the rotation of the screw rotors, the interference phenomenon that a measured point is sheltered by other contours in the measurement process is avoided, and the problem that the included angle between the normal vector of the measured point and the laser emergent direction exceeds the angle range, which can be accurately measured, of the laser displacement sensor is solved. The detection accuracy can be effectively improved, the high-precision detection of the screw rotor end sectional shape is obtained, and the method is also applied to measurement of end sectional shapes of the screw rotors with wide helicoids.

Owner:XIAMEN UNIV +1

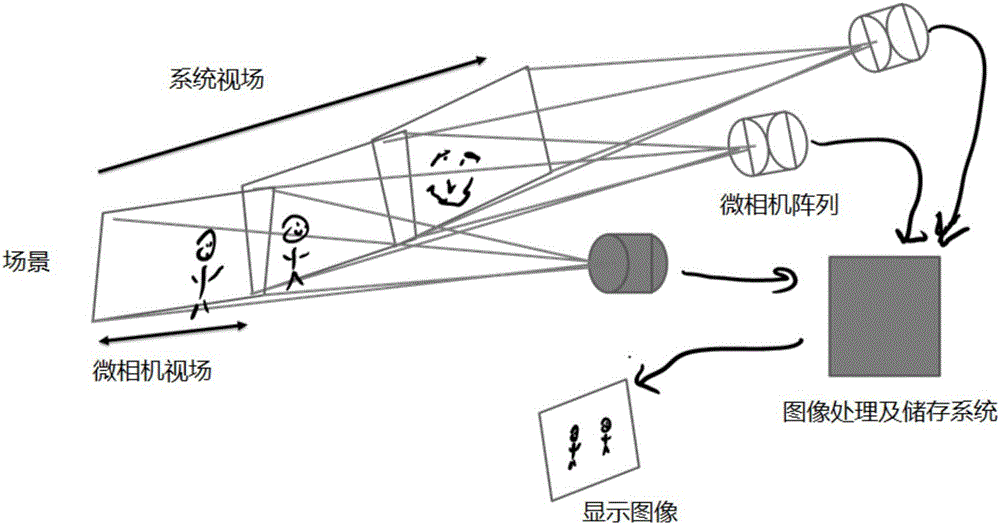

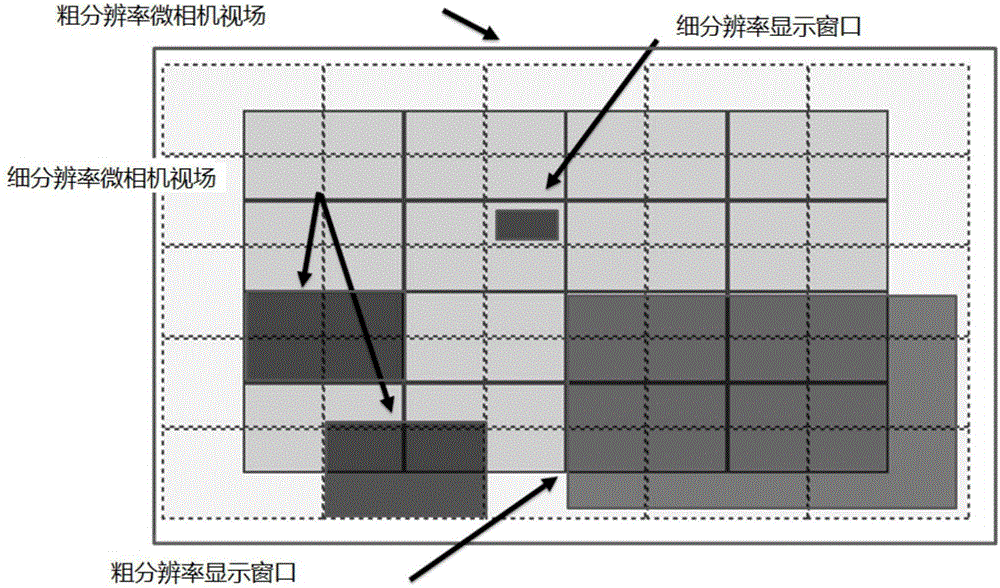

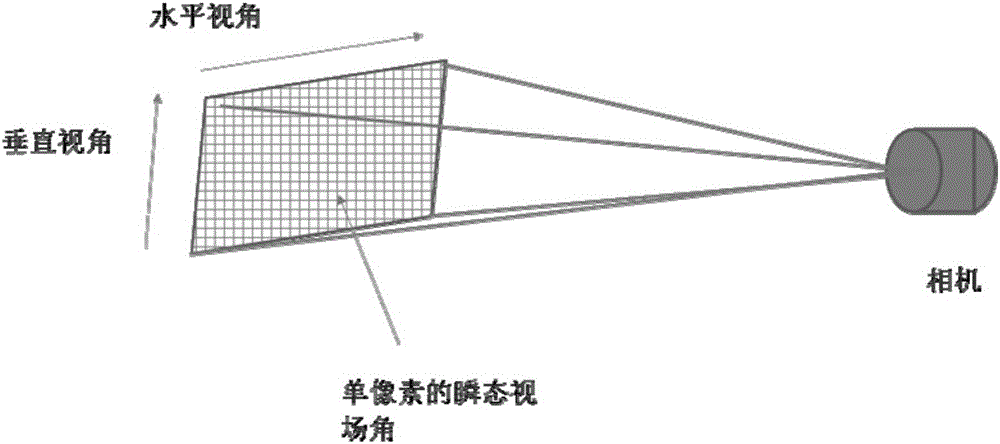

System and method for realizing real-time multi-scale imaging by using camera tiling

ActiveCN106067941AReduce or avoid the use ofReduce usageTelevision system detailsColor television detailsImaging processingImage resolution

The invention relates to a system for realizing real-time multi-scale imaging by using camera tiling. The system includes a camera array, an image processing and storage system and a display, wherein the image processing and storage system processes images acquired by the camera array and sends the processed images to the display. The system is characterized in that the camera array is composed of a plurality of mutually-staggered micro cameras; and the resolution of micro fields of view shot by the micro cameras is higher than the resolution of the display field of view of the display.

