Variable pitch control system, variable pitch control method and wind generating set

A pitch motor and control system technology, applied in the pitch field, can solve the problems of maintenance difficulties, difficulties in the development and manufacture of electrical components and mechanical components, unfavorable development of large or super large wind turbines, etc. Beneficial for installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

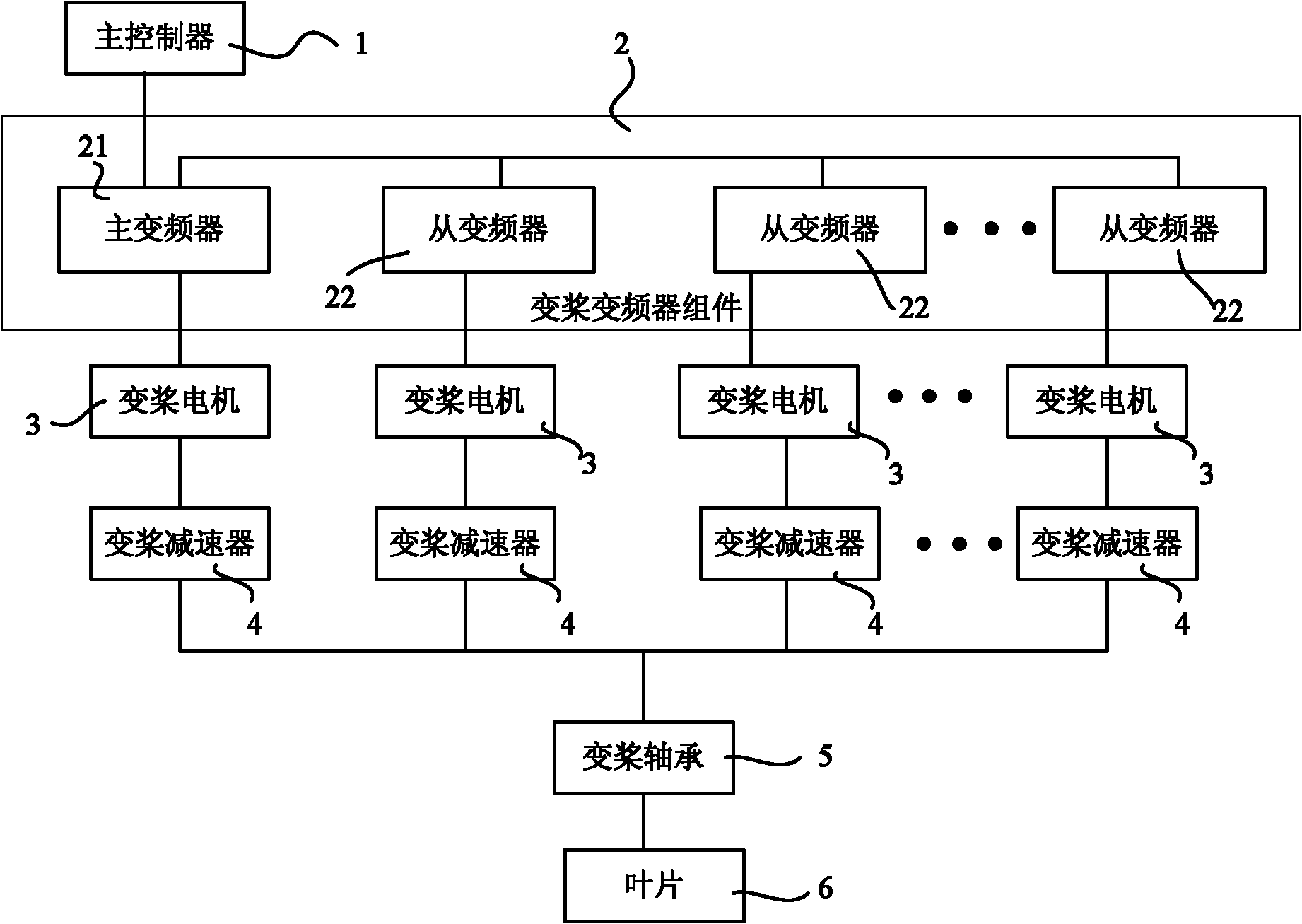

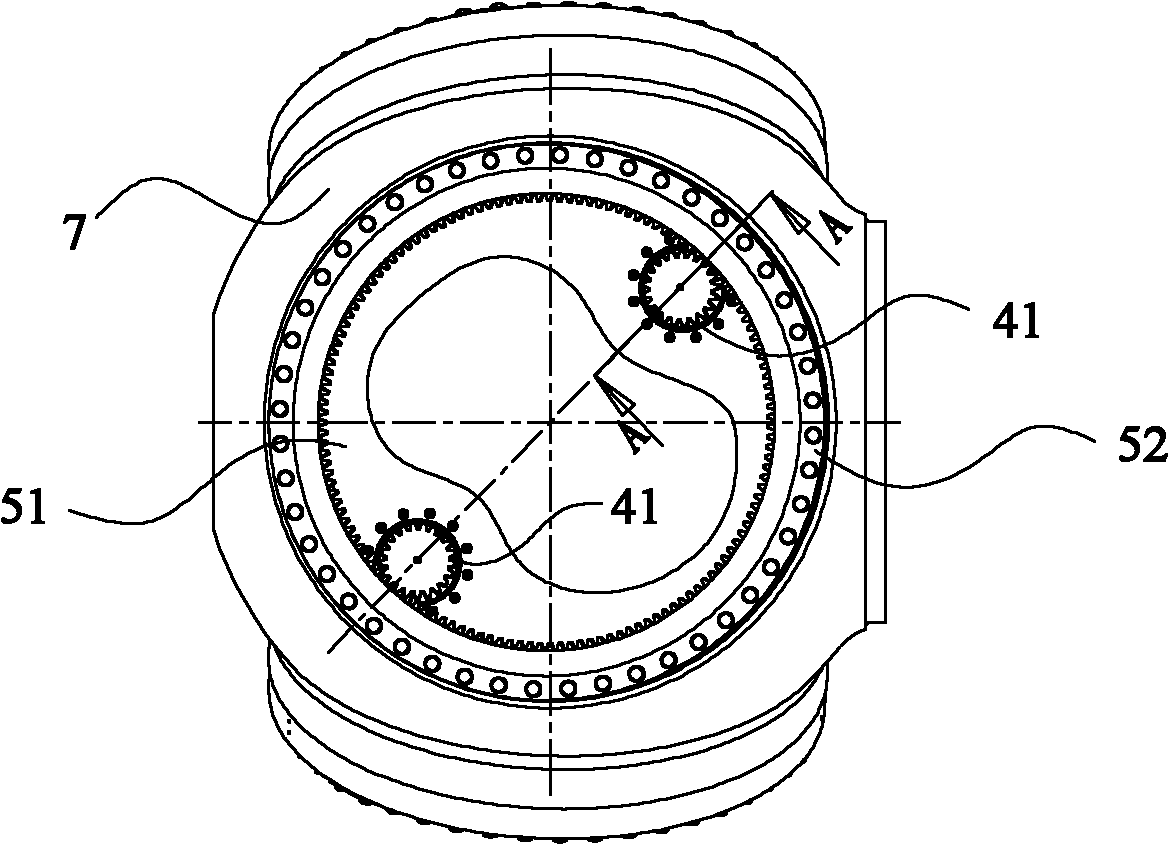

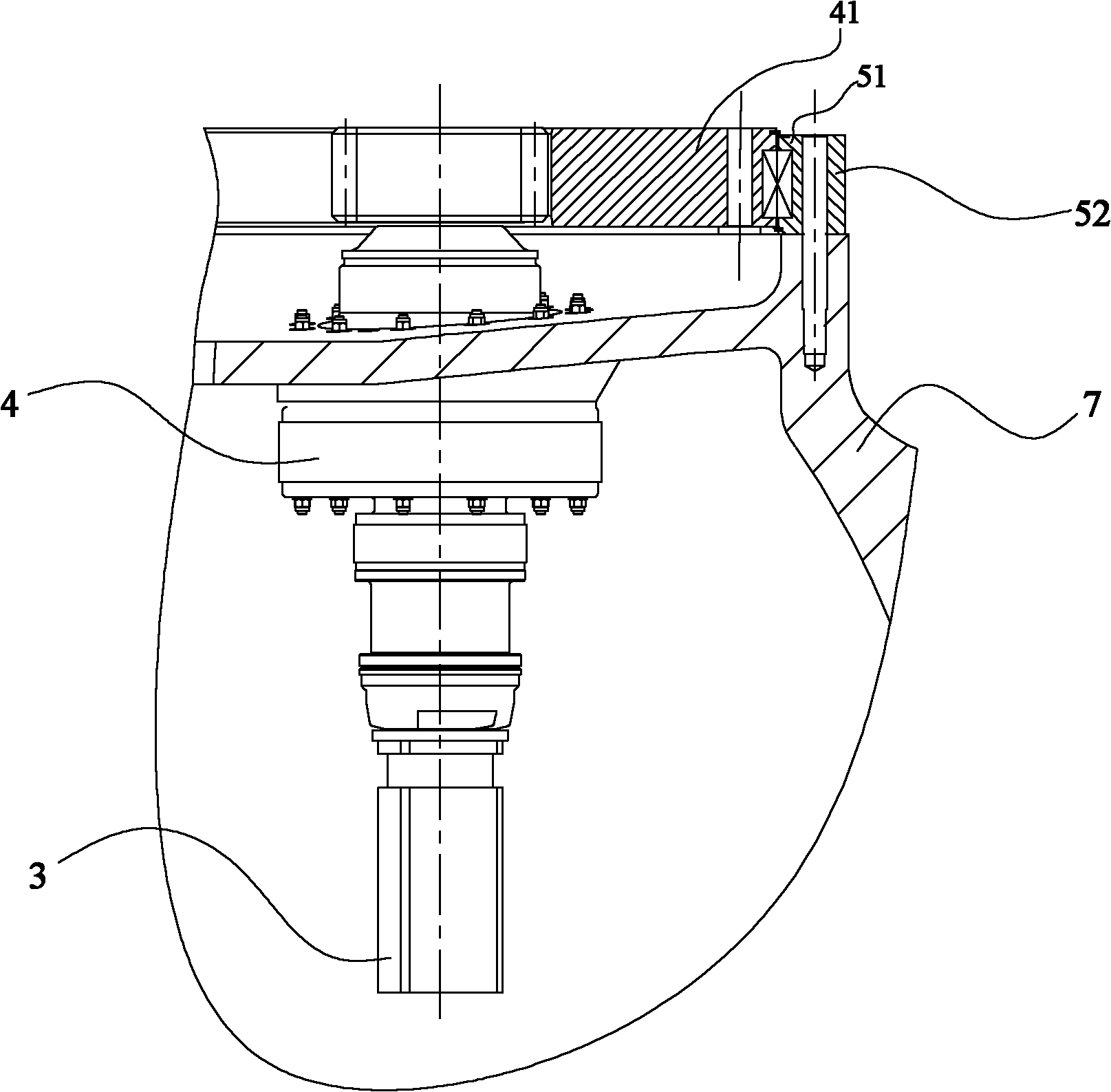

[0040] Embodiment 1 of the present invention provides a pitch control system, figure 1 It is a schematic structural diagram of the pitch control system provided by Embodiment 1 of the present invention, figure 2 It is a schematic diagram of a partial structure of the pitch control system provided by Embodiment 1 of the present invention, image 3 for figure 2 A cross-sectional view of the A-A direction.

[0041] refer to figure 1 , figure 2 with image 3 As shown, the pitch control system includes a main controller 1 , a pitch frequency converter assembly 2 , a pitch motor 3 , a pitch reducer 4 and a pitch bearing 5 .

