Critical speed flow metering system

A flow measurement and critical velocity technology, which is applied in the direction of volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring differential pressure. Achieve the effect of improving measurement efficiency and measurement accuracy, improving use safety, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

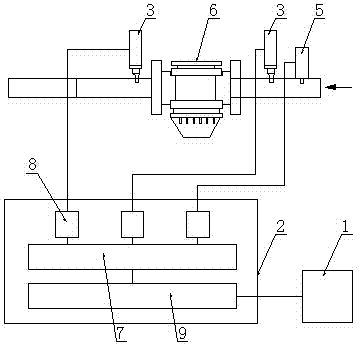

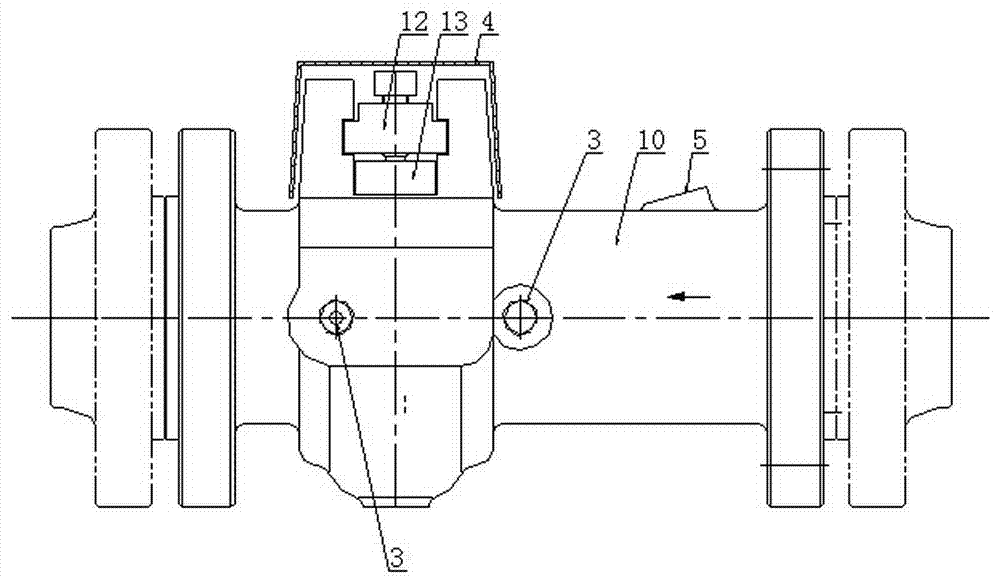

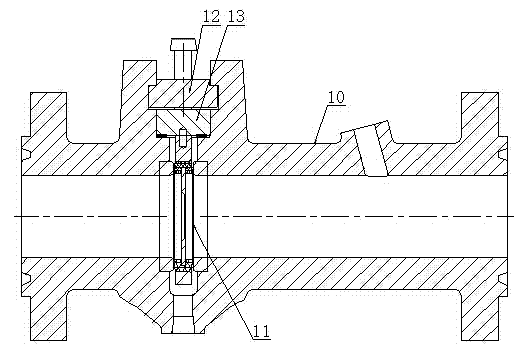

[0024] A critical speed flow metering system, comprising a throttling mechanism 6 and a data acquisition and measurement mechanism, the throttling mechanism 6 includes a valve body 10 and an orifice 11 arranged in the valve body 10, and the data acquisition and measurement mechanism includes a PC 1. Control box 2, temperature sensor 5 and two pressure transmitters 3, the temperature sensor 5 and the two pressure transmitters 3 are fixed on the valve body 10, and one of the pressure transmitters 3 is located in the hole On the downstream side of the plate 11, another pressure transmitter 3 and a temperature sensor 5 are located on the upstream side of the orifice plate 11; the control box 2 is provided with a data acquisition module 7 and a communication module 9, and the temperature sensor 5 and two The pressure transmitters 3 are all connected to the data acquisition module 7, and the data acquisition module 7 transmits the collected data to the PC 1 through the communication ...

Embodiment 2

[0031] A critical speed flow metering system, comprising a throttling mechanism 6 and a data acquisition and measurement mechanism, the throttling mechanism 6 includes a valve body 10 and an orifice 11 arranged in the valve body 10, and the data acquisition and measurement mechanism includes a PC 1. Control box 2, temperature sensor 5 and two pressure transmitters 3, the temperature sensor 5 and the two pressure transmitters 3 are fixed on the valve body 10, and one of the pressure transmitters 3 is located in the hole On the downstream side of the plate 11, another pressure transmitter 3 and a temperature sensor 5 are located on the upstream side of the orifice plate 11; the control box 2 is provided with a data acquisition module 7 and a communication module 9, and the temperature sensor 5 and two The pressure transmitters 3 are all connected to the data acquisition module 7, and the data acquisition module 7 transmits the collected data to the PC 1 through the communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com