Patents

Literature

34results about How to "Save stitching time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

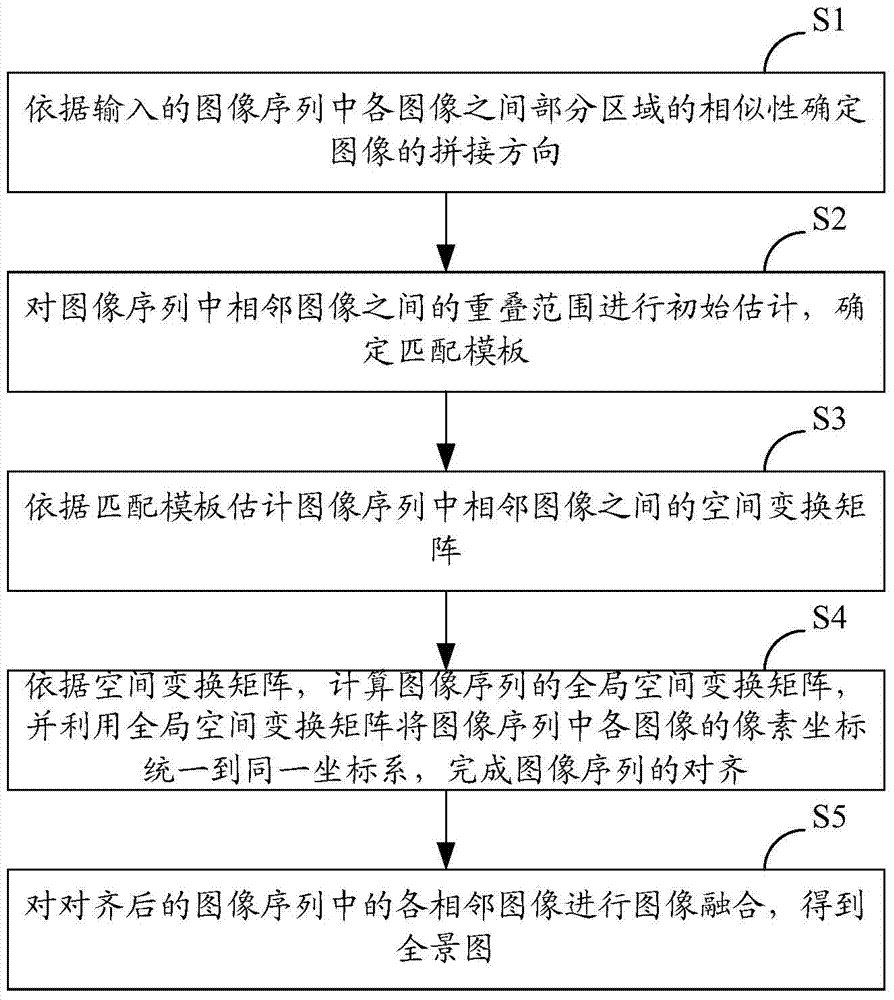

Image registration and multi-resolution fusion-based panoramic image splicing method

InactiveCN108416732AReduce invalid areaUniform exposureImage enhancementImage analysisEqualizationMulti resolution

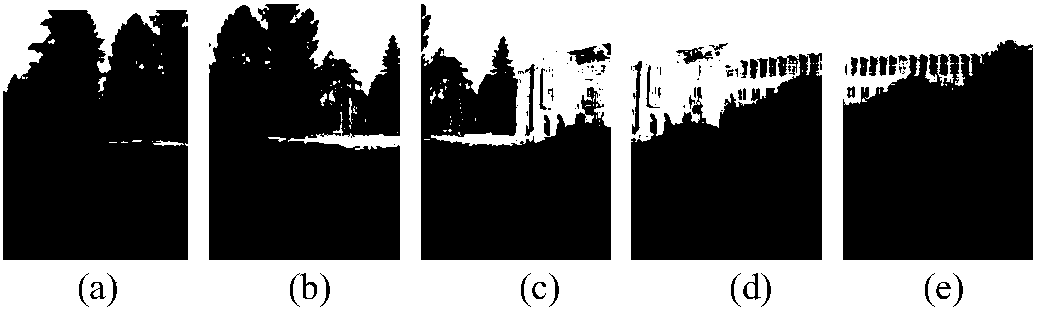

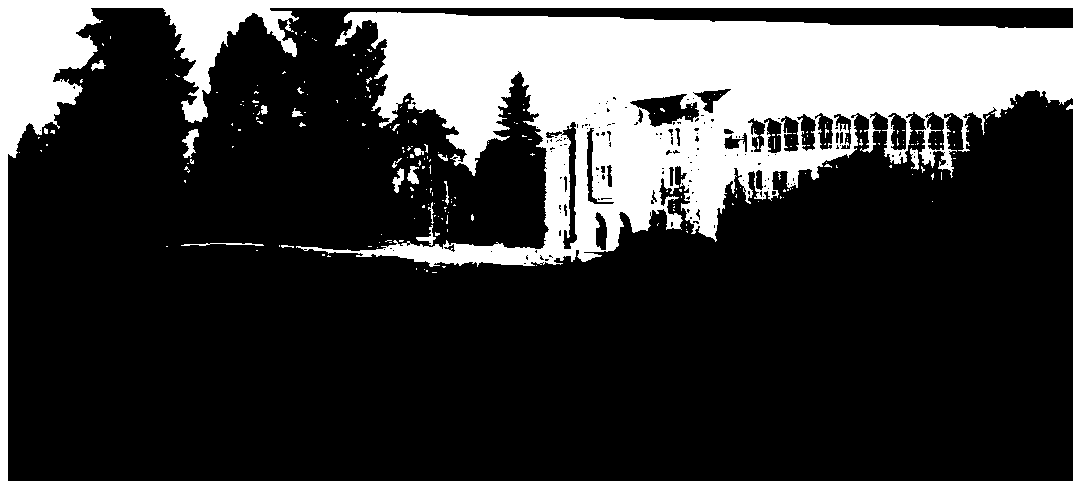

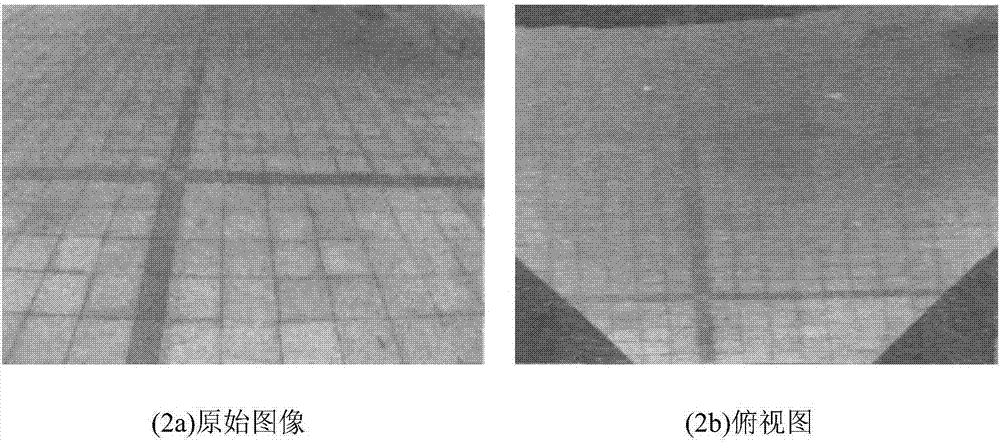

The invention discloses an image registration and multi-resolution fusion-based panoramic image splicing method. An adaptive threshold of sequence images is subjected to binary processing and image contour information is extracted by utilizing a pixel neighborhood relationship; a similar region of an image contour structure is quickly estimated through a similarity measurement method for Hu momentinvariant features; and SIFT feature point extraction is performed in a similar region part of two original images. Moreover, feature point initial matching is performed by using a bidirectional K-nearest classification algorithm; mismatched points are screened by an RANSAC algorithm; and an affine transformation matrix among the images is estimated. In addition, in an image fusion aspect, brightness equalization and local color mapping processing is adopted. Then, through an improved Laplacian pyramid multi-resolution fusion algorithm, spliced images are fused to realize seamless splicing. According to the method, the image splicing time is shortened, the image splicing efficiency is improved, the similar region can be quickly located, the mismatch in splicing is effectively improved, and the image registration precision is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

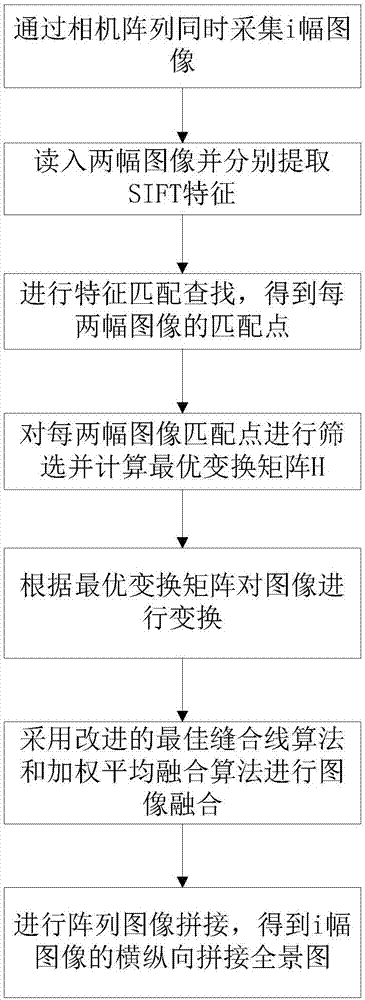

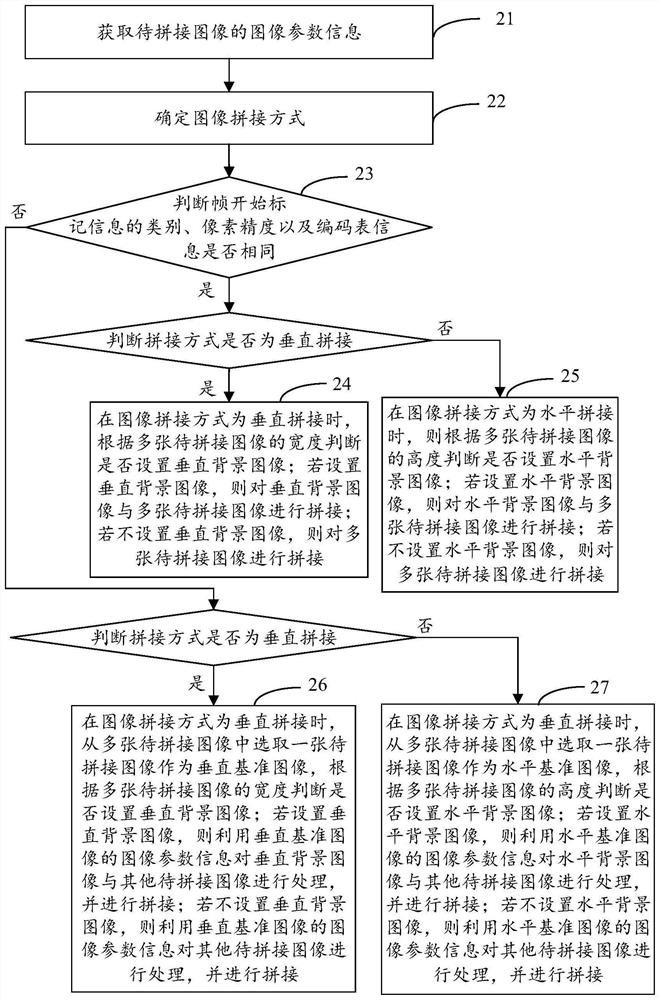

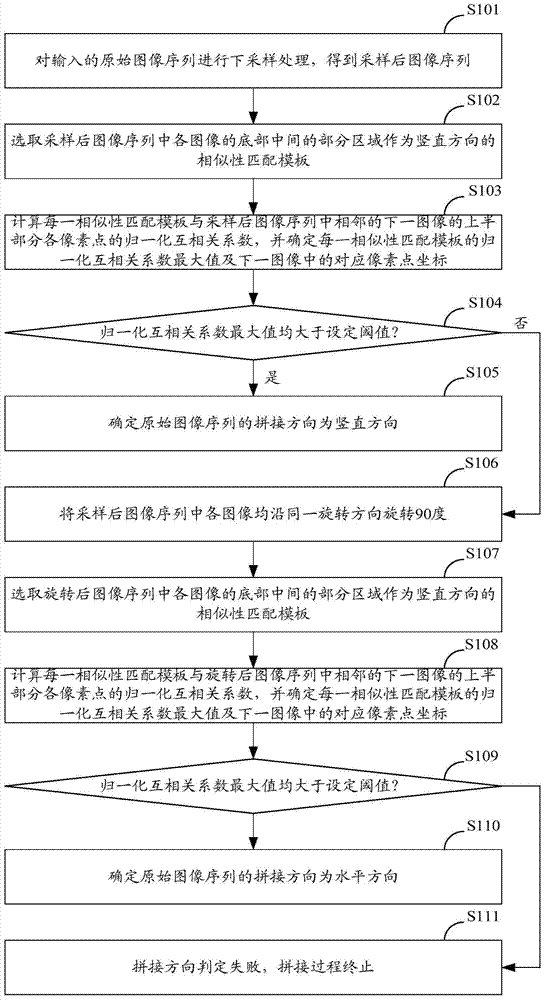

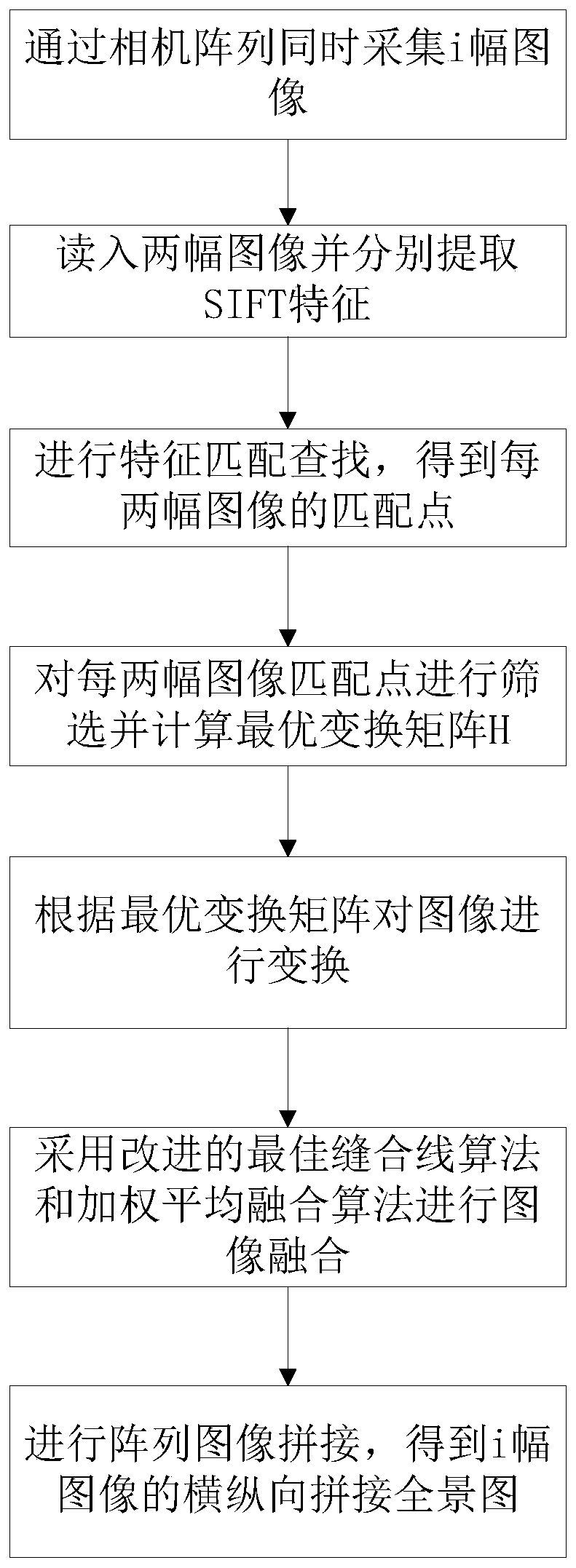

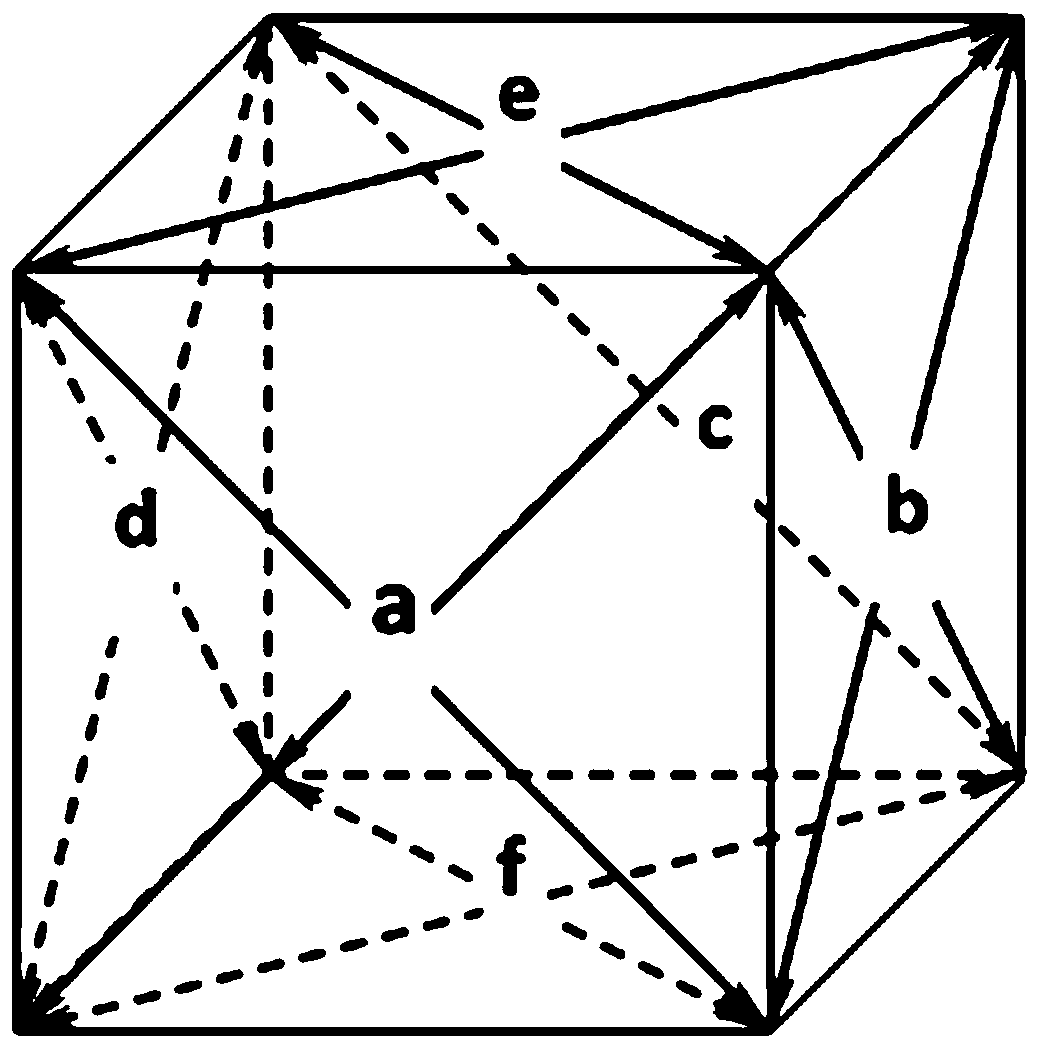

Panoramic imaging method based on camera array

ActiveCN107301620ASave stitching timeRealize the combinationImage enhancementImage analysisImage resolutionFusion splicing

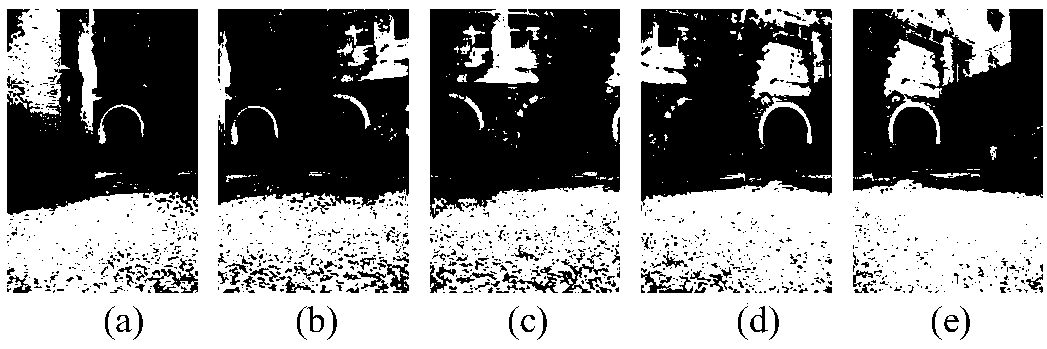

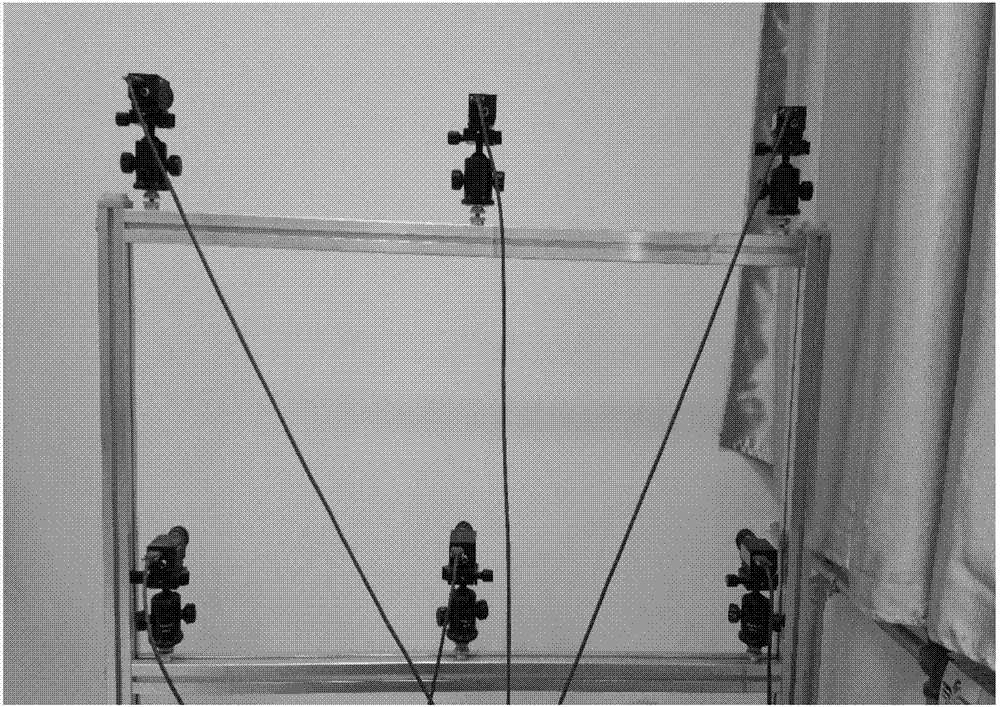

The invention discloses a panoramic imaging method based on a camera array and mainly aims to solve the problems that in the prior art, a splicing scene is small, and a "ghost shadow" exists. According to the scheme, (1) array cameras are used to acquire multiple images, two images are read, SIFT features of the two images are extracted respectively, feature matching search is performed, matching points of the two images are obtained and screened, an optimal transformation matrix is calculated, the images are transformed according to the optimal transformation matrix, and an improved optimal stitching line algorithm and a weighted average fusion algorithm are adopted to perform fusion splicing on the images; and (2) the step (1) is repeated till splicing of the upper image and the lower image is completed, the splicing image is used as a to-be-spliced image, splicing is continued after the to-be-spliced image is rotated counterclockwise by 90 degrees, and the result is rotated clockwise by 90 degrees to obtain a final splicing panoramic image. Through the method, the "ghost shadow" phenomenon is remarkably eliminated, and the obtained panoramic image is large in view field, high in resolution, more approximate to a real panorama and capable of being used for splicing of larger scene images in the horizontal direction and the vertical direction.

