Dynamic dehumidification device for drying plastic particles

A drying technology for plastic particles, applied in the direction of drying gas arrangement, dryer for static materials, drying solid materials, etc., can solve the problems of uneven heating, long drying time, time-consuming and laborious, etc., to improve drying efficiency, good The effect of the dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

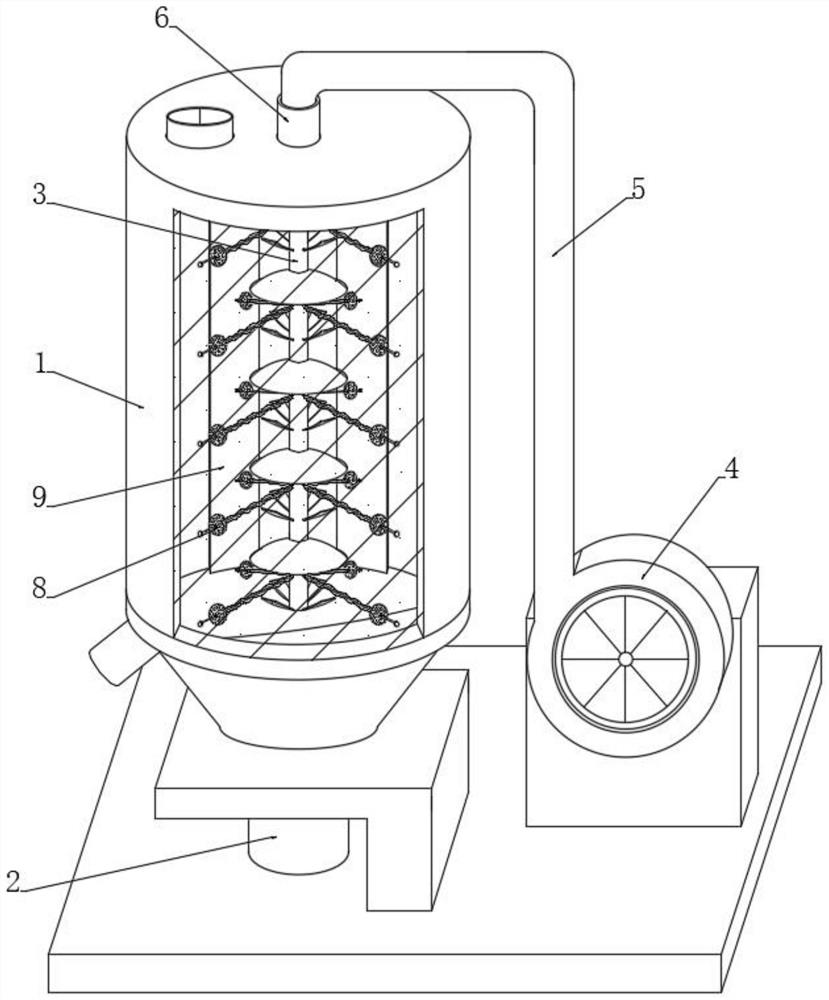

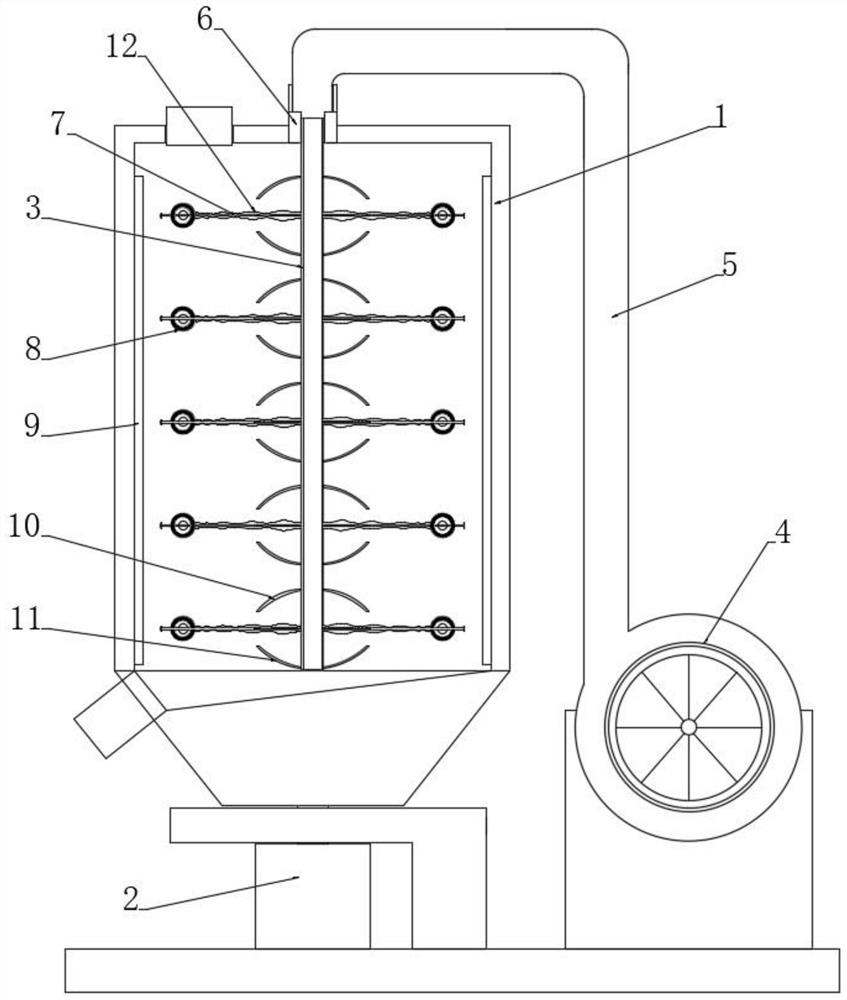

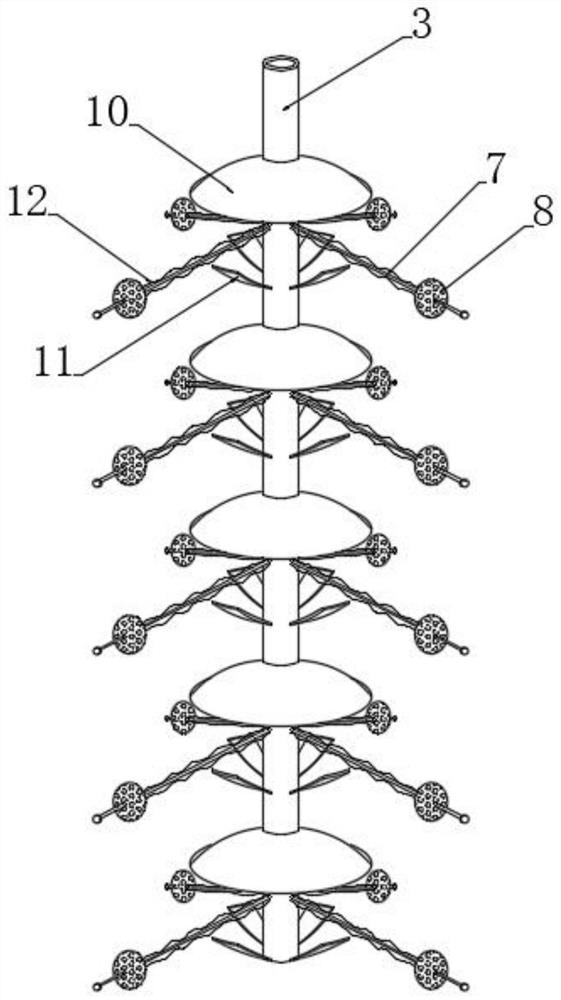

[0042] see Figure 1-2 , a dynamic dehumidification device for drying plastic particles, including a dehumidification cylinder 1 rotatably installed on the operating table, the top of the dehumidification cylinder 1 is provided with an inlet, the bottom slope of the dehumidification cylinder 1 is provided with a discharge port, and the operation table A rotating motor 2 fixedly connected to the bottom of the dehumidification cylinder 1 is fixedly installed on the top. The rotating motor 2 drives the entire dehumidification cylinder 1 to rotate and is used to stir the plastic particles in the dehumidification cylinder 1. The upper end of the console is installed There is a fan 4, the air outlet of the fan 4 is rotatably connected to the top end of the dehumidification cylinder 1 through the air pipe 5, and the top end of the dehumidification cylinder 1 is provided with a drying pipe 3 connected with the air pipe 5, and the lower end of the drying pipe 3 runs through the dehumidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com