Branching conveying device for sheet-like materials

A transmission device and material technology, applied in the direction of transportation and packaging, packaging, pile separation, etc., can solve the problems of wrinkling and slipping of sheet materials, and achieve the effect of solving wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

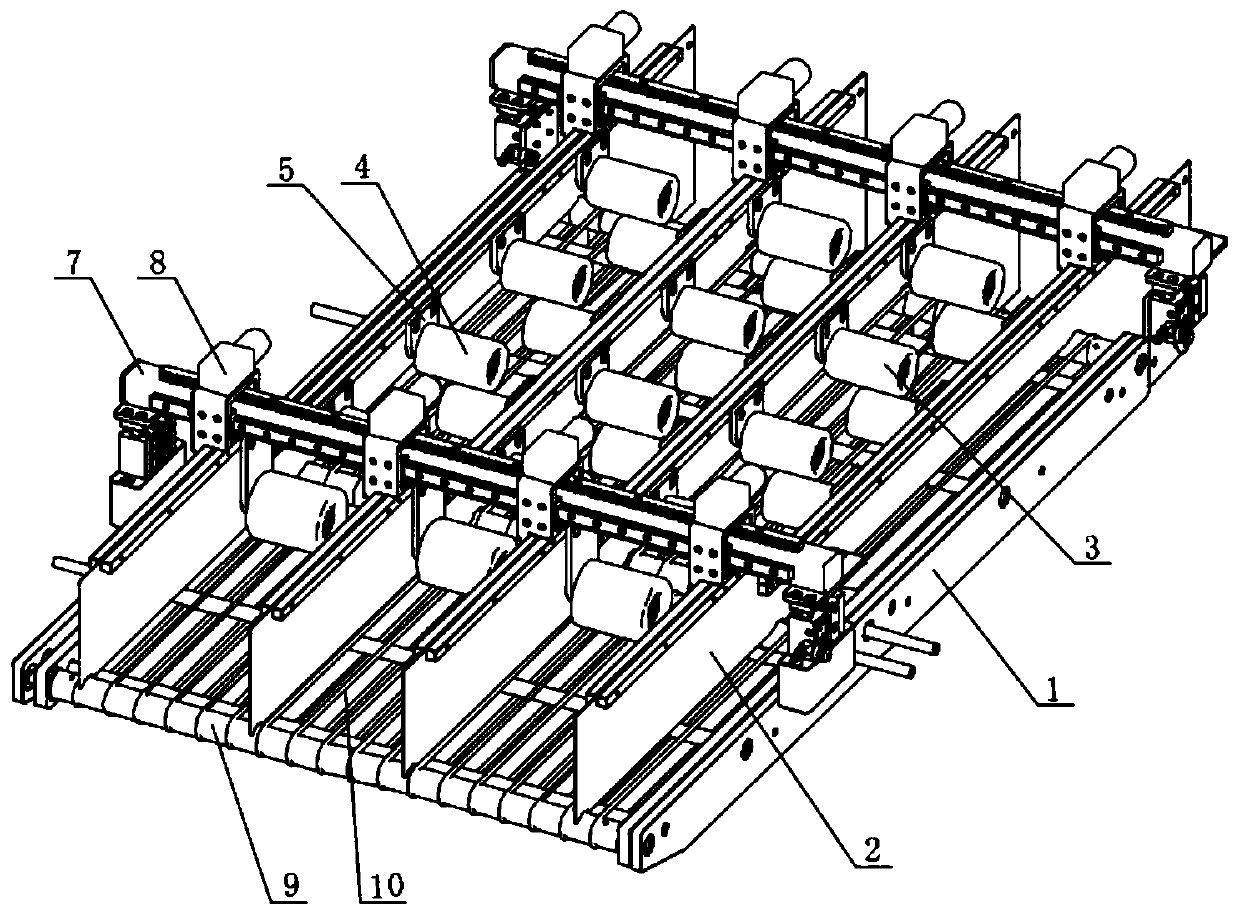

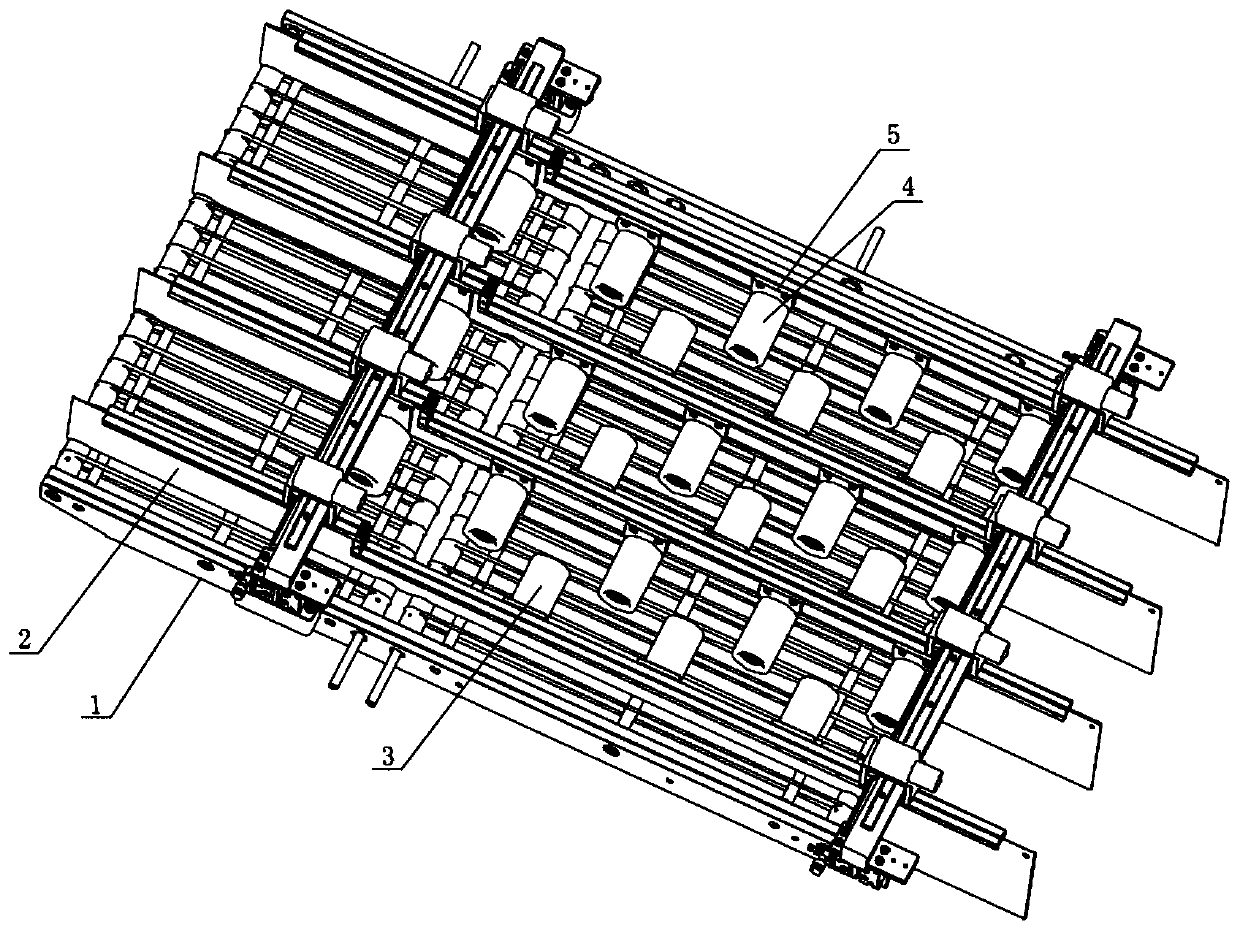

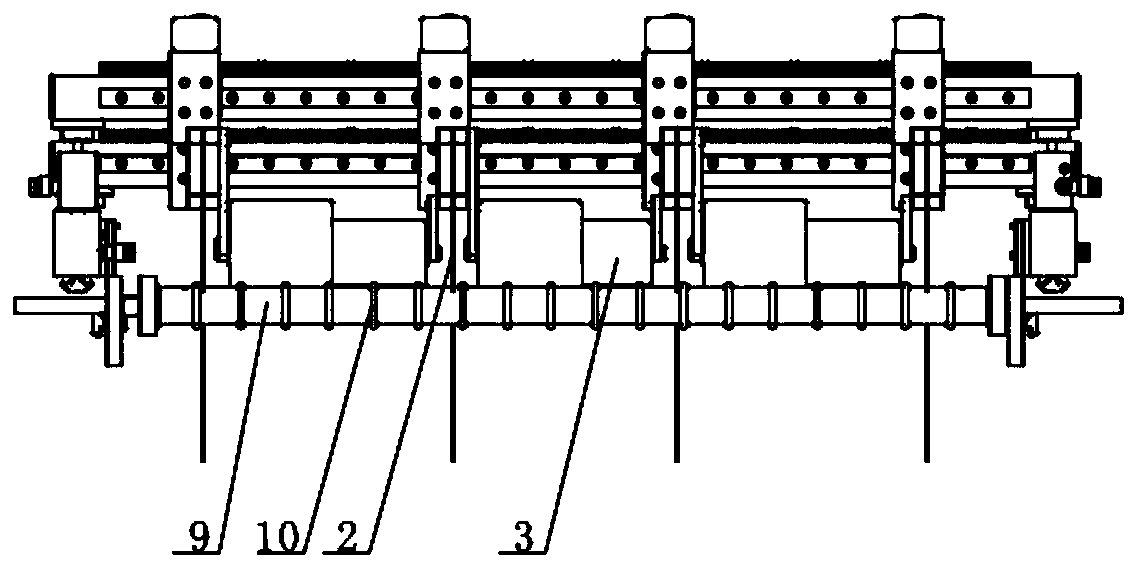

[0033] The branch transmission device of embodiment 1 such as Figure 1 to Figure 4 As shown, the branch transmission device includes a transmission mechanism 1 and a branch baffle 2, the branch baffle 2 is vertically arranged above the transmission mechanism 1 and the transmission direction of the branch baffle 2 and the transmission mechanism 1 In