Owner:XIDIAN UNIV

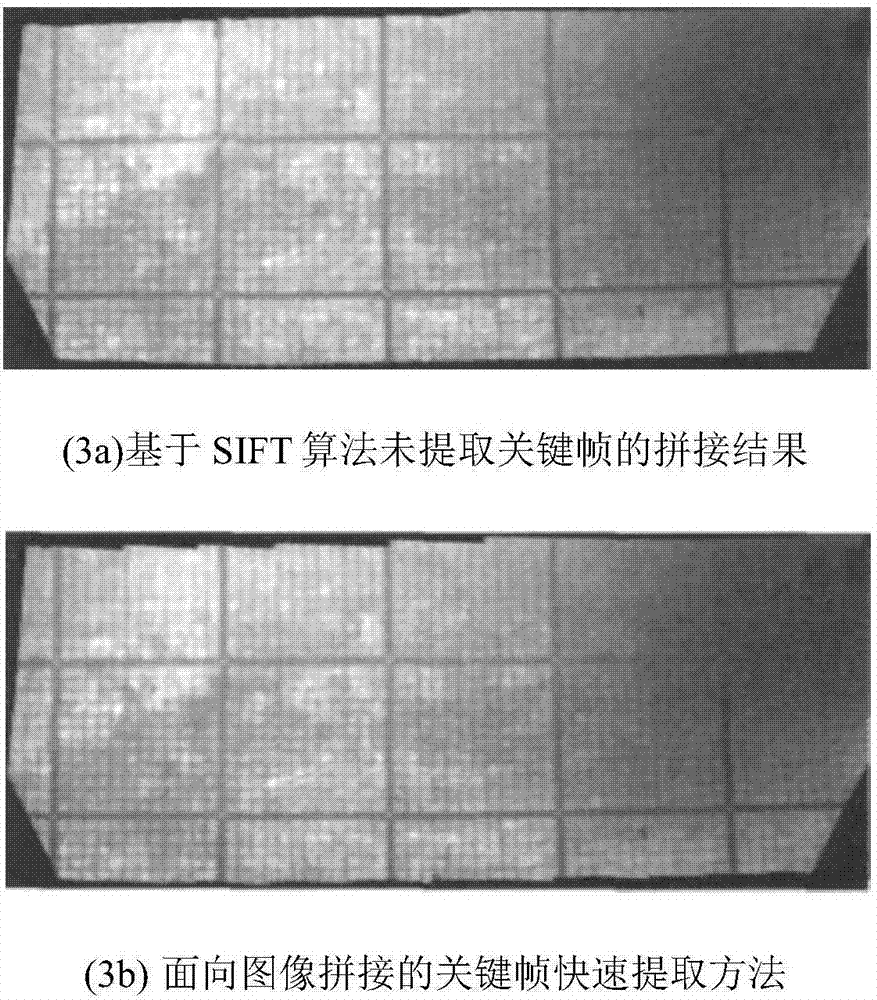

Improved image splicing key frame fast extraction method

InactiveCN107424181ARealize automatic extractionHigh speedImage analysisGeometric image transformationKey frameFeature point matching

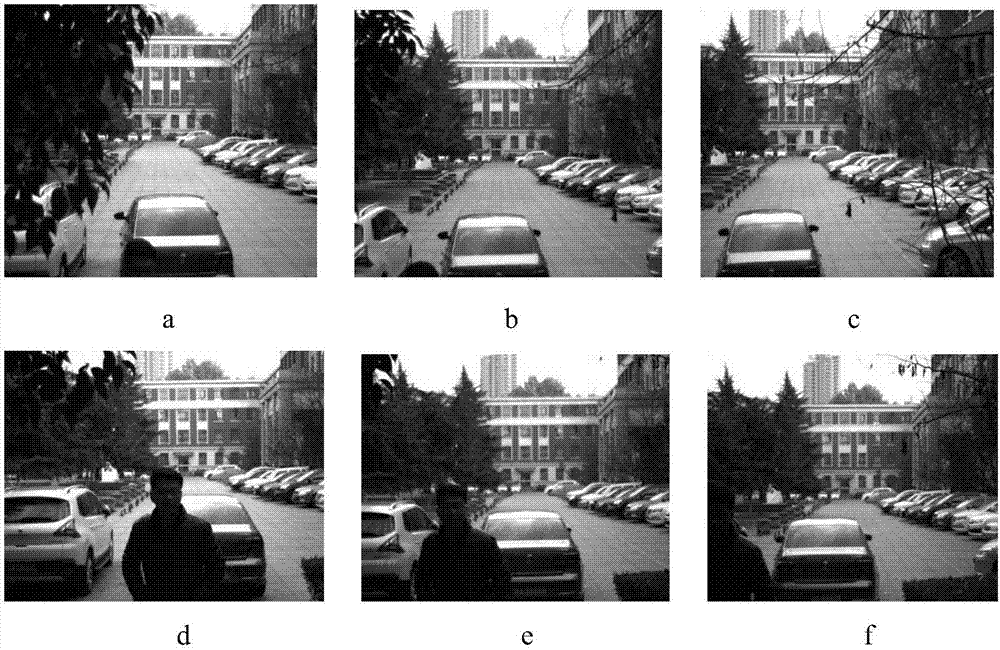

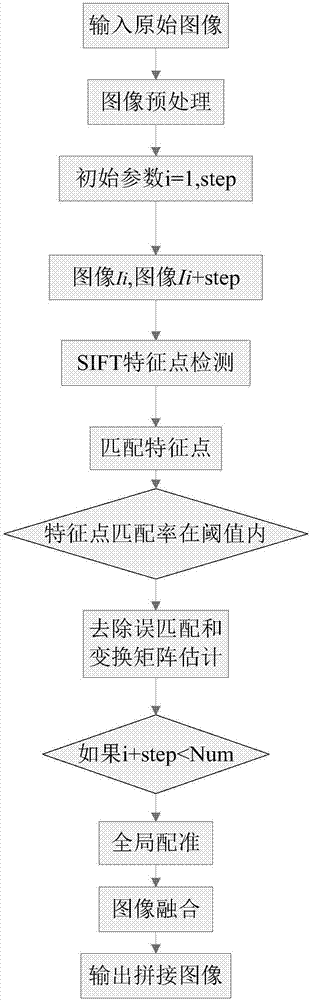

The invention discloses an improved image splicing key frame fast extraction method, and relates to the field of computer vision. The method eliminates the influence of image distortion through image preprocessing, detects feature points by using the SIFT, realizes the automatic extraction of key frames by taking a matching ratio of the feature points of adjacent frames as the similarity measure of images, splices the key frame images, greatly reduces the splicing time of the sequence images, screens initial matching pairs by using an improved RANSAC algorithm, calculates an accurate transformation matrix between the images to achieve image registration, and finally achieves seamless image splicing by using a weighted smoothing fusion method. The method has strong robustness, and the spliced images are natural and clear.

Owner:HUNAN VISION SPLEND PHOTOELECTRIC TECH

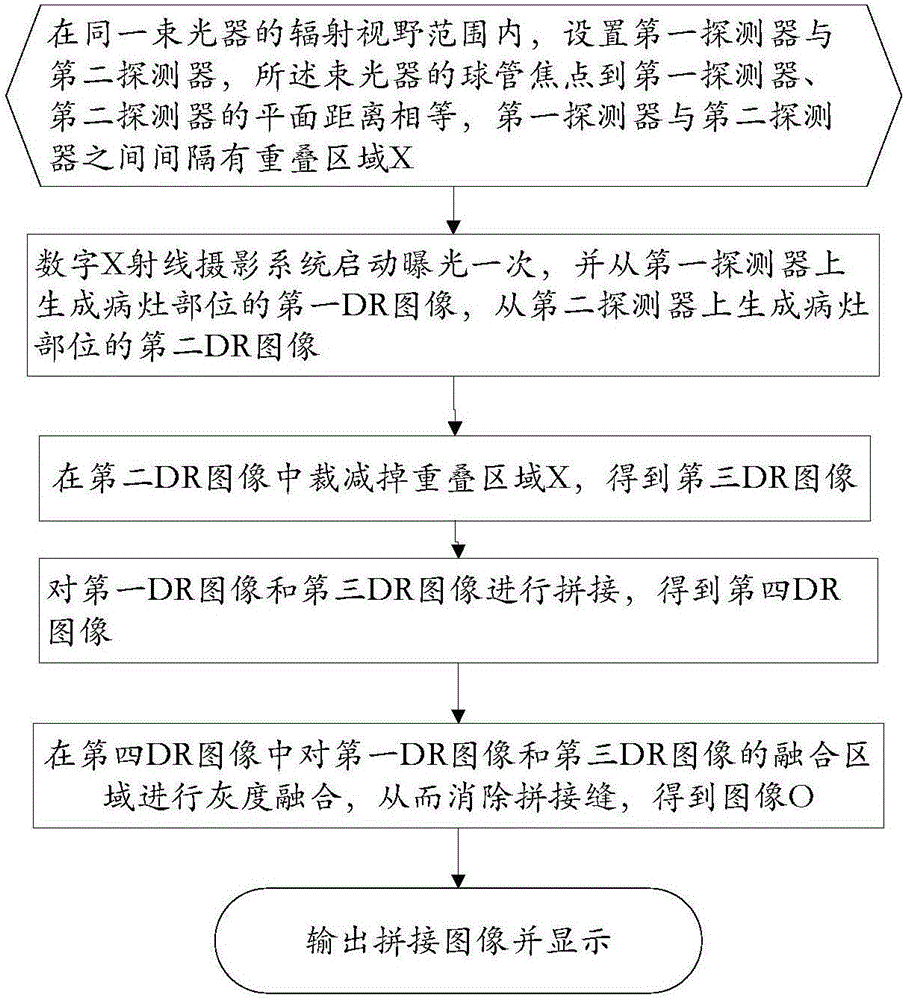

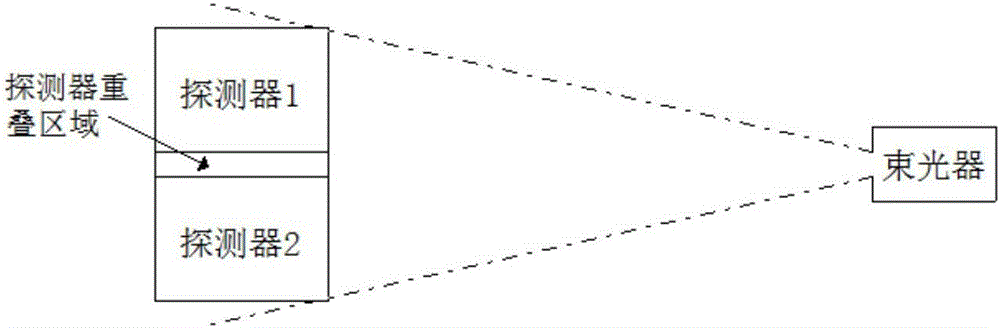

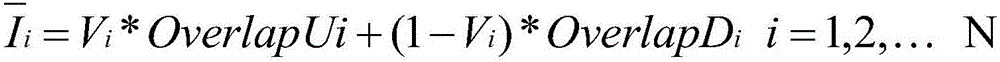

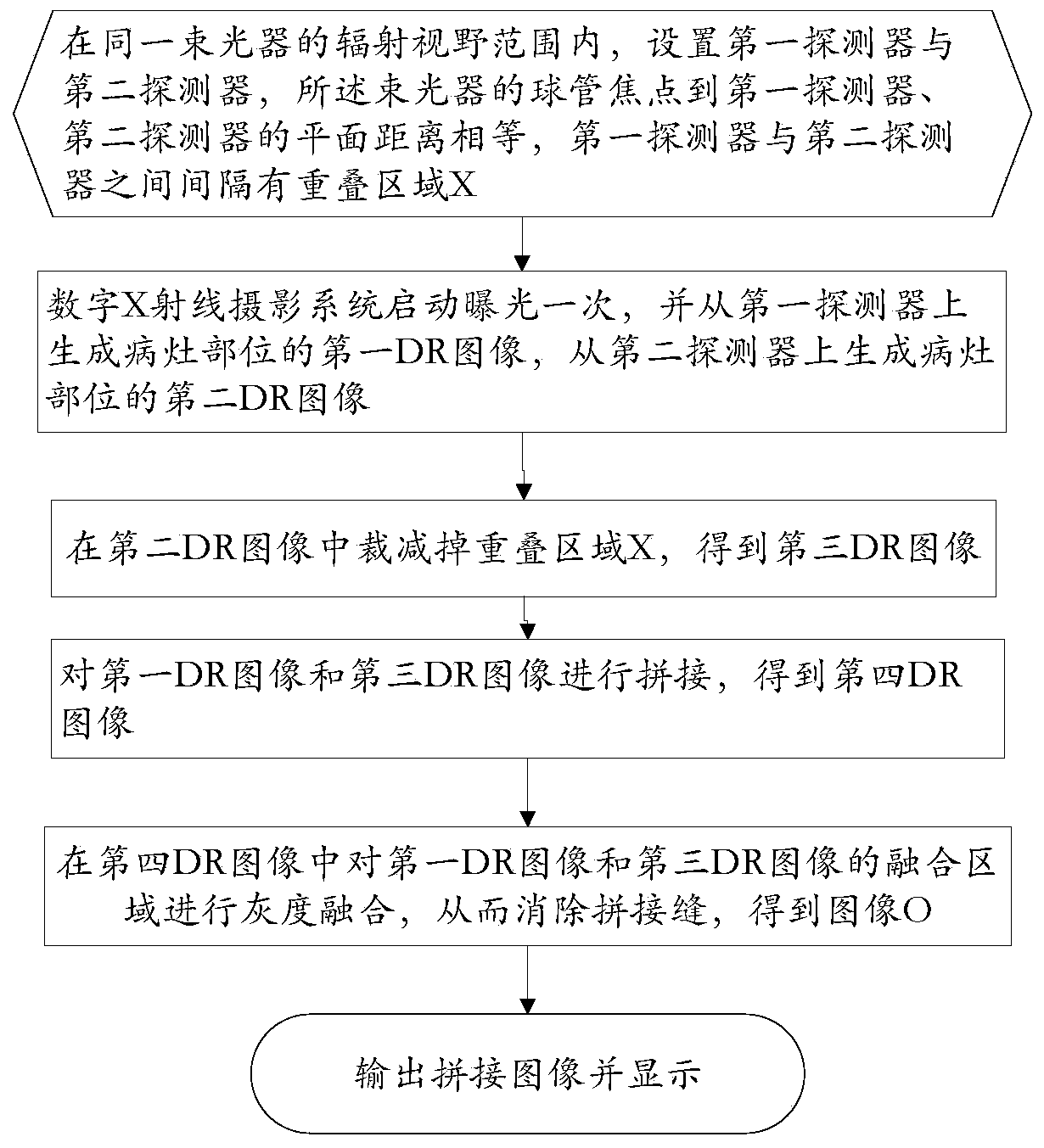

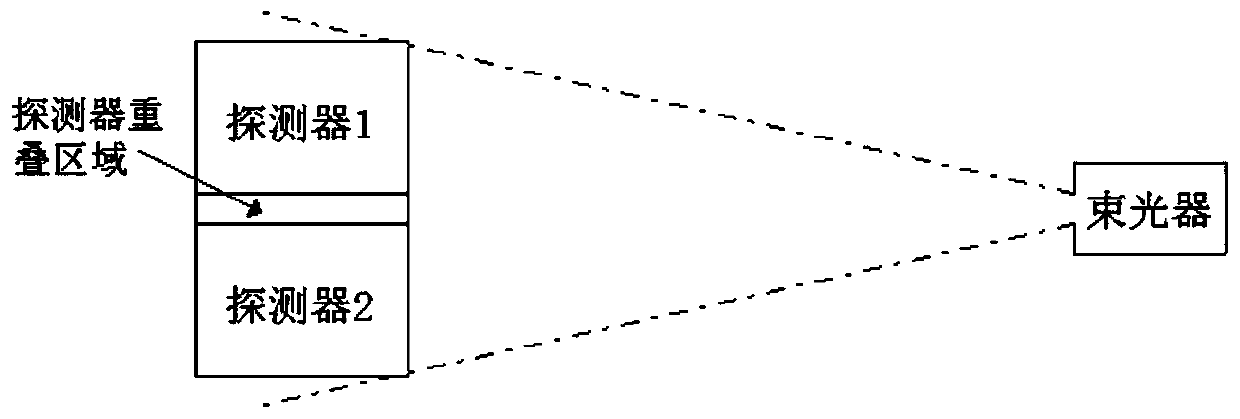

Digital X-ray image splicing method and system

ActiveCN106651771AReduce setup timeEliminate seamsImage enhancementImage analysisSingle exposureX-ray

The invention discloses a digital X-ray image splicing method and system. The digital X-ray image splicing method comprises steps that a first detector and a second detector are arranged in a radiation vision field scope of a same beamer, plane distances from a bulb focus of the beamer to the first detector and the second detector are identical, an overlapping region X is arranged between the first detector and the second detector with intervals; a digital X-ray shooting system starts for exposure for one time, a first DR image of a focus portion is generated on the first detector, and a second DR image of the focus portion is generated on the second detector; the overlapping region X is cut from the second DR image to acquire a third DR image; the first DR image and the third DR image are spliced to acquire a fourth DR image; gray fusion for the splicing region is carried out to eliminate a splicing seam to acquire an image O; the image O is displayed. The method is advantaged in that the spliced image can be acquired through one-time exposure, and thereby a radiation dose and the patient positioning time can be greatly reduced.

Owner:深圳蓝影医学科技股份有限公司

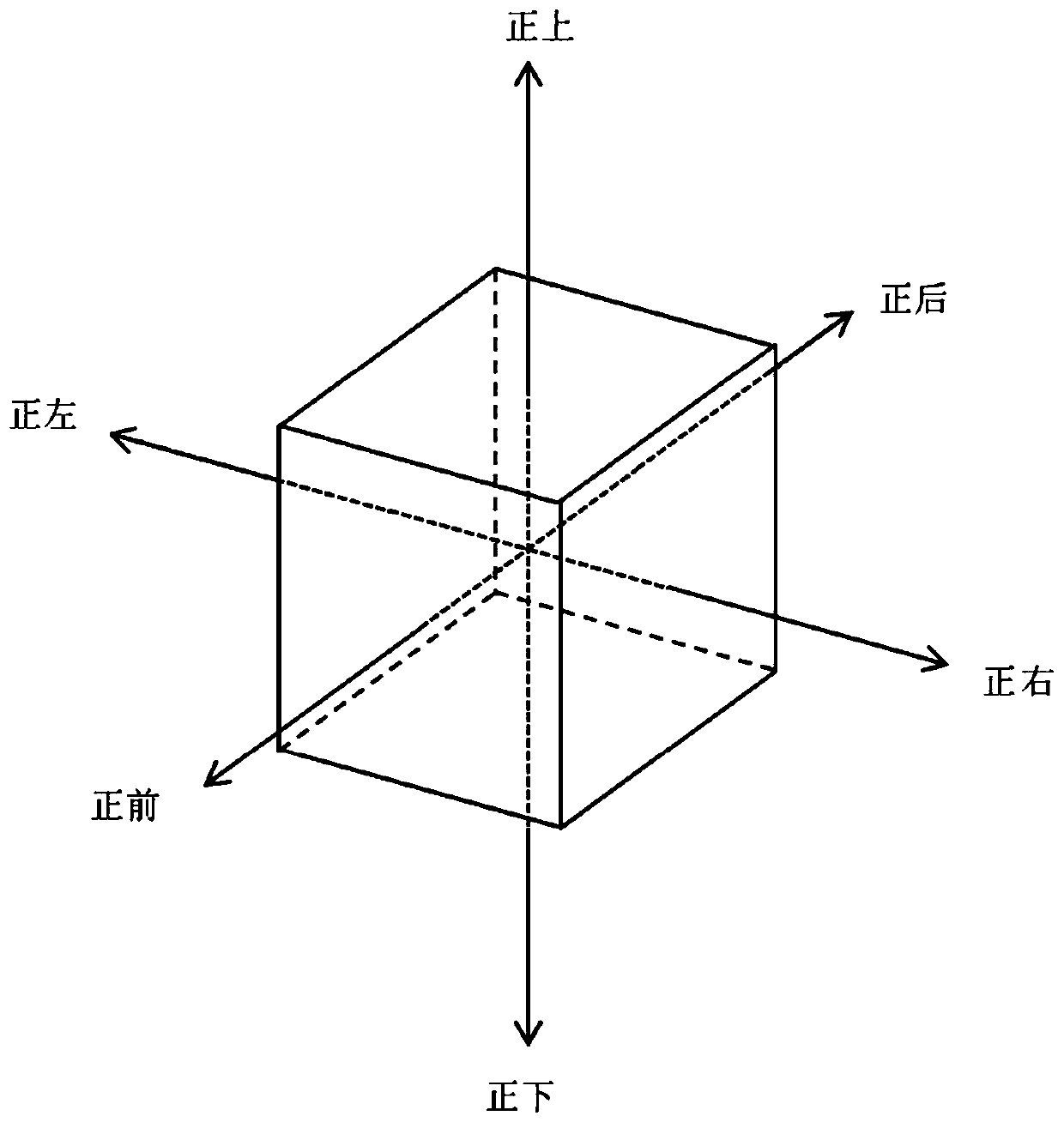

Method for quickly stitching panoramic image of cube

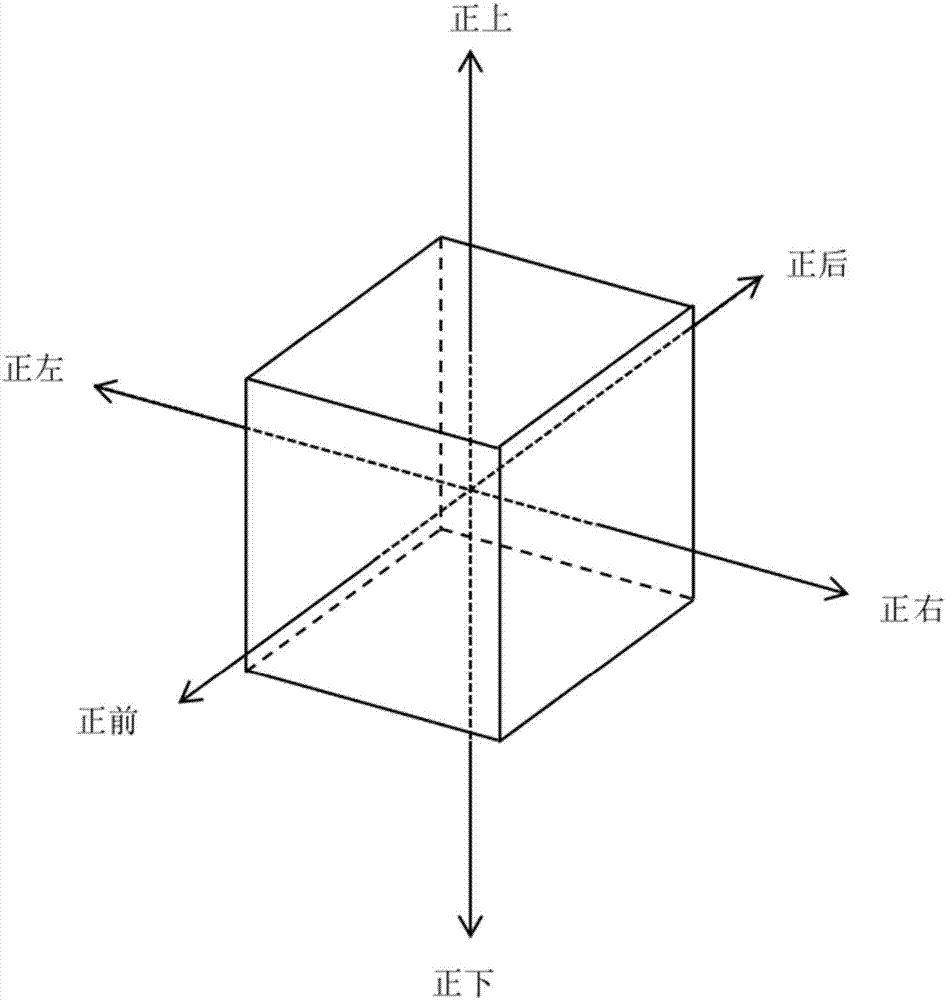

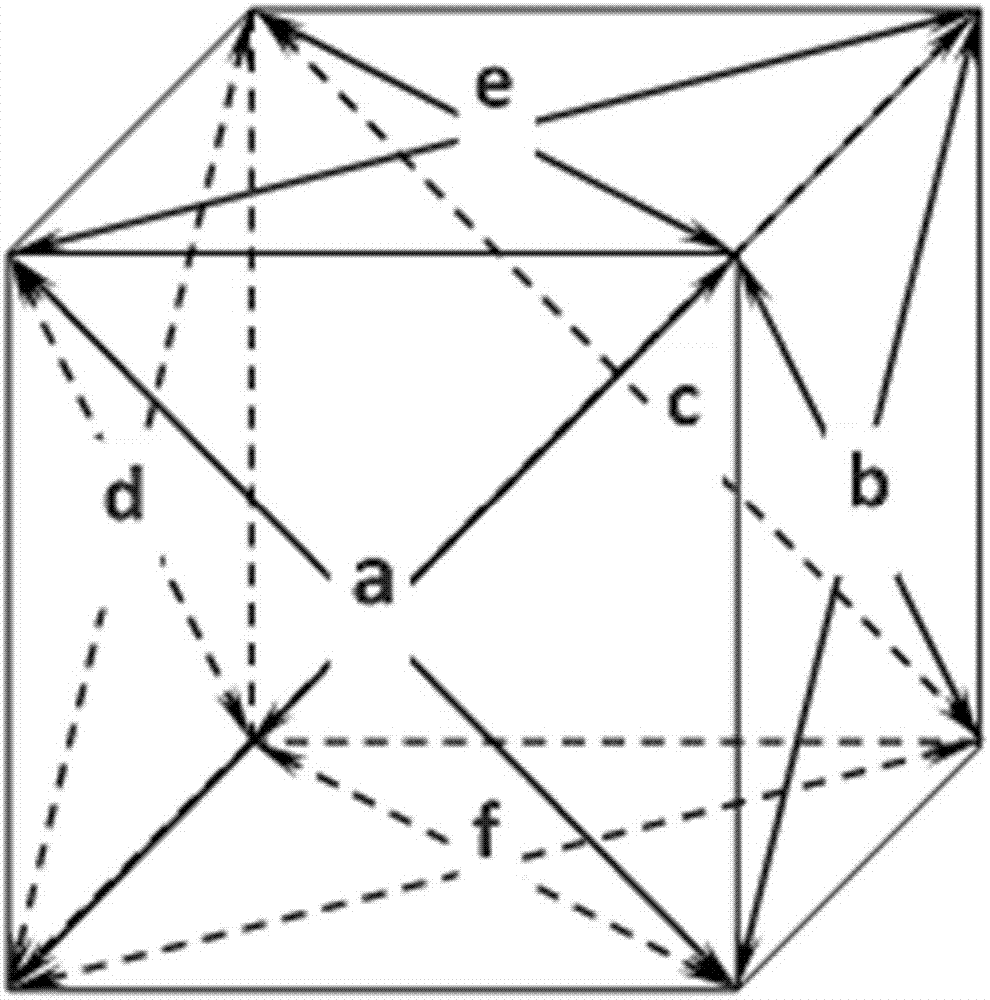

ActiveCN107358577AGood for compression codingQuick stitchingImage analysisGeometric image transformationCamera lensTransformation parameter

The invention discloses a method for quickly stitching a panoramic image of a cube. The method herein includes the following steps: arranging a panoramic camera, simultaneously photographing a front space in the front, rear, left, right, above and below directions; calibrating the panoramic camera, acquiring a distortion correction parameter, further acquiring a linear transformation parameter and a cropping parameter of respective image; photographing scenes by using the panoramic camera, firstly conducting distortion correction on a camera lens by using the distortion parameter, then conducting rotation transformation and transverse transformation on each image by using the linear parameter; cropping the obtained 6 images in the centers in accordance with the cropping parameter, such that the 6 images are approximately the same in size and have a visual angle of 90 degrees in the horizontal direction and the vertical direction, and eventually, separately placing the squares which are obtained by cropping the 6 images at places where the panoramic image of a plane cube and the photographing camera correspond. According to the invention, the method only requires one time calibration process, can repeatedly use calibration parameters, simplifies the stitching process, accelerates the stitching speed, and saves great stitching time.

