Film uncoiling machine having automatic deviation rectifying function

An automatic deviation correction and unwinding machine technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of adhesive film deviation, affecting cross-cut quality, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

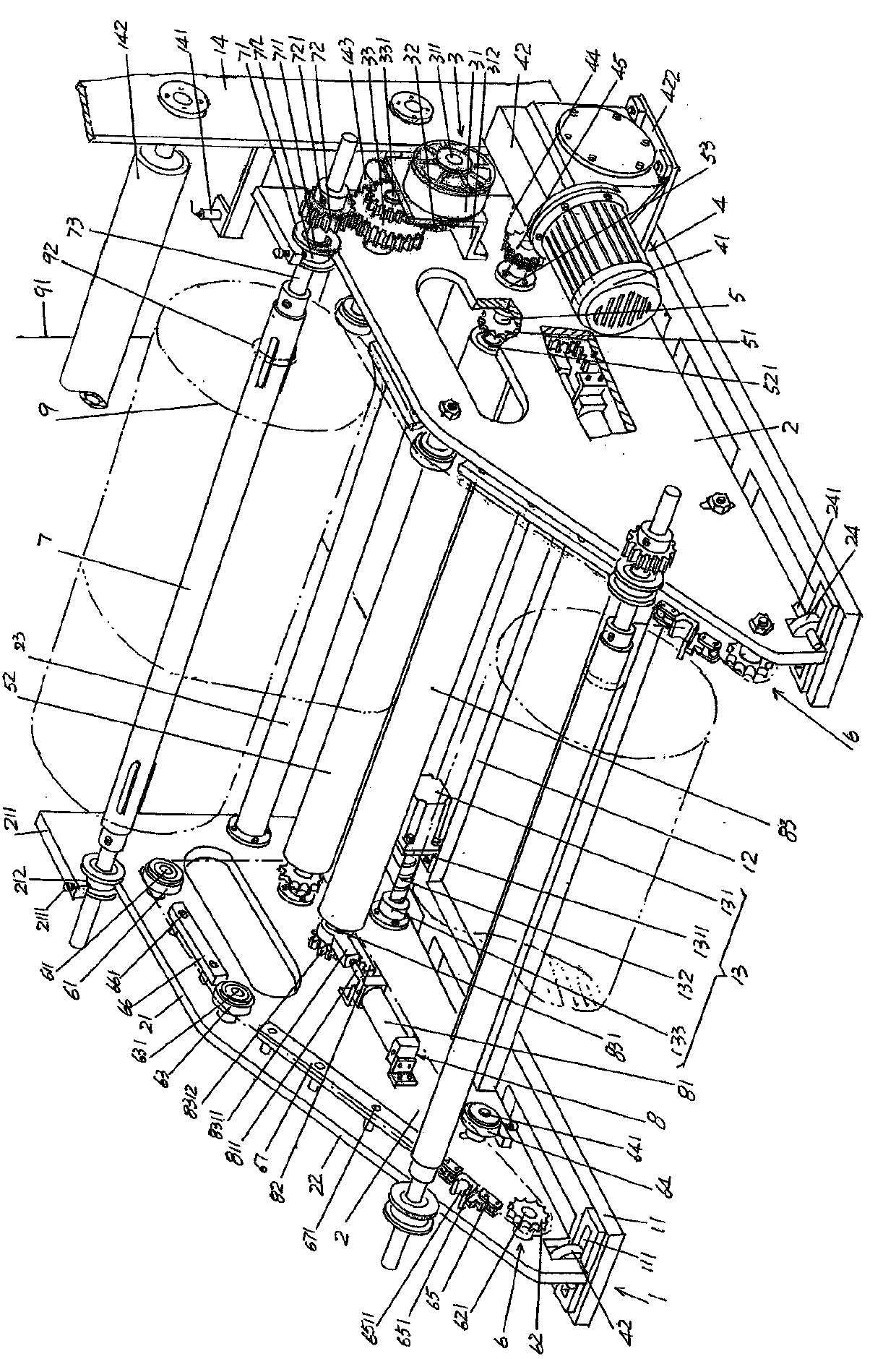

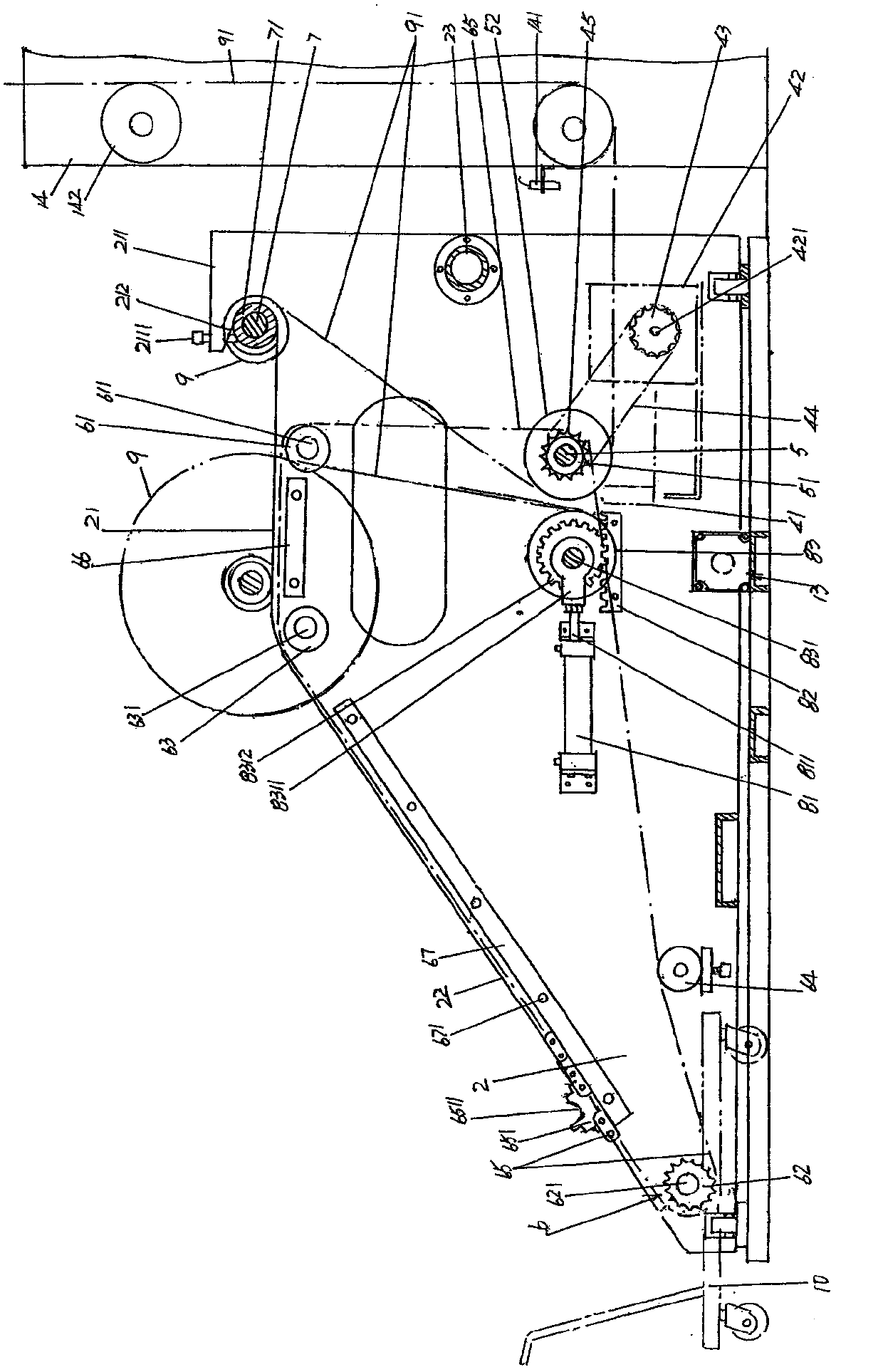

[0024]See figure 1 , a machine base 1 is given, and the machine base 1 may also be called a base or a chassis. Depend on figure 1 It can be seen from the schematic diagram that the base 1 is composed of a pair of base arms 11 parallel to each other, a base arm connecting beam 12 for connecting the pair of base arms 11 into a solid overall structure, and a film guide frame 14. front and rear ends of arm 11 ( figure 1 Shown position state) each constitutes promptly respectively offers a wallboard roller groove 111, and the function of this wallboard roller groove 111 will also be described below. The film guide frame 14 is corresponding to the rear end of a pair of base arms 11 ( figure 1 The shown position state is taken as an example), an upper film guide roller 142 is rotatably arranged on the upper part of the film guide frame 14, and a lower film guide roller 143 is rotatably arranged on the lower part, and a film guide roller 143 is arranged on the right side of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com