Dye metering device for spinning

A metering device and dye technology, applied in the textile field, can solve problems such as low metering accuracy, low metering accuracy, and low efficiency, and achieve the effect of avoiding metering errors and improving metering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

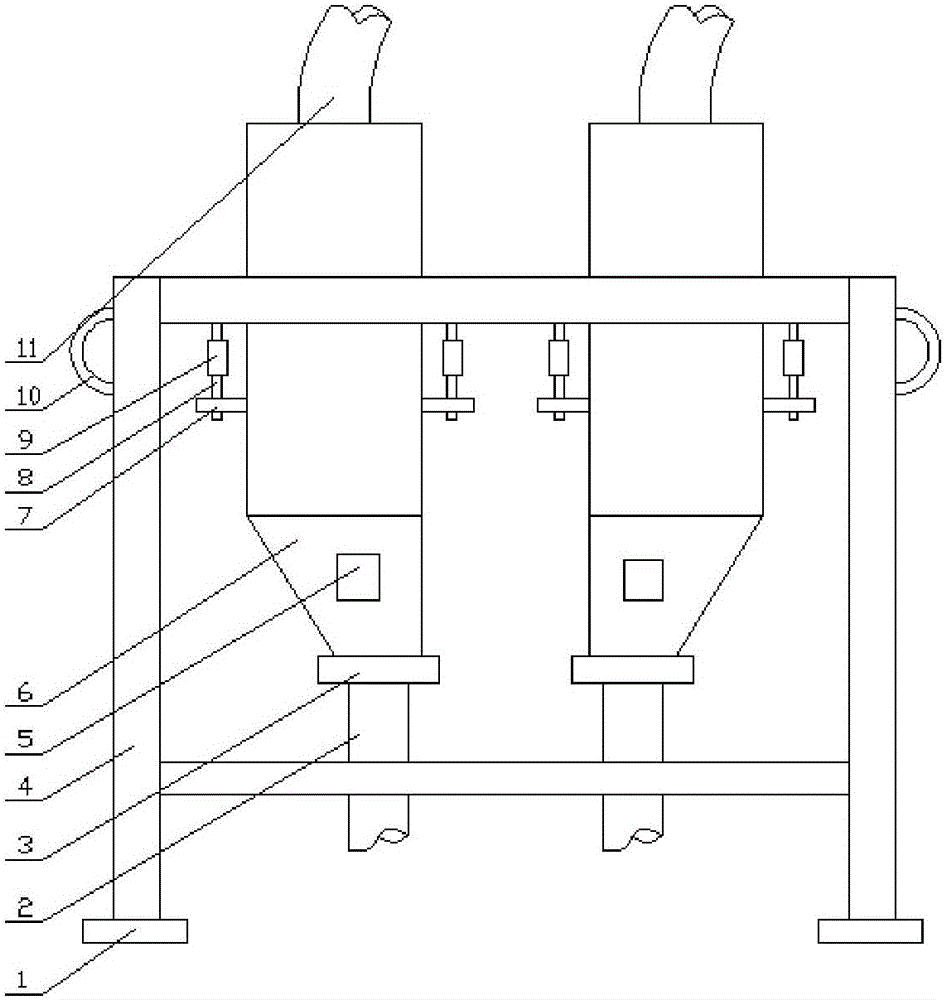

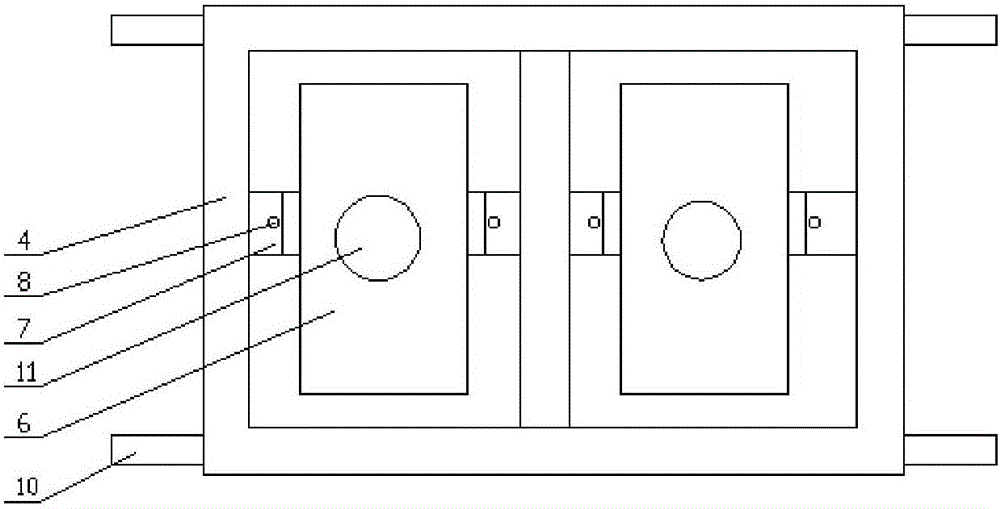

[0021] like figure 1 , figure 2 As shown, the metering device for textile dyes has a structure comprising a metering frame 4; the metering frame 4 is hung with some metering buckets 6 through several lugs 7 and some screw rods 8, and the metering bucket 6 is a hollow structure. The lower part of 6 is a conical structure. When in use, several metering buckets 6 can measure a variety of dyes at the same time, and the conical structure of the lower part of the metering hopper 6 can quickly discharge the dyes that have been metered, improving the metering efficiency of dyes; Sensor 9 is disconnected in the middle part of 8, and the meaning of disconnection is that screw mandrel is disconnected, connects with sensor. The measuring accuracy of the sensor 9 suspended by the screw rod 8 is higher than that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com