Owner:XI AN JIAOTONG UNIV

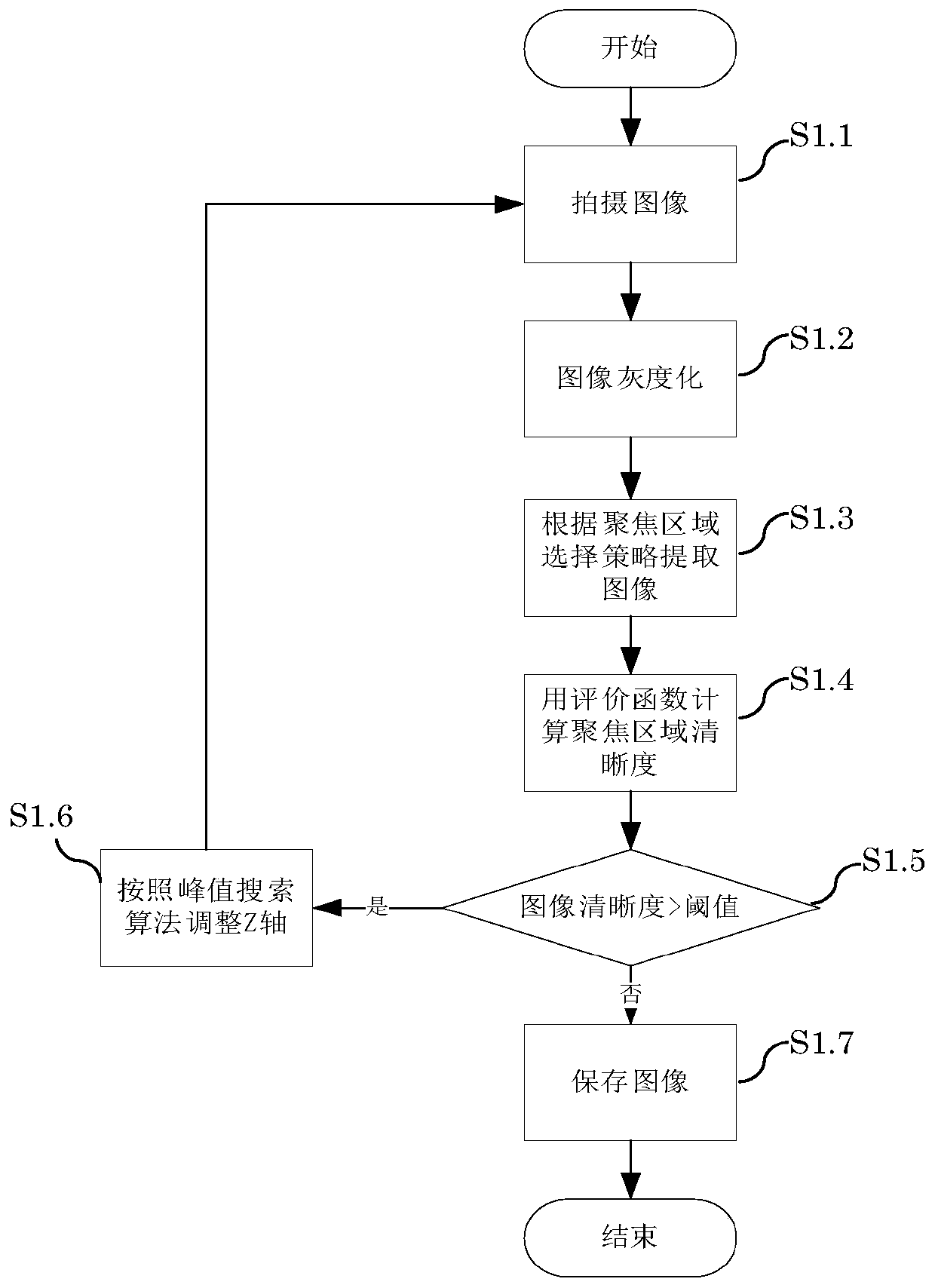

Full-scanning microscopic image splicing method based on peak search and gray template registration

InactiveCN111105346AFix autofocus issuesAccurately obtainedImage enhancementImage analysisMicroscopic imageRegion selection

The invention provides a full-scanning microscopic image splicing method based on peak search and gray template registration, and belongs to the field of image processing. The invention provides a method for selecting a discontinuous focusing region based on a gray histogram. The method comprises the following steps of: extracting a region mainly acted by an evaluation function; making definitioncalculation through an improved Tenegrad gradient evaluation function; and gradually obtaining an optimal focusing position by using an improved hill climbing algorithm; preprocessing the dyed urinarysediment microscopic image through graying and filtering operation; to acquire a smooth gray-scale image with a small calculated amount performing registration on adjacent images by using an improved template registration algorithm based on a gray-scale value, and finally fusing an overlapping region of two images by using an improved fusion method based on a variable weight. The problem of automatic focusing of the sample is solved, the microscopic image can be rapidly and accurately obtained, the problem of microscopic image splicing is also solved, and the image splicing time is also reduced.

Owner:TONGJI UNIV

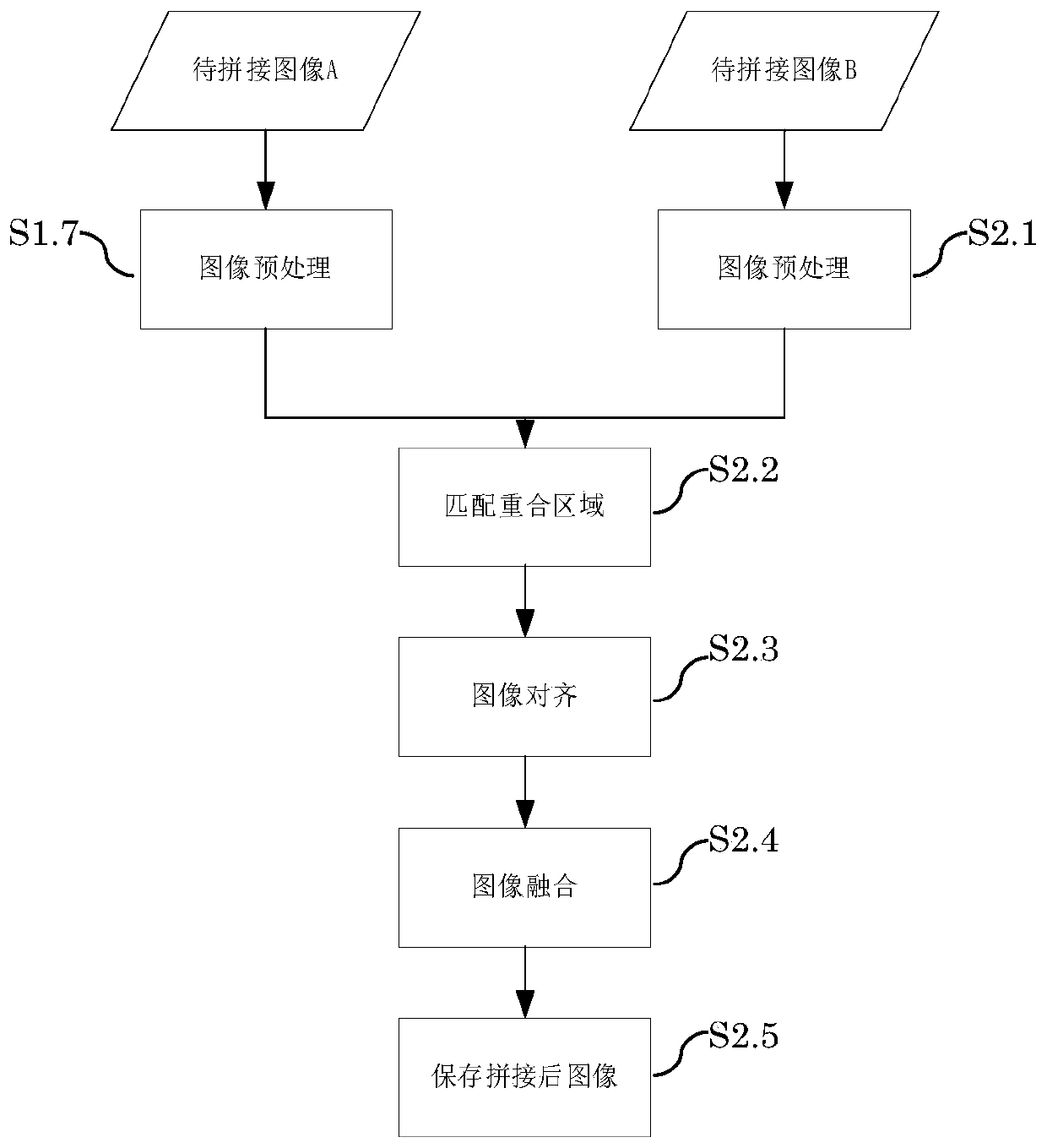

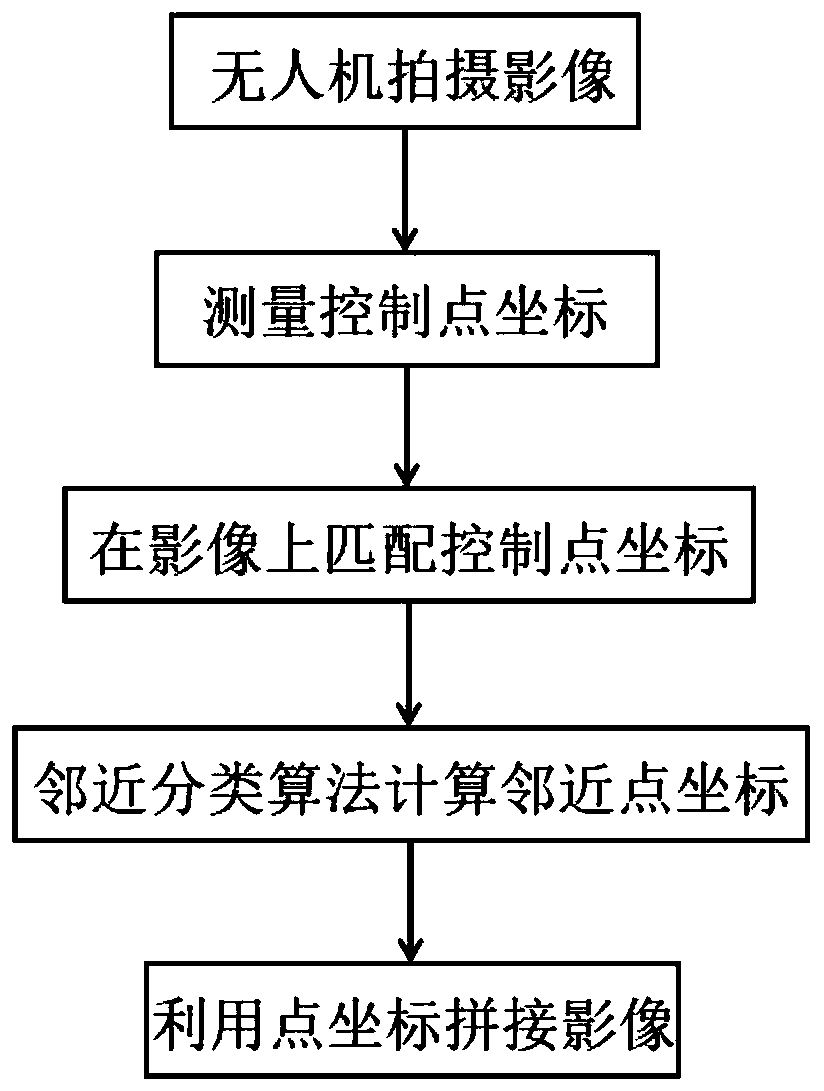

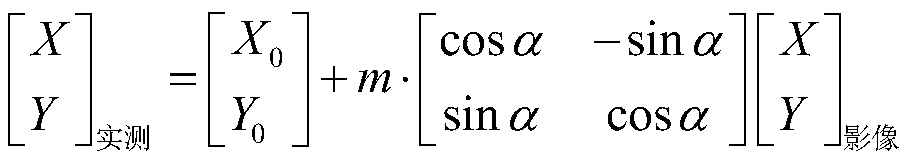

full-automatic orthographic image splicing method based on a GPS ground control point

ActiveCN109801217AHigh precisionSave stitching timeInternal combustion piston enginesGeometric image transformationObject pointUncrewed vehicle

The invention provides a full-automatic orthographic image splicing method based on a GPS ground control point, and the method comprises the following steps: S1, employing an unmanned aerial vehicle to shoot a group of images with a certain overlapping degree, and enabling the images to comprise eye-catching ground control points; S2, measuring coordinates of a ground control point by adopting a GPS RTK method, and sending the coordinates of the control point to the unmanned aerial vehicle through radio frequency equipment; S3, the unmanned aerial vehicle automatically matches the control point coordinates to an image shot by the unmanned aerial vehicle according to the control point coding information; S4, calculating coordinates of adjacent ground object points in the image by using thecontrol point coordinates and an adjacent classification algorithm; S5, repeating S4 operation to process all images; And S6, automatically splicing the images by using the marked coordinates in the processed images. According to the method, manual operation is avoided, the image splicing time is shortened, the automation degree is high, and the splicing precision is good.

