Motor

An iron cover and washer technology, applied in electrical components, electromechanical devices, DC commutators, etc., can solve the problems of large motor volume, low torque and high energy consumption, and achieve the effect of small volume, large torque and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

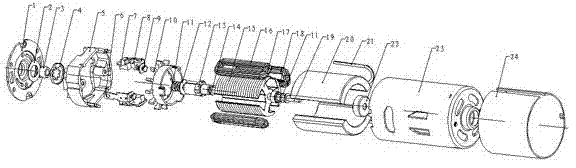

[0010] see figure 1 , the specific embodiment adopts the following technical scheme: it includes iron cover 1, gasket 2, ball cup 3, cup cover 4, inner cover 5, terminal 6, carbon 7, elastic arm 8, rivet 9, fan blade 10 , limit meson 11, oil-proof meson 12, commutator 13, fast bar meson 14, punching piece 15, paint leather wire 16, copper meson 18, shaft 19, magnet 20, slingshot 21, straight cup 22, iron shell 23 , change the magnetic ring 24, the iron cover 1 is installed on the inner cover 5, and the gasket 2, the ball cup 3 and the cup cover 4 are successively arranged between the iron cover 1 and the inner cover 5, and the terminal 6 and the carbon 7 are all installed on the In the inner cover 5, an elastic arm 8 is installed on the carbon 7, and a rivet 9 is arranged on the elastic arm 8. The fan blade 10 is sleeved on one side of the shaft 19, and an oil changer 13 is arranged on one side of the fan blade 10. Between the leaf 10 and the oil changer 13, a limiting meson ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com