Owner:无锡安科迪智能技术有限公司

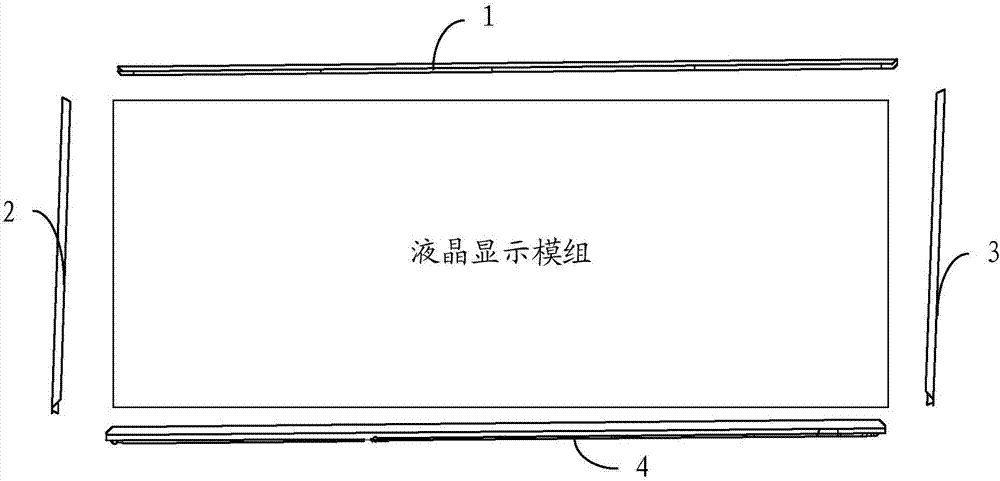

Screen metal frame assembly and liquid crystal display device

InactiveCN106959537AAvoid flippingPrevent collapseNon-linear opticsLiquid-crystal displayEngineering

An embodiment of the invention provides a screen metal frame assembly and a liquid crystal display device, relates to the field of display screen assembling and solves the problem of splicing errors of a screen metal frame. The screen metal frame assembly comprises a first frame and a second frame, wherein a first splicing surface formed at one end of the first frame is correspondingly attached to a second splicing surface formed at one end of the second frame; an elastic piece is arranged at one end, close to the first splicing surface, of the inner wall bottom surface of the first frame; one end of the elastic piece is attached to the inner wall bottom surface of the first frame; the other end of the elastic piece is connected with the inner wall bottom surface of the second frame. The screen metal frame assembly and the liquid crystal display device are applied to metal frame splicing of the liquid crystal display screen.

