Multifunctional plastic with anti-microbial effect, oxidation resistance and metal-chelating property and preparation method thereof

A technology of metal chelation and metal chelating agent, which is applied in the research and development of plastic materials for smog filtration, can solve problems such as easy mold damage and electronic cigarette products are susceptible to metal ions, so as to increase revenue, expand market space, and increase market value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

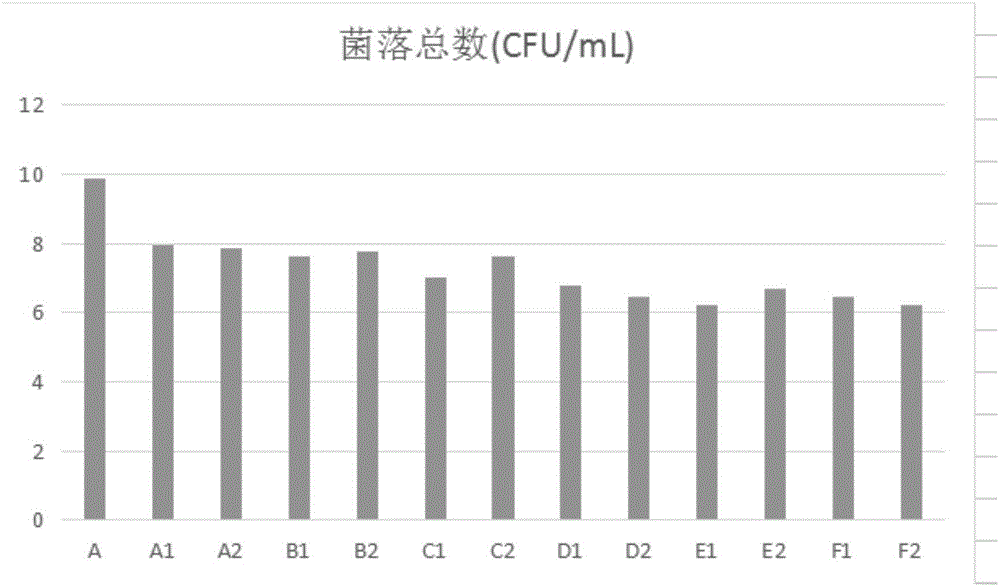

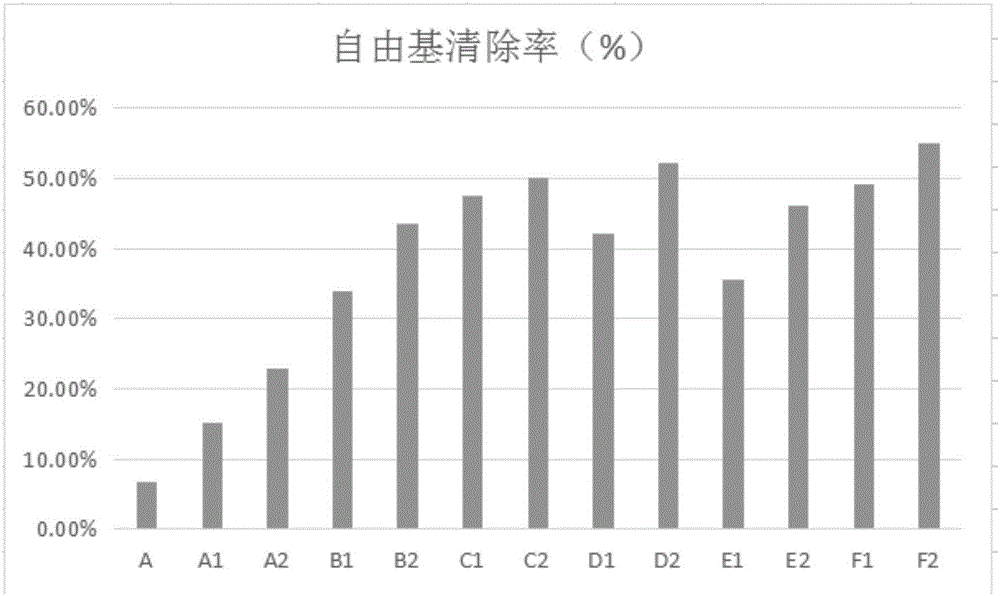

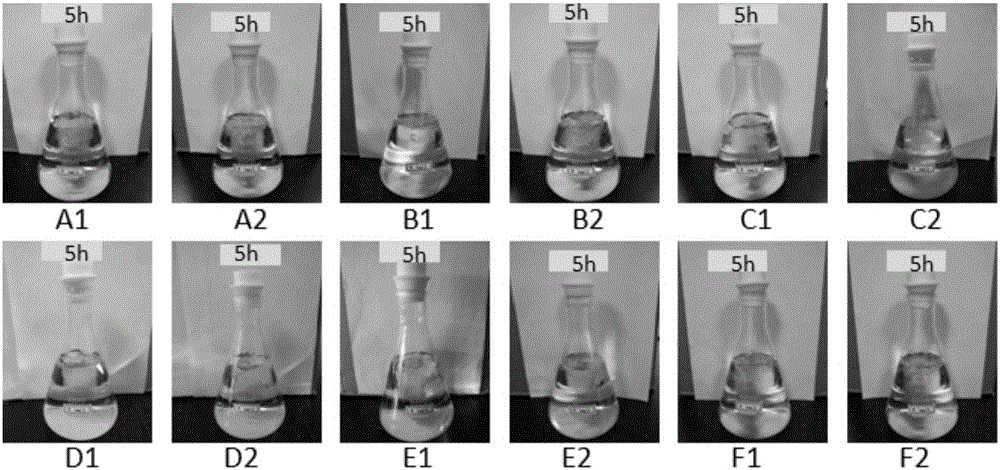

Embodiment 1

[0047] Dry the resin masterbatch PE with component quality at a temperature of 85-100°C for 4-6 hours; add EDTA at a vacuum degree of 0.1Mpa, a temperature of 65-85°C, and pass through a 200-mesh sieve for 2-4 hours. 3% powder, mechanically stirred and mixed for 15-20 minutes, heated, sheared, extruded, and pelletized by a twin-screw extruder to finally obtain spare modified resin masterbatches for metal chelate plastics; the twin-screw extruder from the entrance There are seven heating zones in sequence to the exit, among which the heating temperature of the first zone is 165°C, the heating temperature of the second zone is 180°C, the heating temperature of the third zone is 185°C, the heating temperature of the fourth zone is 185°C, and the heating temperature of the fifth zone is 185°C , the heating temperature in the sixth zone is 175°C, the heating temperature in the seventh zone is 170°C; % of α-tocopherol, mixed, mechanically stirred for half an hour and then ultrasonic...

Embodiment 2

