Material belt joining assembly and material belt splicing method using the same

A tape and component technology, applied in the field of electronic component carrier tape, can solve the problems of reduced equipment utilization rate, low convenience, automatic placement machine jamming, etc., to shorten the splicing time, avoid manual errors, and pass rate-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

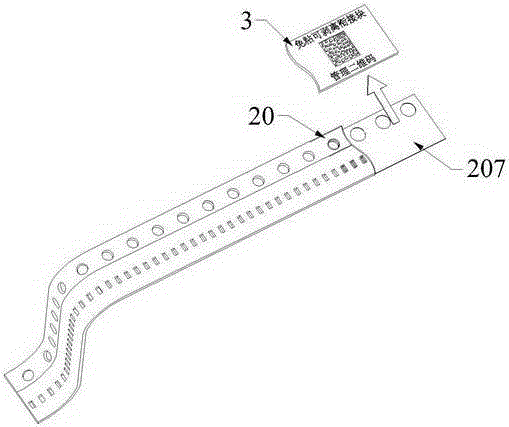

[0028] see figure 2 , the present invention provides a material tape connecting assembly, the material tape connecting assembly includes a non-adhesive and peelable connecting block 3 spliced with the end of the material tape 20, a reinforcing tape 207, and one side of the connecting block 3 is glued to the reinforcing tape 207 , the length of the reinforcing tape 207 is greater than the length of the connecting block 3 .

[0029] The splicing part of the connecting block 3 is in an S configuration; the corresponding end of the material strip spliced with it is also in an S configuration.

[0030] The connecting block 3 is provided with barcodes on both sides.

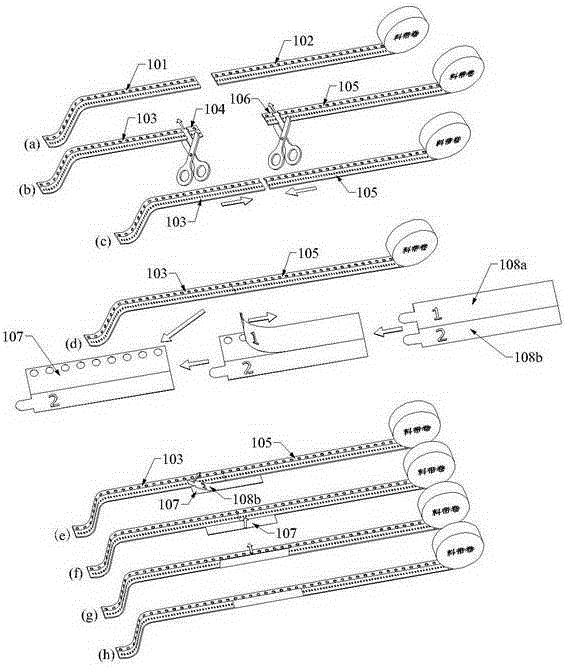

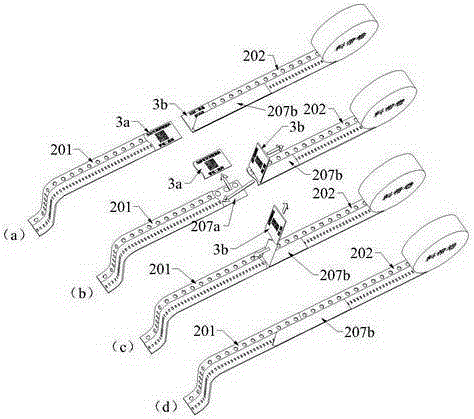

[0031] see image 3 , the present invention also provides a strip splicing method using the above-mentioned strip joint assembly, the specific technical scheme is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com