Spraying-type environment-friendly rubber adhesive cement and preparation method thereof

An environmentally friendly rubber and glue technology, applied in the direction of natural rubber adhesives, adhesives, adhesive types, etc., can solve the problems of difficult processing, low initial adhesion strength, small final adhesion strength, etc., and achieve long-term performance of the glue. Maintain, prevent aging effect, solve the effect of quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

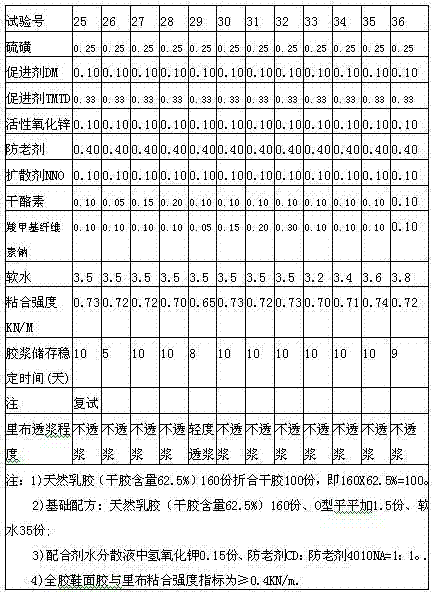

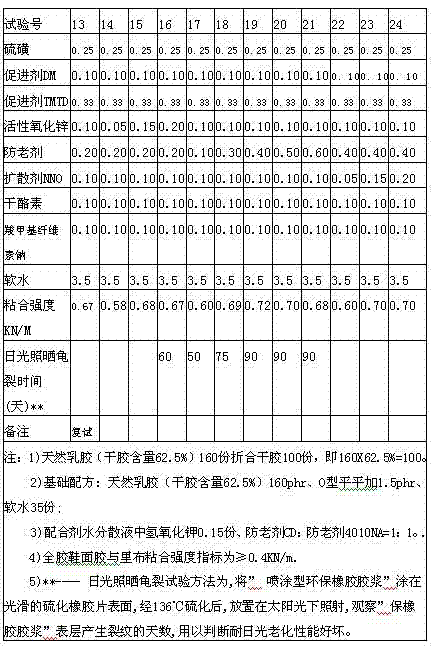

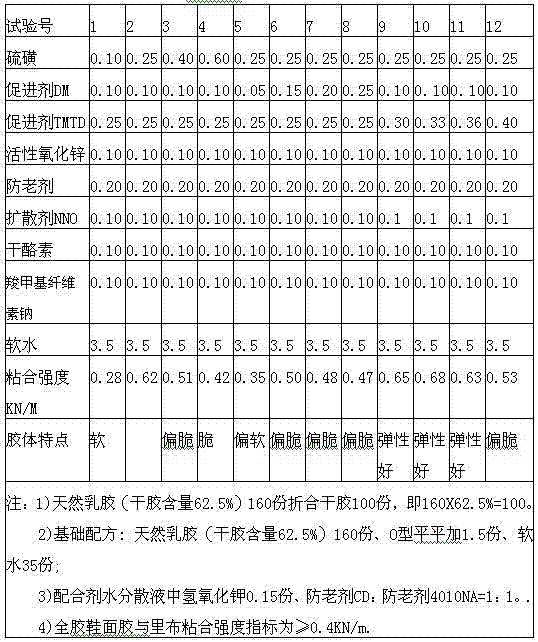

[0060] Embodiment 1 of the present invention: spraying type environment-friendly rubber mortar, calculated according to weight parts, it comprises 160 parts of natural latex that dry glue content is 62.5%, 0.7 part of penetrating agent JFC, 1.6 parts of O-type Pingping, 0.3 part of ammoniacal liquor, 32 parts of soft water and water dispersion of compounding agent; water dispersion of compounding agent consists of 0.25 parts of sulfur, 0.1 part of accelerator DM, 0.33 parts of accelerator TMTD, 0.10 parts of active zinc oxide, 0.20 parts of anti-aging agent CD, 0.20 parts of anti-aging agent 4010NA , 0.80 parts of antifungal agent BCM, 0.10 parts of diffusing agent NNO, 0.15 parts of potassium hydroxide, 0.10 parts of casein, 0.1 parts of sodium carboxymethylcellulose and 3.6 parts of soft water.

[0061] The preparation method of spraying type environment-friendly rubber mortar comprises the steps:

[0062] Step 1. Prepare the aqueous dispersion of the compounding agent: take...

Embodiment 2

[0064] Embodiment 2 of the present invention: spraying type environment-friendly rubber mortar, calculated according to parts by weight, it includes 160 parts of natural latex with a dry rubber content of 62.5%, 0.6 part of penetrant JFC, 1.7 parts of O-type Pingping, 0.4 part of ammoniacal liquor, 30 parts of soft water and water dispersion of compounding agent; water dispersion of compounding agent consists of 0.25 parts of sulfur, 0.1 part of accelerator DM, 0.33 parts of accelerator TMTD, 0.10 parts of active zinc oxide, 0.20 parts of anti-aging agent CD, 0.20 parts of anti-aging agent 4010NA , 0.80 parts of antifungal agent BCM, 0.10 parts of diffusing agent NNO, 0.15 parts of potassium hydroxide, 0.10 parts of casein, 0.1 parts of sodium carboxymethylcellulose and 3.6 parts of soft water.

[0065] The preparation method is the same as in Example 1.

Embodiment 3

[0066] Embodiment 3 of the present invention: spraying type environment-friendly rubber mortar, calculated according to weight parts, it comprises 160 parts of natural latex with dry glue content of 62.5%, 0.6 part of penetrant JFC, 1.6 parts of O-type flat plus, 0.4 part of ammoniacal liquor, 35 parts of soft water and water dispersion of compounding agent; water dispersion of compounding agent consists of 0.25 parts of sulfur, 0.1 part of accelerator DM, 0.33 parts of accelerator TMTD, 0.10 parts of active zinc oxide, 0.20 parts of anti-aging agent CD, 0.20 parts of anti-aging agent 4010NA , 0.80 parts of antifungal agent BCM, 0.10 parts of diffusing agent NNO, 0.15 parts of potassium hydroxide, 0.10 parts of casein, 0.1 parts of sodium carboxymethylcellulose and 3.6 parts of soft water.

[0067] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com