Fabric slitting machine with gray fabric roll fabric-feeding synchronizer

A technology of a synchronizing device and a slitting machine, which is applied in the field of slitting machines, can solve problems such as inconsistency and uneven cutting, and achieve the effects of uniform tension, uniform speed of grey fabrics, and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

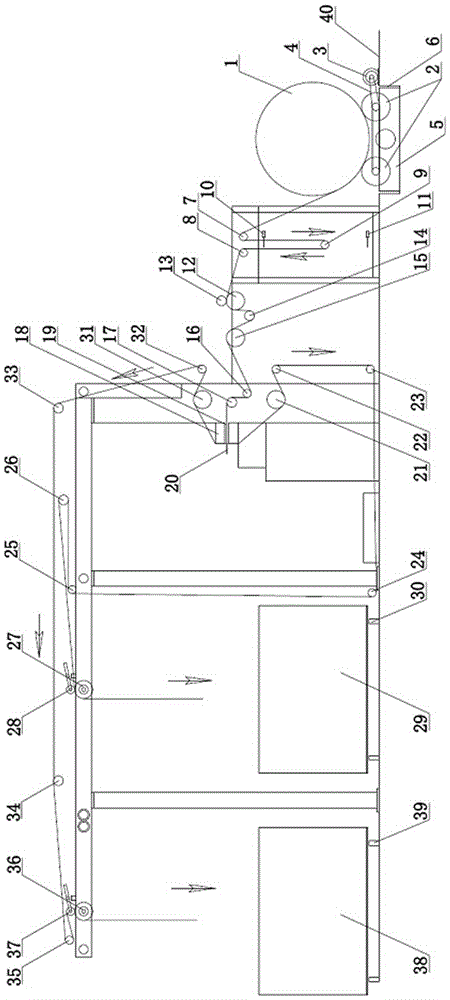

[0025] Example: such as figure 1 As shown, a slitting machine with a gray cloth roll-in synchronous device, including a gray cloth supply mechanism, a cloth feeding guide roller group, a velvet cutting mechanism, an upper cloth outlet guide roller group, an upper cloth outlet collection mechanism, and a lower cloth outlet guide roller Group and lower outlet cloth collecting mechanism.

[0026] The gray cloth supply mechanism includes a gray cloth roll 1 and a cloth feeding synchronous device for placing the gray cloth roll. The cloth feeding synchronous device further includes a pair of synchronous rollers 2 arranged in parallel at intervals. In the lower groove 6. The gray cloth roll 1 is supported on the gap between two synchronous rollers 2, and the two synchronous rollers 2 are connected to the same reduction motor 3 through a synchronous belt 4.

[0027] A tension relief device is added between the gray cloth supply mechanism and the cloth feeding guide roller group. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com