Owner:HISENSE VISUAL TECH CO LTD

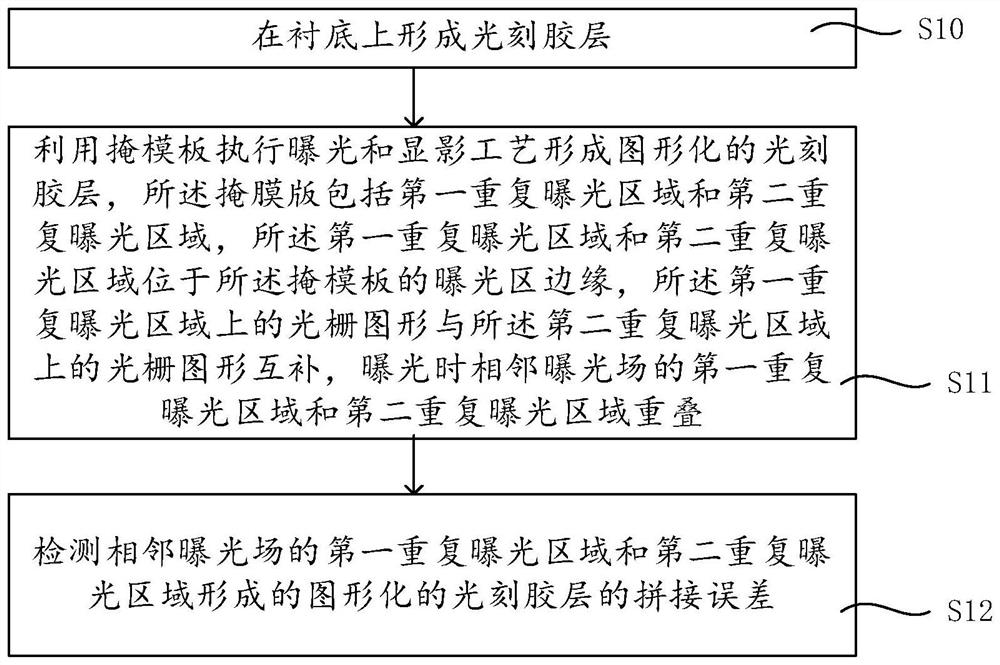

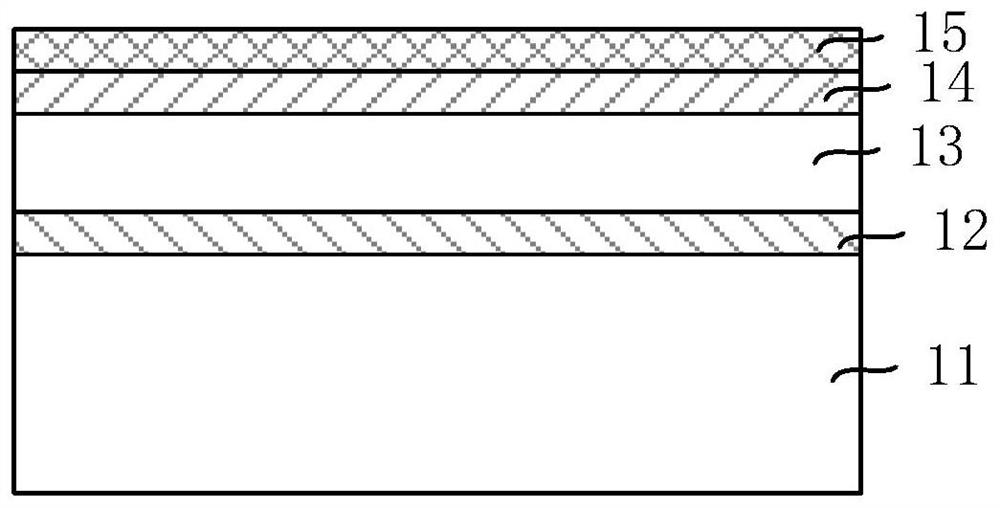

Photoetching splicing error detection method, two-dimensional grating manufacturing method and mask plate

ActiveCN114296321AAvoid stitching errorsIntegrity guaranteedFinal product manufactureDiffraction gratingsGraphicsEngineering

The invention provides a photoetching splicing error detection method, a two-dimensional grating manufacturing method and a mask plate. The photoetching splicing error detection method comprises the following steps: forming a photoresist layer on a substrate; a mask plate is used for executing exposure and development processes to form a graphical photoresist layer, the mask plate comprises a first repeated exposure area and a second repeated exposure area, and the first repeated exposure area and the second repeated exposure area are located on the edge of the exposure area of the mask plate. The grating pattern on the first repeated exposure area and the grating pattern on the second repeated exposure area are complementary, and the first repeated exposure area and the second repeated exposure area of adjacent exposure fields are overlapped during exposure; and detecting splicing errors of the patterned photoresist layers formed in the first repeated exposure region and the second repeated exposure region of the adjacent exposure fields by utilizing defect scanning equipment. According to the splicing error detection result, the position, direction and size of the splicing error of the two-dimensional grating can be determined, process correction is carried out, and the splicing error of the two-dimensional grating is avoided.

