Scanning electron microscope direct-writing photoetching system based on flexible nano servo motion system

A technology of servo motion and scanning electron microscope, which is applied in the field of scanning electron microscope direct writing lithography system, can solve the problems of splicing error, high preparation cost, and difficulty in large-area preparation, so as to achieve no splicing error, avoid splicing error, and facilitate real-time observation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

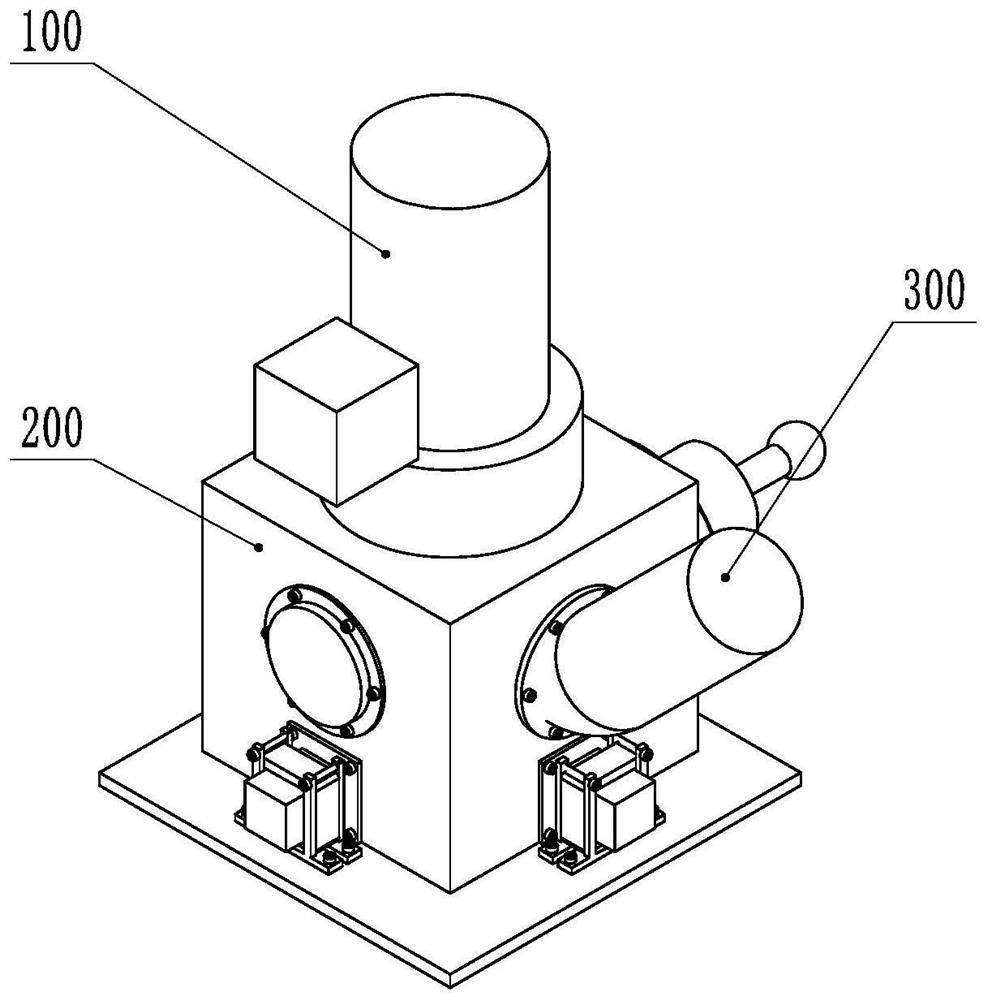

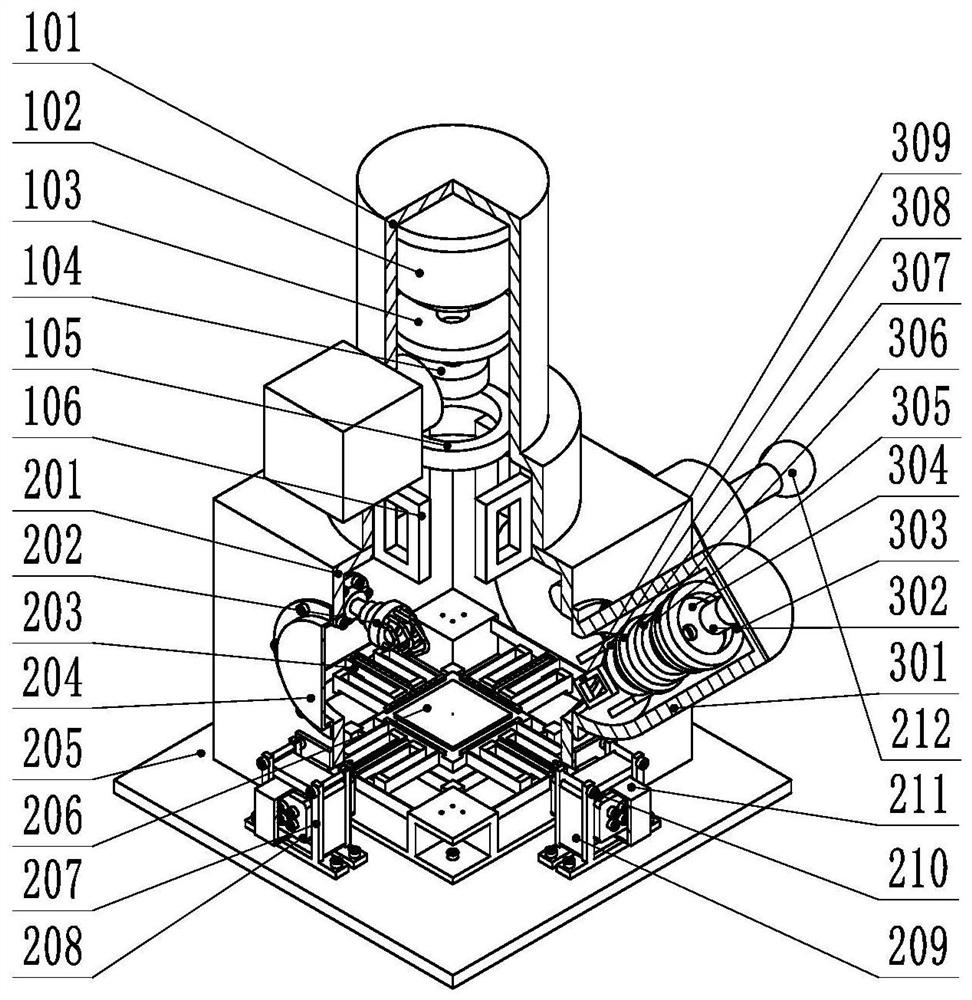

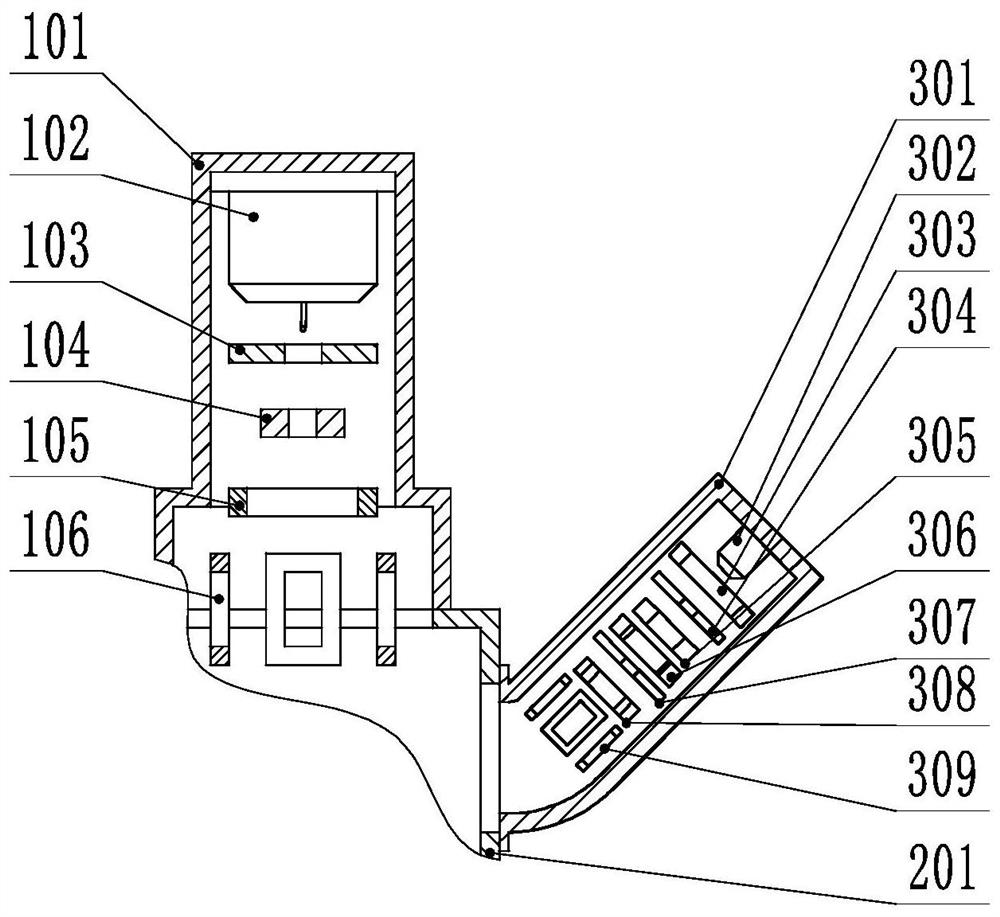

[0032] Such as Figure 1-4 As shown, a scanning electron microscope direct writing lithography system based on a flexible nano servo motion system provided in this embodiment includes an electronic chamber 100, an ion chamber 300, a sample chamber 200 and a control system.

[0033] Electron chamber 100 comprises electron chamber cavity 101, electron gun 102, anode 103, electron beam interrupter 104, electromagnetic lens 105 and electron beam deflection coil 106; Electron chamber 100 is fixedly connected with sample chamber 200; Ion chamber 300 comprises ion chamber cavity Body 301, ion source 302, suppression electrode 303, extraction electrode 304, first stage lens 305, ion beam shutter editor 306, ion beam shutter barrier film hole 307, second stage lens 308 and ion beam scanning deflection electrode 309; The chamber 300 is fixedly connected to the sample chamber 200; the sample chamber 200 includes a sample chamber cavity 201, a secondary electronic detector 202, a nano-pre...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0048] Further, a laser interferometer is also included, which is used to feed back the actual displacement of the flexible motion platform with nanometer precision, so as to realize closed-loop feedback control.

[0049] Further, it also includes a viewing window, which is arranged on the cavity of the sample chamber for observing the internal state of the cavity of the sample chamber.

[0050] In this embodiment, the scanning electron microscope direct writing lithography system based on the flexible nano-servo motion system provided in this embodiment can be prepared using ion beams and at the same time detect the preparation results through electron beams in real time. The specific preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com