[0042] There is one pitch bearing 5 set corresponding to each blade 6, and a plurality of pitch motors 3 drive a plurality of pitch reducers 4, and a plurality of pitch reducers 4 mesh with one pitch bearing 5 to drive the pitch reducer 5 respectively. Paddle bearing 5 rotates.

[0043] The pitch frequency converter assembly 2 corresponding to each bl...

Embodiment 2

[0059] Figure 5 A schematic structural diagram of the pitch control system provided by Embodiment 2 of the present invention, as shown in Figure 5 As shown, on the basis of the first embodiment above, the pitch control system is further provided with a first detection module 81 and a first comparison module 91 .

[0060] The first detection module 81 is connected between the pitch motor 3 controlled by the main inverter 21 and the first comparison module 91 , and is used to feed back the detected current position of the pitch motor 3 to the first comparison module 91 .

[0061] The first comparison module 91 is connected with the main frequency converter 21, and is used to compare the current position of the pitch motor 3 with the expected position to generate a deviation signal, and transmit the deviation signal to the main frequency converter 21 to instruct the main frequency converter 21 according to The deviation signal adjusts the setting parameters.

Embodiment 3

[0063] The technical solution of the above-mentioned embodiment 2 is a closed-loop control solution including position feedback of the pitch motor, Image 6 The structural schematic diagram of the pitch control system provided by Embodiment 3 of the present invention adopts the scheme of feedbacking the position of the pitch bearing to form a closed-loop control, as shown in Image 6 As shown, on the basis of the first embodiment above, the pitch control system further includes a second detection module 82 and a second comparison module 92 .

[0064] The second detection module 82 is connected between the pitch bearing 5 and the second comparison module 92 for feeding back the detected current position of the pitch bearing to the second comparison module 92 .

[0065] The second comparison module 92 is connected with the main frequency converter 21, and is used to compare the current position of the pitch bearing 5 with the expected position to generate a deviation signal, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com