Owner:SOUTHEAST UNIV

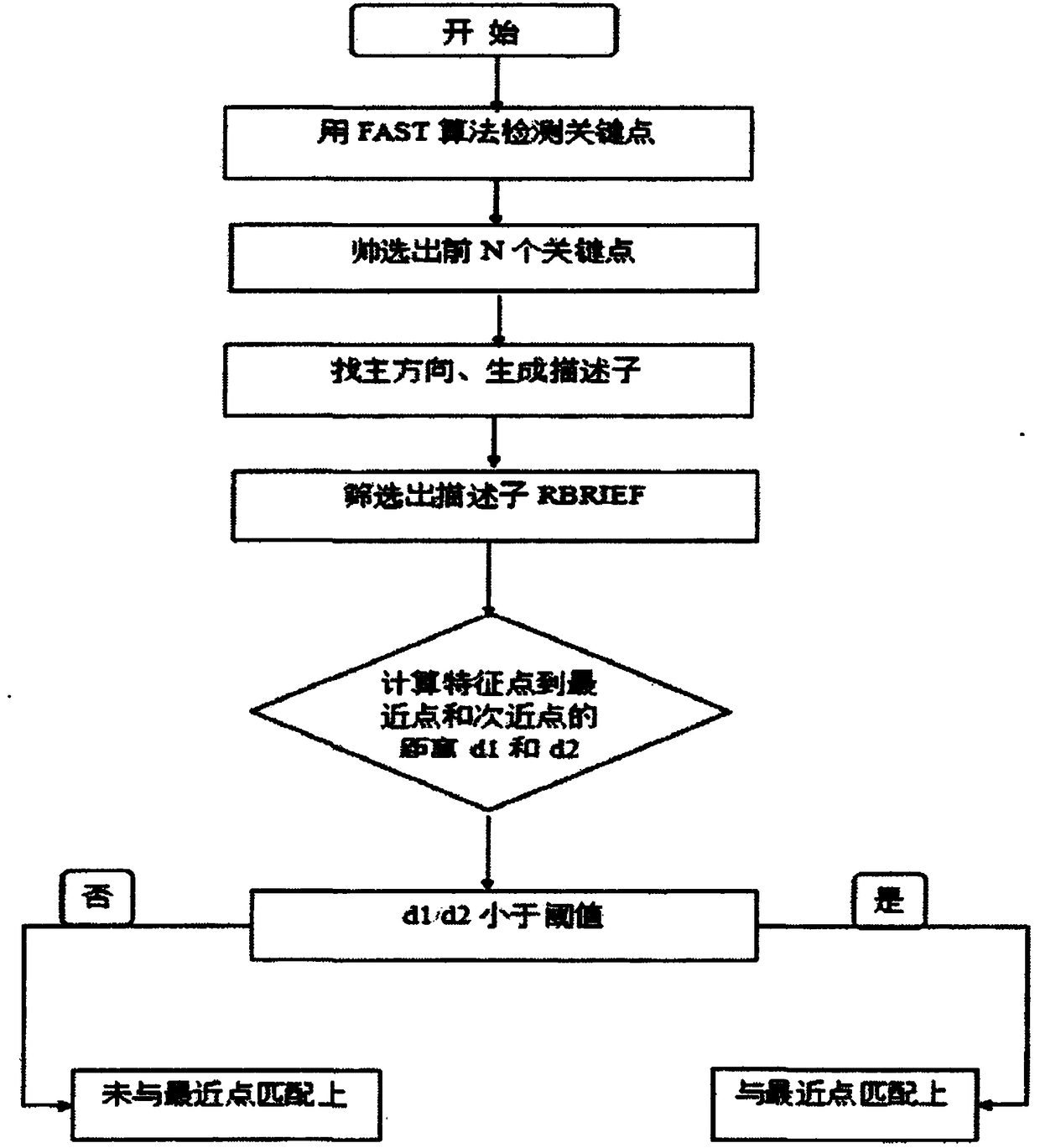

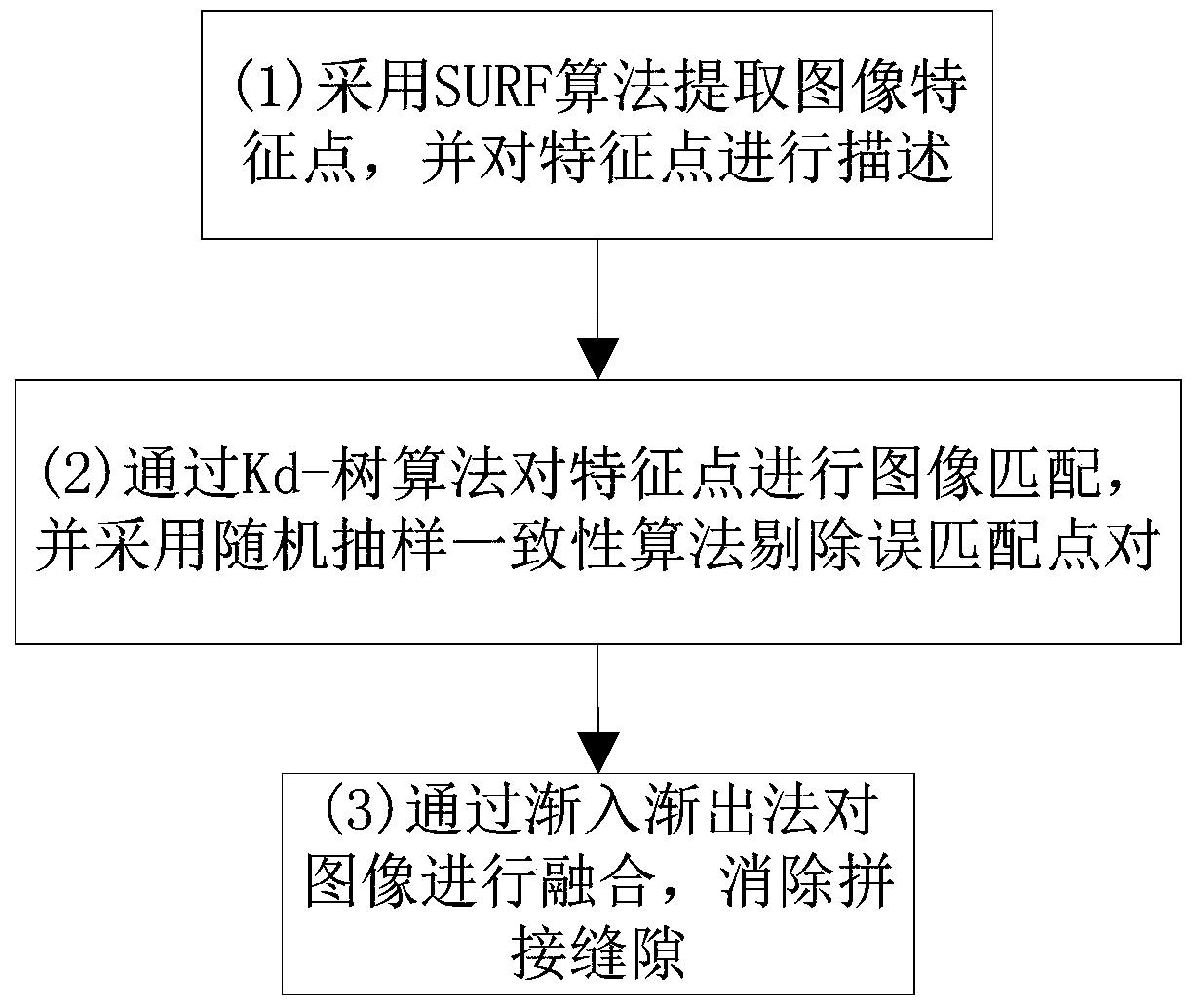

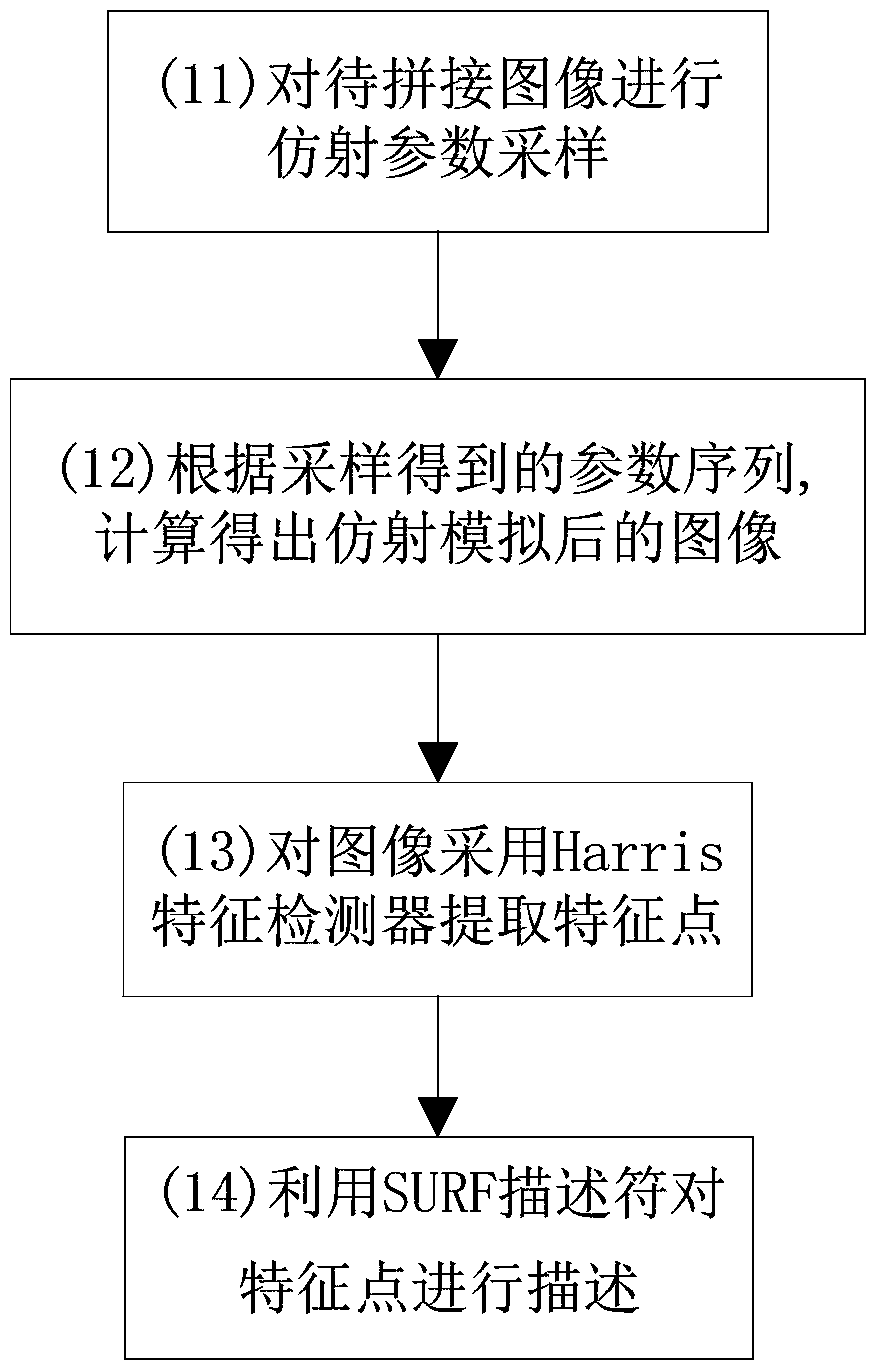

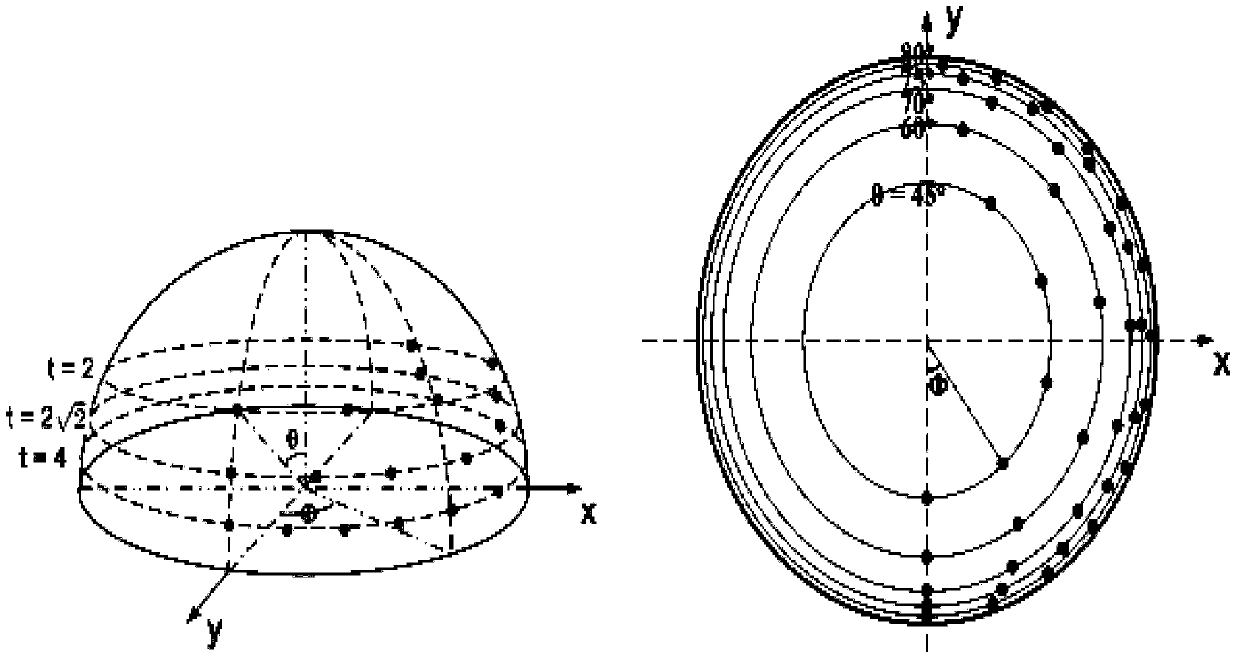

Affine invariant feature-based image splicing method

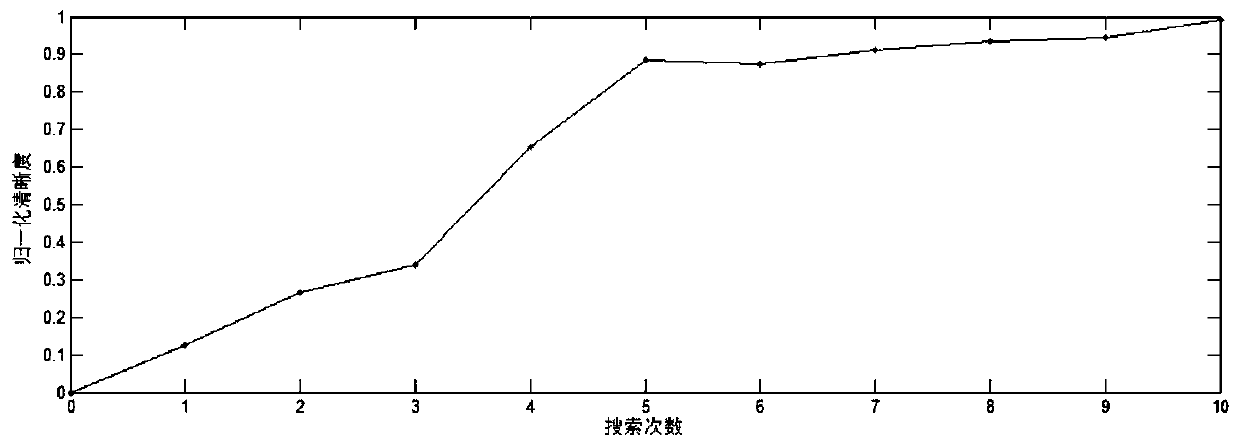

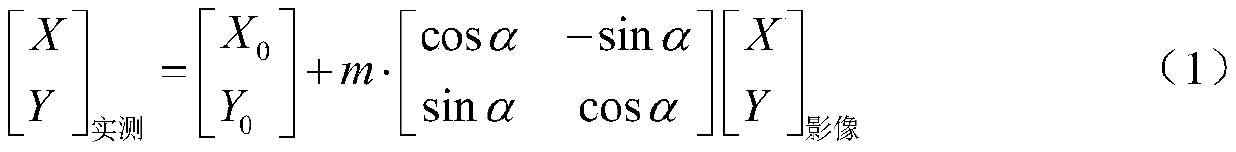

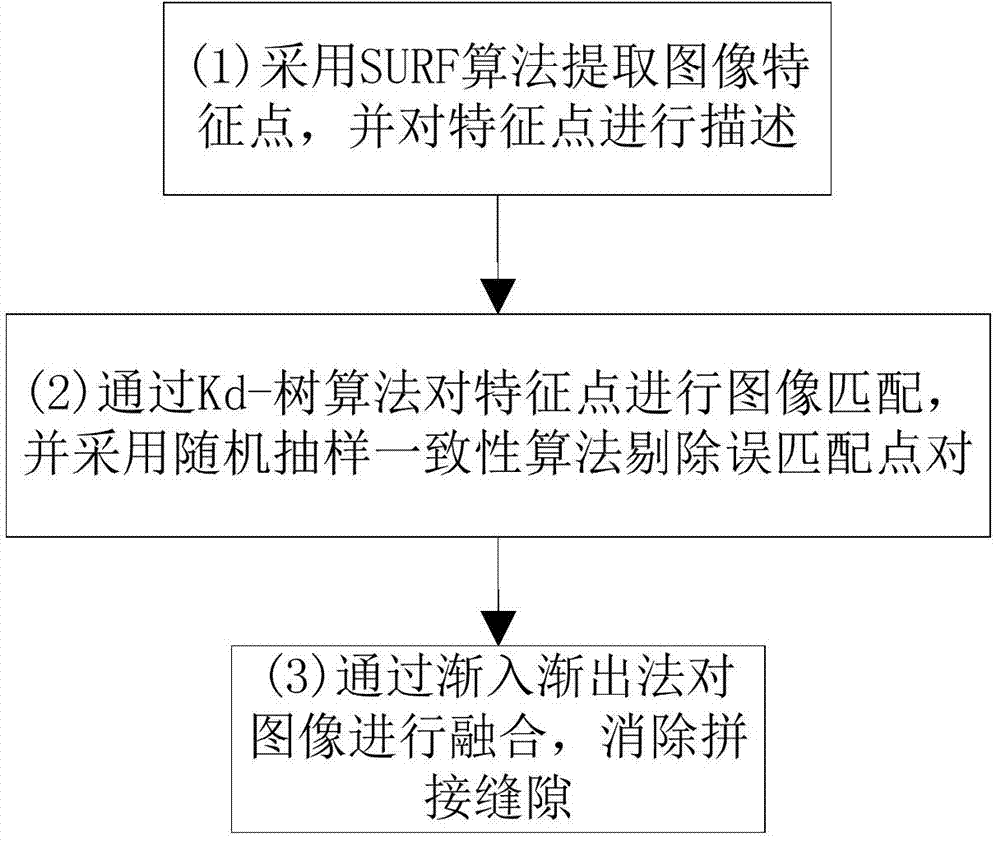

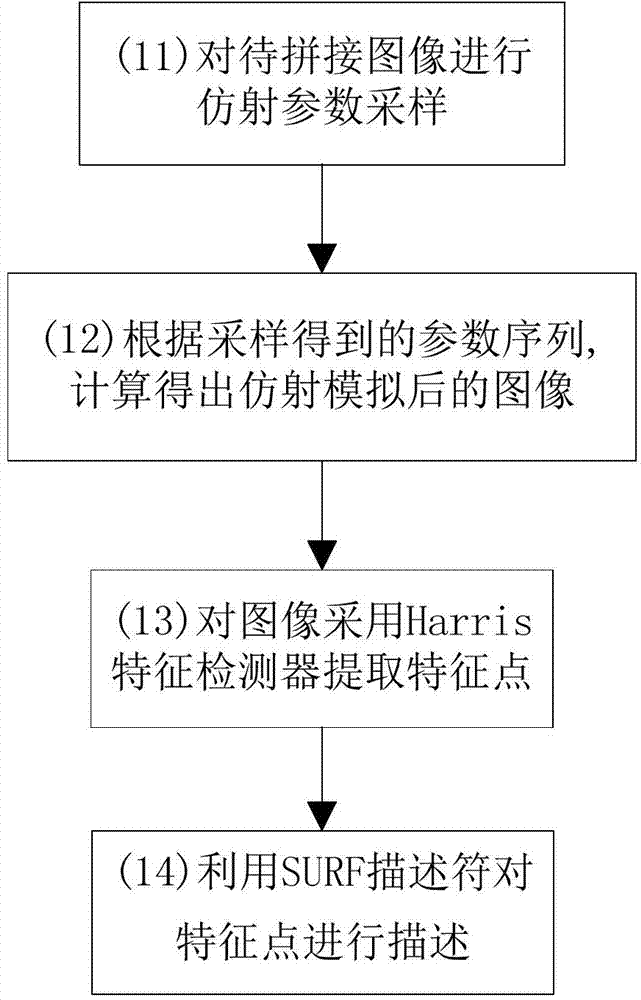

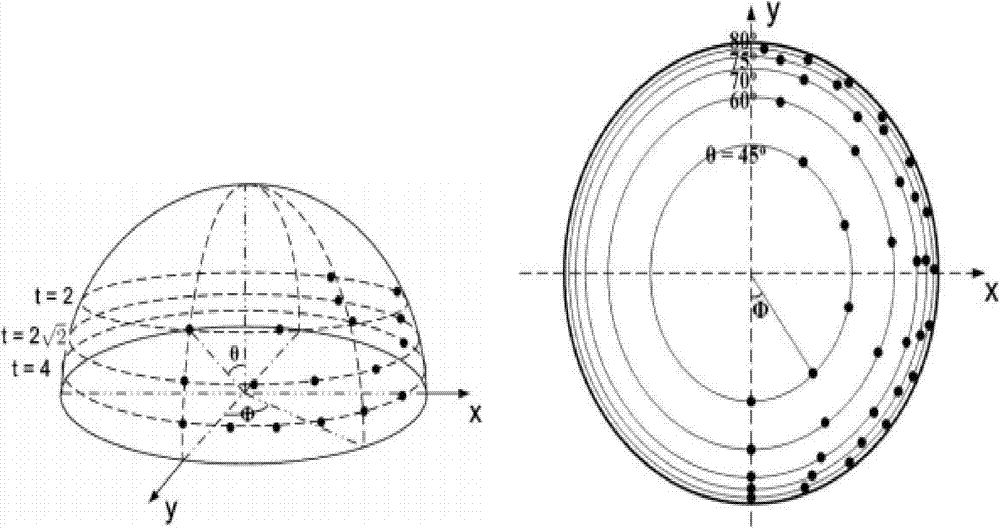

ActiveCN104751412AFully affine invariantImprove stabilityImage enhancementGeometric image transformationFeature basedConsensus algorithm

The invention discloses an affine invariant feature-based image splicing method. The method includes the steps of 1, extracting feature points of images to be spliced, by a SURF algorithm, and describing the feature points; 2, subjecting the feature points to image matching by a Kd-tree algorithm based on the BBF (bacterial biofilm) mechanism, and removing mistakenly matched paired points by a random sample consensus algorithm; 3, fusing the images by a fade-in and fade-out method to eliminate splicing slits. The method has the advantages that the images to be spliced are subjected to extraction of the feature points by the modified SURF algorithm, the feature points are described, the extracted feature points are of affine invariance, the feature points are matched by the Kd-algorithm based on the BBF mechanism, and calculation speed of the algorithm is increased.