[0049] Dry the resin masterbatch LDPE with component quality at a temperature of 85-100°C for 4-6 hours; add NTA with a vacuum degree of 0.1Mpa, a temperature of 65-85°C, and pass through a 200-mesh sieve for 2-4 hours. 8% powder, mechanically stirred and mixed for 15-20 minutes, heated, sheared, extruded, and pelletized by a twin-screw extruder to finally obtain spare modified resin masterbatches for metal chelate plastics; the twin-screw extruder from the entrance There are seven heating zones in sequence to the exit, among which the heating temperature of the first zone is 165°C, the heating temperature of the second zone is 175°C, the heating temperature of the third zone is 180°C, the heating temperature of the fourth zone is 185°C, and the heating temperature of the fifth zone is 180°C , the heating temperature in the sixth zone is 175°C, the heating temperature in the seventh zone is 170°C; % of α-tocopherol, mixed, mechanically stirred for half an hour, and then ultras...

Embodiment 3

[0051] Dry the resin masterbatch PLA with component quality at a temperature of 85-100°C for 4-6 hours; add EDTA at a vacuum degree of 0.1Mpa, a temperature of 65-85°C, and pass through a 200-mesh sieve for 2-4 hours + NTA (1:1) powder 6%, mechanical stirring and mixing for 15-20 minutes, after heating, shearing, extrusion, and pelletizing by a twin-screw extruder, finally obtain a spare modified resin masterbatch for metal chelated plastics; The twin-screw extruder is equipped with seven heating zones sequentially from the entrance to the exit, among which the heating temperature of the first zone is 165°C, the heating temperature of the second zone is 175°C, the heating temperature of the third zone is 180°C, and the heating temperature of the fourth zone is 185°C. The heating temperature of the fifth zone is 180°C, the heating temperature of the sixth zone is 175°C, and the heating temperature of the seventh zone is 170°C; the rotation speed is 40-45rpm; the obtained spare m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com