Owner:SHANGHAI INTEGRATED CIRCUIT EQUIP & MATERIALS IND INNOVATION CENT CO +1

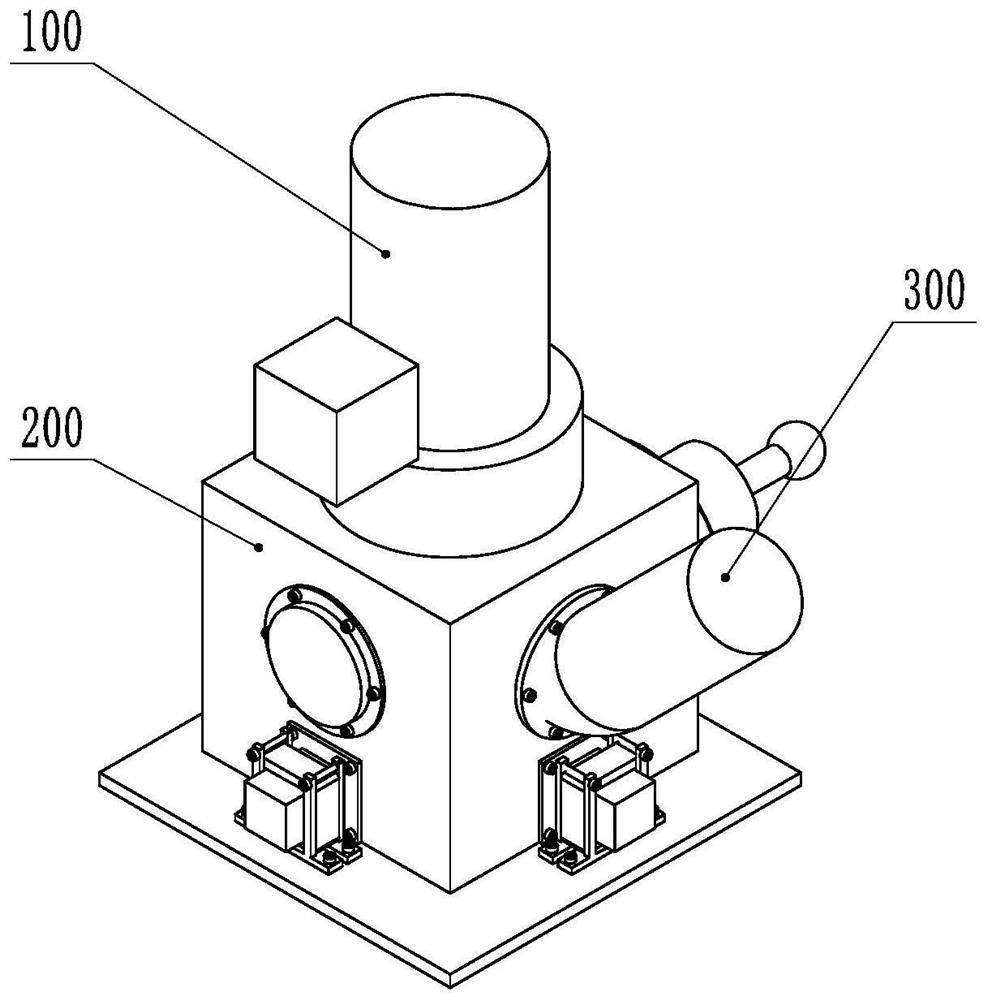

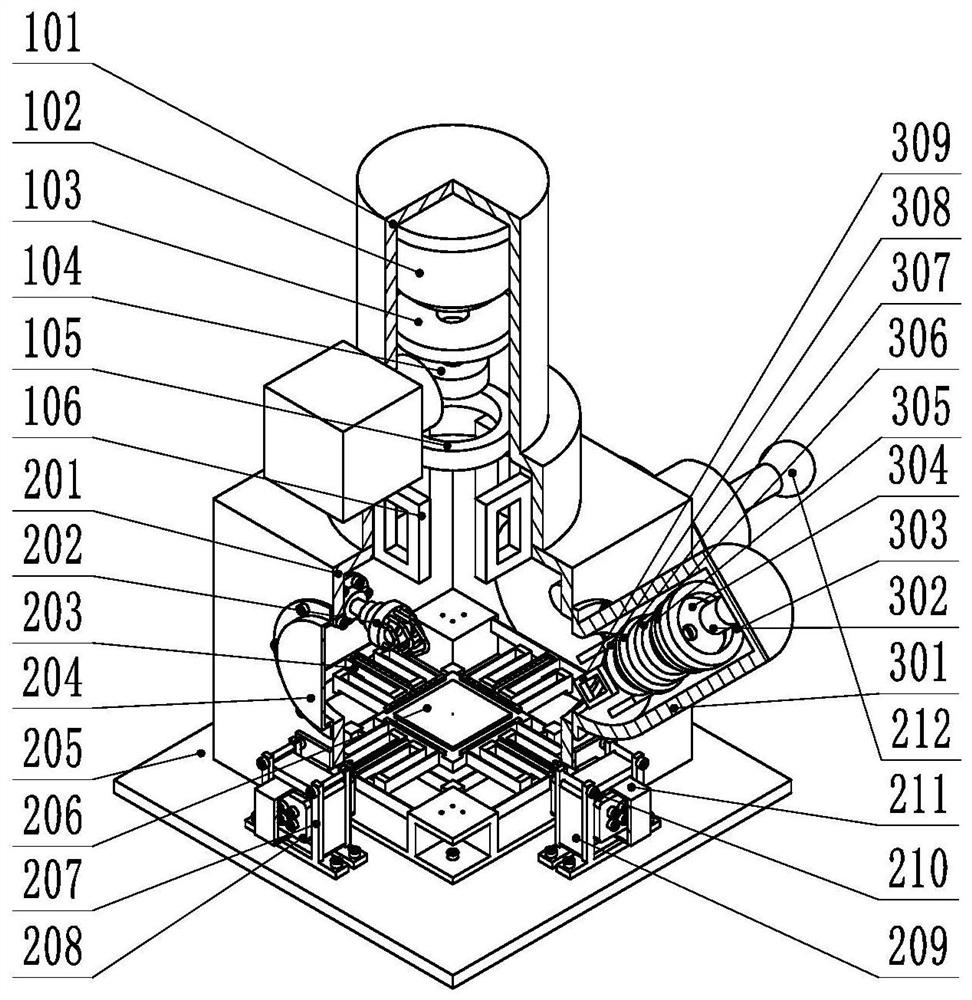

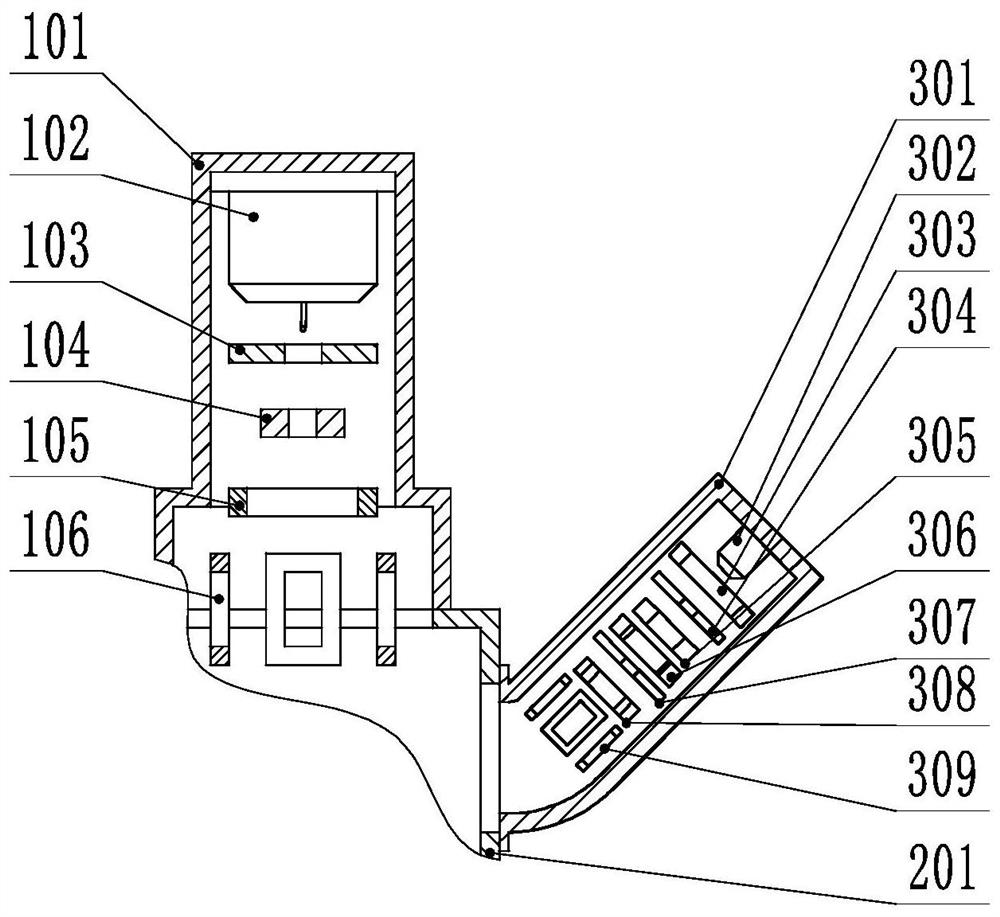

Scanning electron microscope direct-writing photoetching system based on flexible nano servo motion system

ActiveCN112882353AAvoid stitching errorsReal-time observation of preparation resultsElectric discharge tubesPhotomechanical exposure apparatusScanning electron microscopeBeam scanning

