Automatic bending machine for flexible circuit board

A flexible circuit board and automatic bending machine technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as easy scratches on the outer surface, broken internal core wires, and wrinkles on flexible circuit boards, and reduce The risk of being broken, the effect of solving inner wall wrinkles and easy scratches on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

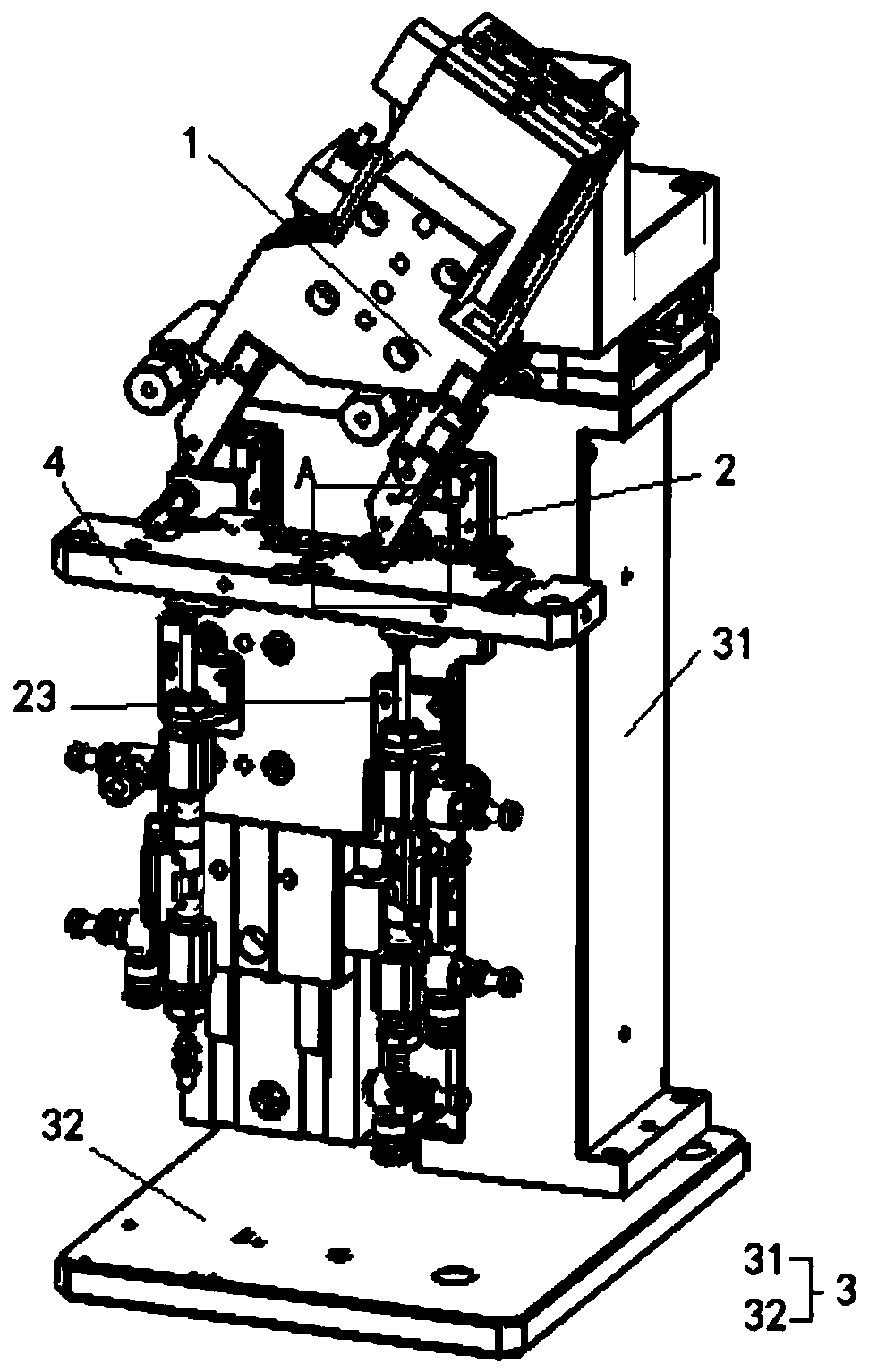

[0030] The following will combine Figure 1 to Figure 5 An automatic bending machine for flexible circuit boards provided by the present invention is described in detail. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are given. However, the present invention The scope of protection is not limited to the following embodiments, and those skilled in the art can modify and embellish it within the scope of not changing the spirit and content of the present invention.

[0031] Please refer to Figure 1 to Figure 5 , an automatic bending machine for flexible circuit boards, comprising:

[0032] Workbench 4, used to carry the flexible circuit board to be bent;

