Multi-material gradient forming fusion extrusion system for 3D printing

A melt extrusion, multi-material technology, applied in the field of material processing, can solve the problems of inability to achieve real-time adjustment and control of the proportion of heterogeneous multi-material components, inability to overcome the problems of FDM wire breakage, blocking nozzles, and inability to achieve composition gradient forming, etc. Achieving the effect of easy control, reduced possibility, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

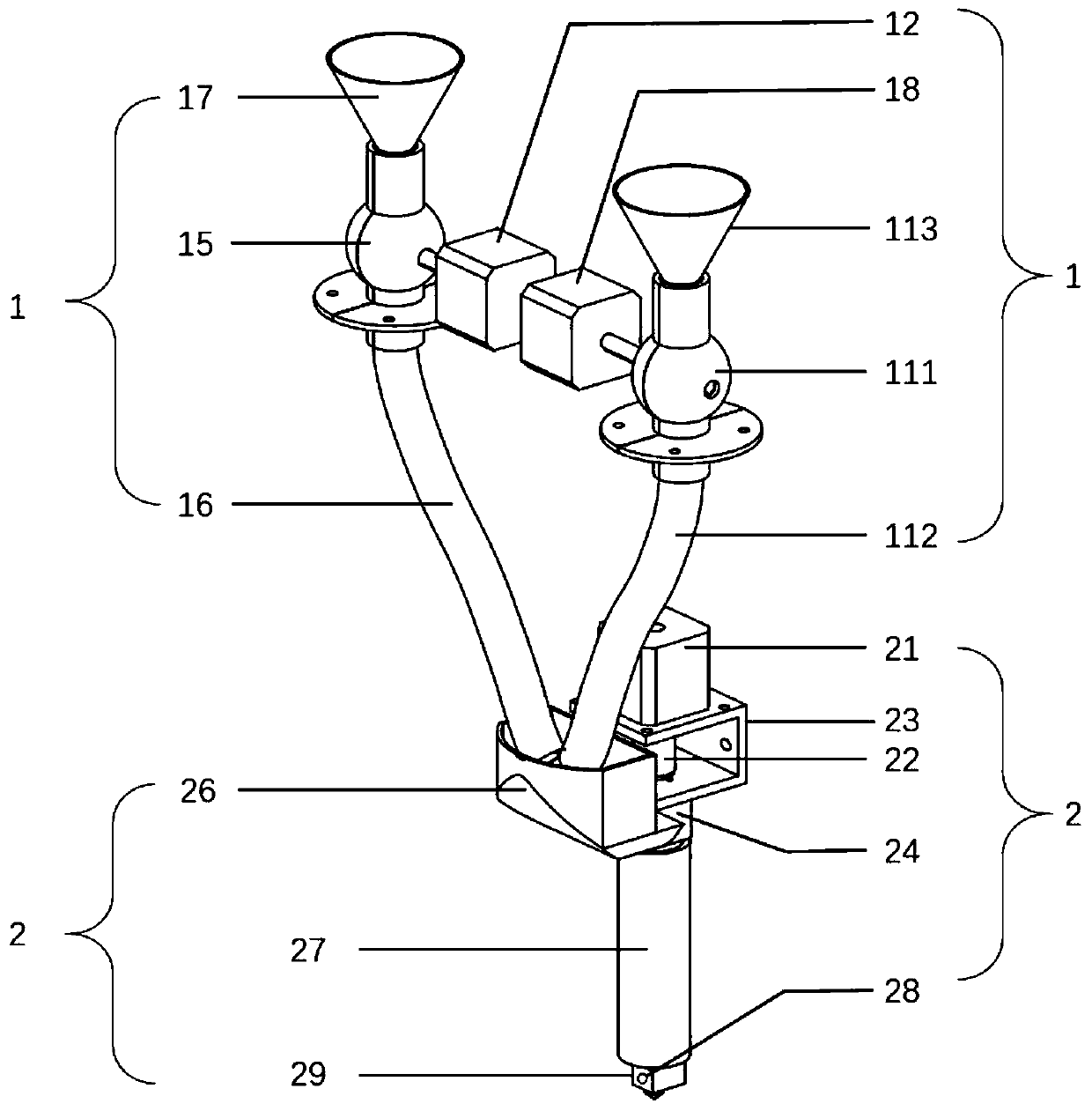

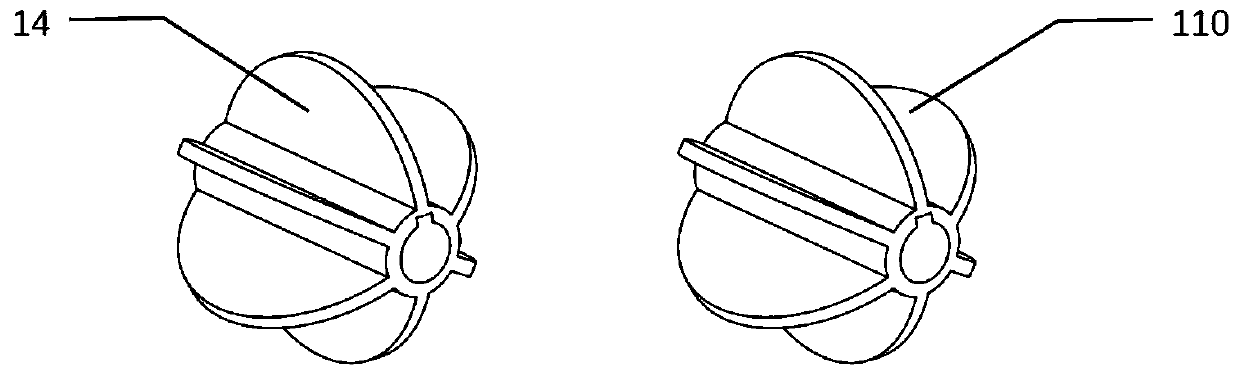

[0046] The first embodiment provided by the present invention is as figure 1 As shown, it includes two parts: a particle differential transmission mechanism 1 and a particle melting extrusion mechanism 2 , and the particle differential transmission mechanism 1 is fixed above the particle melting extrusion mechanism 2 . The particle differential transmission mechanism 1 comprises a first discharge motor 12, a first discharge rotary blade 14, a first stagnation cylinder 15, a first particle conduit 16 and a first charging funnel 17; a second discharge motor 18, a second Discharge rotary blade 110, the second stagnant cylinder 111, the second particle conduit 112 and the second charging funnel 113; the first discharge rotary blade 14 is arranged in the first stagnant cylinder 15, and the first discharge The rotary handle of the material rotating blade 14 is connected with the rotating shaft of the first discharge motor 12 through the small hole on the side of the first material s...

