Movable material stack automatic metering system

A technology of automatic metering and material stacking, applied in the field of metering system, can solve the problems of high maintenance cost and poor metering accuracy, achieve the effect of simple system architecture, improve metering accuracy and metering efficiency, and reduce regular maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

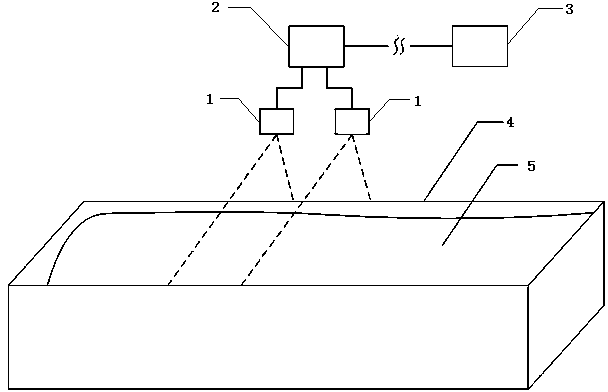

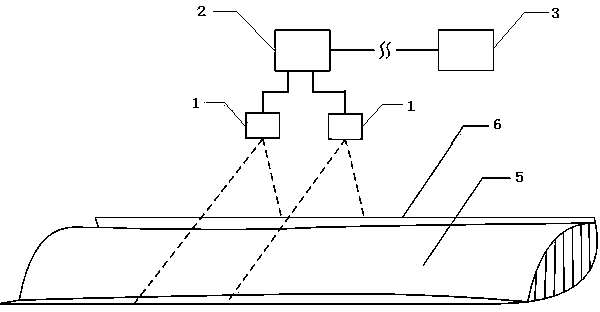

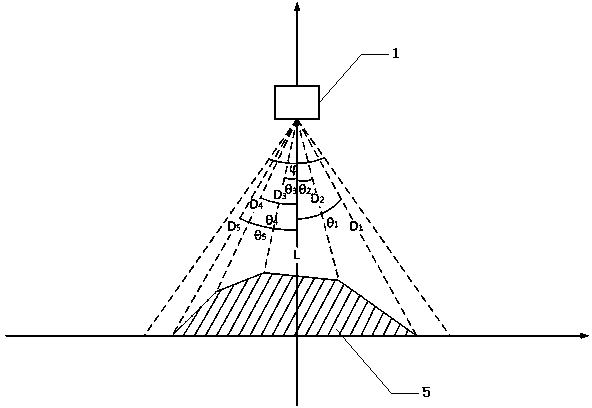

[0025] like figure 1 Shown is an embodiment of the automatic metering system for moving material piles of the present invention, including two high-speed laser ranging scanners 1 and a train 4 carrier. The train 4 is loaded with a pile of materials 5 . The high-speed laser ranging scanner 1 can be LMS511 from SICK, and fixed above the centerline of the material pile 5 through high-strength aluminum profiles, so that the measurement accuracy will not be affected by shaking due to airflow or wind. Its installation height depends on the width of the carrier, so that its scanning section can completely cover the width of the train 4 . The distance between the two high-speed laser ranging scanners 1 is 0.3-1.0 meters, preferably 0.5 meters, and the scanning sections are parallel to each other. The scanning frequency of the high-speed laser ranging scanner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com