The invention discloses a scanning electron microscope direct-writing photoetching system based on a flexible nano servo motion system. The scanning electron microscope direct-writing photoetching system comprises an electron chamber, an ion chamber, a sample chamber and a control system; the electron chamber comprises an electron chamber cavity, an electron gun, an anode, an electron beam blocker, an electromagnetic lens and an electron beam deflection coil; the ion chamber comprises an ion chamber cavity, an ion source, an ion beam scanning deflection electrode and the like; the sample chamber comprises a sample chamber cavity, a secondary electron detector, a nano-precision flexible servo motion platform system and the like; the control system comprises a computer, an electron beam scanning controller, an ion beam scanning controller and the like. The electron beam generated by the electron chamber or the ion beam generated by the ion chamber can be used for nano direct-writing preparation, and the nano-precision flexible motion platform in the sample chamber and the electron beam / ion beam can cooperatively move or be linked, so that splicing errors in preparation are avoided, and large-area nano direct-writing photoetching without splicing errors is realized. The system can also perform in-situ detection in the preparation process, so that the preparation result is convenient to observe in real time.

Owner:TSINGHUA UNIV

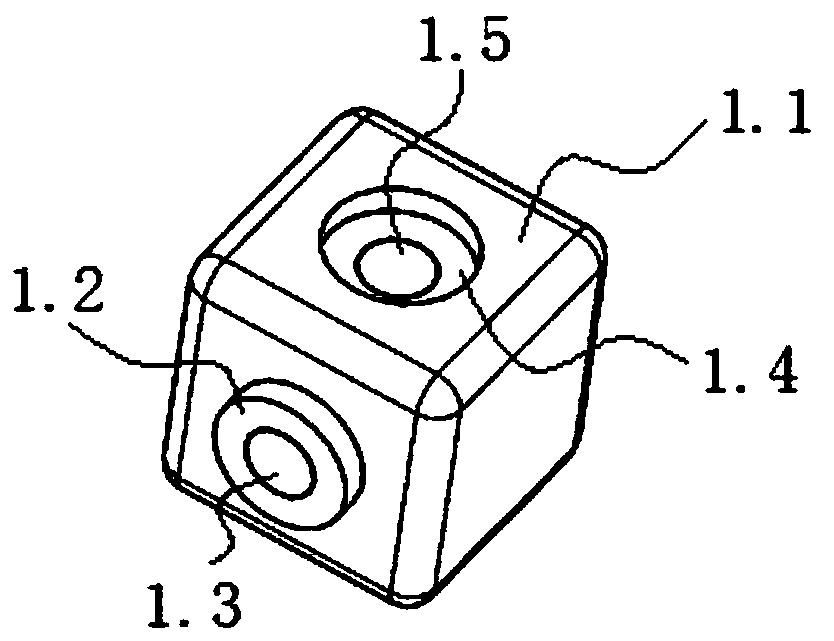

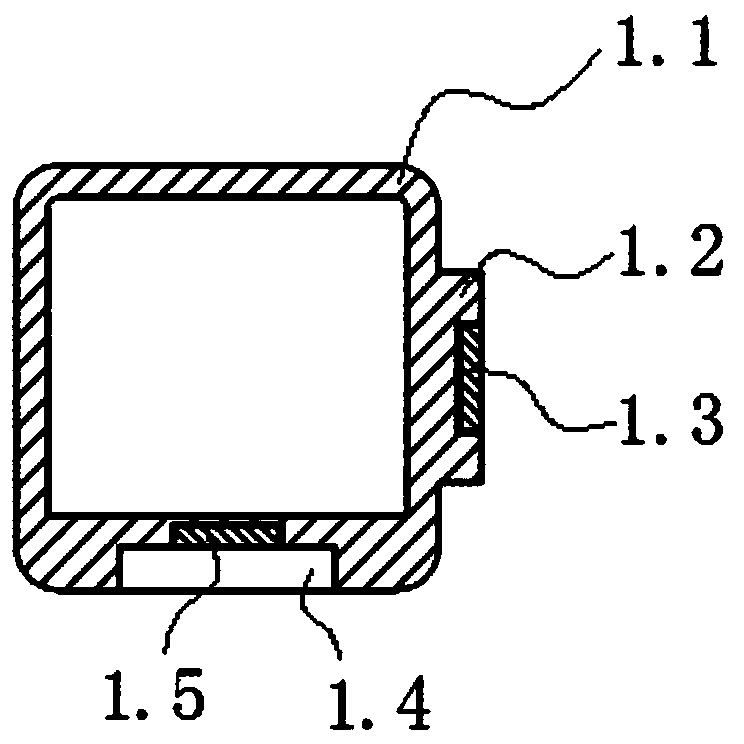

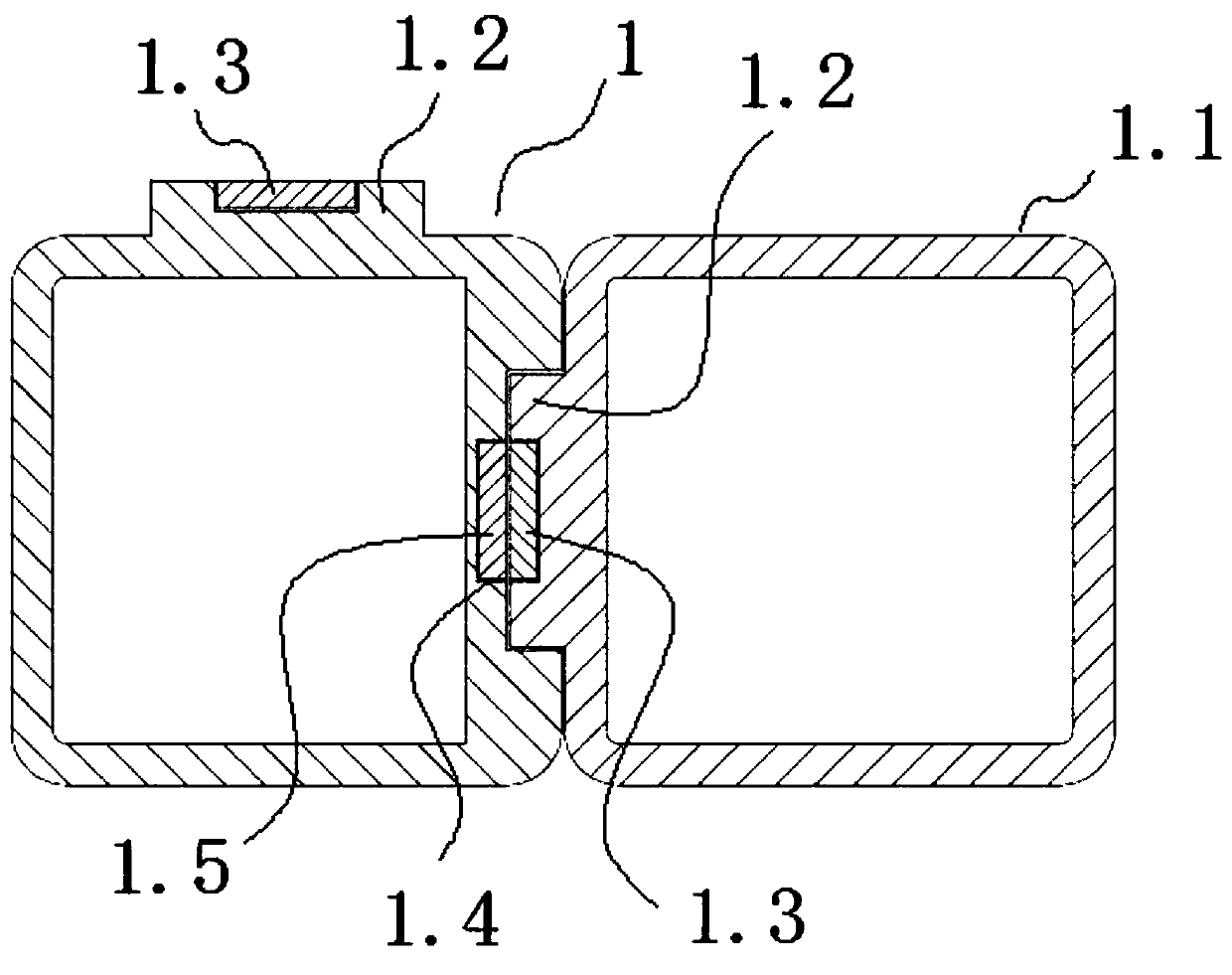

Magnetic splicing assembly and spliced toy with same

The invention relates to a magnetic splicing assembly and a spliced toy with the same. The magnetic splicing assembly comprises a plurality of unit bodies which are spliced together, and convex blocksare arranged on one end faces of the unit bodies and fixedly connected with the unit bodies; first counterbores are formed in the end faces, away from the unit bodies, of the convex blocks, and firstmagnetic sheets are fixedly arranged in the first counterbores; concave holes are formed in the other end faces of the unit bodies; second counterbores are formed in the concave holes, and second magnetic sheets are fixedly arranged in the second counterbores; and when every two adjacent unit bodies are spliced, the convex block on one of the unit bodies can be embedded in the concave hole in theother unit body, and the first magnetic sheet on the convex block and the second magnetic sheet in the concave hole are magnetically attracted. Compared with the prior art, every two unit bodies aremagnetically spliced, thus the connection strength between every two adjacent unit bodies can be enhanced, meanwhile, the connection speed of every two unit bodies can also be increased, the magneticsplicing assembly can be conveniently and quickly assembled, and thus convenience is improved.

Owner:刘思尧

A computer imaging direct plate-making equipment and plate-making method

ActiveCN103955112BQuality improvementReduce usagePhotomechanical apparatusForme preparationEngineeringComputer image

