Adjustable take-up and pay-off stand

An adjustable take-up and pay-off technology, which is applied in the field of adjustable take-up and pay-off racks, can solve problems that affect the smooth progress of production or engineering, waste of space in the reel workshop, and poor unwinding, so as to improve the scope of use and save space. , to avoid the effect of stretching damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

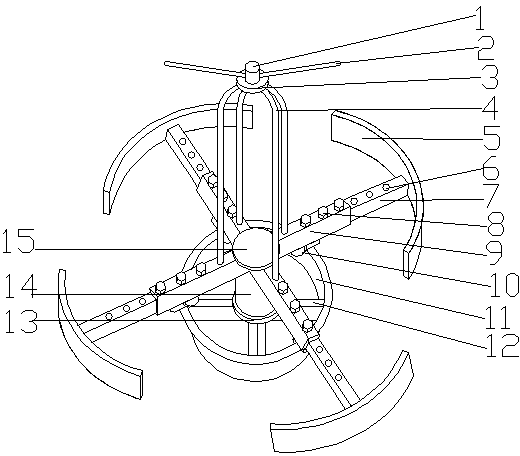

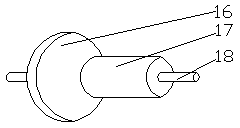

[0022] Such as figure 1 As shown, it includes a fixed part and a rotating part. The fixed part includes a first base 13, a fixed ring 11 and a first connecting rod 12, and the first connecting rod 12 is respectively fixed to the first base 13 and the fixed ring 11. The connection ensures the stability of the pay-off frame during the pay-off process. The rotating part includes a second base 15, a motor 14, a second connecting rod 9, a protective ring 5, a sleeve rod 7, a rotating frame 4, a fixed seat 3, a guide seat 1 and a guide rod 2, and the motor 14 is positive and negative Rotating motor can realize the two operating processes of the present invention, wire take-up and pay-off, and improve its utilization value; and it is located on the upper end of the first base 13, and is fixedly connected with the second base 15, and the motor 14 acts as a motor. Drive the second base 15, control the rotation and stop of the rotating part, realize active wire release, greatly avoid ...

Embodiment 2

[0026] Same as embodiment 1, the difference is that there are 3 guide rods 2, 5 first connecting rods 12 and 5 second connecting rods 9, which can ensure the load of the rotating part and more effectively prevent falling off. line occurrences.

Embodiment 3

[0028] Same as embodiment 1, the difference is that there are 4 guide rods 2, 6 first connecting rods 12 and 6 second connecting rods 9, which can greatly increase the load of the rotating part and expand its application range. And more effectively prevent the occurrence of off-line and winding phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com