parallel, the shunt baffles 2 are arranged oppositely to separate the shunt transmission channel, and the pressure wheel assembly 3 is installed on the shunt baffle 2, and the pressure wheel assembly 3 is located in the shunt transmission channel for The conveying surface of the conveying mechanism 1 presses down the sheet material. When the sheet material is conveyed to the pressure wheel assembly 3, it is pressed and flattened by the pressure wheel assembly 3, which plays the role of auxiliary conveying and solves the problem of wrinkles and slippage during the conveying process of the sheet material. When adjusting the position ...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that the structure of the pressure wheel assembly is different: in embodiment 2, the pressure wheel assembly includes a pressure wheel and a pressure wheel belt, and the pressure wheel is installed on the shunt block through the pressure wheel mounting bracket On the board, the belt of the pinch wheel bypasses the pinch wheel, the belt of the pinch wheel is parallel to the transmission direction of the transmission mechanism, and the belt of the pressure wheel is close to or contacts the transmission surface of the transmission mechanism. The pressure roller assembly that the pressure roller and the pressure roller belt are formed is installed on the shunt baffle plate, which can also achieve the purpose of the present invention.

[0045] The pressure roller installation frame can adopt the structure and installation method similar to Embodiment 1, and the installation position of the pressure roller can move up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com