Middle-temperature high-aluminum reinforced porcelain and process for producing same

A technology for strengthening porcelain and high aluminum, which is applied in the field of medium temperature and high aluminum reinforced porcelain and its production process, can solve the problem of high energy consumption, and achieve the effect of reducing the firing temperature and improving the internal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A medium-temperature high-alumina strengthened porcelain, the body of which includes the following components (by weight): 15% of Datong soil, 10% of weathered potassium feldspar, 11% of alumina, 24% of Hunan washing mud, and 2% of Jiangxi lithium porcelain stone powder , Hunan black feldspar 10%, calcined talc 3%, Jiepai soil 14%, quartz 8% and Guizhou soil 3%.

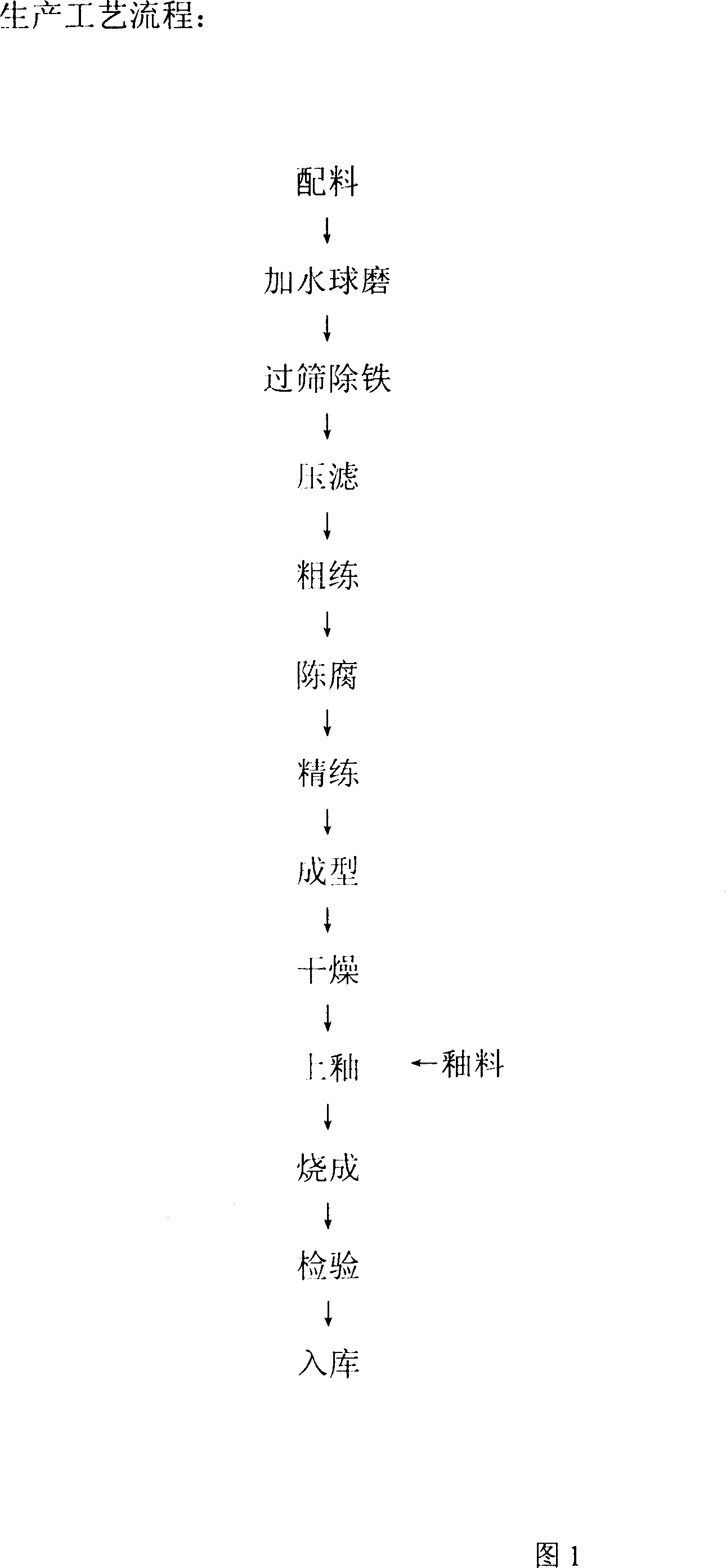

[0014] After batching according to the above ratio, put it into a ball mill and add water to ball mill, sieve to remove iron, press filter, rough smelt, stale, scouring, molding, drying, glazing, firing, inspection, packaging.

[0015] Said billet is added water ball mill according to material: ball: water=1.0:1.9:1.0 weight ratio adds water, ball milling time is 20 hours, ball milling fineness is less than 0.1% by sieve remaining 250 orders, and sieve remaining 325 orders is less than 0.3%; The sieve is 200 mesh; the Gauss intensity of the iron removal is 10000 Gauss intensity, and it is continuously sieved f...

Embodiment 2

[0018] A medium-temperature high-alumina strengthened porcelain, the green body of which is the following components (by weight): 20% of Datong soil, 5% of weathered potassium feldspar, 15% of alumina, 15% of Hunan washing mud, and 2% of Jiangxi lithium porcelain stone powder , Hunan black feldspar 9%, calcined talc 5%, Jiepai soil 20%, quartz 5% and Guizhou soil 4%.

[0019] After batching according to the above ratio, put it into a ball mill and add water to ball mill, sieve to remove iron, press filter, rough smelt, stale, scouring, molding, drying, glazing, firing, inspection, packaging.

[0020] Add water ball mill to the blank according to material: ball: water=1.0: 2.0: 1.2 weight ratio and add water, ball milling time is 20 hours, ball milling fineness is less than 0.1% by sieve remaining 250 mesh, and sieve residue 325 mesh is less than 0.3%; The sieve is 200 mesh; the Gauss intensity of the iron removal is 10000 Gauss intensity, and it is continuously sieved for 3 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com