The invention provides computer imaging type direct plate making equipment and a plate making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, so as to mask the light from the exposure light source, and thus a corresponding exposure image is formed on the printing plate; to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Due to the introduction of a light homogenizing layer, dependence on a light source is further reduced, and in particular, good plate making precision can be obtained by combination of light sources with different specifications, light sources or spot light sources with different surface luminescence uniformity and line light sources. A plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:十二秒融媒体(山东)有限公司

A kind of printing plate-making equipment and plate-making method

ActiveCN103955113BQuality improvementReduce usagePhotomechanical apparatusOriginals for photomechanical treatmentEngineeringEnvironmentally friendly

Owner:十二秒融媒体(山东)有限公司

A digital X-ray image stitching method and system

Owner:深圳蓝影医学科技股份有限公司

Film-free computer direct plate making equipment and making method

ActiveCN103955118AQuality improvementReduce usagePhotomechanical exposure apparatusMicrolithography exposure apparatusLight guideEngineering

The invention provides film-free computer direct plate making equipment and a making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, and the target image masks the light from the exposure light source so that a corresponding exposure image is formed on the printing plate; and in order to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Meanwhile, a plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:青岛斯博锐意电子技术有限公司

A thin-film slicing and cutting device for splicing thin-film reflective surface antennas

InactiveCN105881619BEasy to operateAvoid wrinklesMetal working apparatusParaboloidMechanical engineering

The invention discloses a film slicing and cutting device for a spliced film reflector antenna. The film slicing and cutting device comprises an annular movement mechanism, an arc-shaped movement mechanism, a steering mechanism, a regulation mechanism, a cutting mechanism and a film mold, wherein the annular movement mechanism is composed of a circular track, skidding trolleys and arc-shaped guide rail placing tables; the arc-shaped movement mechanism is composed of an arc-shaped guide rail and a skidding sleeve; the steering mechanism is composed of an upper steering block and a lower steering block; the regulation mechanism is composed of a square cavity, regulation blocks, sleeves and pressure shafts; the cutting mechanism is composed of a cutting device and compacting devices; the cutting device is composed of a hob and a connecting board; each compacting device is composed of an annular flat band, flat band wheels and a linking board; the film mold is arranged at the middle part of the annular movement mechanism and with the same axis with the circular track; and the upper surface of the film mold is in a shape of a paraboloid of revolution. The film slicing and cutting device can circumferentially and radially cut a film reflector in a blocking manner, is simple in cutting operation, good in cutting effect and high in cutting accuracy and can effectively prevent cutting folds from ocurring.

