General wood substance grain processing technique and system

A general-purpose technology of wood pellets, applied in wood processing appliances, applications, household components, etc., can solve the problems of popularization and application, high production cost, and sharp increase in energy consumption, so as to reduce the total investment of equipment, low production cost, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

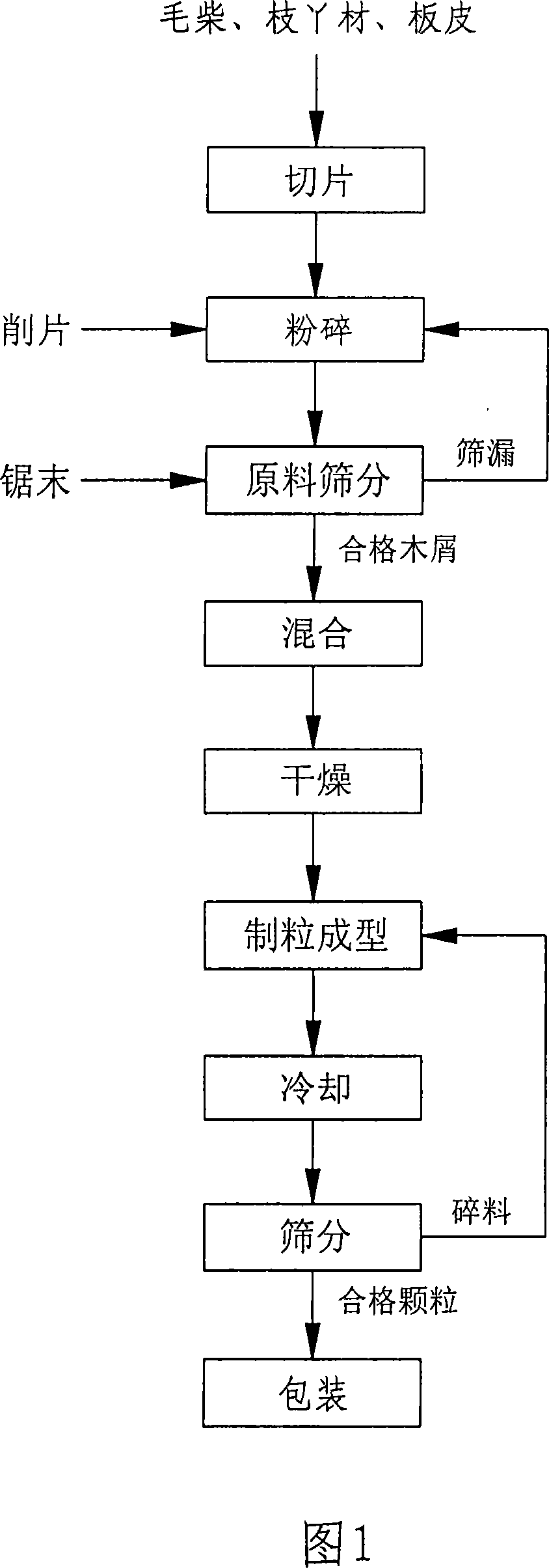

[0031] As shown in Figure 1, A. The slicing process is to send the woody wood or branches and branches into the slicer as raw materials for chopping. The particle size of the chopped wood chips is 15-20mm, and the water content is 40-50mm. %, after storage and natural drying, the water content will drop to 25-35%;

[0032] B, the pulverization process is that the chip is pulverized into most (about 70%) particle size is 3~5mm, moisture is the sawdust of 25~35%;

[0033] C. The raw material screening process is to use a shaking sieve or a rolling sieve to screen a small amount of super-large-grained material contained in the crushed wood chips (or sawdust) through a sieving machine (screen hole Φ5mm~Φ6mm), and the qualified wood chips with a particle size of 3~4mm Entering the next process, the super-sized sieve is returned to B (crushing process) by the belt conveyor;

[0034] D. The mixing process is to mix all kinds of raw materials evenly, so that the quality of the formed...