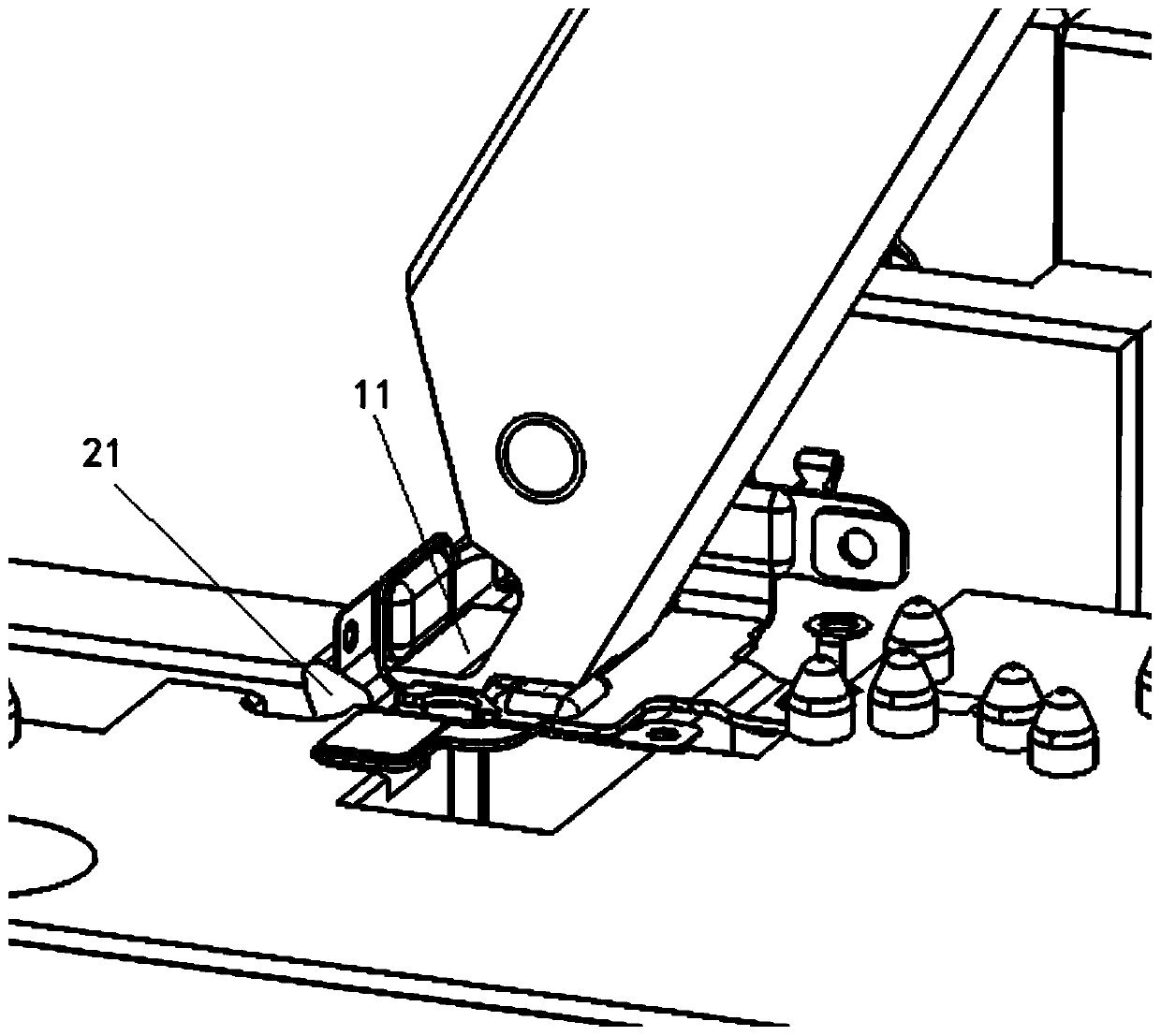

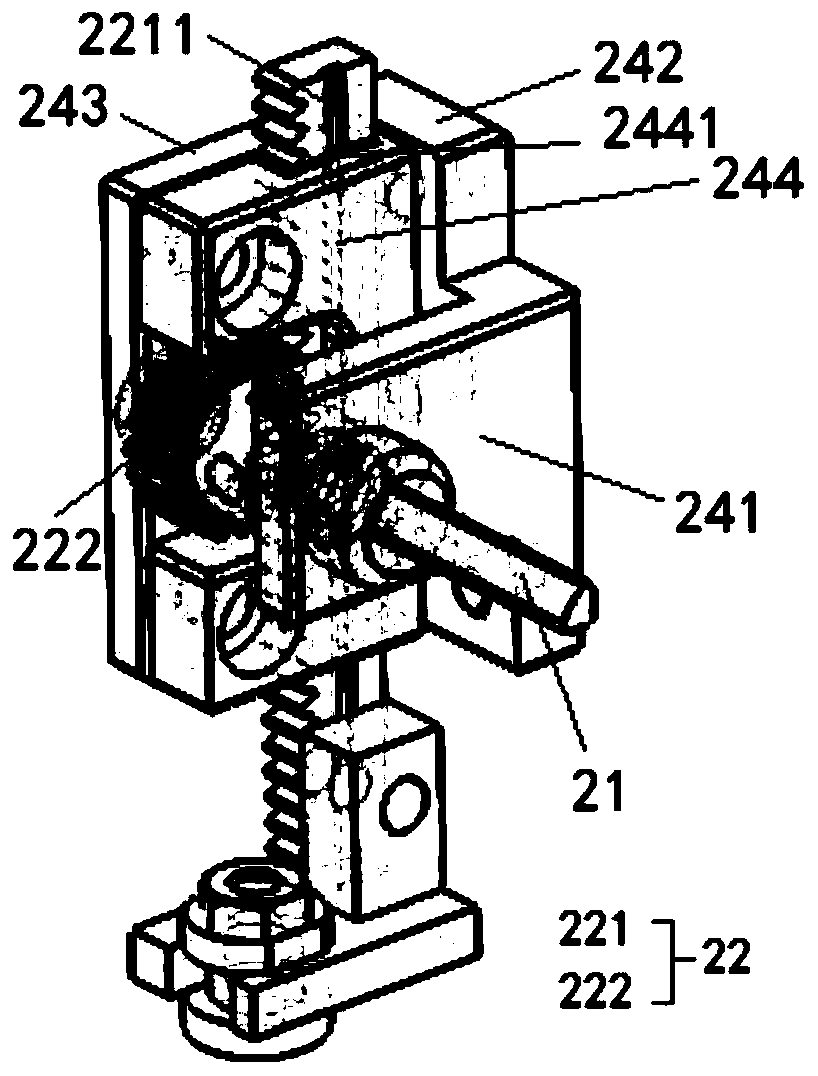

[0033] The upper knife pressing mechanism 1 includes an upper knife 11 and a first cylinder, and the upper knife 11 is connected to the first cylinder by driving; the upper knife 11 is located above the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com