Silk-screen printing based plate-free hot-stamping process

A technology of screen printing and plate hot stamping, applied in printing, printing devices, etc., can solve problems such as cracks, wrinkles, and orange peels in the gold foil layer, and achieve the effect of solving cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The screen printing-based plateless bronzing process provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014]

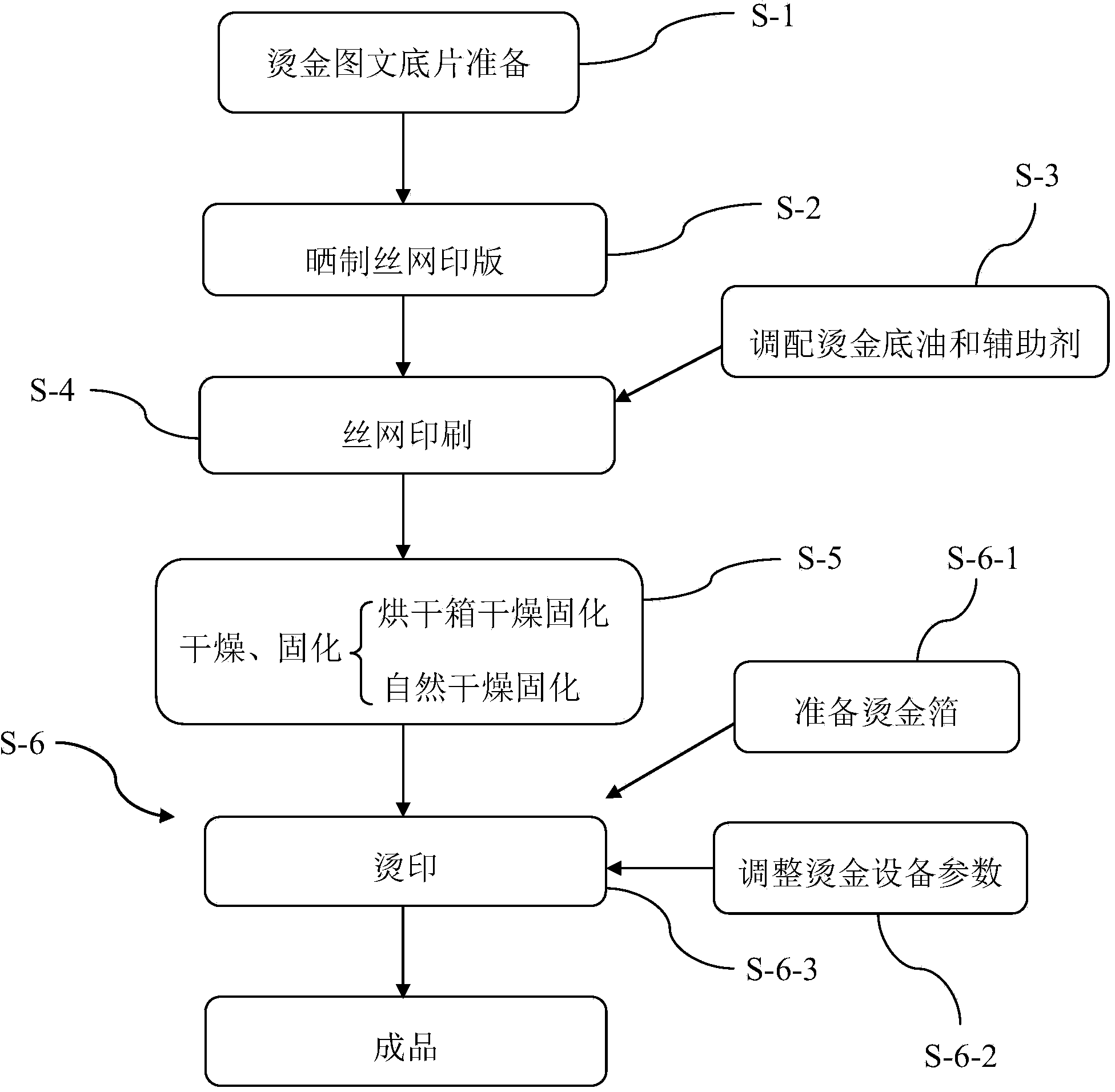

[0015] figure 1 It is a flow chart of the plateless bronzing process based on screen printing in the present invention.

[0016] Such as figure 1 As shown, the plateless bronzing process based on screen printing includes the following steps:

[0017] Step S-1, preparing a bronzing graphic negative. Bronzing pictures and texts can be large-area patterns and texts above size 5. The pattern is composed of solid bottom or lines, and the text font is not limited. The positive image negative is selected as the graphic negative, and the quality of the graphic negative must meet the quality requirements for screen printing.

[0018] Step S-2, making a screen printing plate. Choose a polyester net with a mesh number of 300 lines. The direct photosensitive plate-making method is used for the dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com