Owner:重庆信科设计有限公司

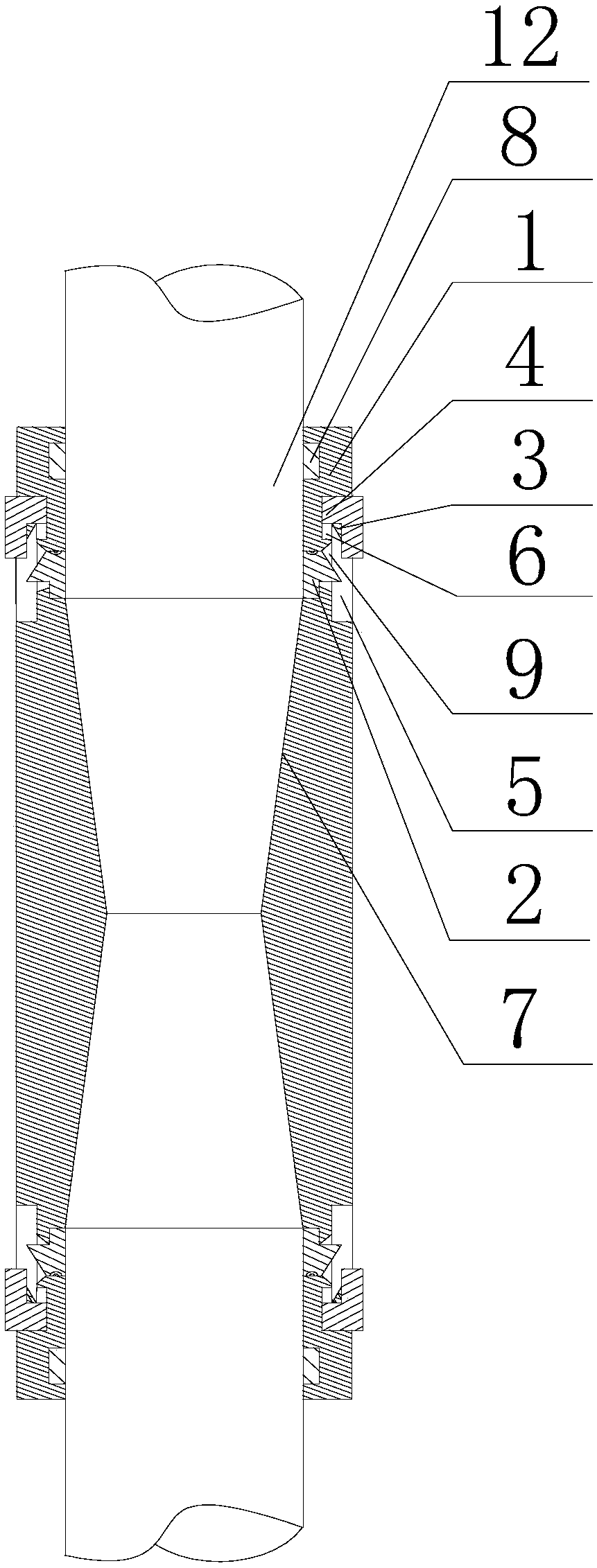

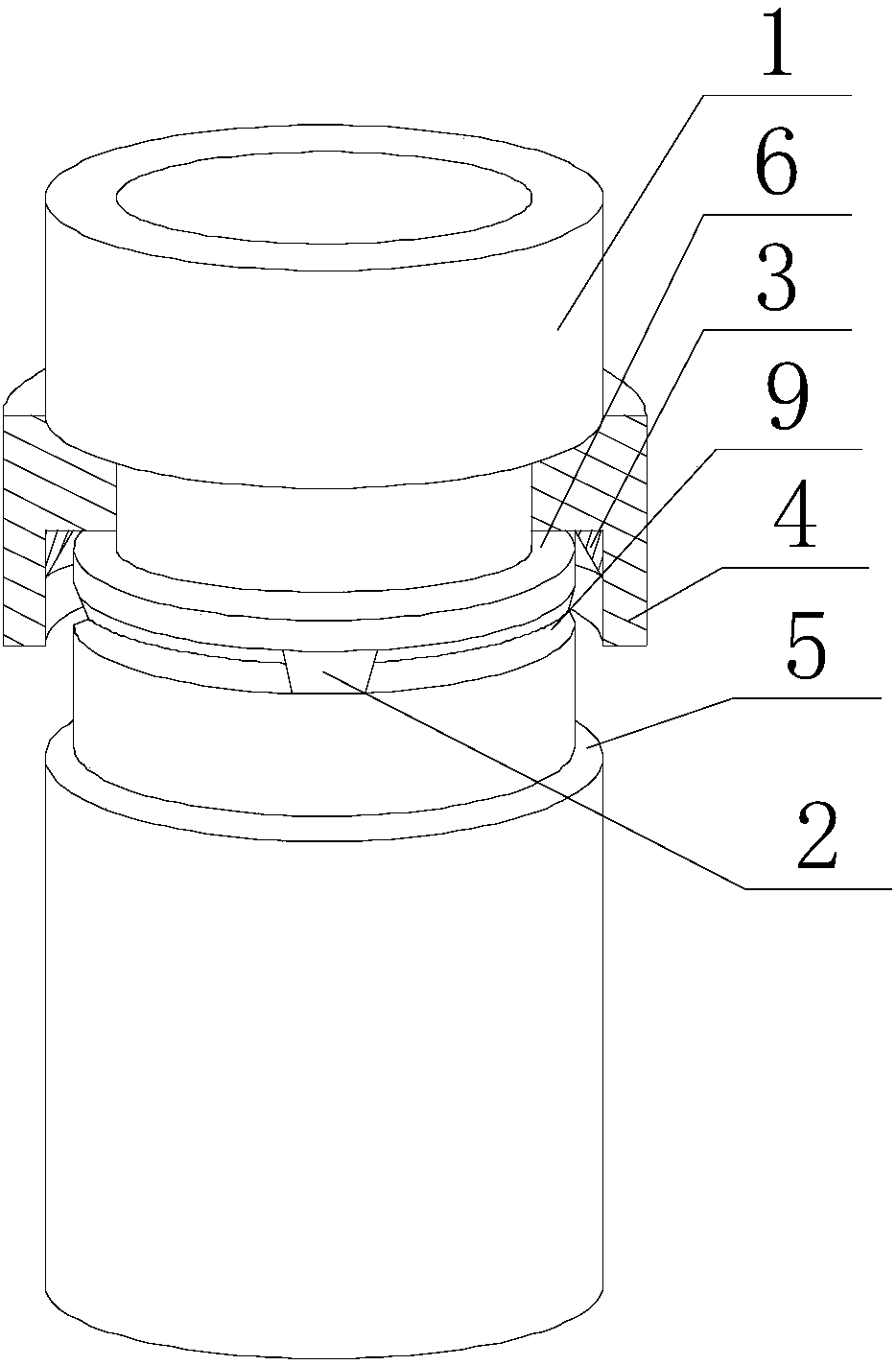

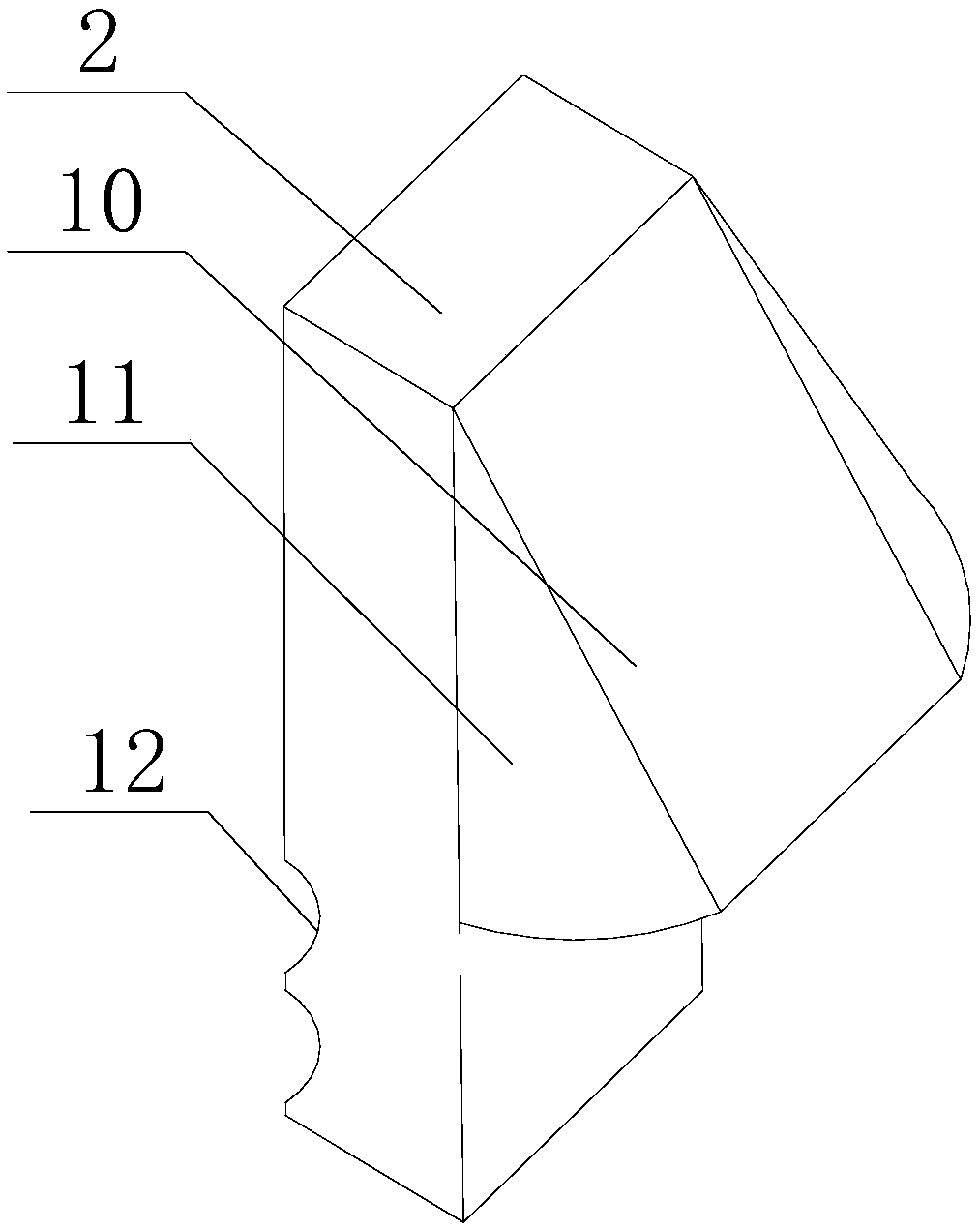

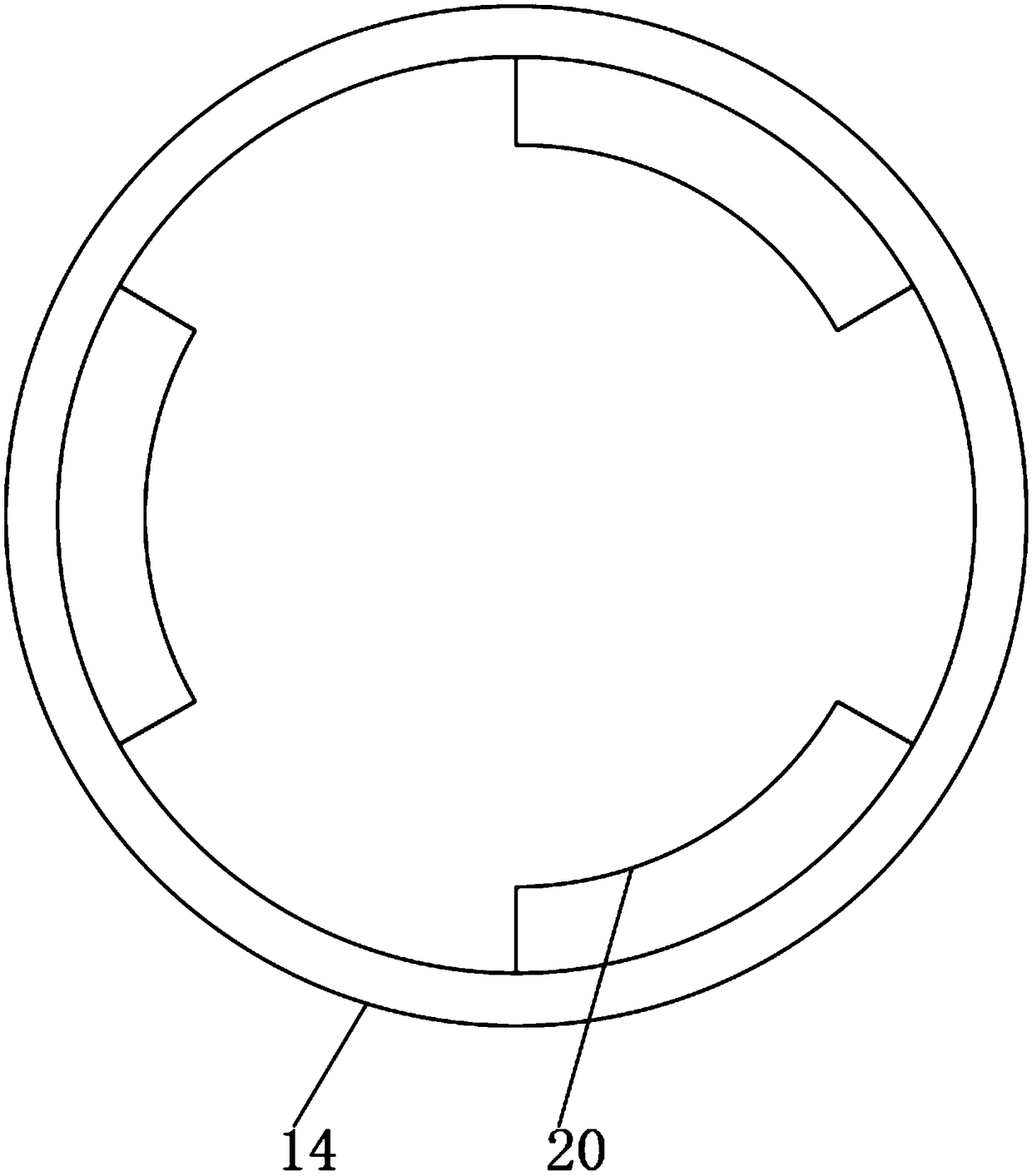

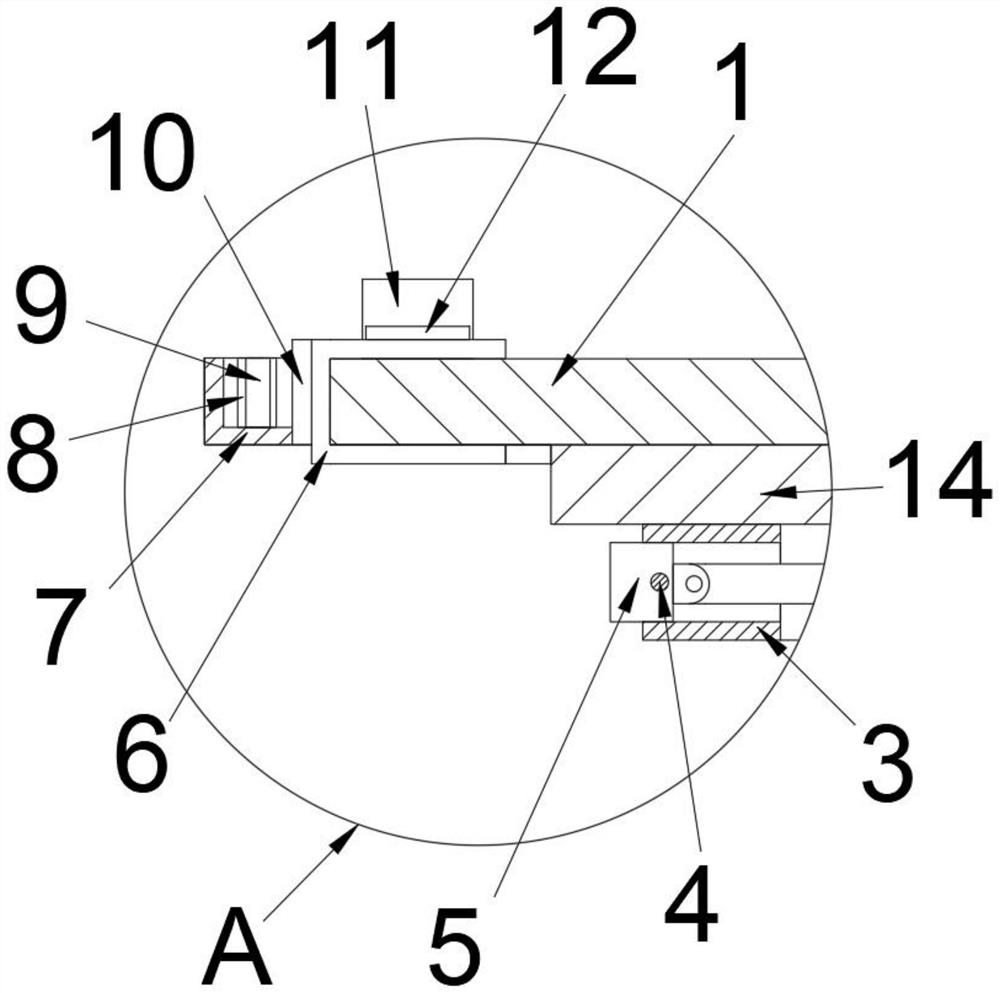

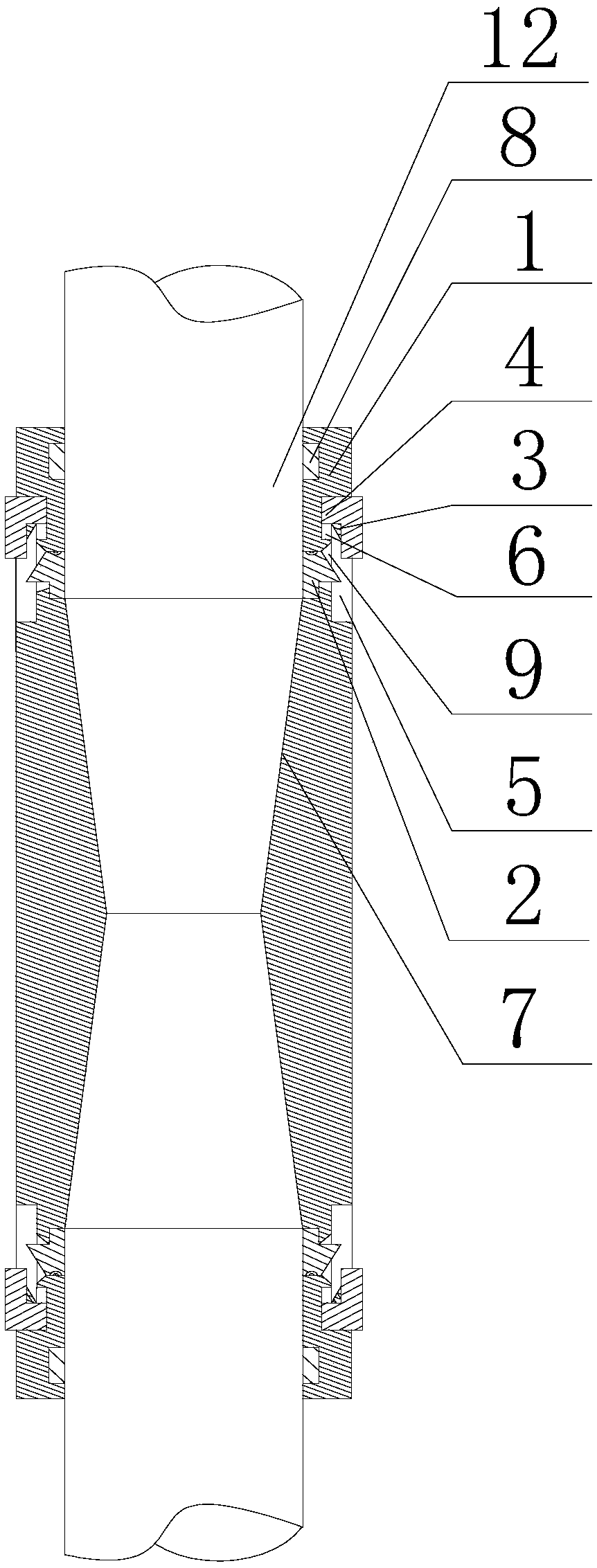

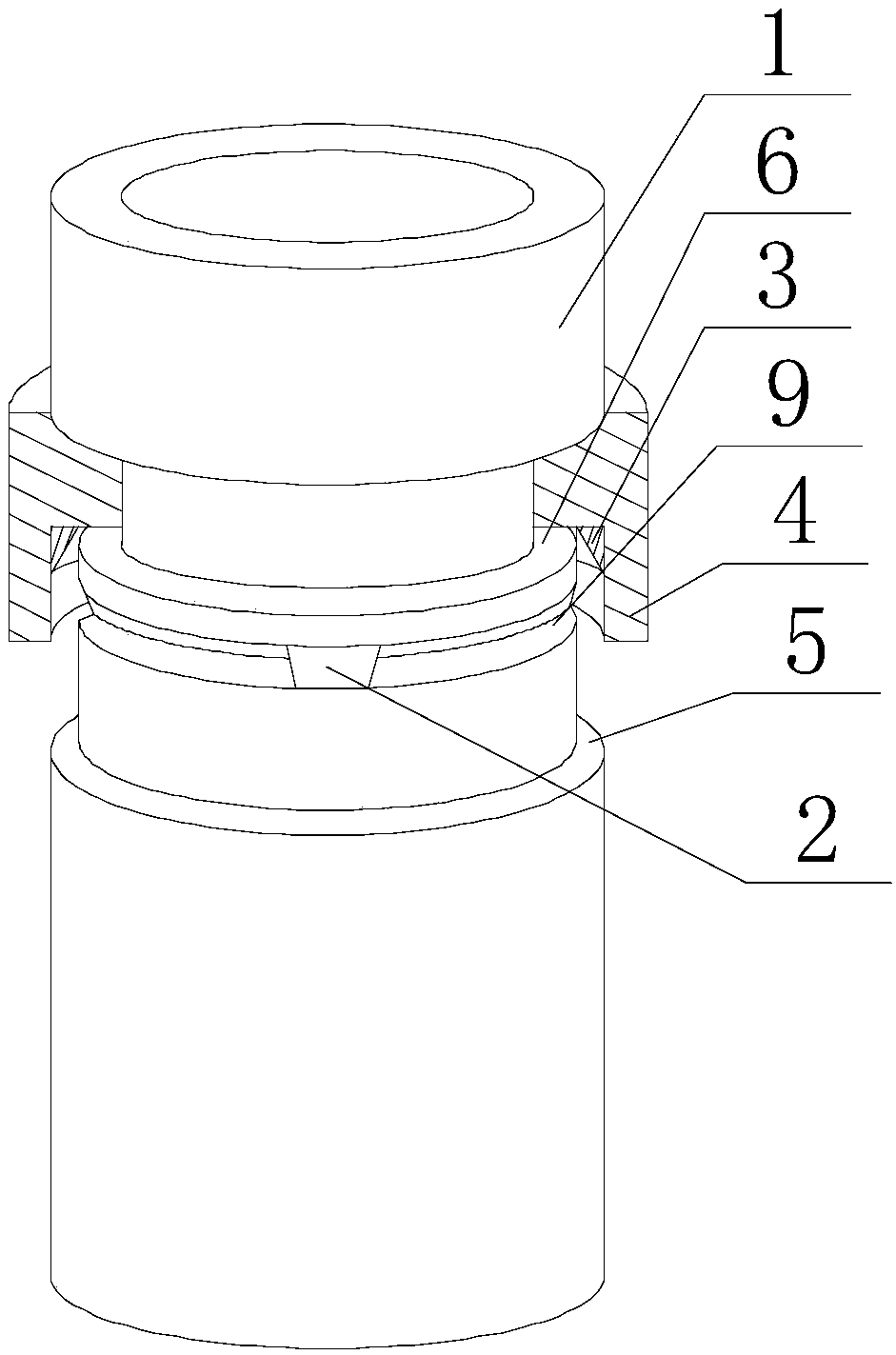

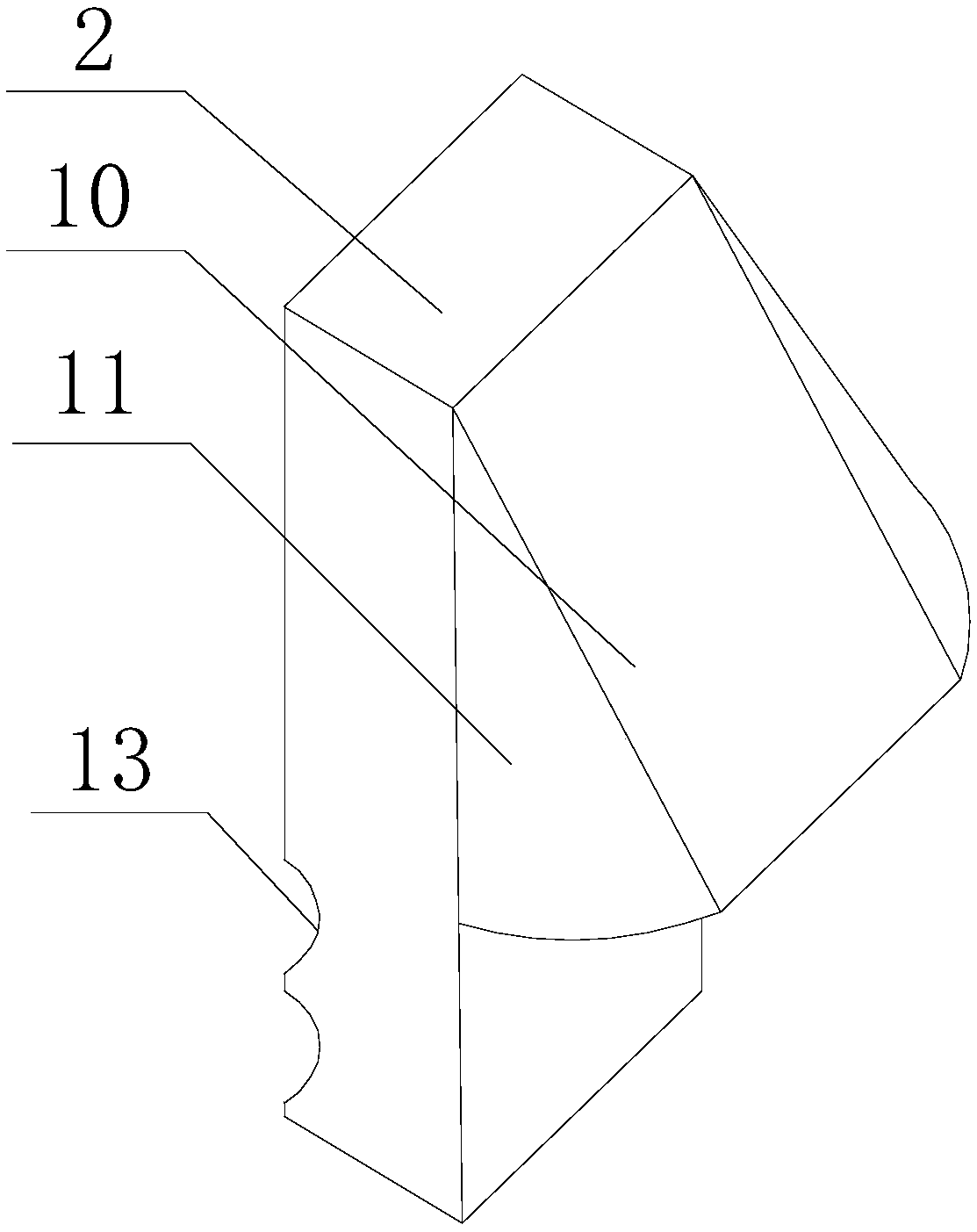

Steel bar connection component for construction of high-rise building bearing piles

ActiveCN107724604AGuaranteed clamping forceReduce wearBuilding reinforcementsArchitectural engineeringRebar

The invention discloses a steel bar connection component for construction of high-rise building bearing piles. The steel bar connection component comprises a connection cylinder and a snap ring. A nutis arranged on the connection cylinder. A sliding groove and a limiting groove communicated with the sliding groove are formed in the outer circumferential wall of the connection cylinder. An annulargroove is formed in the bottom of the sliding groove. A through hole is formed in the annular groove. The inner side wall of a press block is flush with the inner circumferential wall of the connection cylinder. The outer side wall of the press block is protruded on the outer end wall of the through hole and disposed in the annular groove. Threads are arranged at the bottom of the sliding groove.A press ring is arranged in the sliding groove in a sleeved mode. A protrusion is arranged on the inner circumferential wall of the press ring. The inner diameter of the protrusion increases gradually from one end, where the press ring is located, to the direction close to the connection cylinder along the axis of the connection cylinder. A contact block is arranged on the outer side wall of thepress block. One end of the connection cylinder is fixed to a rotating disc, and the other end of the connection cylinder clamps and fastens a main rib, so that the main rib is prevented from overturning in the connection cylinder to influence the welding effect between the main rib and transverse ribs, and the strength of a reinforcement cage is guaranteed.

Owner:西安建工绿色建筑集团有限公司

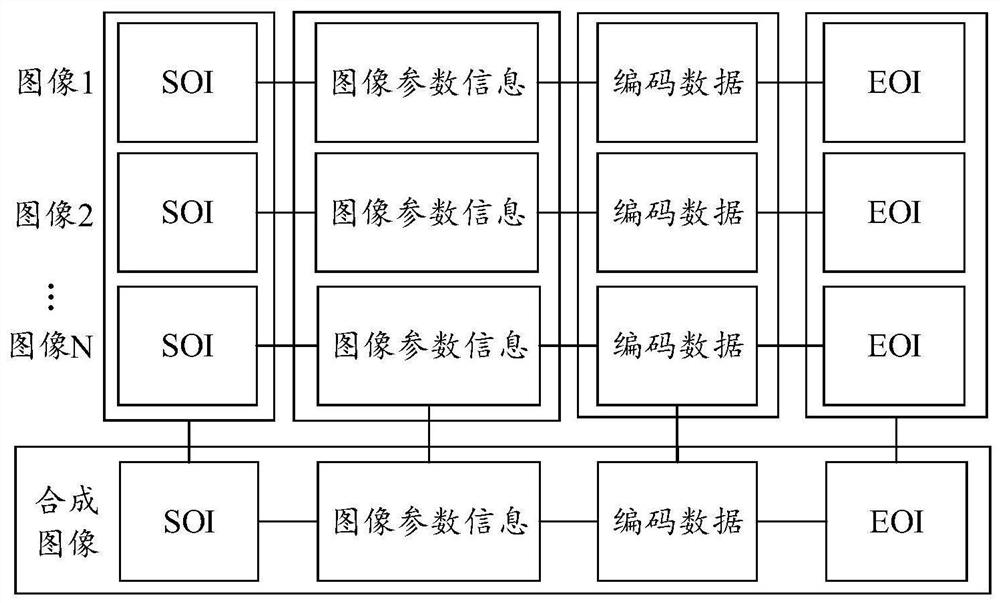

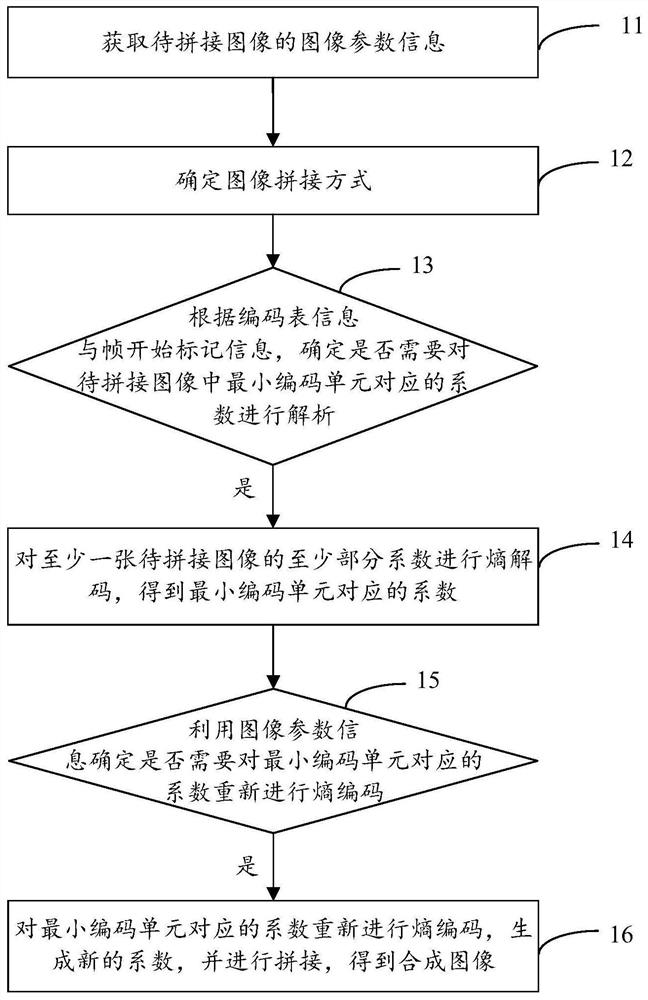

Image splicing method and device, storage medium and electronic device

PendingCN111968031AReduce processingTroubleshoot conversion issuesGeometric image transformationImage codingPattern recognitionEngineering

The invention discloses an image splicing method and device, a storage medium and an electronic device. The method comprises the steps of obtaining image parameter information of a to-be-spliced image; determining an image splicing mode; determining whether a coefficient corresponding to the minimum coding unit in the to-be-spliced image needs to be analyzed or not according to the coding table information and the frame start marking information; if analysis needs to be carried out, carrying out entropy decoding on at least part of coefficients of the at least one to-be-spliced image to obtaina coefficient corresponding to the minimum coding unit; determining whether entropy coding needs to be conducted on the coefficient corresponding to the minimum coding unit again or not through the image parameter information; and if entropy coding needs to be carried out again, carrying out entropy coding on the coefficient corresponding to the minimum coding unit again to generate a new coefficient, and carrying out splicing to obtain a composite image. By means of the mode, images of different formats can be spliced, and splicing of images of any width / height is supported.

Owner:ZHEJIANG DAHUA TECH CO LTD

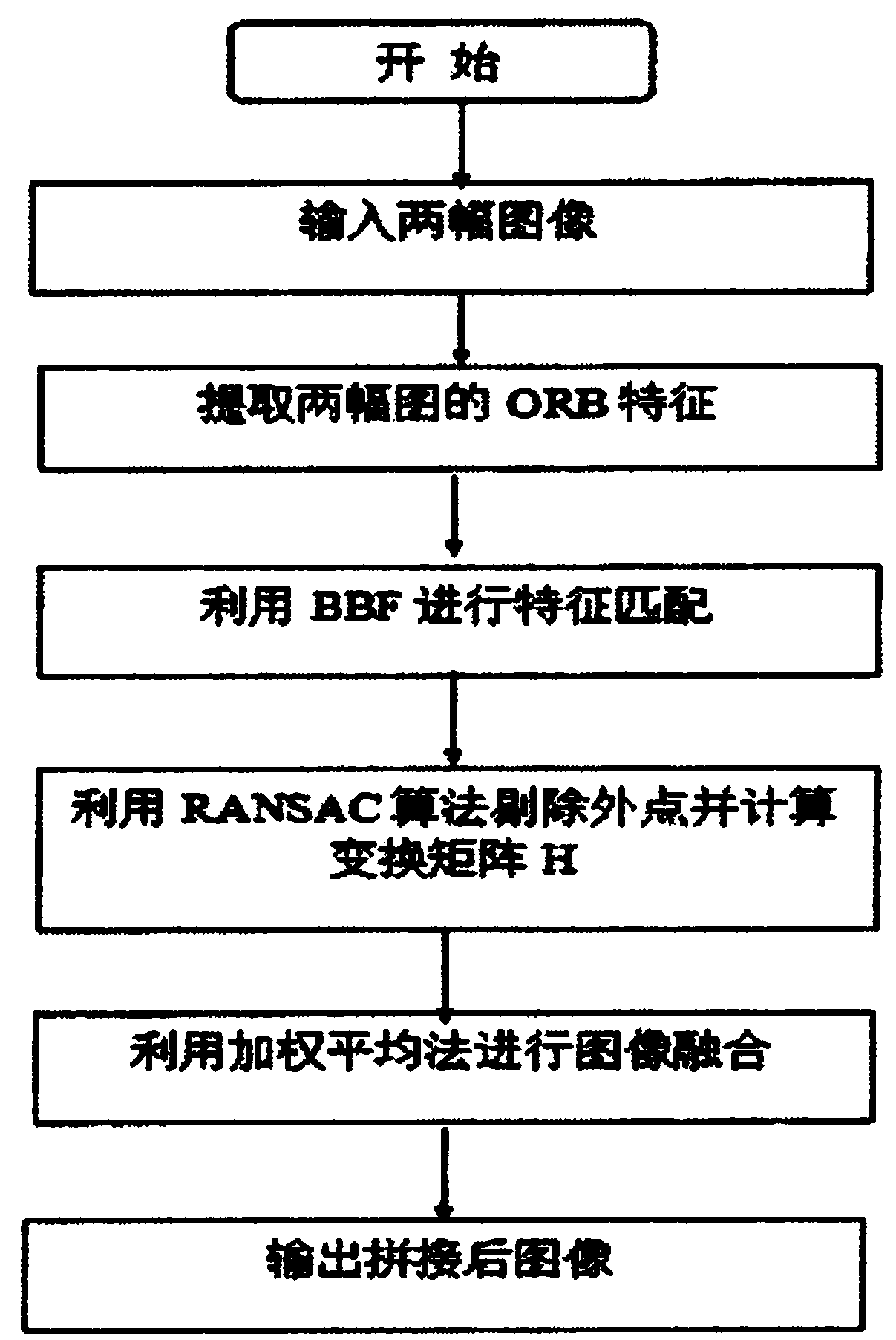

Image stitching method for light field imaging

InactiveCN108961159ASave stitching timeSpeed up fusionImage enhancementImage analysisWeighted average methodImage fusion

