Amide phosphonic acid metal complex, corresponding composite material and preparation methods thereof

A technology of metal complexes and amidophosphonic acid, which is applied in metal material coating technology, liquid chemical plating, coating, etc., can solve the problems of unfavorable promotion of production, and achieve the goal of reducing geometric size, simplifying production process and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

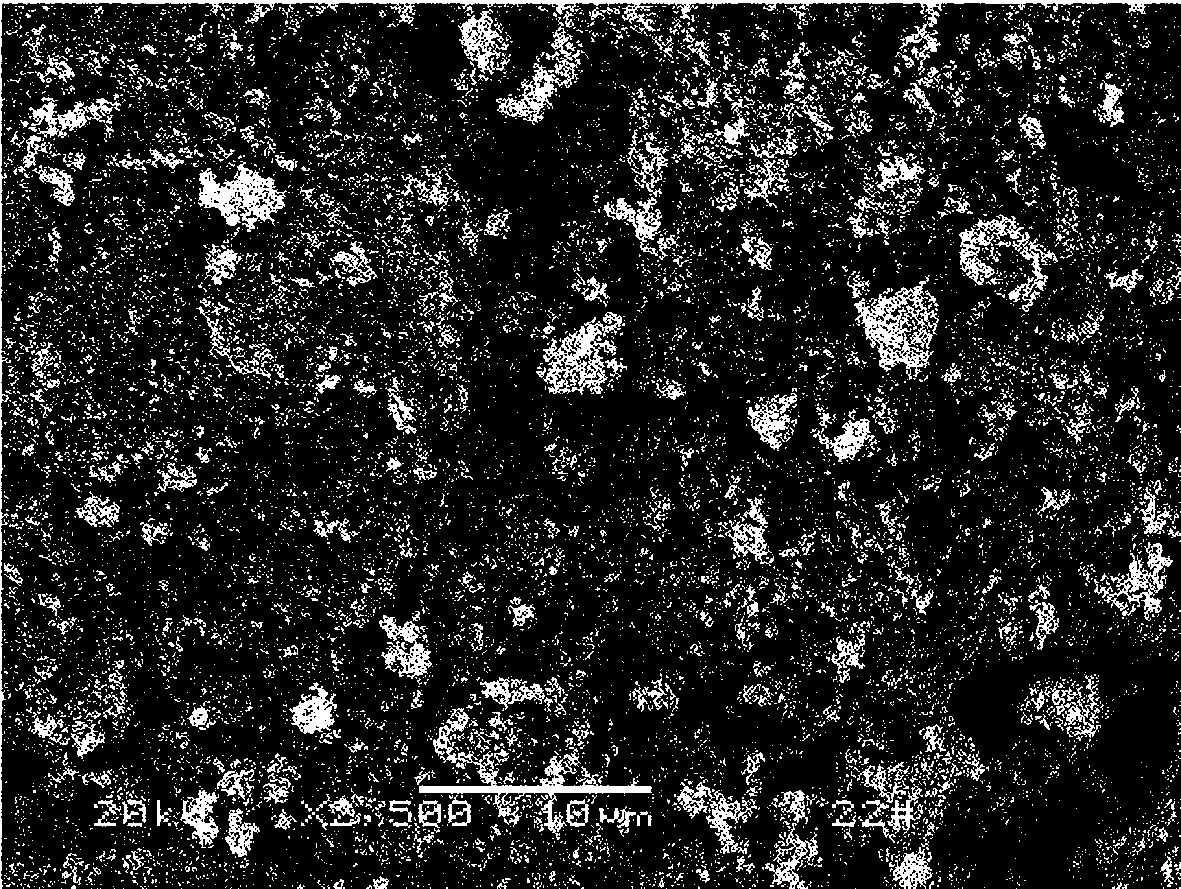

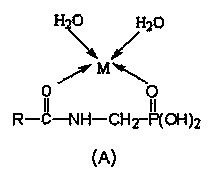

[0037] Add 0.1mol of acetamide and 200ml of water into a 500ml three-neck flask with a magnetic stirrer and a reflux condenser, stir and dissolve, then add 0.1mol of NaOH dropwise to adjust the pH of the solution to 10~11, and then add 0.1mol (1.77 g) of paraformaldehyde was stirred at 25°C under normal pressure for 2.5 hours to carry out the methylolation reaction. Then add 0.15mol of phosphorous acid, and stir at 30~35°C for 2.5 hours, the reaction precipitate is washed to neutral with 0.05mol of dilute hydrochloric acid and water, and dried in vacuum to obtain acetamidomethylene dihydroxyphosphonic acid with a yield of 85 %. Then it was dissolved in 150ml of n-amyl alcohol, and then slowly dripped into 50ml of n-amyl alcohol solution containing 0.1mol copper acetate with a constant pressure funnel, and heated to reflux for 0.5 hours to obtain acetamide methylene dihydroxyl with an average particle size of 15 μm. Phosphonic acid copper complex (A) (abbreviated as acetamide...

Embodiment 2

[0039] Add 0.1mol of formamide and 200ml of ethanol to a 500ml three-neck flask with a magnetic stirrer and a reflux condenser, stir and dissolve, then add 0.1mol of NaOH dropwise to adjust the pH of the solution to 10~11, then add 0.1mol Formaldehyde was stirred under normal pressure at 25°C for 1.5 hours to carry out methylolation reaction. Then add 0.15mol of phosphorous acid, and stir at 35~40°C for 1.5 hours, the reaction precipitate is washed to neutral with 0.05mol of dilute hydrochloric acid and water, and dried in vacuum to obtain formamide methylene dihydroxyphosphonic acid with a yield of 75 %. Then dissolve it in 150ml of DMF, slowly drop into 50ml of DMF solution containing 0.1mol copper acetate, heat and reflux for 1 hour to obtain formamide methylene dihydroxyphosphonic acid copper complex (A) with an average particle size of 25 μm (referred to as formamide phosphonate copper complex (A)).

Embodiment 3

[0041] Add 0.1mol of benzamide and 250ml of methanol into a 500ml three-neck flask equipped with a magnetic stirrer and a reflux condenser, stir and dissolve, then add 0.1mol of NaOH dropwise to adjust the pH of the solution to 9~10, then add 0.1 mol of paraformaldehyde (the degree of polymerization n is 8), stirred at 35°C under normal pressure for 1.5 hours to carry out the methylolation reaction. Then add 0.15 mol of phosphorous acid, and stir at 40~45°C for 2.0 hours, wash the reaction precipitate with 0.05 mol of dilute hydrochloric acid and water to neutrality, and dry it in vacuum to obtain benzamide dimethylene dihydroxyphosphonic acid. The rate is 75%. Then it was dissolved in 150ml of isoamyl alcohol, slowly dripped into 50ml of isoamyl alcohol solution containing 0.1mol cobalt acetate, heated to reflux for 1.5 hours to obtain cobalt benzamidomethylene dihydroxyphosphonate with an average particle size of 20 μm Complex (A) (referred to as cobalt benzamide phosphonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com