Owner:XIDIAN UNIV

Film-free computer-to-plate-making equipment and plate-making method

ActiveCN103955118BQuality improvementReduce usagePhotomechanical exposure apparatusMicrolithography exposure apparatusComputer to plateLight guide

The invention provides film-free computer direct plate making equipment and a making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, and the target image masks the light from the exposure light source so that a corresponding exposure image is formed on the printing plate; and in order to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Meanwhile, a plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:十二秒融媒体(山东)有限公司

A step-by-step splicing 3D printing system and printing method

ActiveCN108274745BImprove printing accuracyAvoid stitching errorsManufacturing platforms/substrates3D object support structuresComputer printingControl system

The present invention provides a step-by-step splicing 3D printing system and printing method, including a control system and a 3D printer, the control system is connected to the 3D printer through communication, and the 3D printer includes a fixed platform and an upper end of the fixed platform. A lens fixing column and a printing mechanism, the lens fixing column is provided with a lithography lens corresponding to the position of the printing mechanism, an XY-axis movement platform is arranged between the printing mechanism and the fixed platform, and the XY-axis movement The platform includes an X-axis motion mechanism and a Y-axis motion mechanism. Setting up the XY-axis motion platform can ensure high printing accuracy while increasing the printing format through step-by-step splicing, and can effectively solve the splicing error in the splicing process.

Owner:BMF NANO MATERIAL TECHNOLOGY CO LTD

A Real-time Stitching Method for UAV Aerial Images

ActiveCN107507132BEnsure overlapIncrease overlapImage enhancementImage analysisImaging processingComputer graphics (images)

The invention relates to the field of image processing, in particular to a real-time splicing method for unmanned aerial vehicle aerial stereo images. According to the splicing method for the unmanned aerial vehicle aerial stereo images, an inter-frame interval of key aerial stereo images is adjusted and extracted in real time according to the overlapping ratio of adjacent to-be-spliced aerial stereo images; a transformation matrix of every two adjacent frames is obtained according to a matching relation between homonymy points of every two adjacent frames, and the serial aerial stereo images are transformed to a coordinate system of reference images; and reference frames are adjusted in real time according to set reference frame adjustment judgment conditions, so that accumulative errors generated in the process that the aerial stereo images are transformed to a coordinate system of the reference frames are dispersed to all frames of images, and the situation that serious distortion of subsequent images is caused by error accumulation is avoided.

Owner:CHENGDU JOUAV AUTOMATION TECH

A Pose Estimation System and Method for Complex Parts Based on 3D Measurement Point Cloud

ActiveCN109373898BAccurate measurementWide measurement rangeUsing optical meansPattern recognitionPoint cloud

The invention belongs to the field of automatic measurement, and specifically discloses a complex part pose estimation system and method based on three-dimensional measurement point cloud, which realizes the complex part pose estimation through the following steps: calibration of the six-degree-of-freedom industrial robot terminal flange and The grating area scanner measures the transformation matrix between the coordinate systems; the six-degree-of-freedom industrial robot drives the grating area scanner to scan the workpiece to obtain the three-dimensional point cloud data of the workpiece; it will be The 3D point cloud data of the measured workpiece is converted to the robot base coordinate system to obtain the converted 3D point cloud data; the converted 3D point cloud data is matched with the 3D design model of the measured workpiece to obtain the measured workpiece relative to the robot. The pose of the base coordinate system is used to complete the estimation of the pose of complex parts. The invention has a wide measurement range, can realize accurate measurement of multi-regions and complete shape of the workpiece to be measured, and can accurately obtain the pose of the workpiece to be measured.

