Reviving waste product of bearing with inner and outer bearing ring over size

A technology of bearing ring and outer diameter size, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as inevitable economic losses, and achieve the effect of saving steel and obvious economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

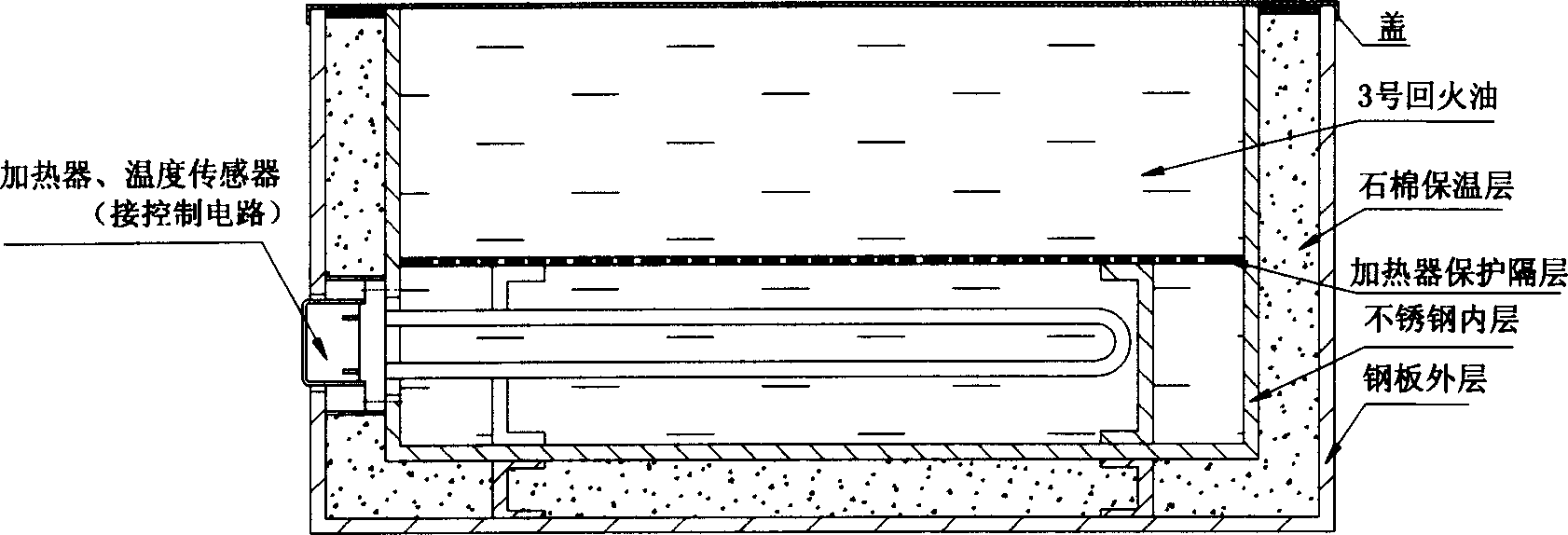

[0045] Production application of the present invention can adopt two kinds of modes

[0046] 1. Manufacturers with an annual output of more than 1.2 million sets of bearings (inner diameter Φ>20mm) can set up and use them for their own use. The site is 60 square meters, the staff is 2-3 people, and the investment in equipment is 30,000 yuan.

[0047] 2. Areas where small bearing factories are relatively concentrated can set up specialized factories to serve bearing manufacturers and charge processing fees. The scale can be large or small, and the investment is within 100,000 yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com