Fuse for detecting failure of gas trap

A fuse and air trap technology, applied in the field of existing devices, can solve the problems of complex and expensive gas sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

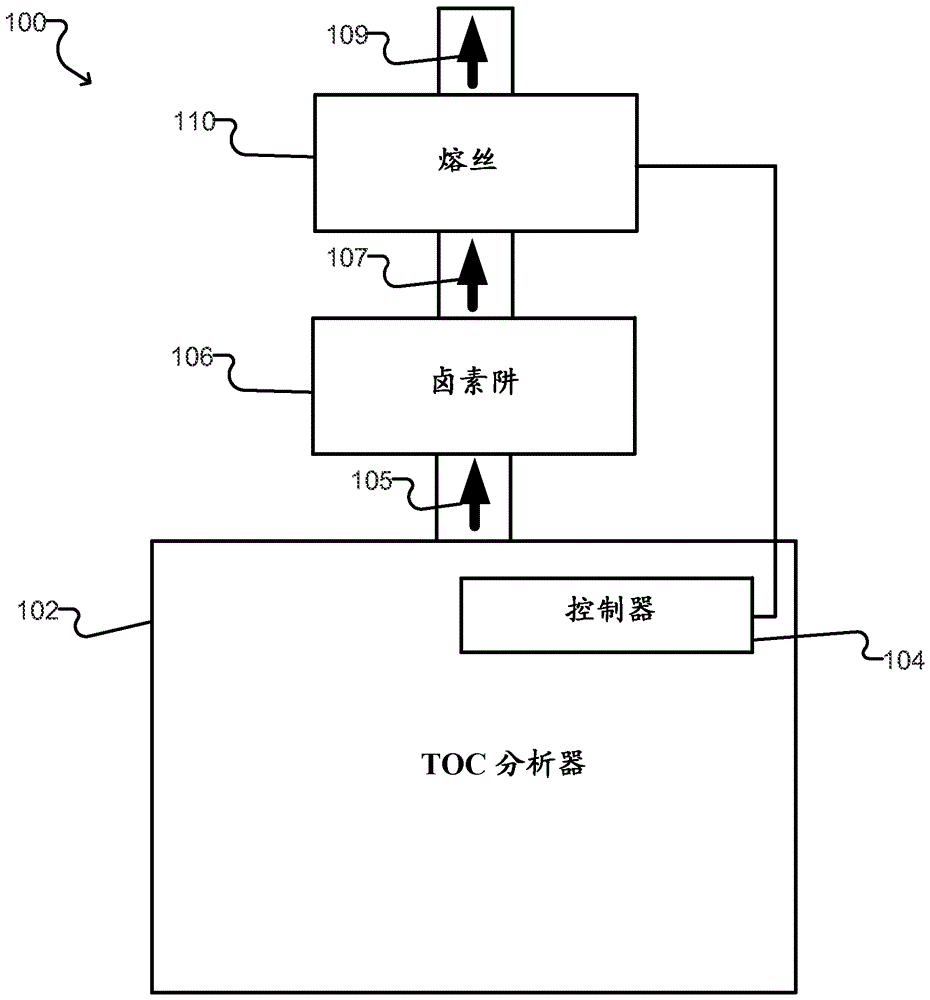

[0016] figure 1 An example system 100 is shown that includes a gas detection fuse 110 according to one embodiment. The system 100 includes a TOC analyzer 102, which may be any suitable sample analyzer as known in the art. TOC analyzer 102 generates exhaust gases 105 as it analyzes a sample, and these exhaust gases are directed to halogen trap 106 . The halogen trap 106 may, for example, comprise a bed of activated carbon. The halogen trap 106 typically absorbs the halogen gas so that the gas 107 exiting the trap 106 is substantially free of halogen. However, once trap 106 is saturated, or if trap 106 fails, gas 107 may contain chlorine or other halogen gas. After passing through trap 106 , gas 107 contacts gas detection fuse 110 and is then exhausted through outlet 109 to the surrounding environment.

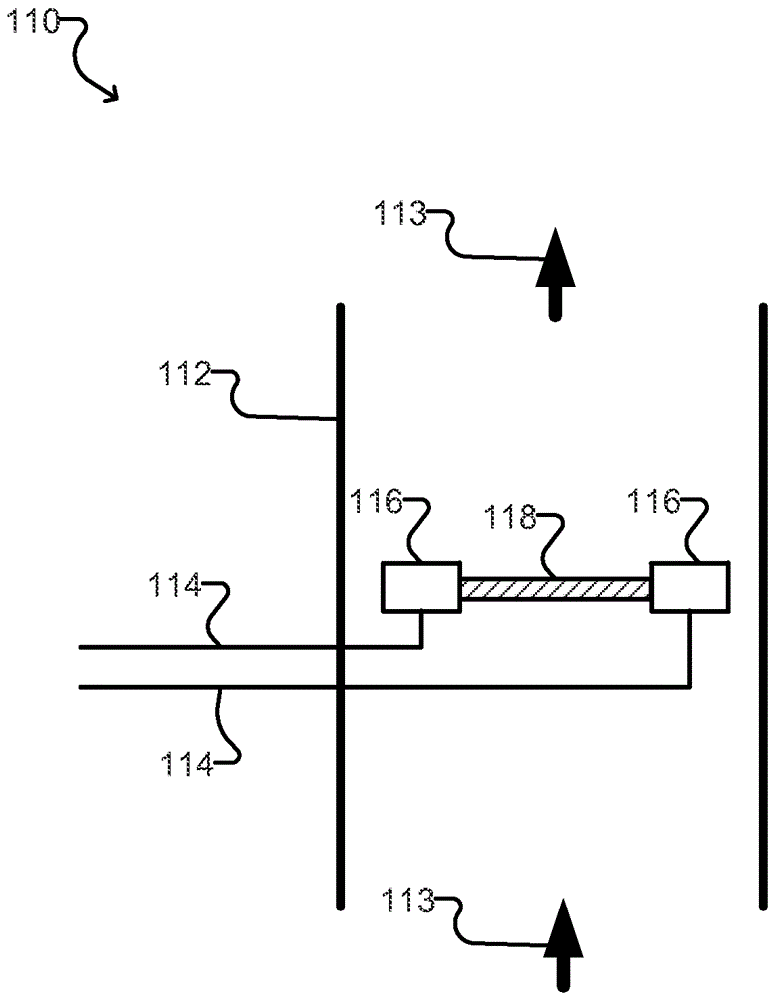

[0017] As described further below, the fuse 110 includes a connection member of a conductive material connected between two electrodes. The conductive material is selected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com