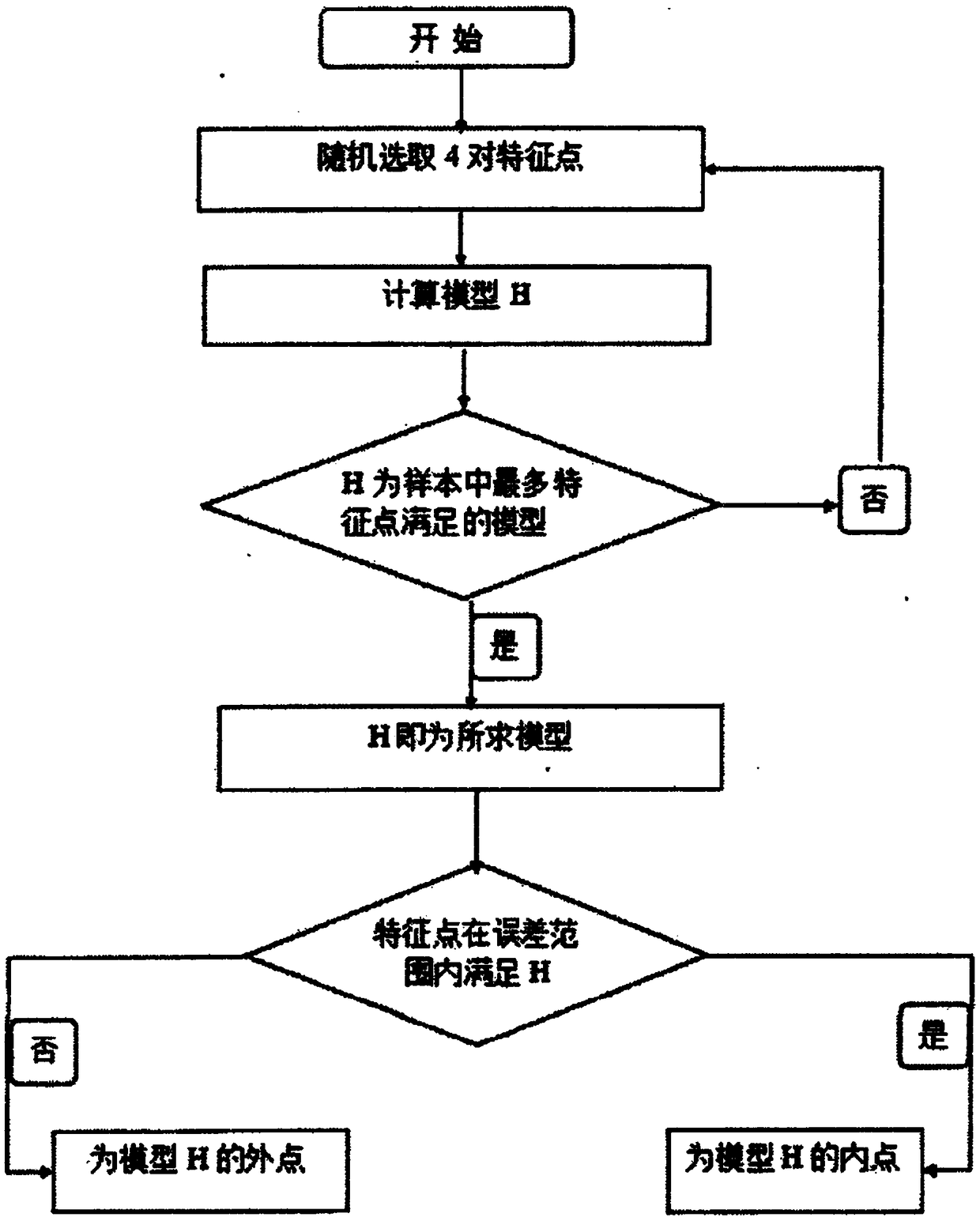

The invention provides an image stitching method for light field imaging, and relates to the technical field of image stitching. The image stitching method for light field imaging includes the following steps: 1) inputting images to be stitched; 2) constructing a scale space, and extracting ORB characteristics from the images to be stitched; 3) performing characteristic matching by means of a BBF(best-bin-first) algorithm (a threshold is set as 0.6 in the description); 4) removing error matching points by using an RANSAC (random sample consensus) algorithm, and calculating a transformation matrix H (the invention selects 4 pairs of matching points to calculate the transformation matrix H, and H is a 3*3 matrix); 5) fusing the images by using a weighted average method to stitch the two images into one image; and 6) outputting the stitched image. The image stitching method for light field imaging adopts a characteristic-based registration method, uses an image matching strategy based onthe ORB characteristics, fully utilizes the superior performance of the ORB algorithm, and in the image fusion part, fuses the images by the means of the weighted average method.

Owner:BEIJING WEIMEI YUNXI SOFTWARE CO LTD

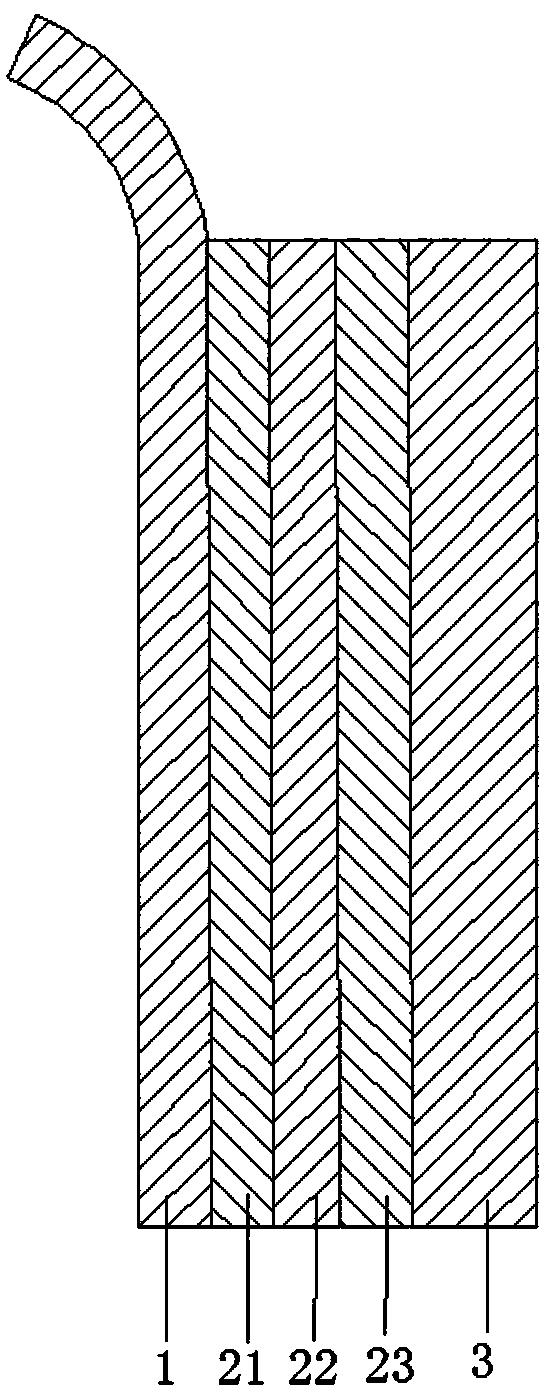

Strippable composite film for optical cable

InactiveCN108274848ASave stitching timeGuaranteed anti-corrosionSynthetic resin layered productsMetal layered productsEngineeringSteel belt

The invention discloses a strippable composite film for an optical cable. The strippable composite film for the optical cable comprises a chrome-plated steel belt arranged on the innermost layer, a co-extrusion film arranged on the intermediate layer as well as a PE sheath layer arranged on the outermost layer, wherein the co-extrusion film comprises a layer A arranged on the outer layer of the chrome-plated steel belt, a layer B arranged on the outer layer of the layer A, and a layer C arranged on the outer layer of the layer B; the layer adheres to the chrome-plated steel belt; the layer C adheres to the PE sheath layer. The co-extrusion film is divided into three layers, the three layers exist as a whole; the layer A adheres to the chrome-plated steel belt; the layer B is the intermediate layer; the layer C adheres to the outer PE sheath layer; a controllable stripping interlayer is arranged between the layer B and the layer C and has certain layering strength; the layering strengthis about 3 N / cm.

Owner:JIANGSU JIUTIAN PHOTOELECTRIC TECH CO LTD

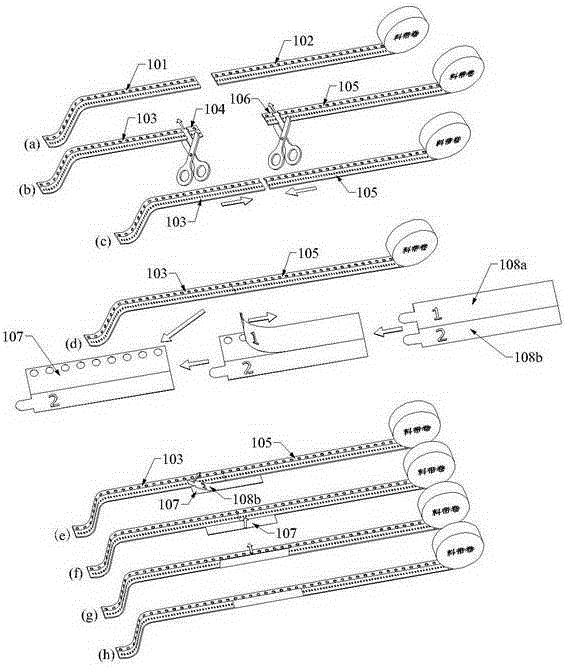

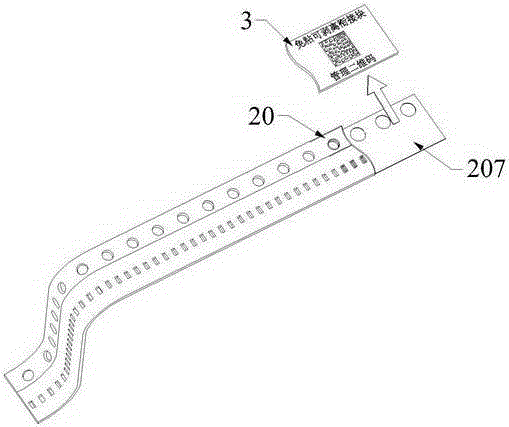

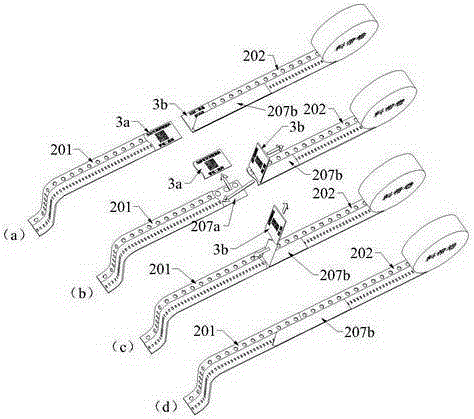

Material belt joining assembly and material belt splicing method using the same

InactiveCN105263306ASave stitching timeImprove pass rateElectrical componentsSurface mountingPass rate

The invention discloses a material belt joining assembly and a material belt splicing method using the same. The material belt joining assembly comprises an adhesive-free strippable joining block jointed to the end part of a material belt and a reinforcing adhesive tape. One face of the joint block is adhered to the reinforcing adhesive tape. The length of the reinforcing adhesive tape is larger than the length of the joint block. The material belt splicing method comprises the step that joint blocks are gradually removed from two material belts whose end parts use the material joining assembly, so firm splicing of the material belts are achieved. The beneficial effects are that 1) splicing time of the material belts is greatly reduced; 2) via the S-shaped cutting, contact length of the splicing and support force of splicing faces are increased, the material belts will not be bent in right angle when external force is imposed on the spliced place, and the passing rate is much high when the spliced material belts are used in an automatic surface mount device; 3) in the splicing process, any cutting tool is not required and manual errors generated in cutting can be avoided; and 4) by managing colors, labels or bar codes on the surfaces of the joint blocks and then adding necessary information, false materials can be avoided.

Owner:AMERICAN TEC CO LTD

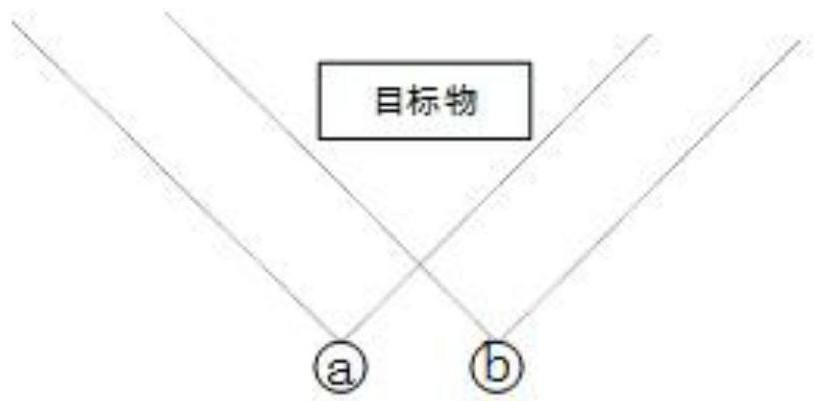

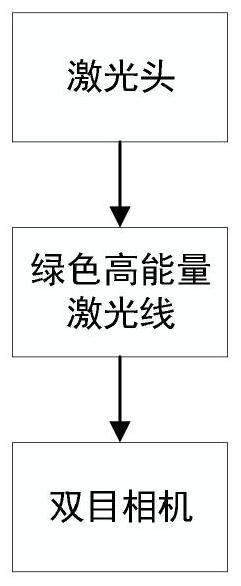

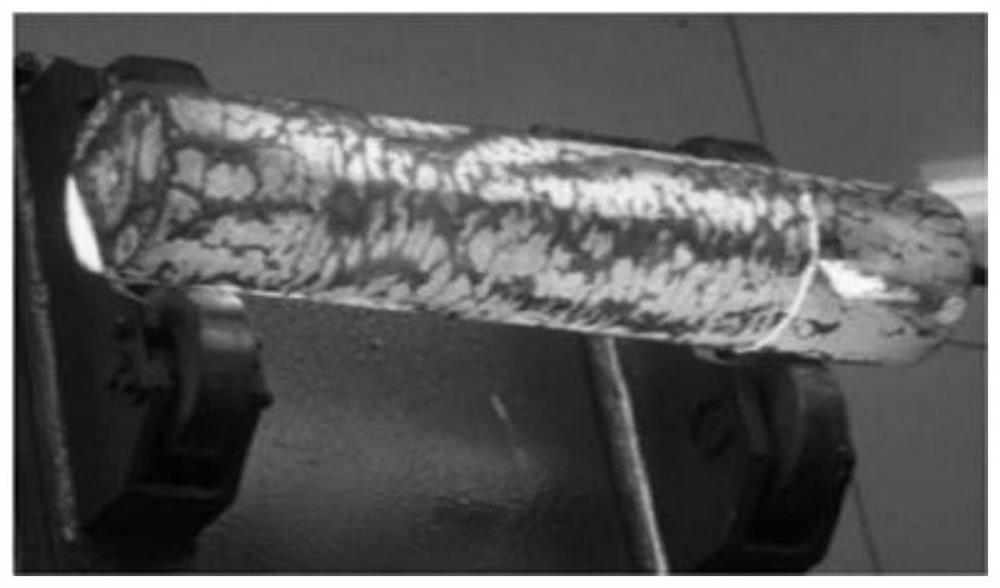

Binocular laser vision three-dimensional measurement method for high-temperature red hot target

PendingCN114111574ASave stitching timeGuaranteed real-timeUsing optical meansOphthalmologyThree dimensional measurement

The invention discloses a binocular laser vision three-dimensional measurement method for a high-temperature red hot target, and the method specifically comprises the following steps: 1, collecting images through a binocular camera, and respectively defining the images collected by the binocular camera as Alm * n and Arm * n; 2, processing the image obtained in the step 1, and obtaining laser line coordinates of the image; 3, the gravity centers Dri and Dli of laser rays in the images are solved according to the images Arm * n and the images Arm * n obtained in the step 2; and step 4, calculating the distance Di from the binocular camera to the target object according to the result obtained in the step 3. According to the invention, real-time three-dimensional contour detection can be carried out on the forge piece with high precision.

Owner:XIAN UNIV OF TECH

An Image Mosaic Method Based on Affine Invariant Features

ActiveCN104751412BFully affine invariantImprove stabilityImage enhancementGeometric image transformationFeature extractionImaging Feature

The invention discloses an image mosaic method based on affine invariant features, which comprises the following steps: (1) using the SURF algorithm to extract image feature points from the image to be stitched, and describing the feature points; (2) using the BBF mechanism-based The Kd-tree algorithm performs image matching on the feature points, and uses the random sampling consensus algorithm to eliminate the mismatched point pairs; (3) The images are fused by the gradual in and gradual out method to eliminate stitching gaps. An image mosaic method based on affine invariant features of the present invention first adopts the improved SURF algorithm to extract image feature points of the image to be stitched, and describes the feature points so that the extracted feature points have affine invariance, and then adopts the method based on The Kd-tree algorithm of the BBF mechanism matches the feature points, which improves the algorithm operation speed.

Owner:重庆信科设计有限公司

A digital X-ray image stitching method and system

Owner:深圳蓝影医学科技股份有限公司

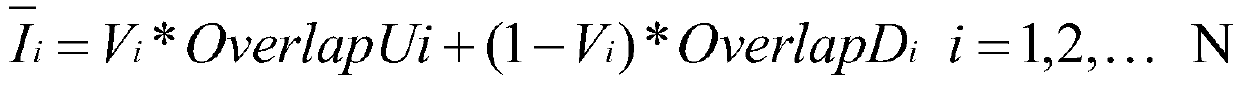

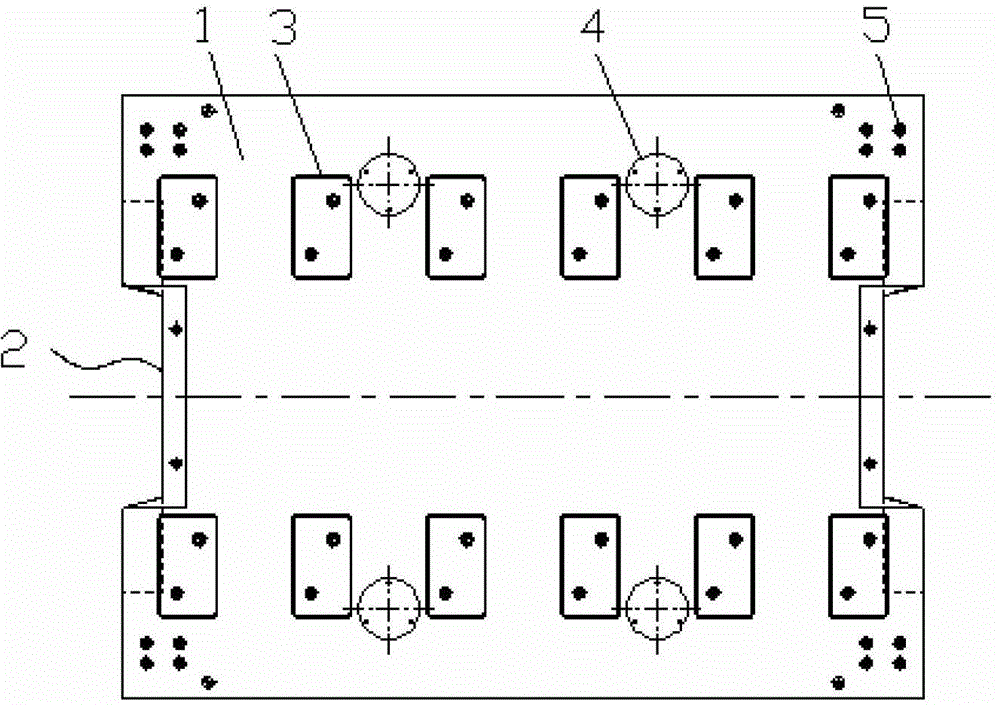

Floating track bed precast slab and construction method for precast slab assembled floating track bed

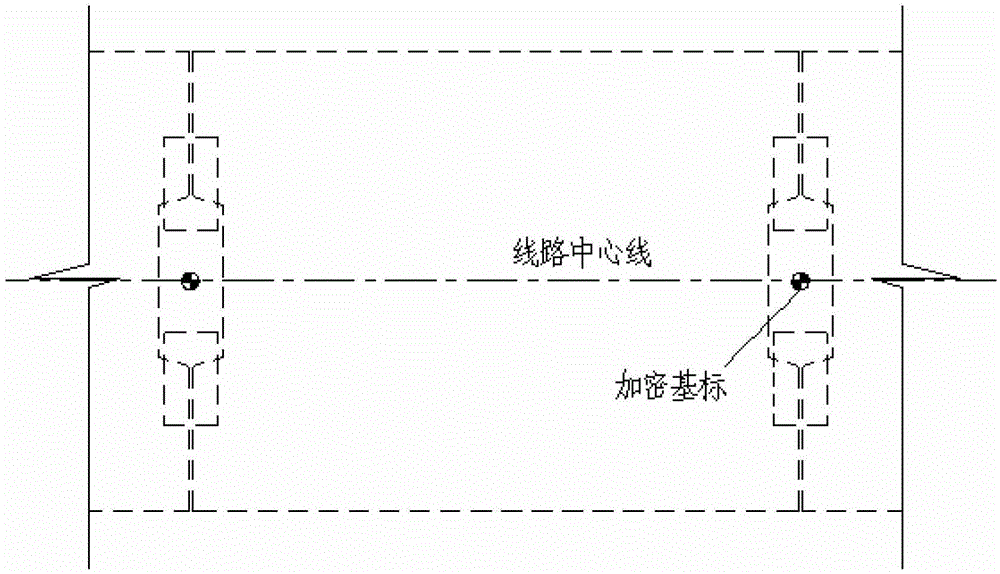

ActiveCN102912693BSimple structureEasy to useBallastwayRailway track constructionControl linePosition control

The invention discloses a construction method for a precast slab assembled floating track bed, which includes the following steps: laying a circuit center line of a base of a floating track bed and encrypted disjunction marks for positioning of precast slab main bodies; laying a hoisting control line of the precast slab main bodies and placing a position control line of side vibration isolators; mounting the side vibration isolators and present precast slab main bodies; placing vibration isolator inner sleeves in outer sleeve devices; laying adjacent precast slab main bodies along the extending direction of the circuit of the base of the floating track bed and connecting the adjacent precast slab main bodies with the present precast slab main bodies into a whole; and sequentially laying a plurality of precast slab main bodies along the extending direction of the circuit of the base of the floating track bed until an integral floating track bed is formed. The invention further provides a floating track bed precast slab for splicing the floating track bed. The construction method for the assembled floating track bed, provided by the invention, has simple construction procedures, short construction period, high construction efficiency and high construction quality, and facilitates safety inspection on the floating track bed in the follow-up utilization, and damaged components in failure are replaceable.

