Cylindrical probe and method for measuring and scanning blade profile of blisk

A technology of integral blade disc and blade body profile, which is applied to measuring devices, instruments, etc., and can solve problems such as data discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

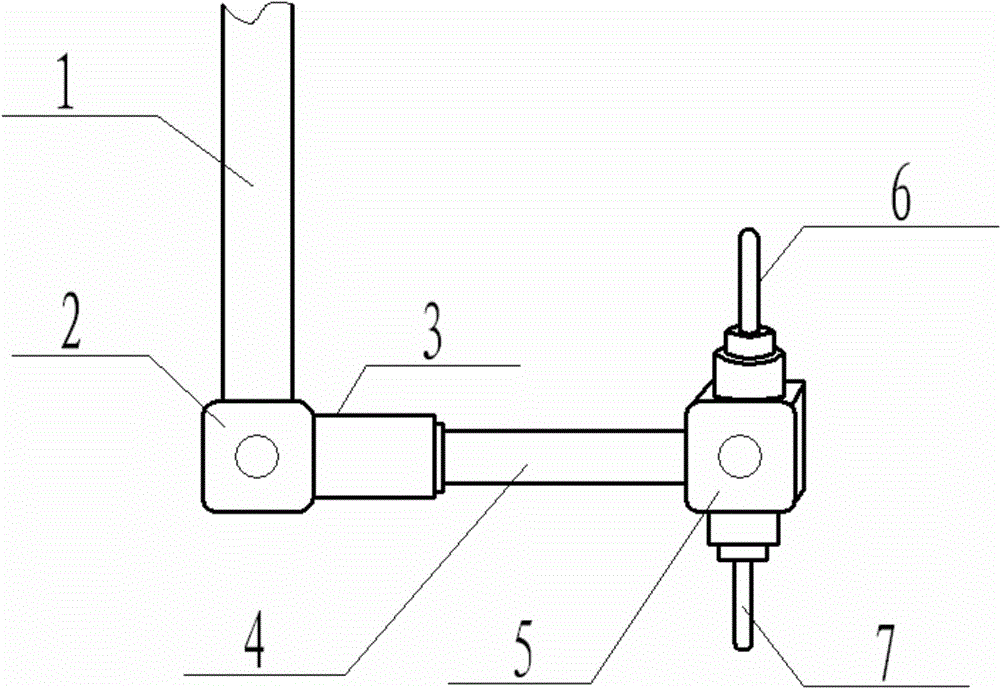

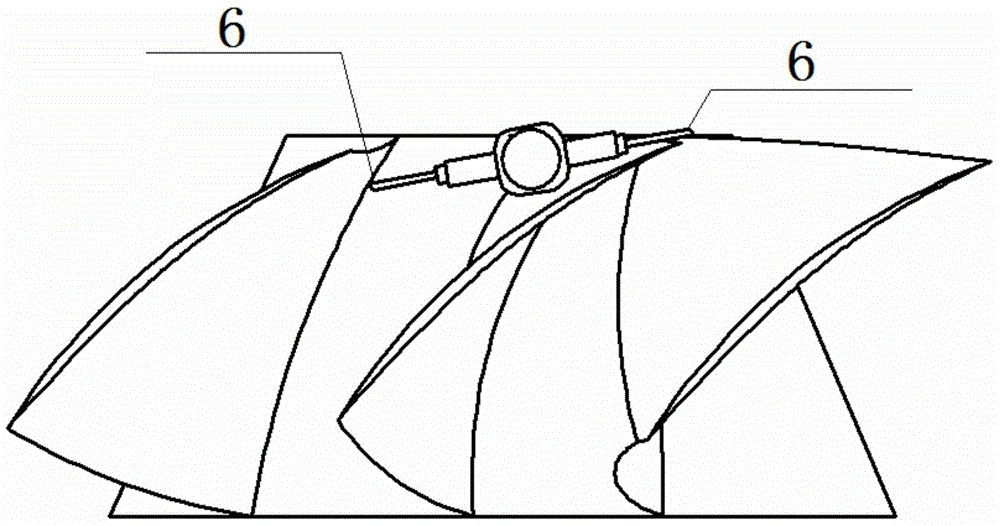

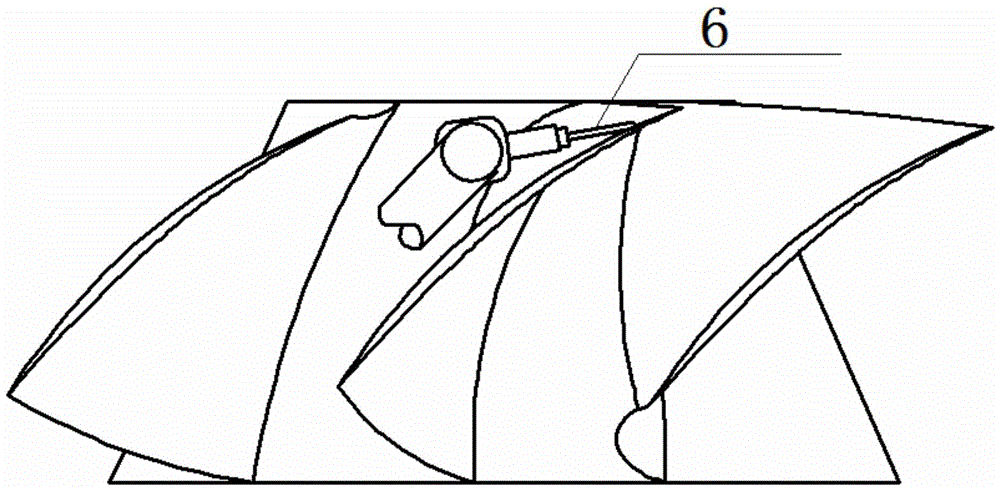

[0039] The cylindrical probe consists of the following: extension rod I1, five-dimensional adapter I2, universal joint 3, extension rod II4 and five-dimensional adapter II5; one end of the extension rod II4 passes through the five-dimensional adapter I2 and The universal joint 3 is connected with the extension rod I1, and the other end of the long rod II4 is connected with the five-dimensional adapter II5, and the five-dimensional adapter II5 is connected with a cylindrical probe I6 and a cylindrical probe II7.

[0040] The method for measuring and scanning the blade body profile of the whole blade disk has the following steps:

[0041] ①Establish the overall blisk coordinate system

[0042] Align the reference circle of the blisk with the center of rotation of the single-axis high-precision turntable, then fix the blisk and calibrate the high-precision turntable, collect corresponding elements according to the drawing requirements to establish a coordinate system, and save th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com