Cut section storage device for tent cloth processing

A storage device and tent fabric technology, applied in the field of tents, can solve the problems of inability to guide fabrics of different thicknesses, increase the labor intensity of staff, and inability to quickly cut tent fabrics, etc., to achieve convenient operation, avoid excessive feeding, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

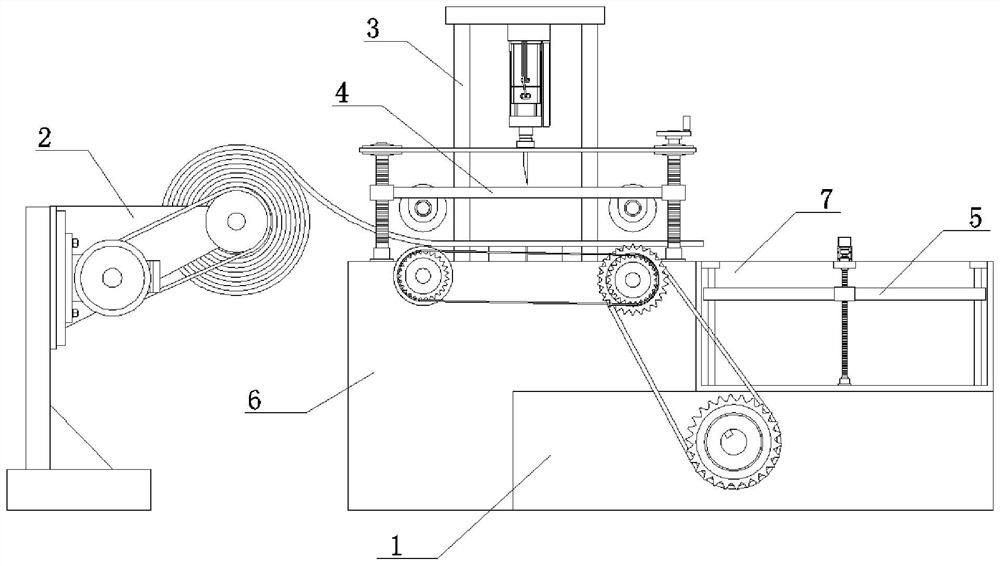

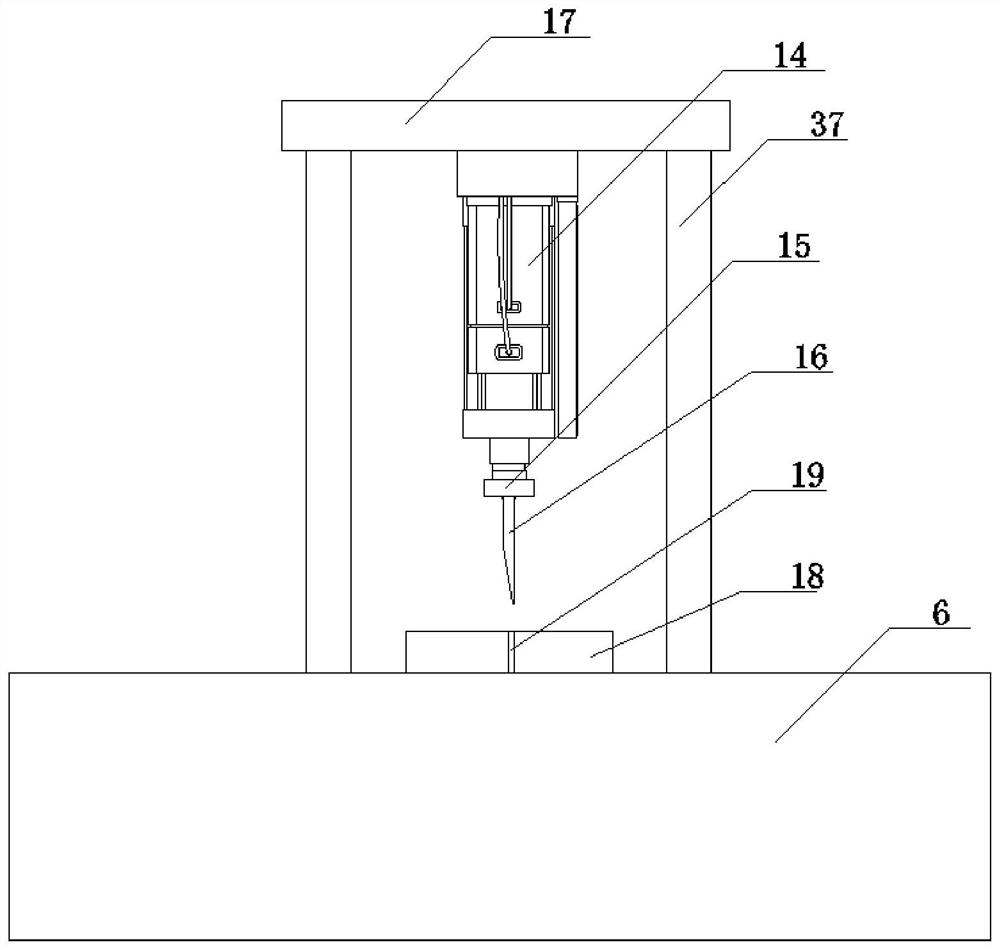

[0037] A cutting section storage device for tent fabric processing, comprising a machine base 1, including a discharge mechanism 2, a cutting mechanism 3, a material guide mechanism 4 and a storage mechanism 5, and a workbench 6 and a storage tank are fixedly connected to the machine base 1 7. The cutting mechanism 3 and the material guiding mechanism 4 are arranged on the upper end of the workbench 6, and the storage mechanism 5 is arranged in the storage groove 7.

