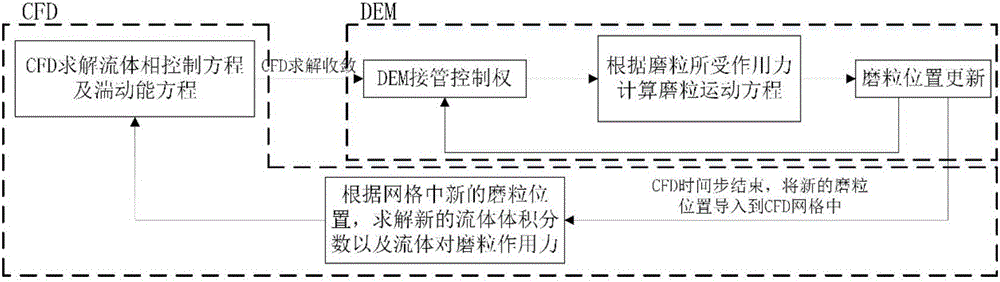

Abrasive particle flow field analysismethod based on CFD-DEM coupling model

A technology of coupling model and abrasive flow, which is applied in special data processing applications, complex mathematical operations, instruments, etc., and can solve problems such as difficult to precisely control processing parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be described in detail below in conjunction with a specific example.

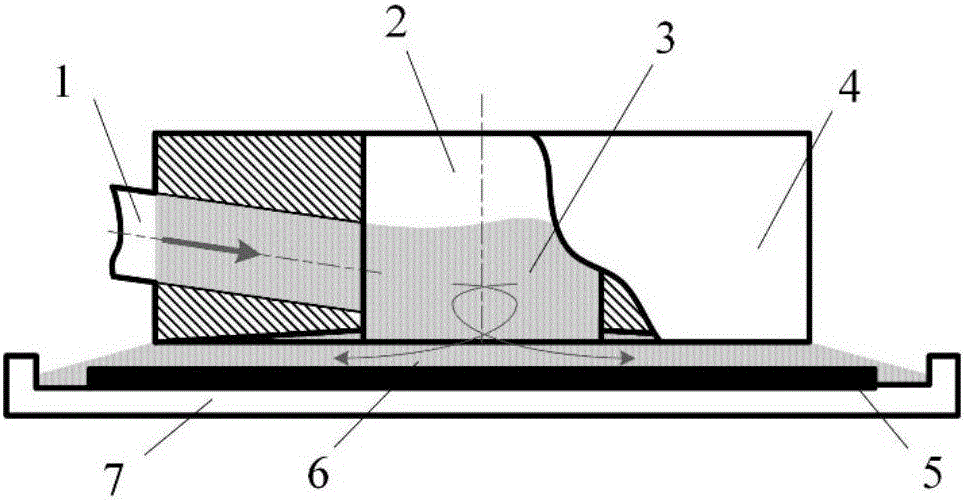

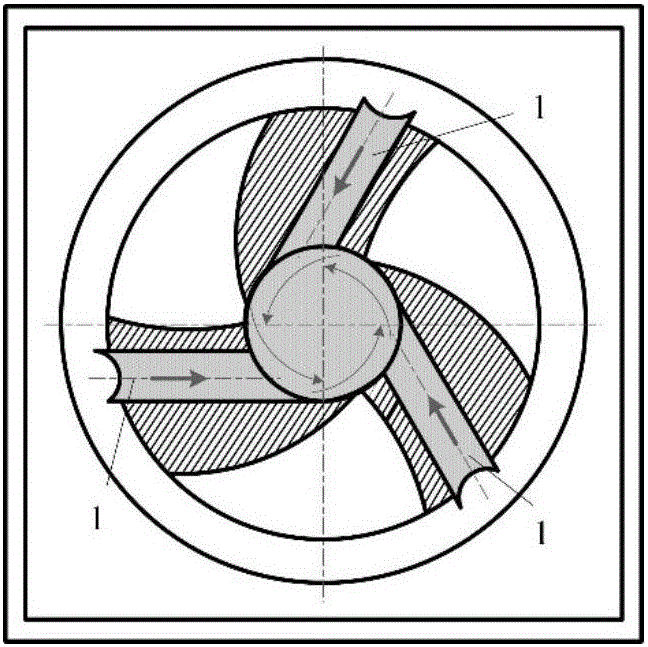

[0085] Such as Figure 1-6 As shown, the specific embodiment adopts a three-inlet-surface restricted abrasive flow processing device to process the workpiece 2. The circular processing tool has three abrasive particle flow inlets 1 along the circumferential direction, and the abrasive particle flow 3 is driven by the water pump. From the abrasive particle flow inlet 1 into the unrestricted space 2 in the middle of the circular processing tool; after being fully mixed, the abrasive particle flow 3 enters the restricted space 6 at a higher flow rate, and then the abrasive particle flow 3 installed at the bottom of the circular processing tool The workpiece 2 is finished. Adopt the present invention to analyze the abrasive particle flow field at the workpiece surface in the processing method, the specific process is as follows:

[0086] (1) Establish the finite element model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com