Owner:BEIJING JIUZHOUYIGUI SHOCK & VIBRATION ISOLATION

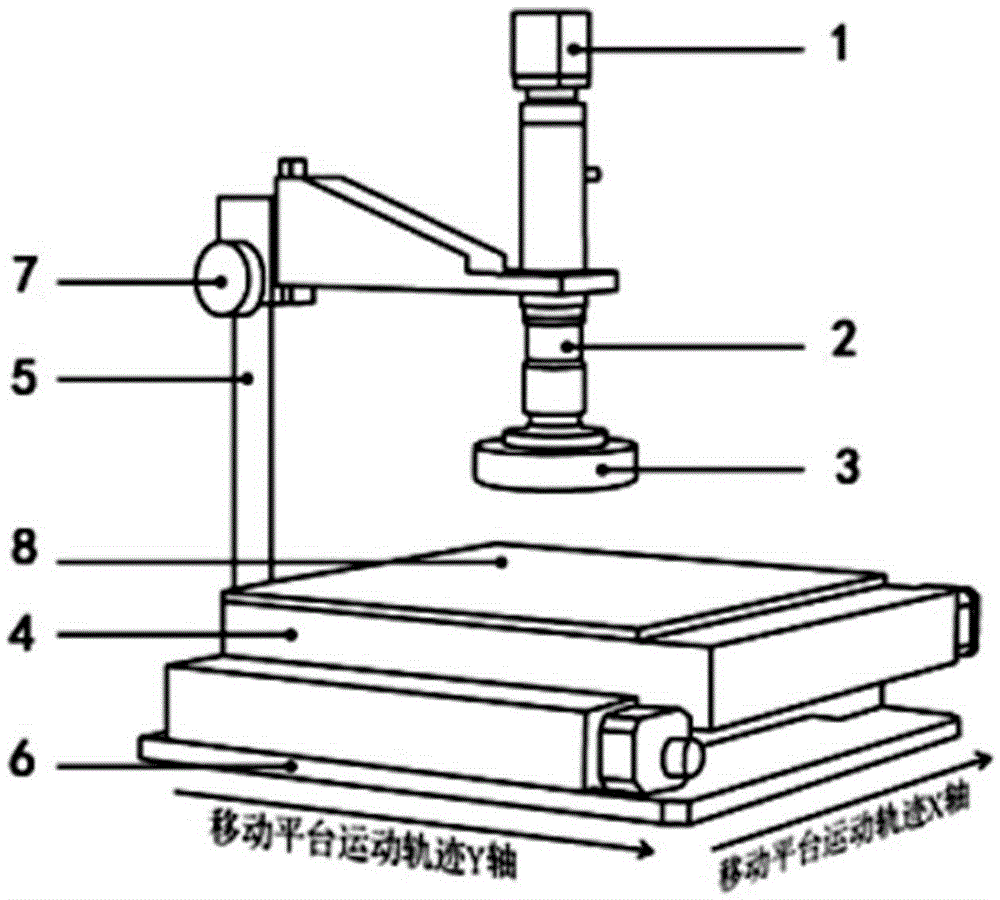

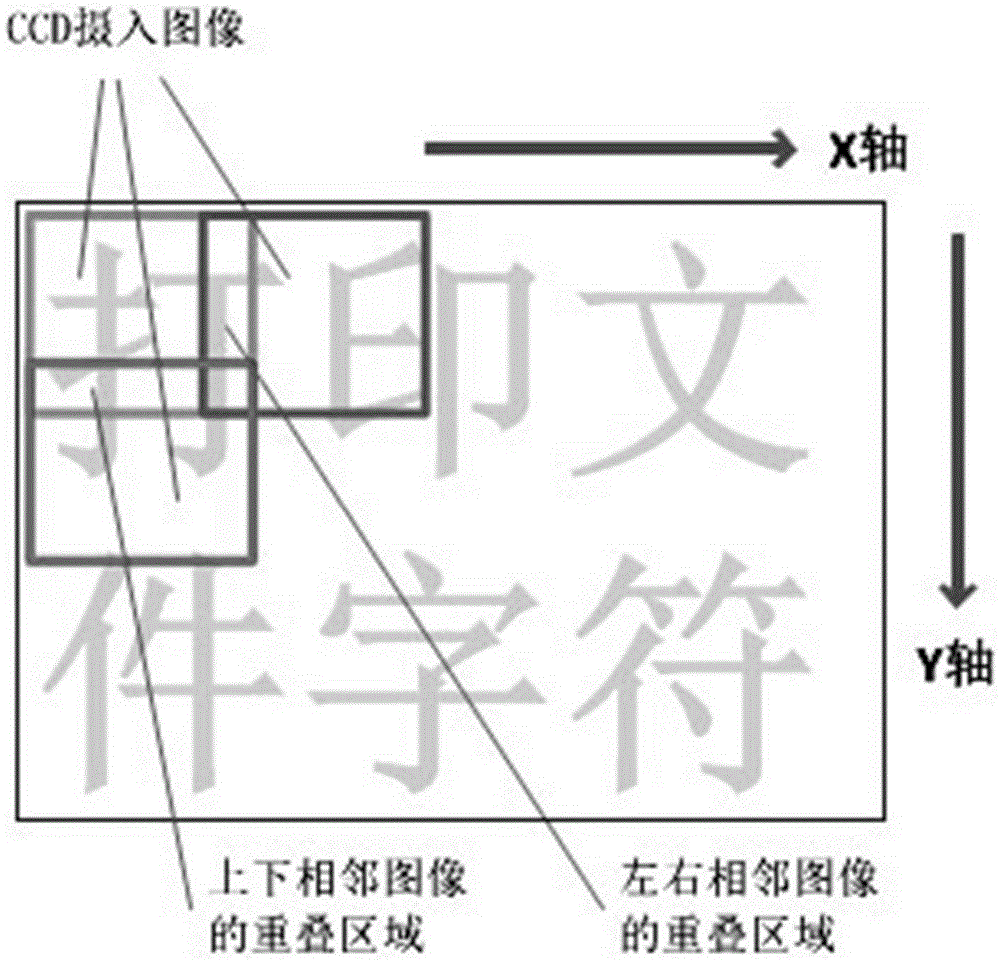

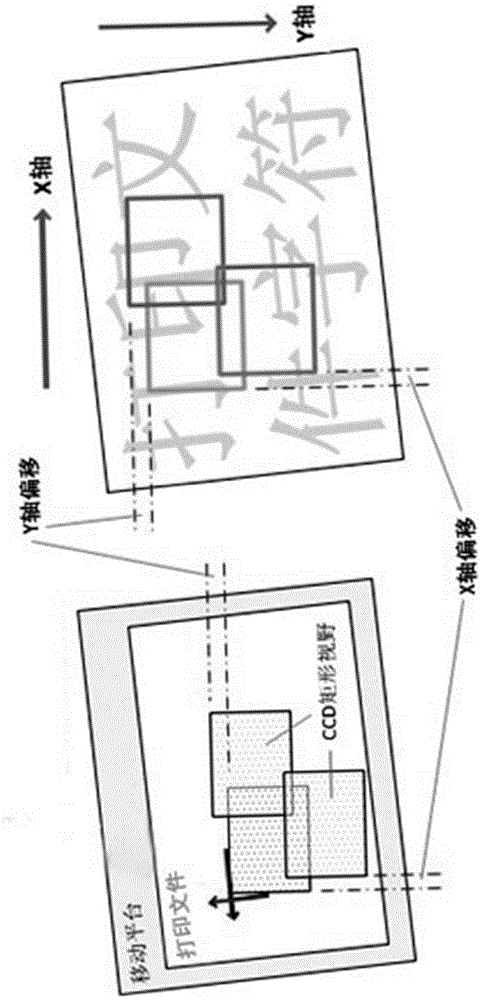

Splicing method for printing file scanning and amplification images

ActiveCN106651769AFit closelySave stitching timeGeometric image transformationOverlap ratioPerformed Imaging

The invention discloses a splicing method for printing file scanning and amplification images. Splicing is realized by discovering the maximum overlap ratio between the photographed images. The technical scheme is that binary processing is performed on the photographed images of a printing file; an X-axis overlap value and a Y-axis deviation value are calculated; a Y-axis overlap value and an X-axis deviation value are calculated; a global overlap value and a deviation value are obtained; and corresponding deviation is performed by using the global overlap value and the deviation value so as to perform image splicing.

Owner:上海蓝渺智能工程有限公司

Gardening guardrail with warning function

PendingCN109339567ASave stitching timeImprove work efficiencyFencingTraffic signalsEngineeringMechanical engineering

Owner:钱辉

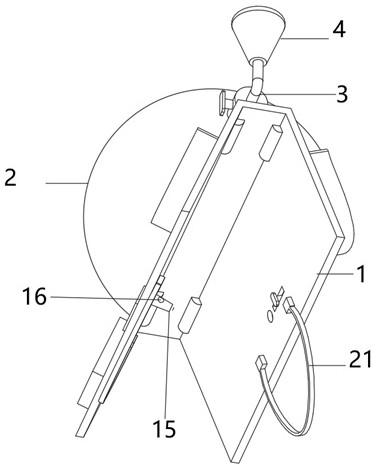

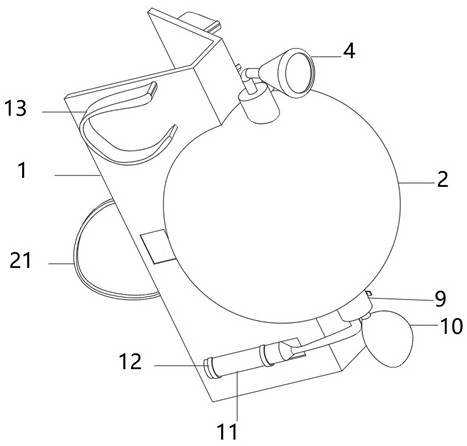

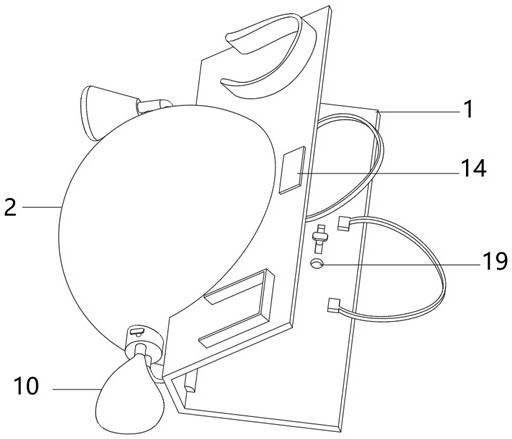

Breathing device convenient to assemble and carry for medical emergency treatment

The invention discloses a breathing device convenient to assemble and carry for medical emergency treatment, which comprises a shell, an air bag is mounted on one side of the shell, a first valve is mounted on the top surface of the air bag, a mask is arranged on the first valve, a second valve is mounted on the bottom surface of the air bag, an oxygen bag is arranged on the second valve, and a light oxygen bottle is arranged on the second valve. Two magnetic suction plates are arranged on the shell, a limiting column is fixedly connected to the other side of the shell, a limiting hole is formed in the limiting column, a second spring is fixedly connected into the shell, one end of the second spring is fixedly connected with a fixing rod, the fixing rod is slidably connected into the shell, and a positioning hole is formed in one side of the shell. And people can carry the device conveniently, so that people can use the device more conveniently and quickly.

Owner:鄂东医疗集团市中医医院(市传染病医院黄石市中医医院)

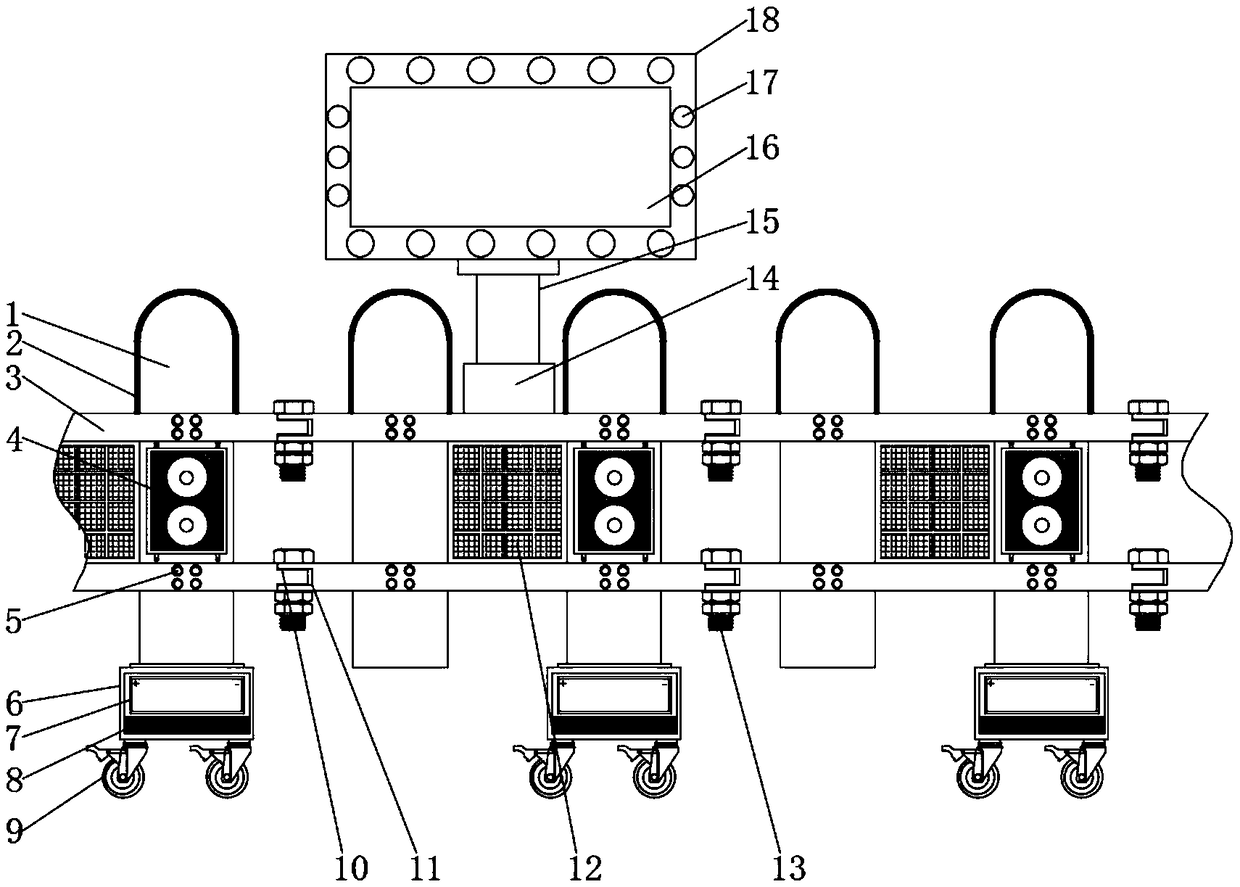

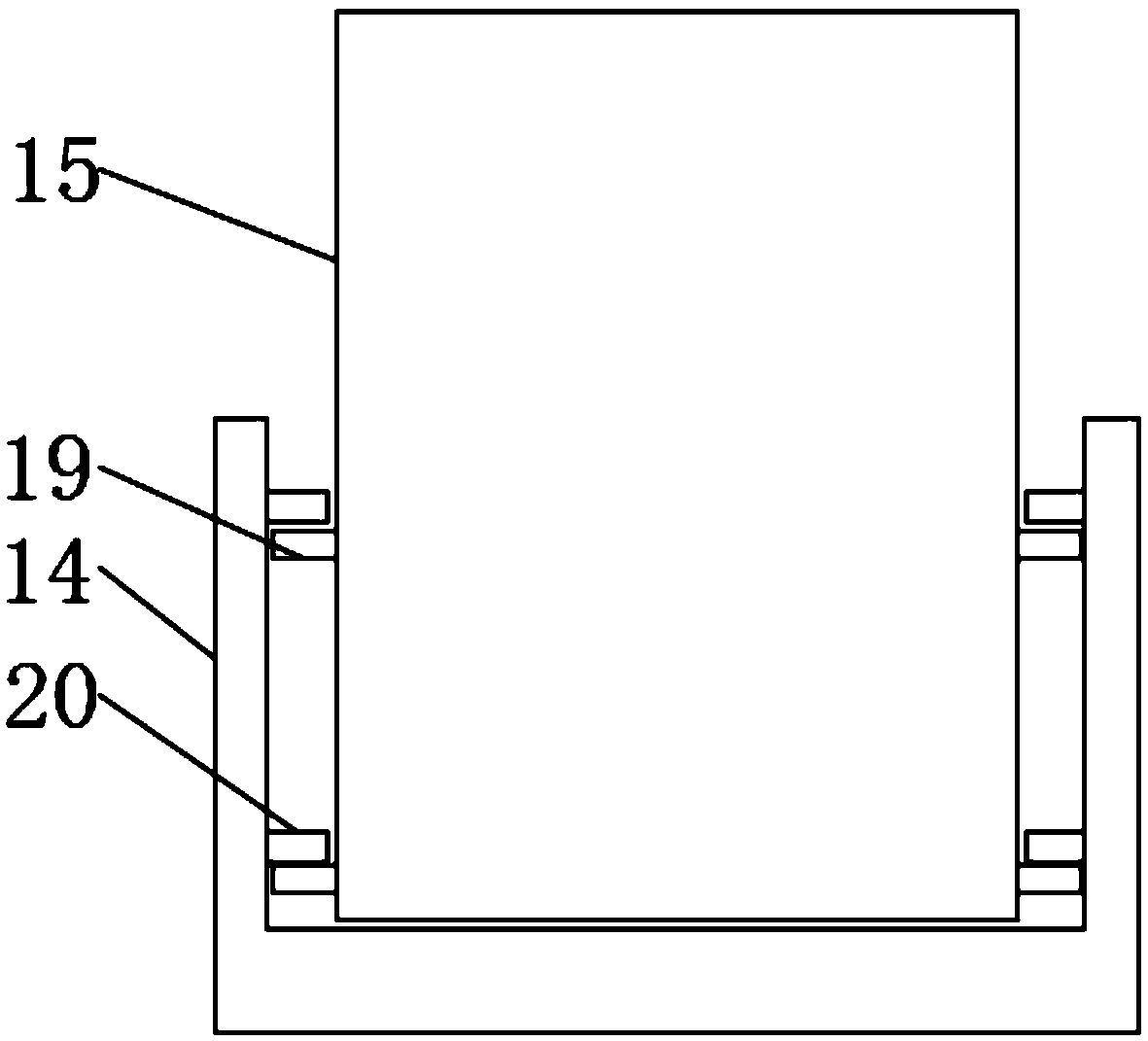

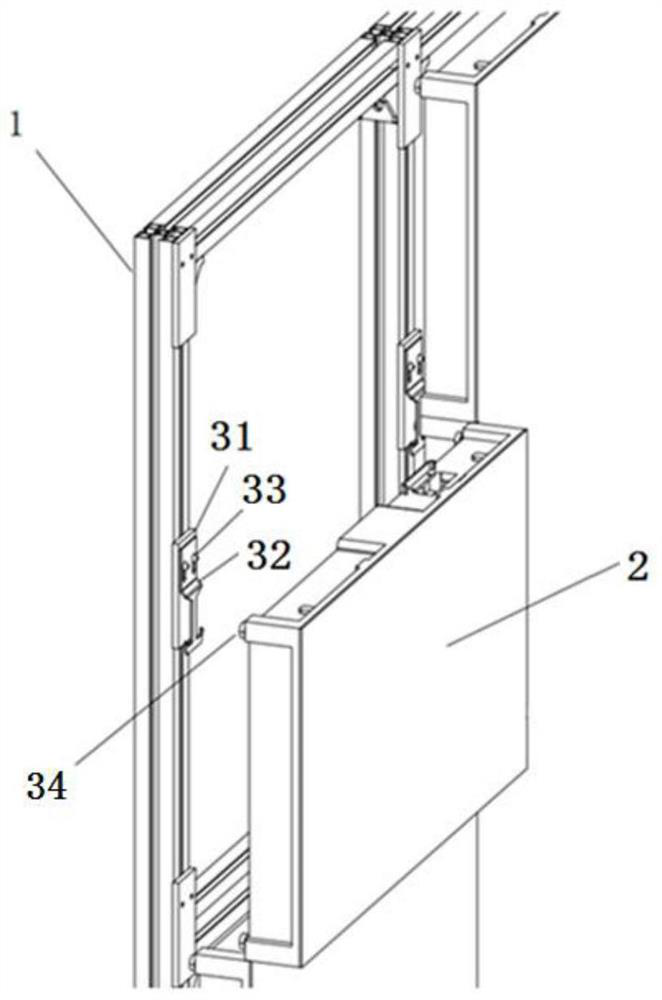

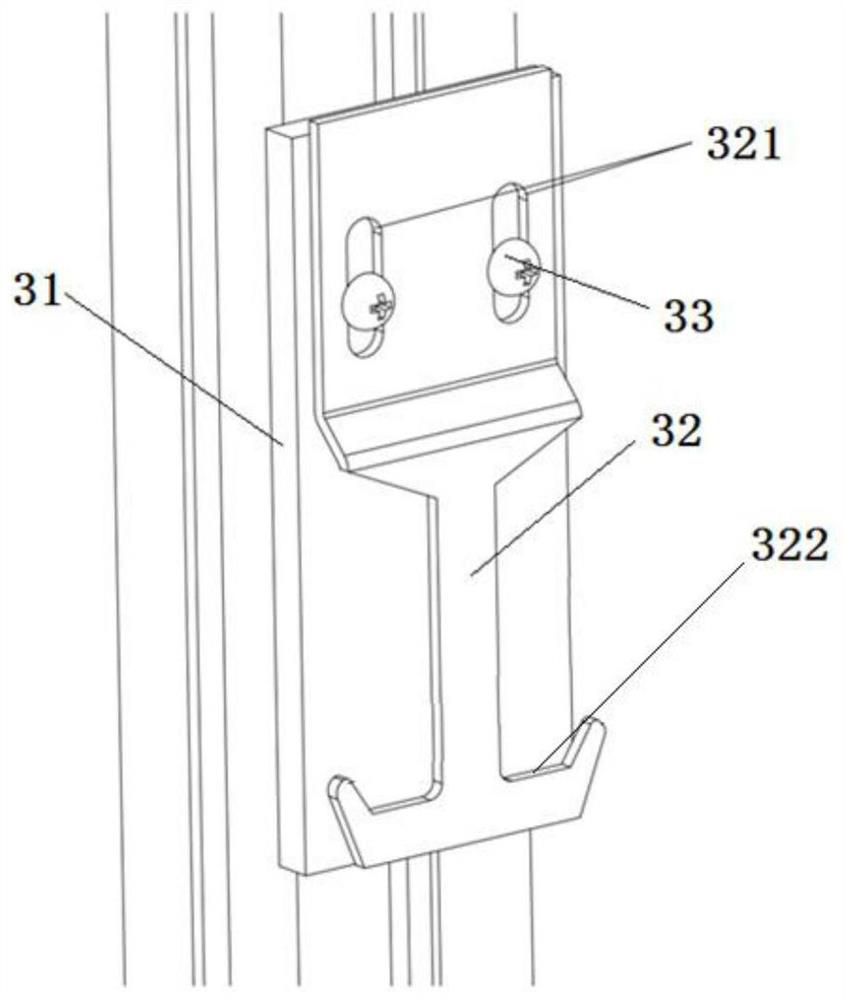

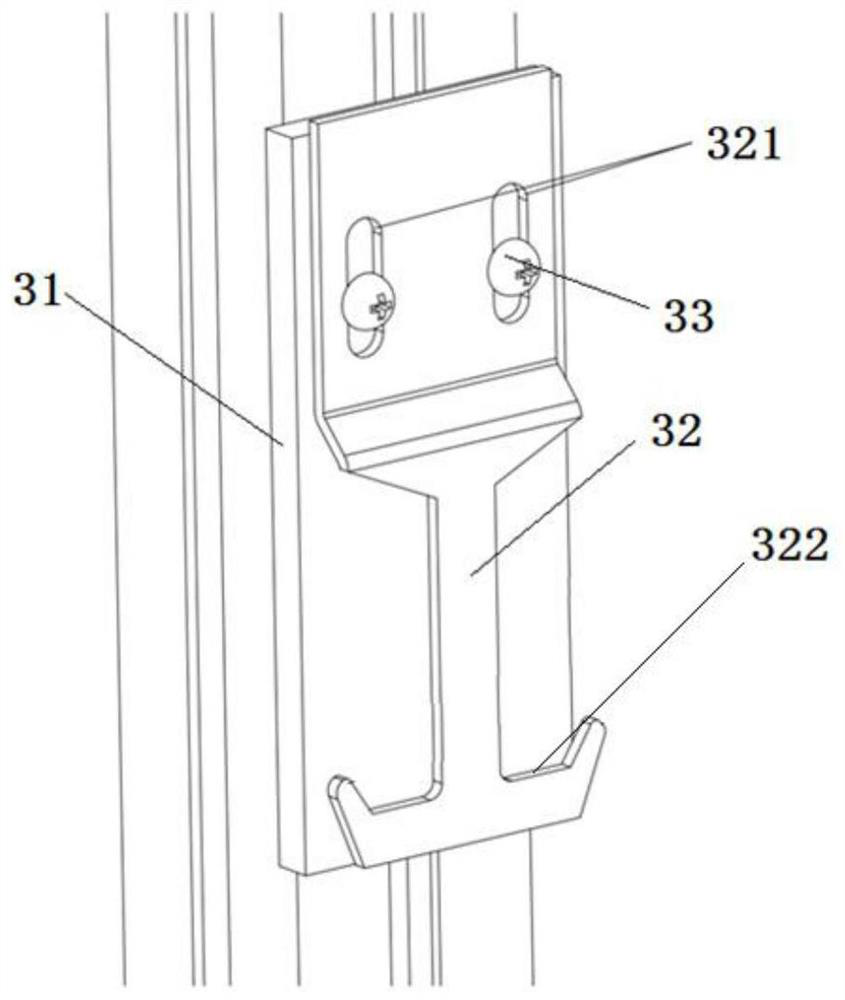

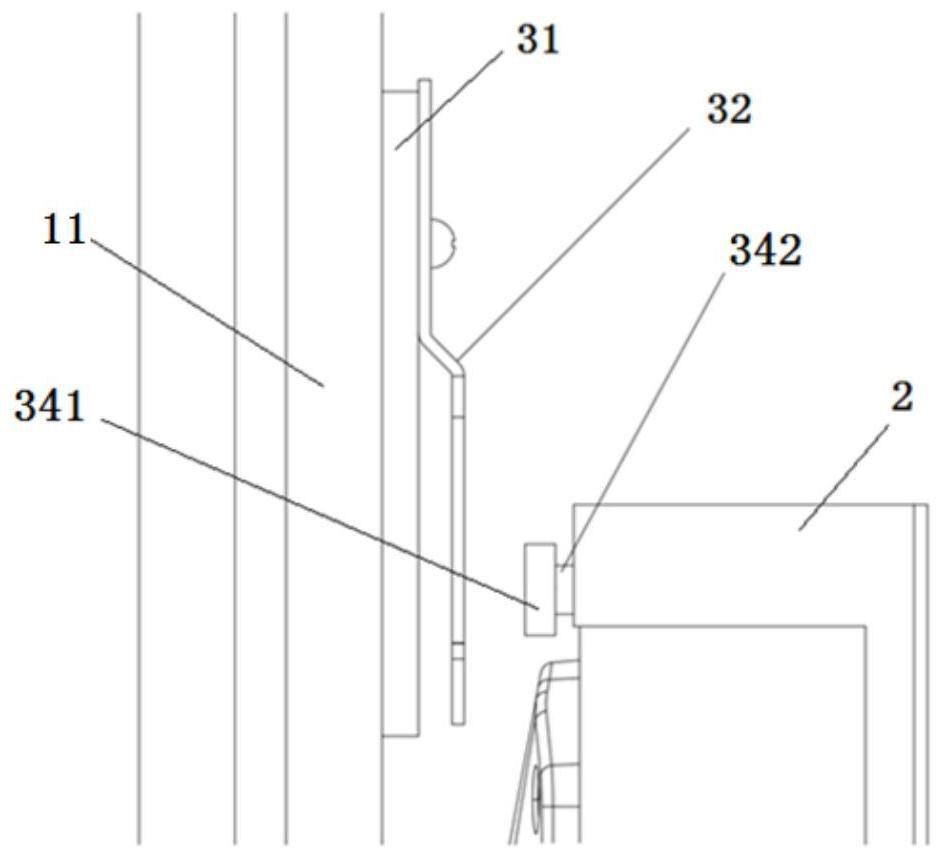

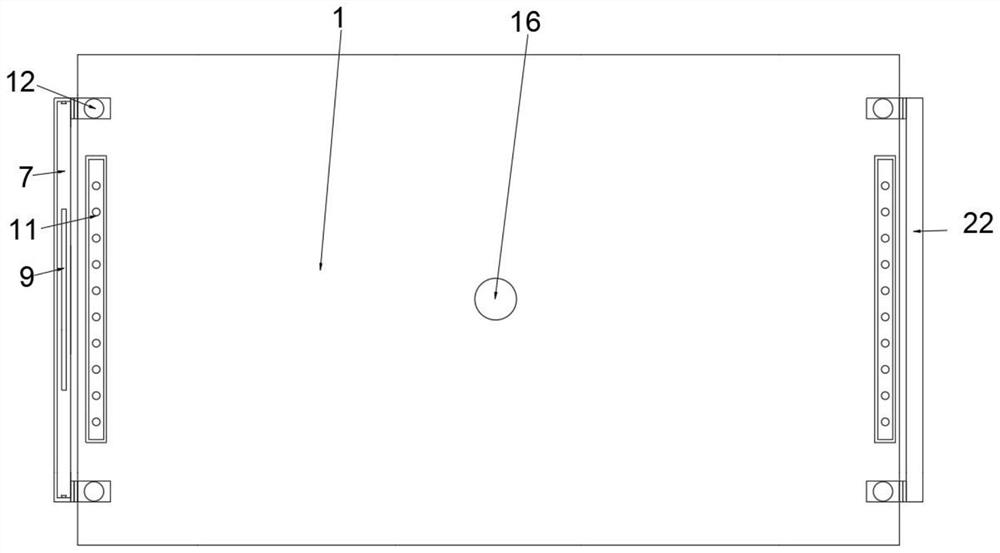

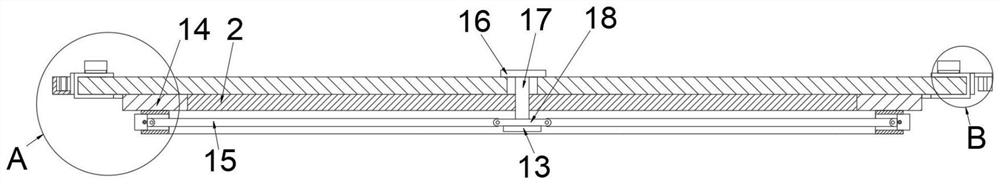

Front maintenance device of LED display box body and assembling method of LED display screen