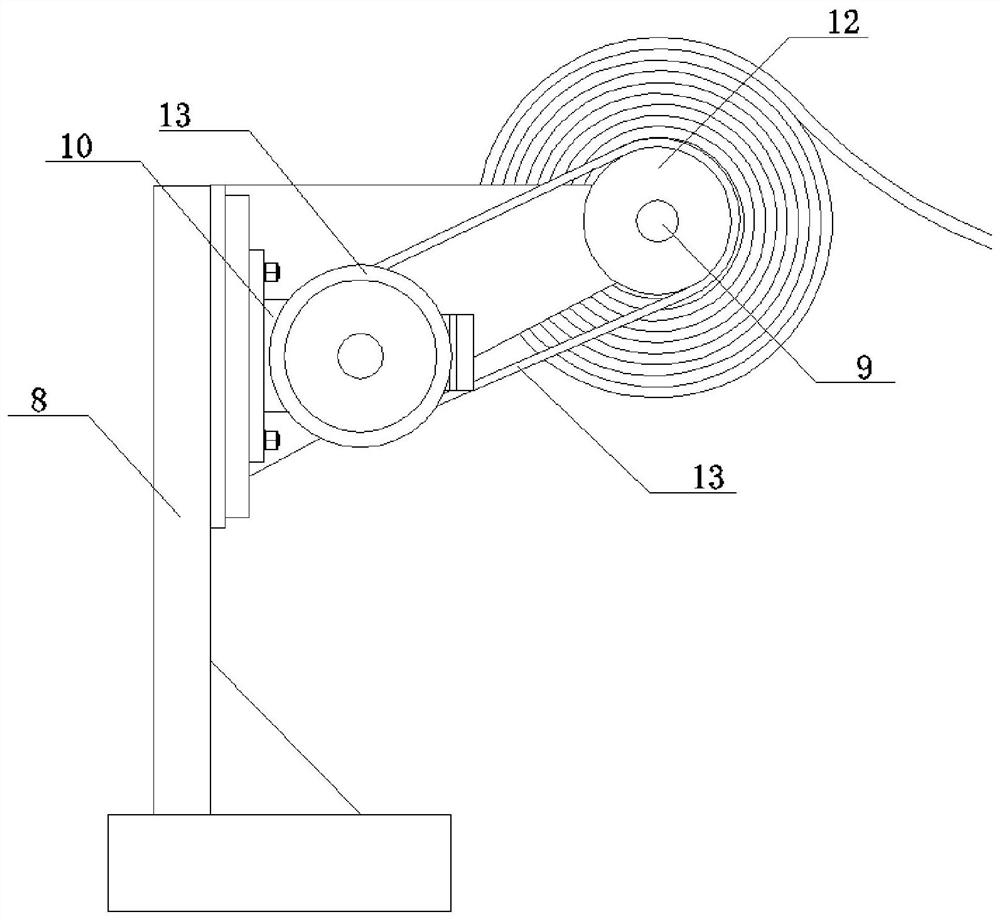

[0038] Wherein, the discharge mechanism 2 comprises a fixed frame 8, and one side of the upper end of the fixed frame 8 is rotatably connected with a discharge roller 9, and one end of the discharge roller 9 is connected to the output shaft of the discharge motor 10 through a belt transmission mechanism, and the discharge motor 10 is fixed in fixed frame 8; Belt transmission mechanism-comprises driving pulley-11 and driven pulley-12, and driving pulley-11 is fixedly connected to an end of discharge roller 9, and d...

Embodiment 2

[0043] A section storage device for tent cloth processing, the specific operation method is as follows:

[0044] Step 1, the tent cloth is rewound by the unwinding roller 9, and one end of the tent cloth is passed through the guide mechanism;

[0045] Step 2, turn the rocker 30, drive a screw rod 29 to rotate through the rocker 30, and drive another screw rod 29 to rotate synchronously through the belt transmission mechanism, and the two screw rods 29 drive the upper guide through the moving seat 31 The material roller 20 is in contact with the upper surface of the tent fabric;

[0046] Step 3, start the drive motor to drive the drive shaft 21 to rotate, and drive a lower guide roller 20 to rotate through the chain transmission mechanism 2, and drive the two lower guide rollers 20 to rotate synchronously through the chain transmission mechanism 1, and the two lower guide rollers The roller 20 drives the tent cloth to guide the material, and at the same time, the discharge mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com