Method for machining steam turbine honeycomb seal with electric sparks

A technology of EDM machine tools and steam turbines, which is applied in the processing field of steam turbine air seals, and can solve the problems of low efficiency, high material consumption, and time-consuming segmental processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

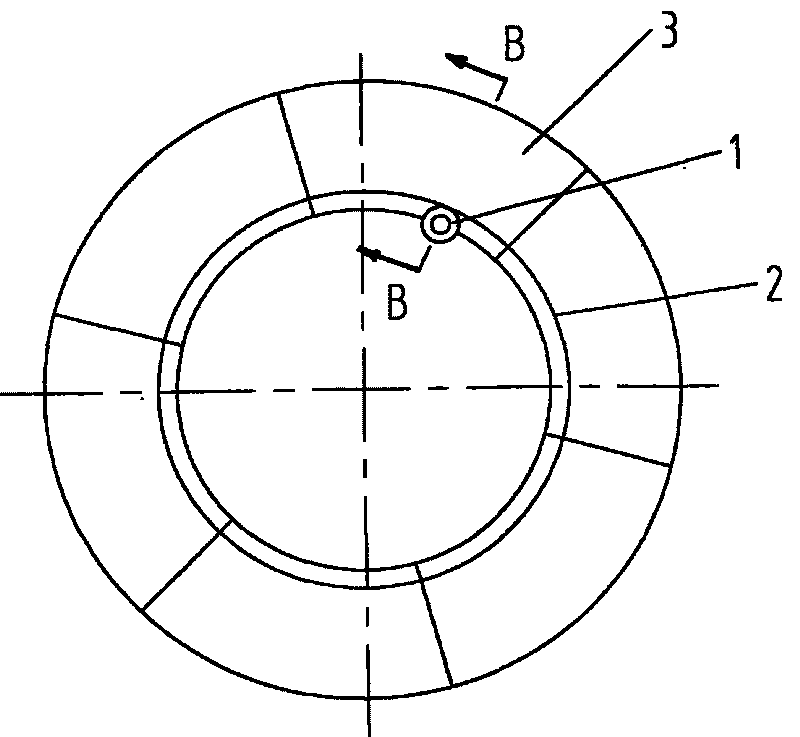

[0024] The key of the present invention is to change the traditional EDM method of feeding the tool electrode in the normal direction relative to the workpiece processing surface, feed along the circumference of the workpiece processing surface, and use the new method of online continuous compensation for electrode wear. This idea is the innovation point of this application, which can solve many problems existing in the traditional electric discharge machining process.

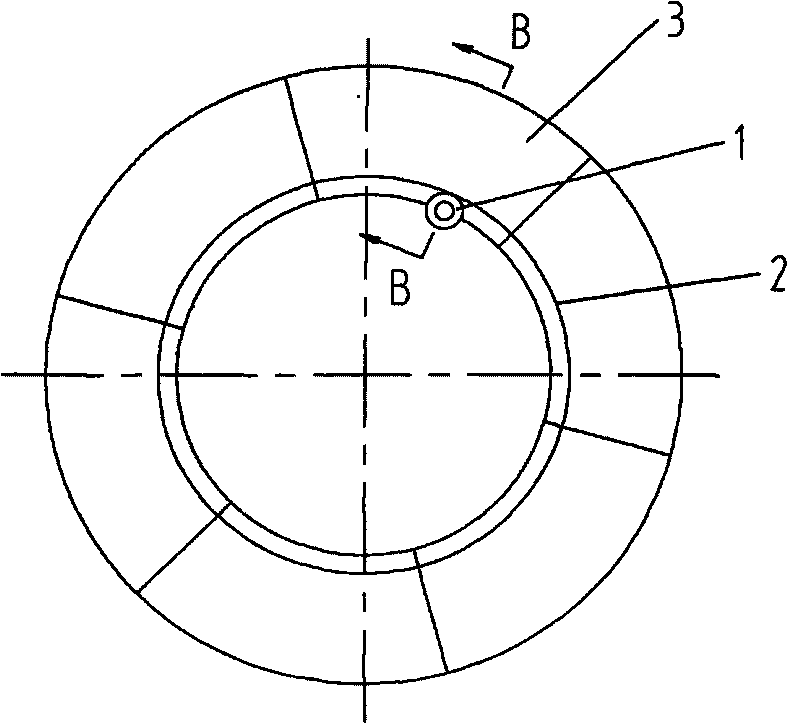

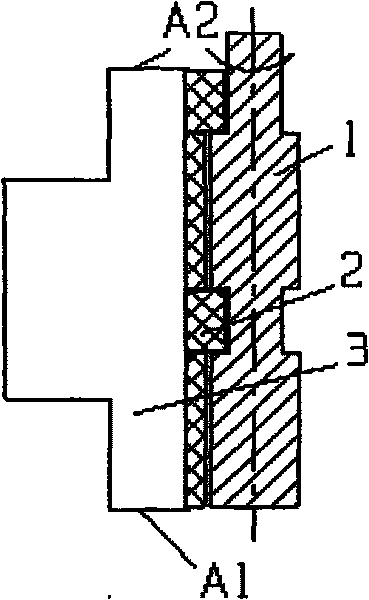

[0025] First of all, the tool electrode is fed along the circumference of the workpiece processing surface, which can greatly simplify the tool electrode structure and facilitate processing; and can greatly reduce its geometric size, reducing material consumption and cost. see figure 2 , the tool electrode 1 used in the present invention has a stepped shaft structure, its contour line is the same as the theoretical contour line of the processing surface, and the peripheral surface of each step is the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com