Tool magazine reliability test bench tool change position adaptive centering adjustment device and method

A centering adjustment and reliability technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of complex operation, time-consuming and laborious, low adjustment accuracy, etc., to reduce the time and inconvenience of adjustment , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

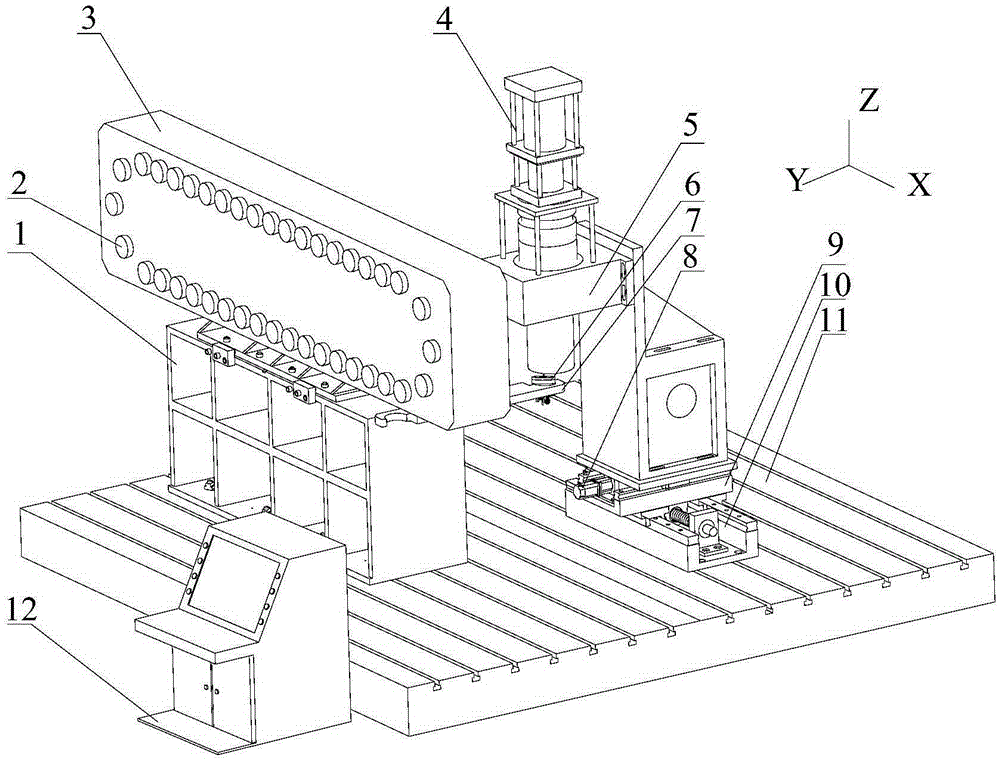

[0047] See attached figure 1 , the tool change position adaptive centering adjustment device of the tool magazine reliability test bench of the present invention includes a measuring taper handle 27, an automatic mechanical detection device 6 and a main shaft bottom feed unit, and the main shaft bottom feed unit and the tool magazine support 1 Install it on the T-shaped iron 11 to ensure that its levelness meets the requirements. At the same time, the main shaft support seat 5 is installed on the feed unit at the bottom of the main shaft to ensure that the verticality of the main shaft meets the requirements;

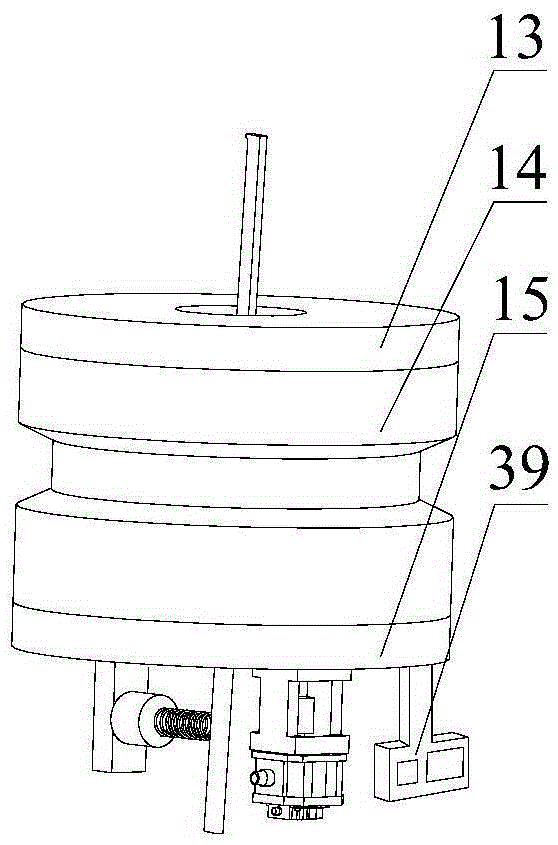

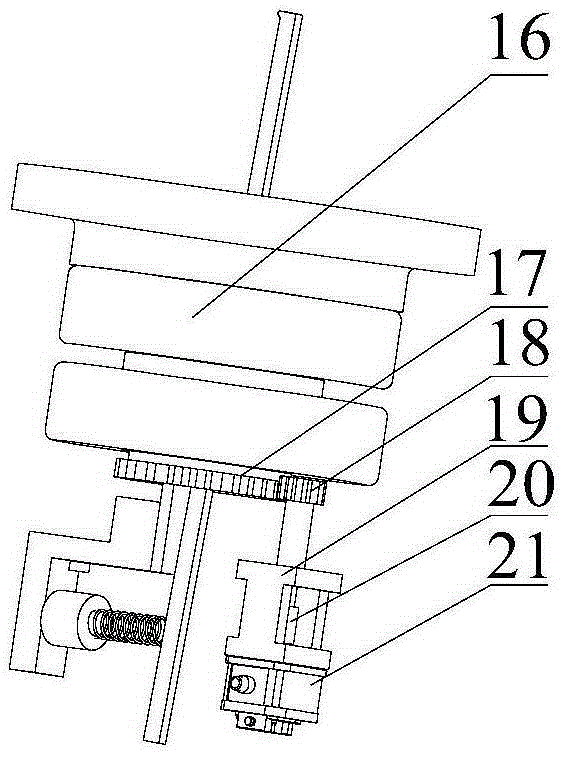

[0048] See attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 And attached Figure 6 , the automatic mechanical detection device 6 includes grabbing cutter head 14, driven gear 17, driving gear 18, servo motor A2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com