Binocular laser vision three-dimensional measurement method for high-temperature red hot target

A three-dimensional measurement, line laser technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of inability to obtain the overall structure, uneven light fill, interference, etc., to save splicing time and ensure real-time effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

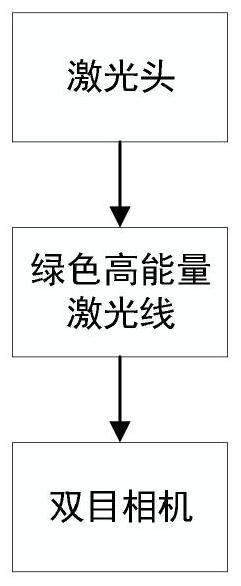

[0026] The binocular line laser vision three-dimensional measurement method for a high-temperature red-hot target specifically includes the following steps:

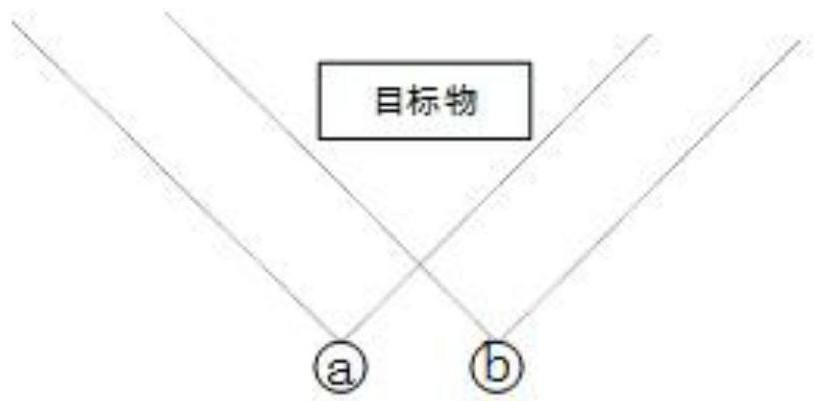

[0027] Step 1, collect images through the binocular camera, and define the images collected by the binocular camera as Al m×n , Ar m×n ; binocular camera means dual camera camera, Al m×n Represents the image matrix detected by the left eye camera, Ar m×n Represents the image matrix detected by the right eye camera, m represents the image A m×n The number of pixels in the horizontal direction, n represents the image A m×n The number of pixels in the vertical direction. The binocular camera includes a left-eye camera and a right-eye camera. figure 1 The a in the middle represents the left eye camera, figure 1 The middle b represents the right eye camera.

[0028] In step 2, the imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com