A step-by-step splicing 3D printing system and printing method

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problems of high cost and poor use flexibility, achieve high printing accuracy and solve the effect of splicing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

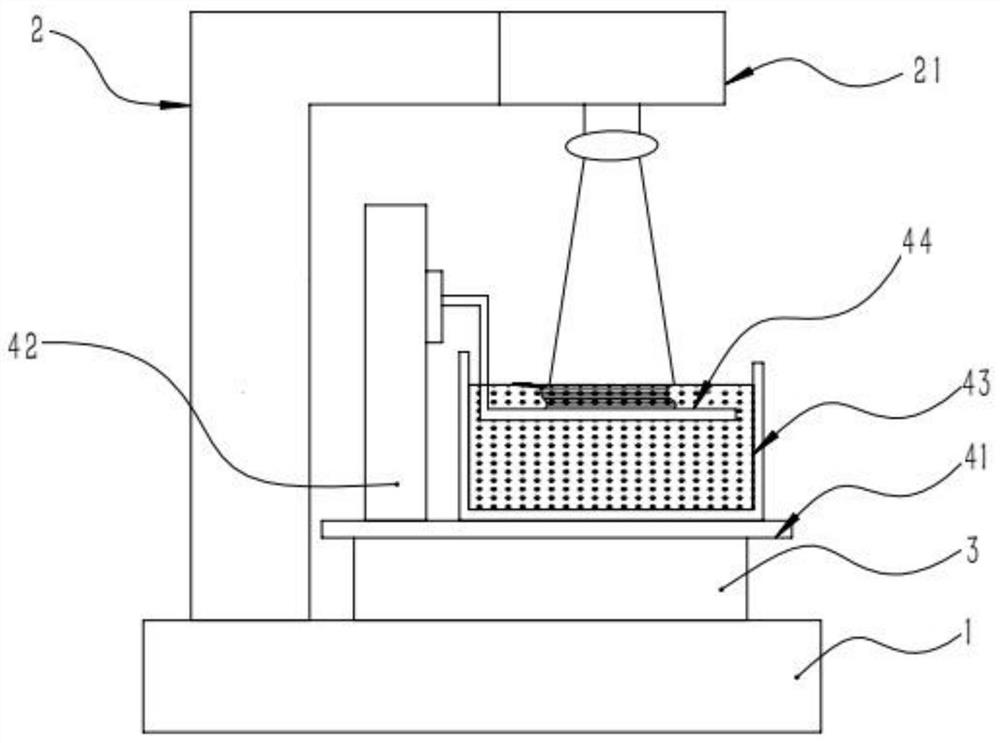

[0028] like figure 1 As shown, the present invention discloses a step-by-step splicing 3D printing system, including a control system and a 3D printer. The control system is connected to the 3D printer through communication. The 3D printer includes a fixed platform 1 and a The lens fixing column 2 and the printing mechanism at the upper end, the lens fixing column 2 is provided with a lithography lens 21 corresponding to the position of the printing mechanism, and an XY-axis motion platform is arranged between the printing mechanism and the fixed platform 1 3. The XY-axis motion platform 3 includes an X-axis motion mechanism and a Y-axis motion mechanism.

[0029] Both the X-axis movement mechanism and the Y-axis movement mechanism are screw movement mechanisms.

[0030] Described printing mechanism comprises connecting plate 41 and is located at the printing platform 44 on described connecting plate 41, printing platform elevating mechanism 42 and liquid tank 43, and describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com