Two-dimensional image splicing method based on optical grating positioning in automatic visual inspection

A technology of automatic visual inspection and two-dimensional image, applied in image enhancement, image data processing, instrument and other directions, can solve the problems of local feature coincidence, splicing error, influence of detection accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

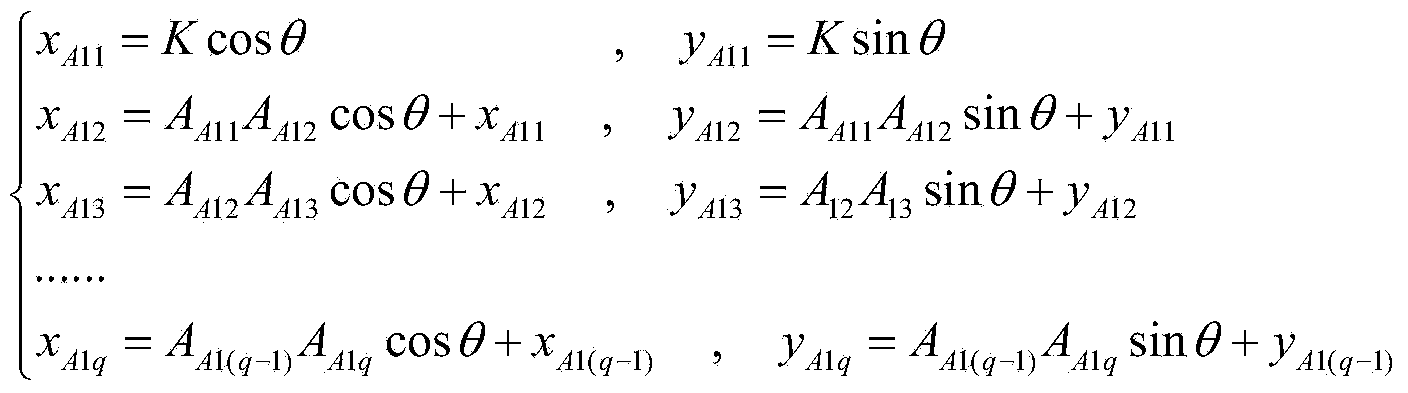

[0052] A two-dimensional image mosaic method based on grating positioning in automatic visual inspection. The coordinate value of the sub-picture in the large picture is corrected by the angle parameter between the shooting platform and the camera coordinates, and the position coordinates of the four corners of each sub-picture are calculated. The actual physical distance to get the size of the large image, use bilinear interpolation to calculate the pixel gray level of the sub-pixel coordinate position in the sub-image to obtain the pixel gray level in the large image, and obtain the large image after splicing. The specific steps are:

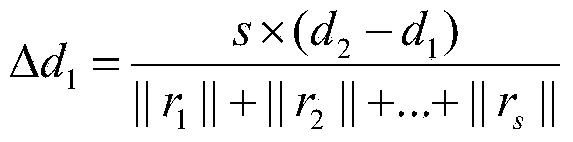

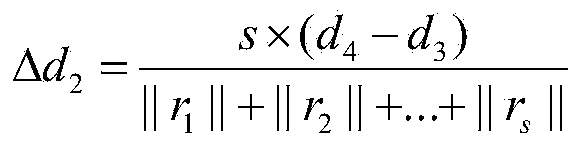

[0053] S1: Calculate the physical size Δd represented by a single pixel in the image, the steps are:

[0054] S11: Make a disc grid calibration sheet, set non-overlapping calibration dots on the disc grid calibration sheet, the calibration dots and the disc grid calibration sheet have a clear boundary, the calibration dots are set in e rows and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com