Adjustable pay-off stand

An adjustable pay-off rack technology, which is used in the delivery of filamentous materials, thin material handling, transportation and packaging, etc., can solve problems that affect the smooth progress of production or engineering, waste of space in the reel workshop, and tensile damage. Achieve the effect of simple structure, save space and avoid stretching damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

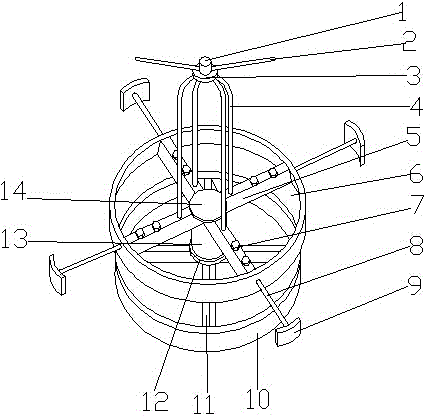

[0020] In addition, the swivel frame 4 is located between 1 / 3 and 1 / 4 of the upper end surface of the second connecting rod 5 from the side of the second base 14, which ensures that the present invention can be placed to a greater extent. More wires also ensure the pay-off effect. There are 2 guide rods 2, 4 first connecting rods 11 and 4 second connecting rods 5, and at least 2 screws 7 are arranged in the screw holes on the second connecting rod 5, so that The increase of the stress point of the strut 8 and the increase of the force range greatly increase the stability of the strut 8 in the through hole provided on the second connecting rod 5, and can improve the stability of the strut 8. 8 load, not easy to deform. The guard plate 9 is an arc-shaped plate, its inner diameter is equal to the outer diameter of the protective ring 6, and its upper end surface is 5-10 cm higher than the pole 8 fixed in the middle, and the guard plate 9 effectively avoids The wire material br...

Embodiment 2

[0024] Example 3

Embodiment 3

[0026] The above schematically describes the present invention and its implementation, which is not restrictive, and what is shown in the drawings is only one of the implementations of the present invention, and the actual structure is not limited thereto. Therefore, if a person of ordinary skill in the art is inspired by it, without departing from the inventive concept of the present invention, without creatively designing a structural mode and embodiment similar to the technical solution, it shall all belong to the protection scope of the present invention .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com