PVC profile raw material automatic metering, mixing, conveying, storing and feeding process

A technology for automatic metering and raw materials, which is applied in the field of automatic metering, mixing, conveying, warehousing and feeding technology of PVC profile raw materials, can solve the problems of limiting the efficiency of PVC production and processing, consuming a lot of manpower and material resources, and increasing the labor intensity of workers. The effect of reducing energy consumption and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

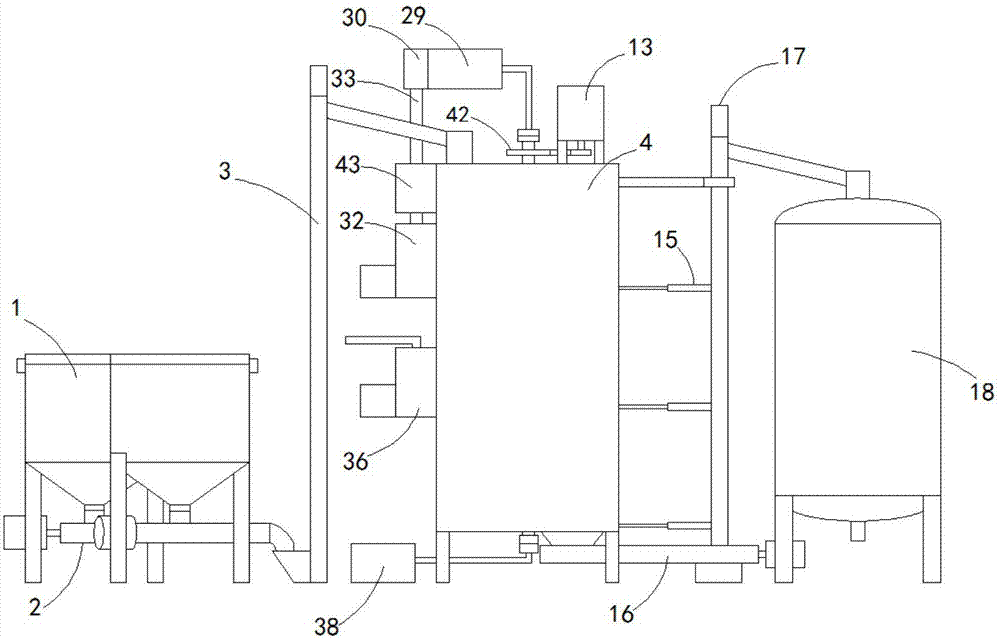

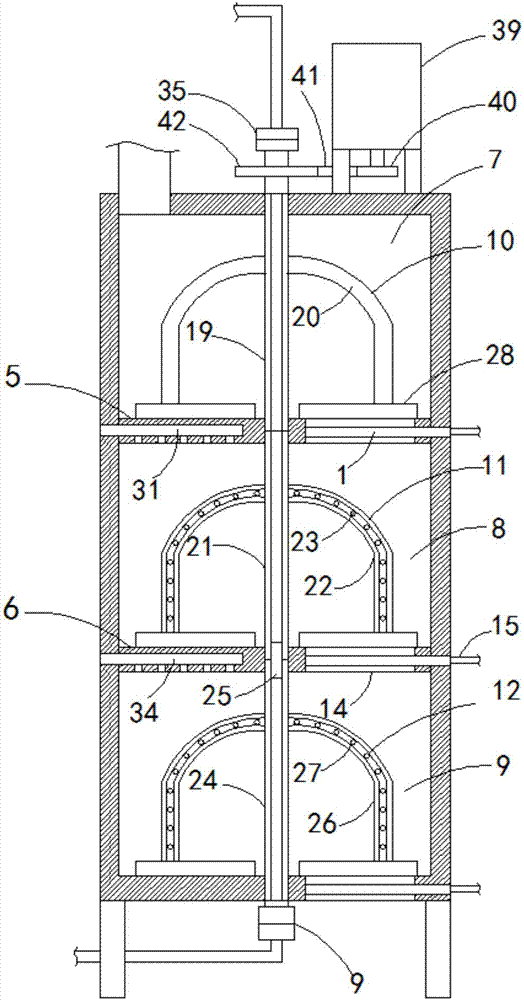

[0020] Such as Figure 1-2 As shown, an automatic metering, mixing, conveying, storage and feeding process for PVC profile raw materials includes a metering process, a mixing process, and a conveying and storing process. The metering process includes a plurality of raw material bins 1, the discharge end of the raw material bin 1 and the screw quantitative feeder 2, and the output ends of all screw quantitative feeders 2 are connected to the feeding trough of the first vertical elevator 3, and the output end of the first vertical elevator 3 is connected to the mixing tank 4 in the mixing process , the interior of the mixing tank 4 is divided into a pre-stirring chamber 7, a heating and stirring chamber 8 and a cooling and stirring chamber 9 from top to bottom by the first partition 5 and the second partition 6 arranged horizontally, the pre-stirring chamber 7, the heating and stirring chamber 8 The first stirring mechanism 10, the second stirring mechanism 11 and the third stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com