Link tooth saw

A technology of chain saws and sprockets, which is applied in the direction of chain saws, sawing equipment, sawing machine devices, etc., which can solve the problems of increased manufacturing cost, increased number of parts, and poor operability of locking mechanisms, and achieves simple structure and cost suppression Ascending, sequentially simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described based on the drawings.

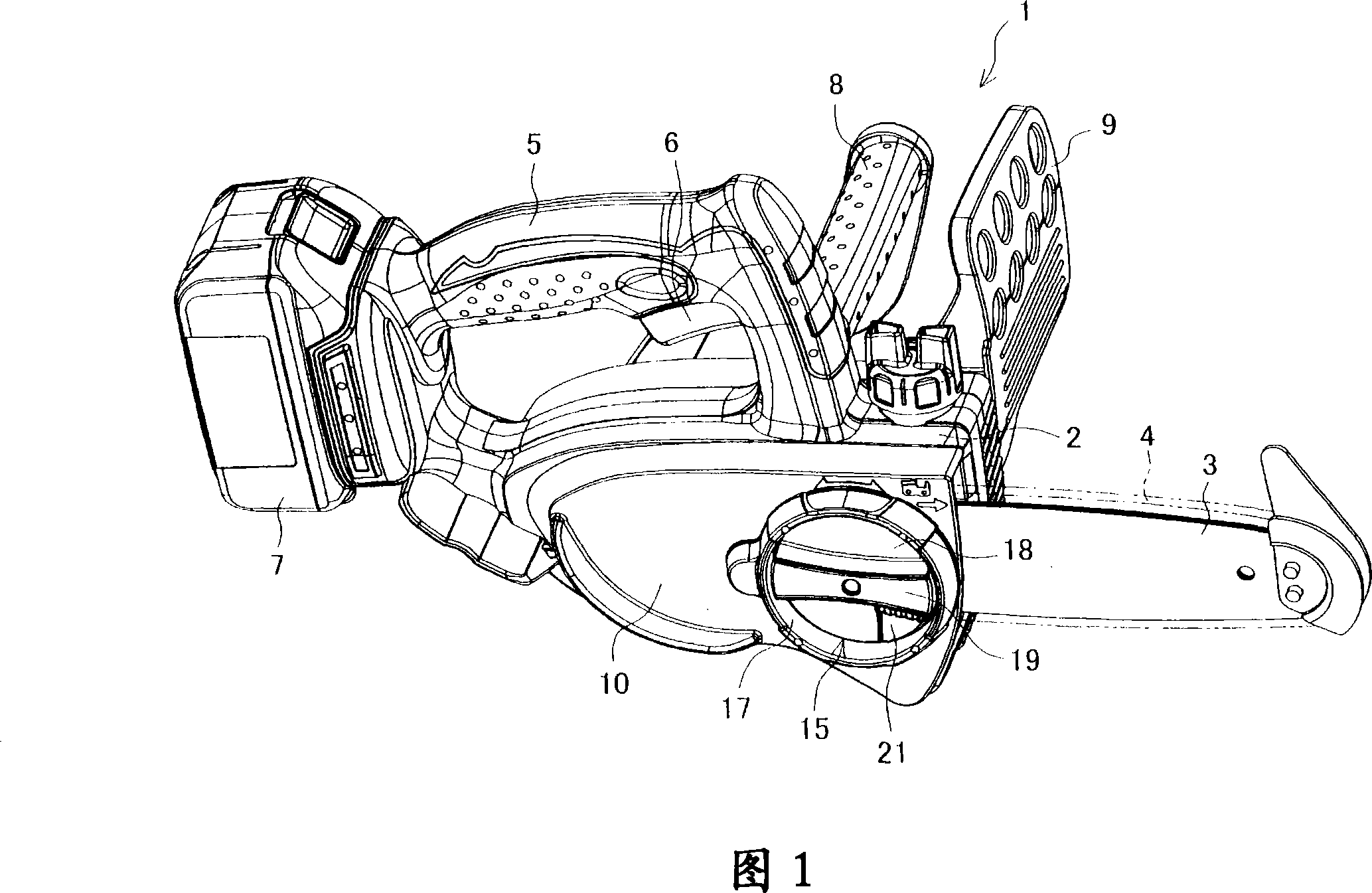