Owner:HUAZHONG UNIV OF SCI & TECH

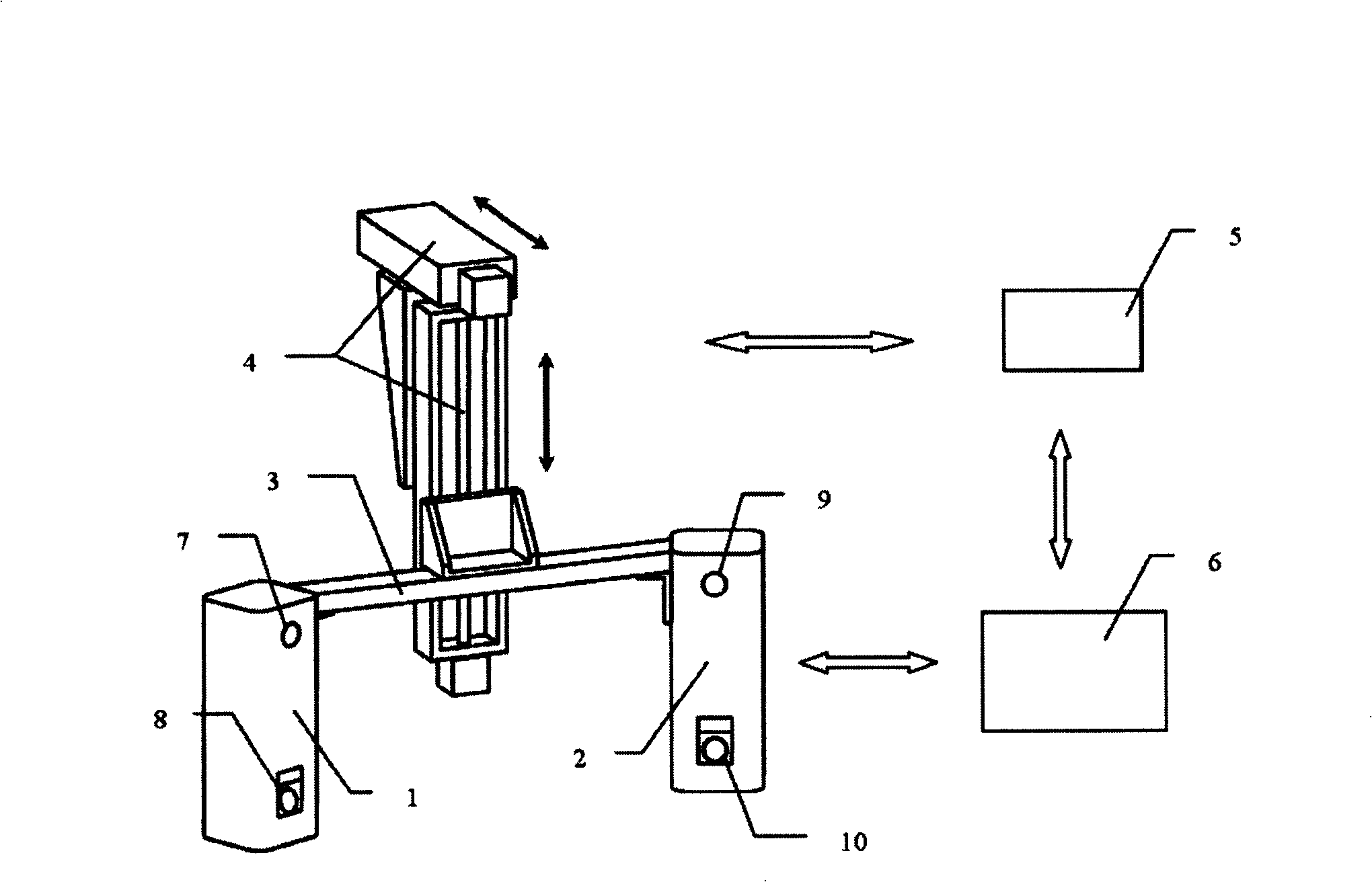

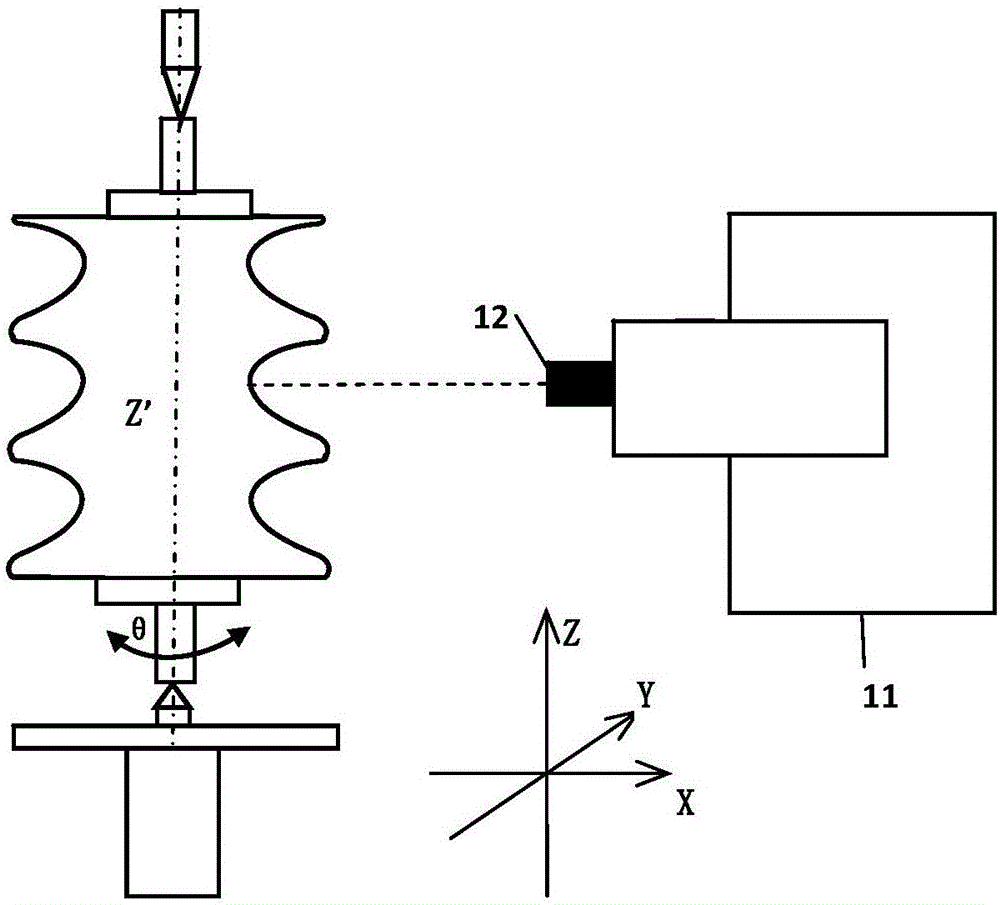

Laser cutting method used for medical long solenoid

ActiveCN104625426AAvoid stitching errorsGuaranteed accuracyLaser beam welding apparatusControl systemLaser cutting

The invention discloses an automatic laser cutting method used for a medical long solenoid. The method includes the steps that after to-be-machined length L data of the medical long solenoid are input into a control system, and the medical long solenoid is accurately clamped, the position at the moment is recorded as the initial position O by the control system; the retreating distance D of a precise rotary two-dimensional platform is compared with the to-be-machined length L, and the precise rotary two-dimensional platform retreats and pushes laser cutting heads many times for synchronous cutting to form cut spiral lines. The control system is adopted for controlling and accurately repeating operations, low efficiency is improved, and large splicing errors are avoided.

Owner:KUNSHAN THETA MICRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com