Embodiment 2

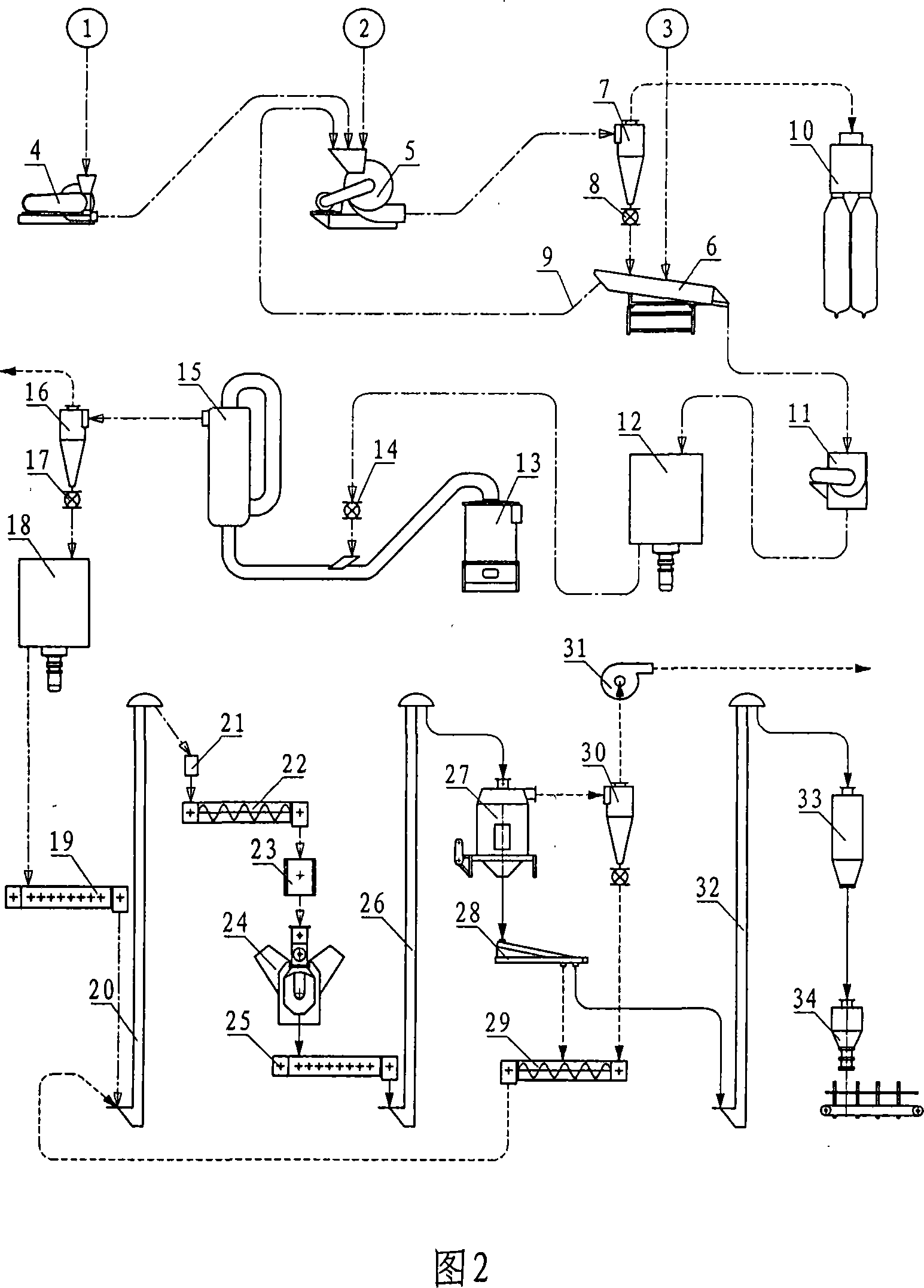

[0041] Referring to Fig. 2, slicing machine 4 of the present invention, pulverizer 5, unloading sacron 7, pulverizing unloading blower fan 8, raw material screening machine 6, mixer 11, dry feeding flat-bottomed bin 12, hot blast stove 13, drying Feeding and closing fan 14, air dryer 15, drying and unloading Sacron 16, drying and unloading closing fan 17, drying and discharging flat bottom warehouse 18, scraper conveyor 19, raw material hoist 20, permanent magnet cylinder 21, raw material Screw conveyor 22, bin to be granulated 23, granulator 24, granule scraper conveyor 25, hot granule elevator 26, cooling machine 27, screening machine 28, crushed material screw conveyor 29, finished granule elevator 32, The finished product warehouse 33 and quantitative packaging machine 34 are sequentially connected to form a material processing flow;

[0042] Another large material sieve leak 9 of the raw material screening machine 6 is connected to the feed port of the pulverizer 5 to for...

Embodiment 3

[0048] Process operation method and parameters

[0049] In Figure 2, according to three different wood raw materials: hair wood, branch wood, board raw material 1, shavings, shaving raw material 2, and sawdust raw material 3, they are respectively fed from different entrances: wood wood, branch wood, board raw material 1. After being sliced by the slicer 4, the particle size of the chips after slicing is controlled at 15-20mm; for the shavings and shavings raw materials 2, they are sent to the pulverizer 5 for crushing, and the particle size of the raw materials after crushing is 70% to 3-5mm; for the sawdust raw materials 3 , directly sent to the raw material screening machine 6 to screen out the big material with excessive particle size, the large material sieved out 9 returns to the pulverizer 5 for crushing, and then sieves again, and the large material that exceeds the standard is returned to the pulverizer 5 to pulverize again, and so on. Until the raw materials after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com