Embodiment 2

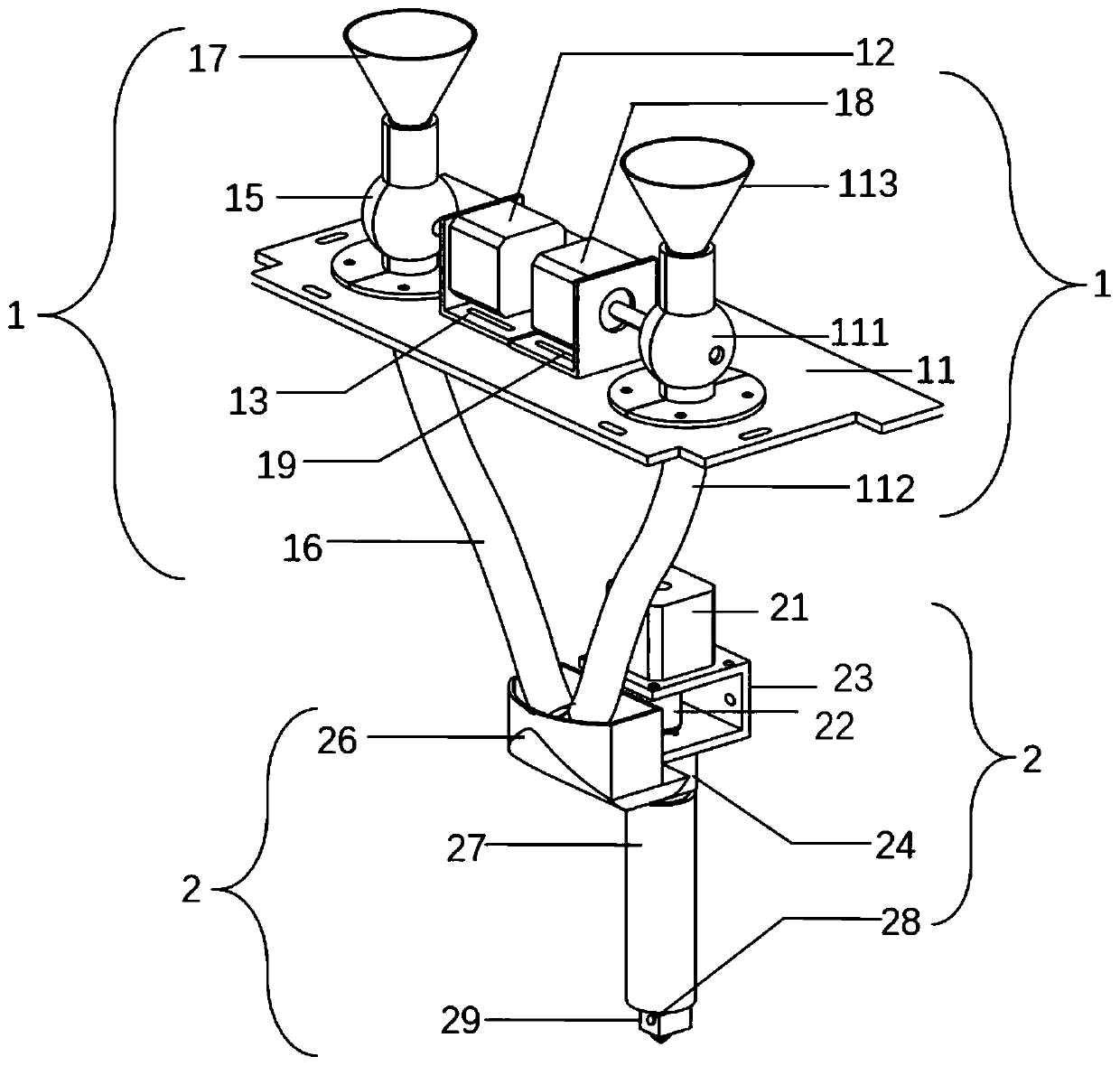

[0052] like figure 2 In this embodiment, on the basis of Embodiment 1, a support substrate 11, a first discharge motor support 13 and a second discharge motor support 19 are also provided in the particle differential transmission mechanism 1, and the first stagnation cylinder 15 and the second stagnant barrel 111 are respectively fixed on the support substrate 11 through flanges, and the corresponding parts of the support substrate 11 and the first stagnant barrel 15 and the second stagnant barrel 111 are provided with two circular through holes , the lower ends of the first sluggish cylinder 15 and the second sluggish cylinder 111 respectively pass through the respective circular through holes, and are connected with the upper ends of the first particle conduit 16 and the second particle conduit 112; the first discharge motor 12 The first discharging motor bracket 13 is fixed on the supporting substrate 11 ; the second discharging motor 18 is fixed on the supporting substrat...

Embodiment 3

[0055] In this embodiment, on the basis of Embodiment 2, the parameters of each component are as follows:

[0056] The first discharge motor 12 and the second discharge motor 18 are 42 series two-phase stepping motor standard parts;

[0057] The first stagnation cylinder 15 and the second stagnation cylinder 111 are customized parts for processing, and the diameter of the top cylinder is Height 35mm, middle sphere diameter Lower cylinder diameter Height 10mm, wall thickness 3mm;

[0058] The first charging funnel 17 and the second charging funnel 113 are standard parts, top diameter lower diameter 70mm high;

[0059] The first discharge motor support 13 and the second discharge motor support 19 are 42 series two-phase stepper motor fixed support standard parts;

[0060] The support substrate 11 is a custom-made part made of transparent acrylic, the length*width*thickness is 390mm*156mm*5mm respectively, and the diameters of the holes punched on it are The length a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com