Unattended remote automatic measuring system for steel billets and steel products, and method of the same

An automatic metering and steel billet technology, applied in the direction of calculation, instrumentation, data processing applications, etc., can solve the problem of not realizing the scheduling forecast of metering materials, automatic metering of multi-pound one machine, remote signage printing voice intercom, and not realizing billet to steel Problems such as process control and tracking, measurement equipment and personnel cannot be dynamically balanced and dispatched, so as to improve the efficiency of information transmission, improve the level of informatization, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

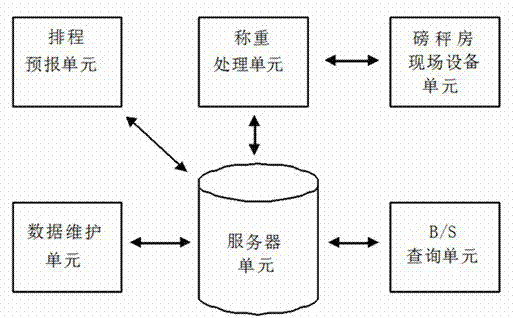

[0035] The unattended remote automatic metering system for steel billets and steel products described in the present invention is logically divided into 6 units. Such as figure 1 As shown, the present invention is composed of a schedule forecast unit, a weighing processing unit, a scale room field equipment unit, a data maintenance unit, a B / S query unit, and a server unit. The scale room field unit is connected with the weighing processing unit, and the weighing processing The unit, the schedule forecast unit, the data maintenance unit and the B / S query unit are respectively connected with the server unit through data transmission. The equipment components are described as follows:

[0036] The schedule forecasting unit consists of a computer. The forecast terminal plus the forecast program running on it is the schedule forecast unit of this embodiment.

[0037] The weighing processing unit consists of a computer. The metering terminal in the metering control center plus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com