Deviation-correcting automatic discharge tension braking device

A technology of automatic feeding and automatic device, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of stretch break, material deformation, affecting production efficiency, etc., to reduce production costs and ensure Product quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

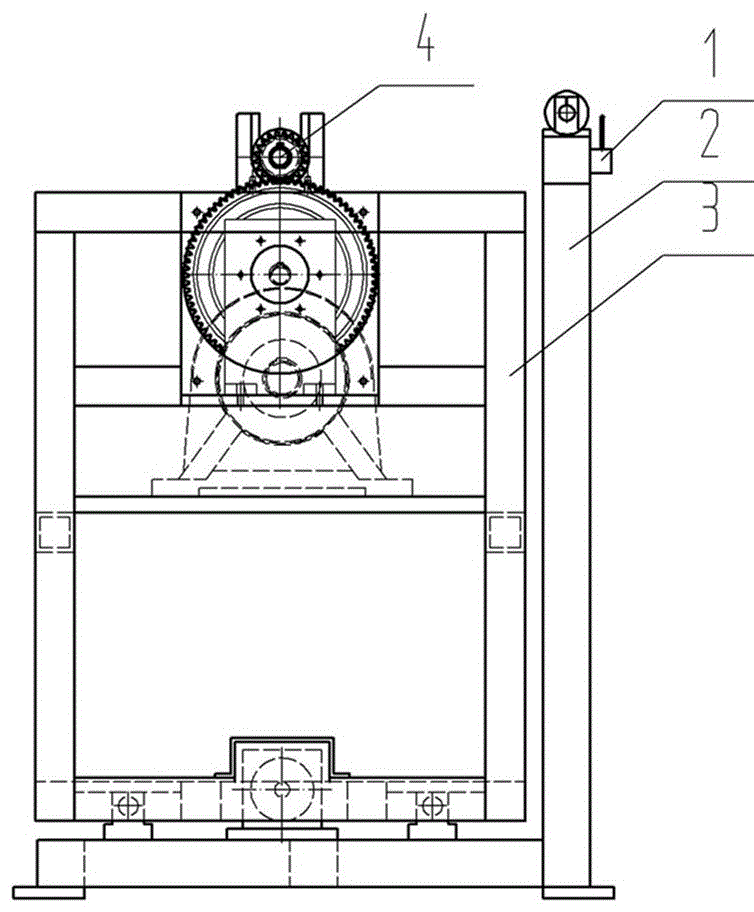

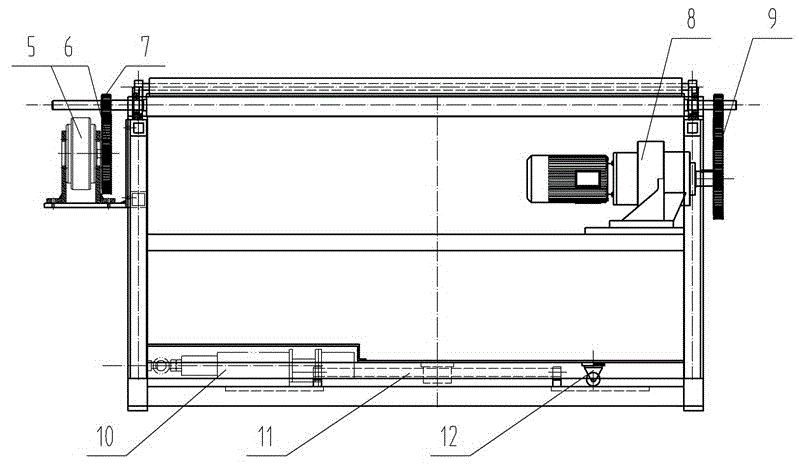

[0013] The present invention mainly consists of light deviation sensor, deviation correction feeding device low frame, deviation correction adjustment frame body, loading roller shaft, magnetic powder brake, brake wheel, driven wheel, cycloidal pin wheel reducer, driving wheel, synchronous motor driving device , linear bearing guide device, and horizontal rollers. The bottom frame of the correction device is equipped with a bilateral optical deviation sensor device, a linear bearing guide device, and a synchronous motor drive device. Offset direction, and send induction data to the general control computer; the general control computer determines the working state and movement direction of the synchronous motor through the judgment data; the linear bearing guide device and rollers are used to realize the lateral precise movement and adjustment of the deviation correction adjustment frame, and the correction is automatic The feeding tension brake device realizes the brake contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com