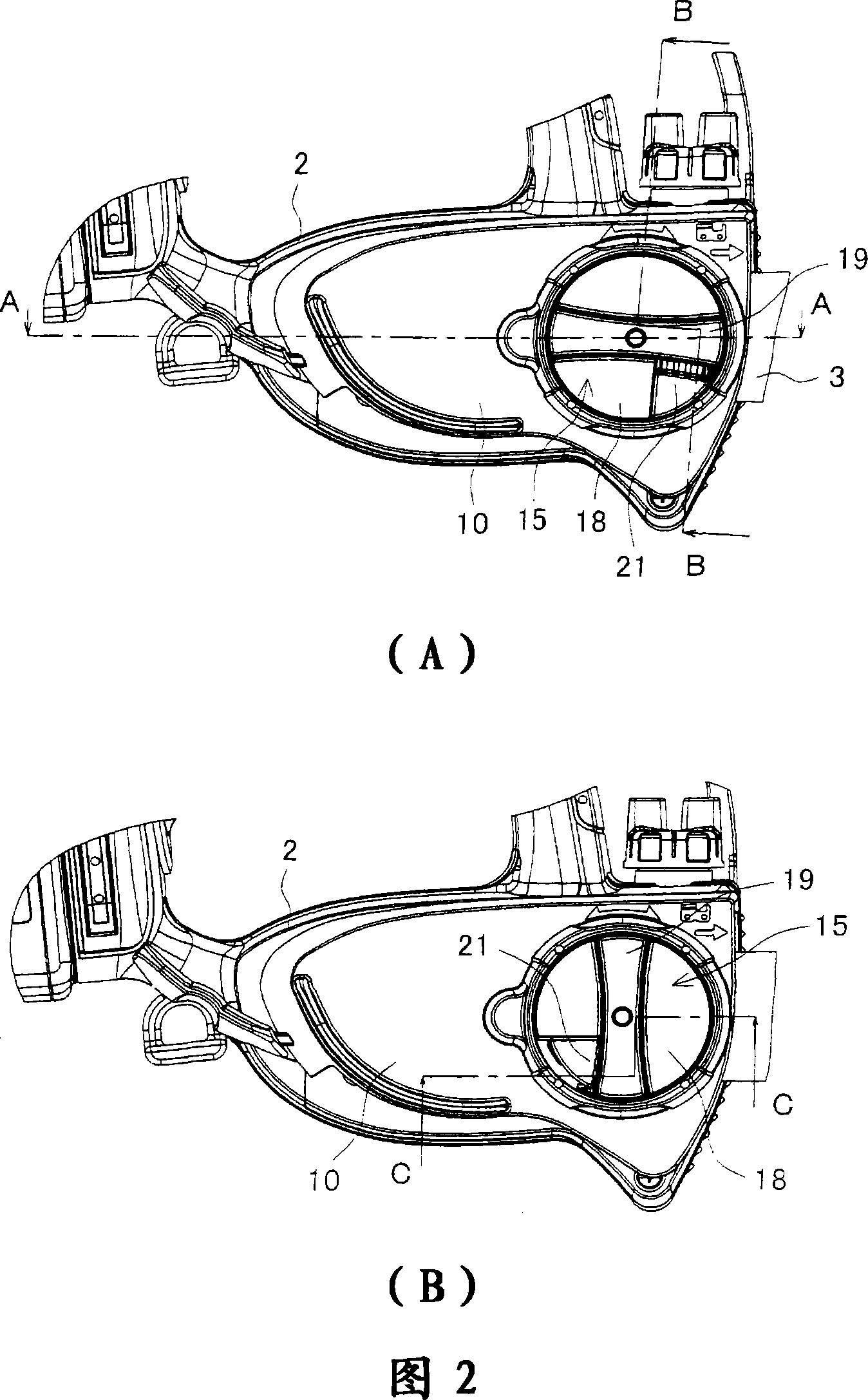

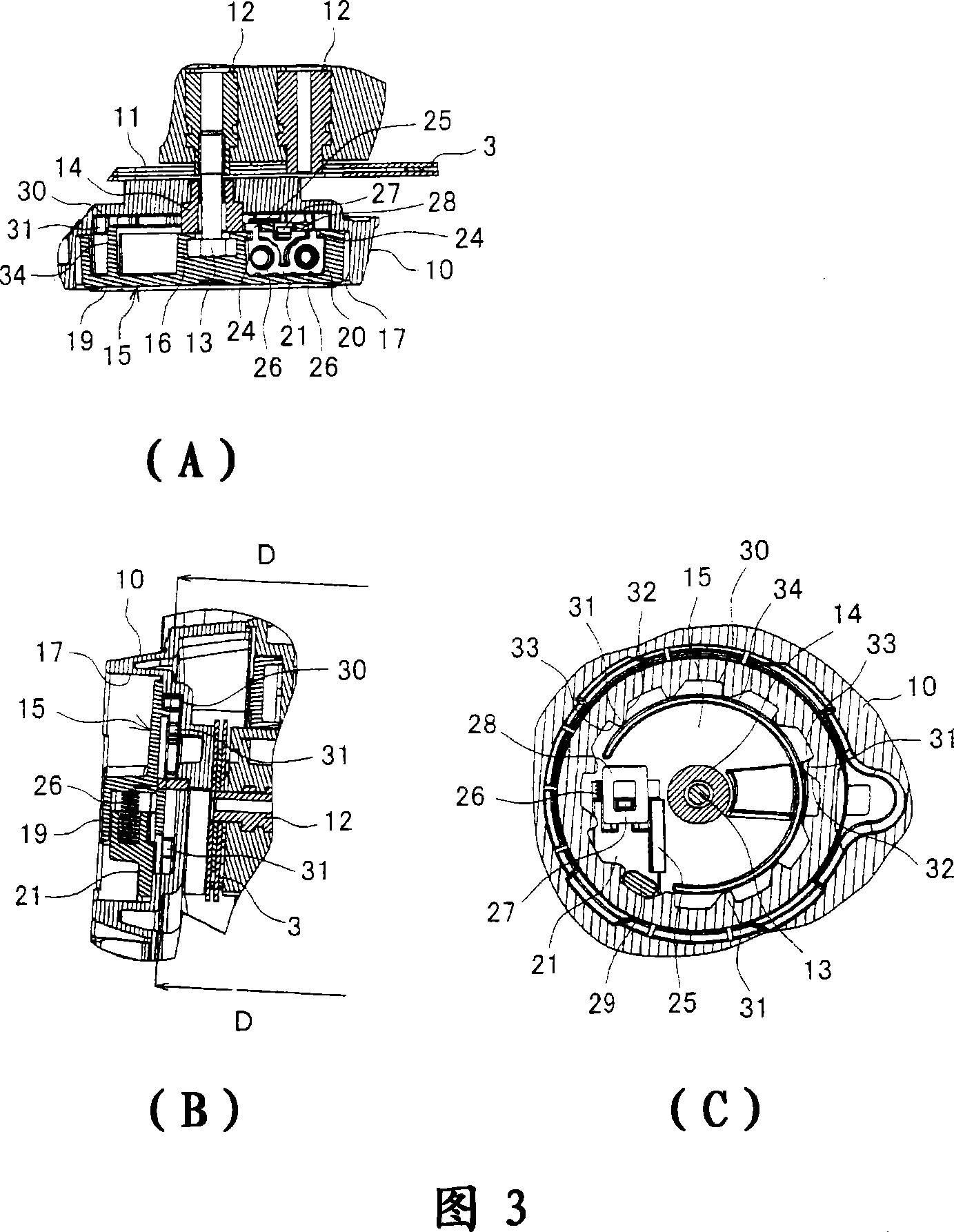

[0020] 1 is a perspective view showing an example of a chain saw. In this figure, the main body 2 of the chain saw 1 has a built-in motor and its speed reduction mechanism, and a sprocket and a guide plate 3 (not shown) are provided on the side of the main body 2. The sprocket is arranged on the output shaft of the reduction mechanism, and the guide plate 3 is in the shape of a long disc, which is in front of the sprocket (the right side in Fig. 1 ) and protrudes forward than the main body 2, and 3 sheets are wound around the sprocket and the guide plate. A saw chain 4 is provided, and the saw chain 4 is rotated along the periphery of the guide plate 3 along with the rotation of the sprocket, thereby cutting the object to be cut. A handle 5 is extended above the main body 2, a switch lever (trigger) 6 for switching the motor is provided on the handle 5, and a battery pack 7 as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com