ActiveCN111968533AAchieve the goal requirements of pre-maintenanceSave stitching timeCasings/cabinets/drawers detailsIdentification meansLED displayEngineering

The invention relates to a front maintenance device of an LED display box. The device comprises an adsorption connecting part corresponding to odd rows of an LED display box body of an LED display screen and an adsorption limiting hanging mechanism part corresponding to even rows of the LED display box body of the LED display screen, wherein magnetic steel on the LED display box body in the adsorption connecting part and a magnetic steel adsorption plate on a vertical back frame are adsorbed and fixed; and step magnetic steel on the LED display box body in the adsorption limiting hanging mechanism part is hung on a box body clamping piece and is adsorbed and fixed by a magnetic steel sticking plate on a vertical back frame. During maintenance, the LED display box body in odd-numbered rowscan be directly pulled out for maintenance; for the LED display box body in the even-numbered rows, the LED display box body in the previous row is horizontally drawn out, and then the LED display boxbody is upwards lifted and drawn out, so that the LED display box body can be maintained. The assembling efficiency of the display screen can be improved, and later maintenance is convenient.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

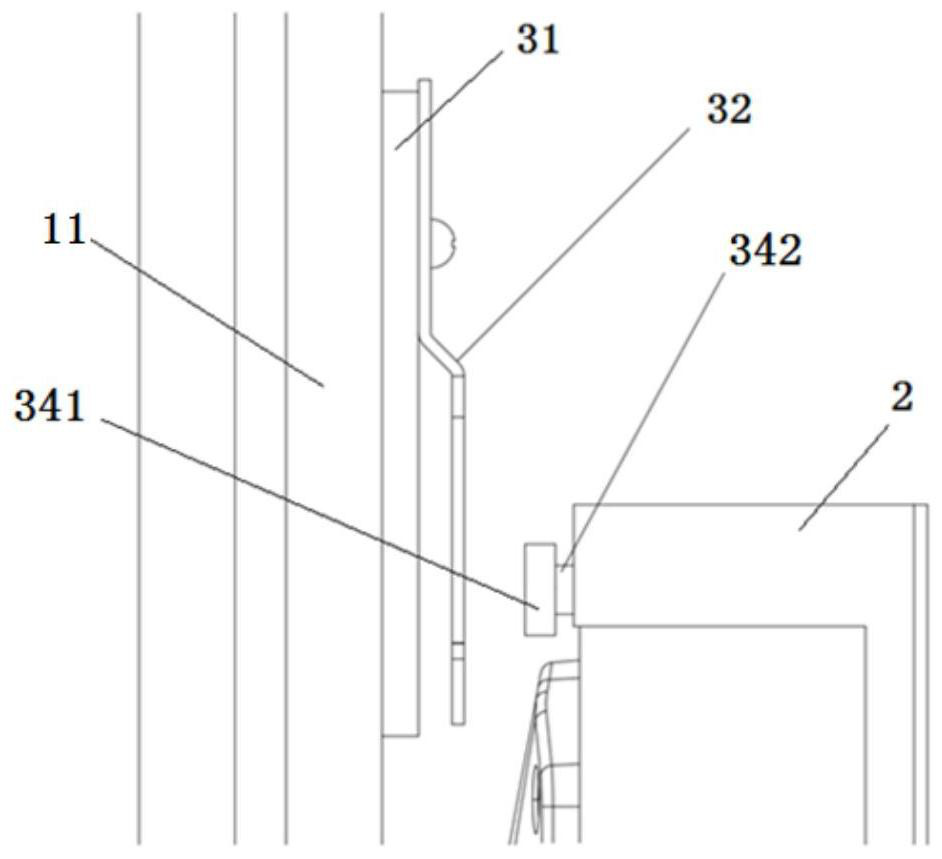

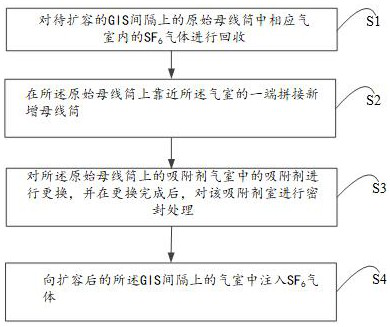

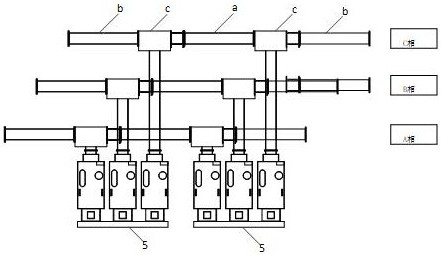

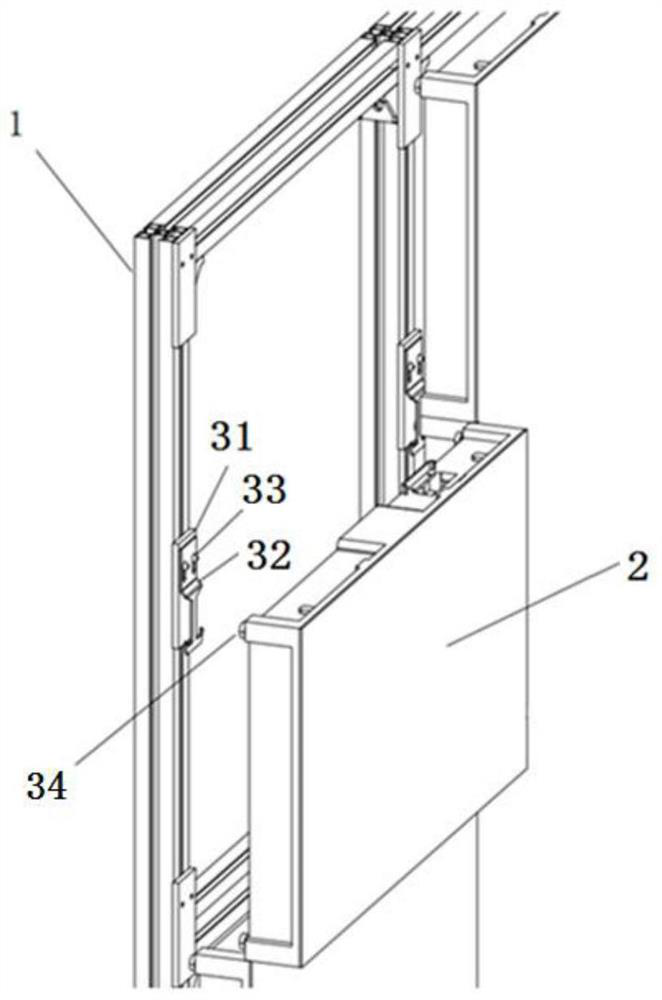

Expansion method for sub-box type GIS bus cylinder

PendingCN113964707ASave stitching timeImprove securitySwitchgear arrangementsEconomic benefitsProcess engineering

The invention provides an expansion method for a sub-box type GIS bus cylinder. The expansion method comprises the steps that SF6 gas in a corresponding gas chamber in an original bus cylinder on a GIS interval to be expanded is recycled; splicing a newly added bus tube at one end, close to the air chamber, of the original bus tube; replacing an adsorbent in an adsorbent gas chamber on the original bus cylinder, and sealing the adsorbent chamber after replacement is completed; and SF6 gas is injected into the corresponding gas chamber on the expanded GIS interval. According to the invention, the working efficiency is improved, the splicing time of the bus cylinder is greatly shortened, the safety coefficient of the working personnel during working is improved, particularly, the time for recovering the production power consumption in advance is ensured, the normal operation of the expanded GIS interval is ensured, and considerable economic benefits are created.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH +1

LED display box front maintenance device and LED display assembly method

ActiveCN111968533BAchieve the goal requirements of pre-maintenanceSave stitching timeCasings/cabinets/drawers detailsIdentification meansLED displayMechanical engineering

The invention relates to a front maintenance device for an LED display cabinet, which includes an adsorption connection part corresponding to the LED display cabinet with odd rows of LED display screens, and an adsorption limit hanging part corresponding to the LED display cabinets with even rows of LED display screens. The mechanism part; the magnetic steel on the LED display box in the adsorption connection part is adsorbed and fixed by the magnetic steel adsorption plate on the vertical back frame; the step magnetic steel on the LED display box in the adsorption limit hanging mechanism part body clip and is fixed by the magnetic steel adhesive plate on the vertical back frame. During maintenance, you can directly pull out the odd-numbered LED display cabinets for maintenance; for the even-numbered LED display cabinets, first pull out the upper row of LED display cabinets horizontally, and then pull the LED display cabinets upwards and out. Repair it. The invention can improve the assembly efficiency of the display screen and is convenient for later maintenance.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

A stitching method and system for digitized x-ray images

ActiveCN104732485BSave stitching timeImprove efficiencyGeometric image transformationTemplate matchingX-ray

Owner:深圳市深图医学影像设备有限公司

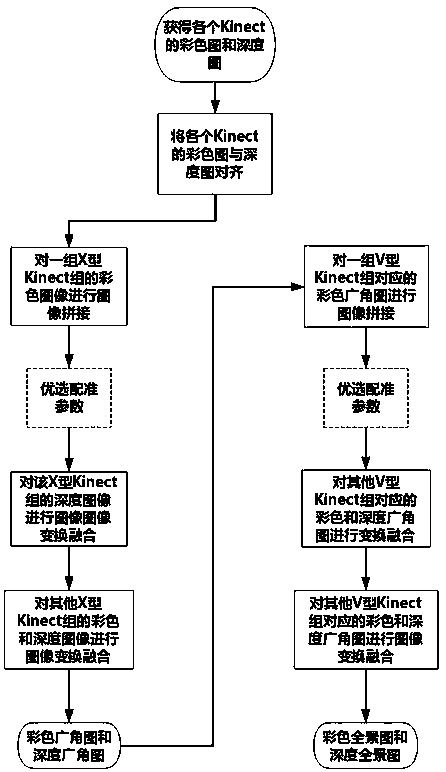

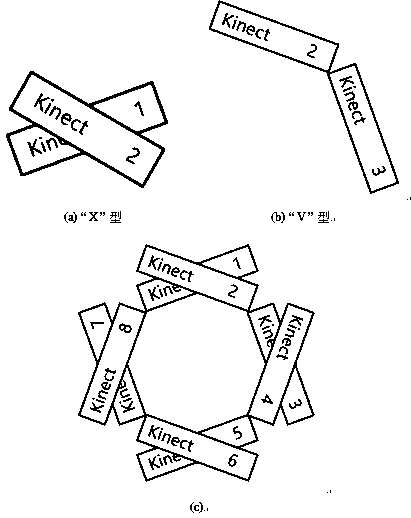

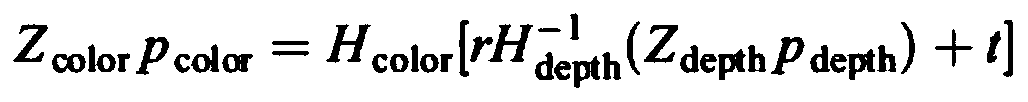

A real-time color and depth panoramic image stitching method

ActiveCN107154014BHighlight substantiveSignificant progressImage analysisGeometric image transformationColor imagePanorama

The invention relates to a real-time color and depth panoramic image splicing method, which aligns the depth image and the color image generated by the depth sensor, uses the registration information of the color image to perform image transformation and image fusion on the depth image, and then generates the color and depth panorama. Image; the image splicing process is optimized. In the same scene, the registration parameters of the same group type are estimated only once. Subsequent images directly use this registration parameter for transformation and fusion, which greatly reduces the image splicing time and achieves Panoramic image stitching in real time. The spliced depth panorama of the present invention has smaller distortion, the splicing method is more flexible, and the generation of a color panorama and a depth panorama can be completed at the same time. The present invention proposes an evaluation standard based on average structural similarity to evaluate the geometric quality and photometric quality of the generated spliced image, so that the system can always perform splicing with optimal splicing parameters, and the quality of image splicing is higher.

Owner:SHANGHAI UNIV

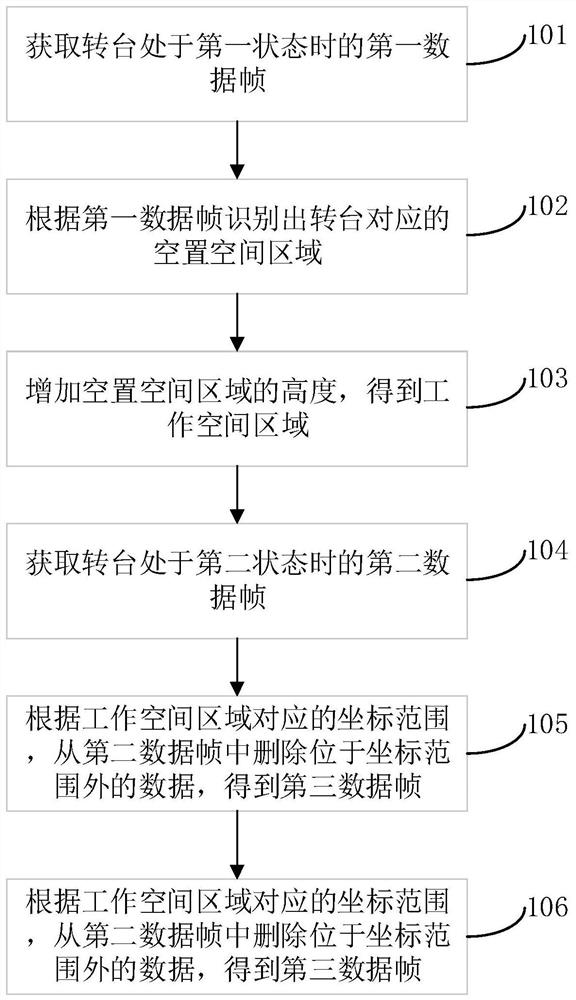

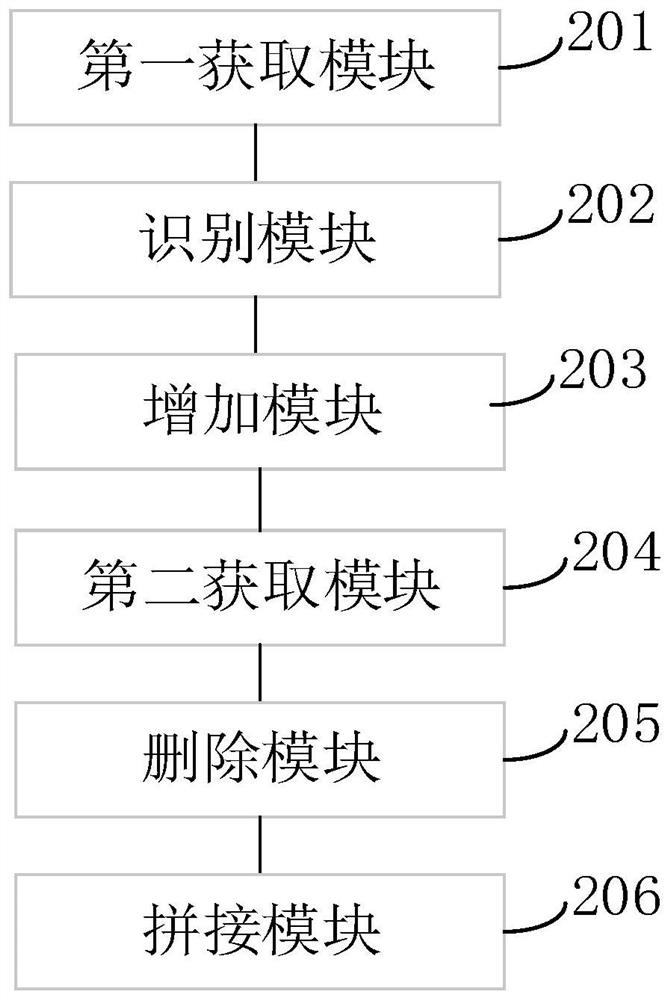

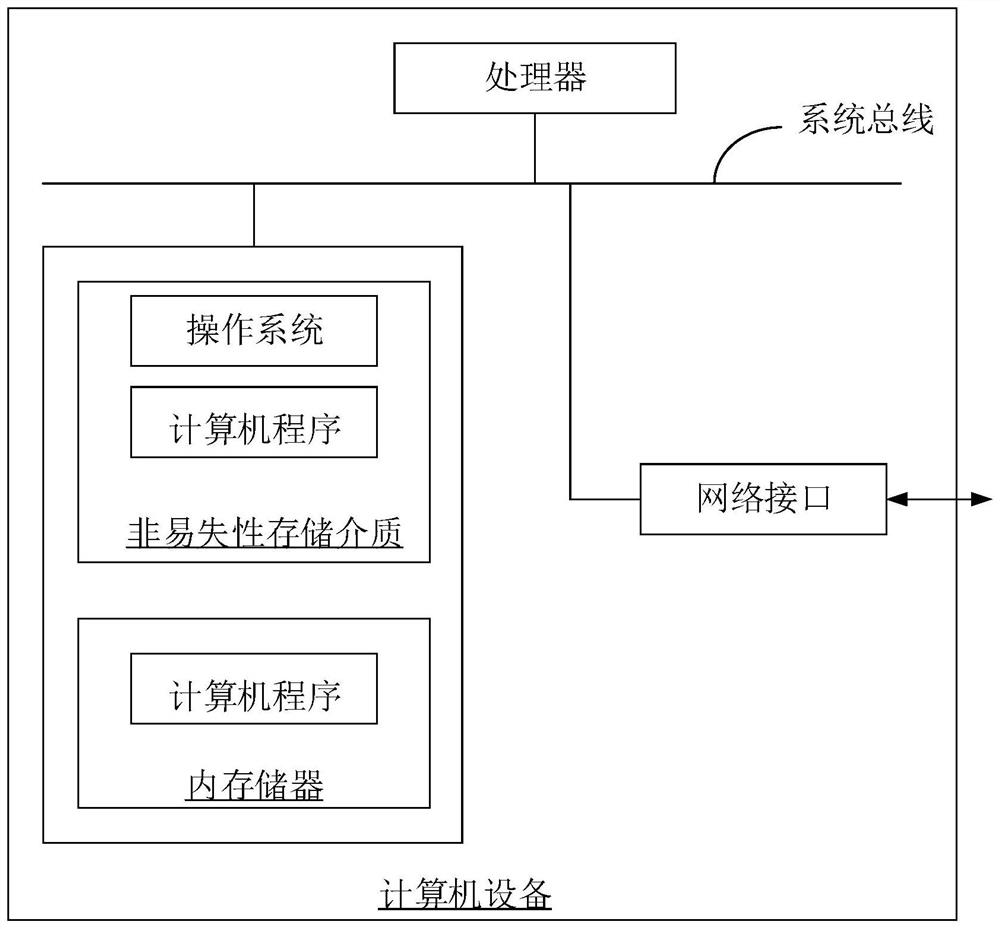

3D scanning method and device

ActiveCN114234838AReduce stitching errorsSave stitching timeUsing optical meansComputer graphics (images)Engineering

The invention provides a 3D scanning method and device, and the method comprises the steps: obtaining a first data frame when a rotary table is in a first state, recognizing a vacant space region corresponding to the rotary table according to the first data frame, increasing the height of the vacant space region, obtaining a working space region, acquiring a second data frame when the rotary table is in a second state, deleting data outside the coordinate range from the second data frame according to the coordinate range corresponding to the working space area to obtain a third data frame, and splicing the plurality of third data frames to obtain a second data frame when the rotary table is in the second state when the scanned object is placed on the rotary table; and obtaining a three-dimensional model corresponding to the scanned object. By identifying the vacant space area corresponding to the rotary table and deleting the interference data outside the vacant space area corresponding to the rotary table, the splicing error caused by the interference of useless data is reduced, so that the correct splicing of the scanning data in the scanning process of the rotary table is ensured, the splicing time is reduced, and the splicing accuracy is improved.

Owner:武汉尺子科技有限公司

Panoramic Imaging Method Based on Camera Array

ActiveCN107301620BSave stitching timeRealize the combinationImage enhancementImage analysisImage resolutionFusion splicing

Owner:XIDIAN UNIV

Single-sided circuit board capable of being spliced for use

PendingCN114828391AImprove installation efficiencyChange splicing methodPrinted circuit detailsCircuit thermal arrangementsCircular discHeat conducting

The invention discloses a single-sided circuit board capable of being spliced for use. Comprising a single-sided circuit board body, a first connecting rod, a first limiting seat, a second connecting rod, a first moving block, a first clamping seat, a first clamping block, a second clamping block, a plugging terminal, a first fastening bolt, a limiting disc, a mounting frame, a swinging rod, a rotating block, a stud, a moving plate, a third clamping block, a first clamping groove, a limiting plate, a second fastening bolt, a heat conducting sheet, a second clamping groove and a second limiting seat. According to the device, a first clamping block and a second clamping block are correspondingly connected with a first clamping groove and a second clamping groove, so that the device is spliced, the splicing time of the device is shortened, and the splicing efficiency of the device is improved. The second limiting seat is moved so that the second limiting seat can be connected with the fixing seat at the position needing to be fixed in a matched mode, and therefore the single-face circuit board body is fixed, and the installation efficiency of fixing the single-face circuit board body is improved.

Owner:东莞市洪港电子有限公司

A steel bar connection assembly for bearing pile construction of high-rise buildings

The invention discloses a steel bar connection component for construction of high-rise building bearing piles. The steel bar connection component comprises a connection cylinder and a snap ring. A nutis arranged on the connection cylinder. A sliding groove and a limiting groove communicated with the sliding groove are formed in the outer circumferential wall of the connection cylinder. An annulargroove is formed in the bottom of the sliding groove. A through hole is formed in the annular groove. The inner side wall of a press block is flush with the inner circumferential wall of the connection cylinder. The outer side wall of the press block is protruded on the outer end wall of the through hole and disposed in the annular groove. Threads are arranged at the bottom of the sliding groove.A press ring is arranged in the sliding groove in a sleeved mode. A protrusion is arranged on the inner circumferential wall of the press ring. The inner diameter of the protrusion increases gradually from one end, where the press ring is located, to the direction close to the connection cylinder along the axis of the connection cylinder. A contact block is arranged on the outer side wall of thepress block. One end of the connection cylinder is fixed to a rotating disc, and the other end of the connection cylinder clamps and fastens a main rib, so that the main rib is prevented from overturning in the connection cylinder to influence the welding effect between the main rib and transverse ribs, and the strength of a reinforcement cage is guaranteed.

Owner:西安建工绿色建筑集团有限公司

A Fast Stitching Method for Cube Panorama

ActiveCN107358577BGood for compression codingQuick stitchingImage analysisGeometric image transformationCamera lensComputer graphics (images)

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com