Patents

Literature

52results about How to "Avoid imprints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

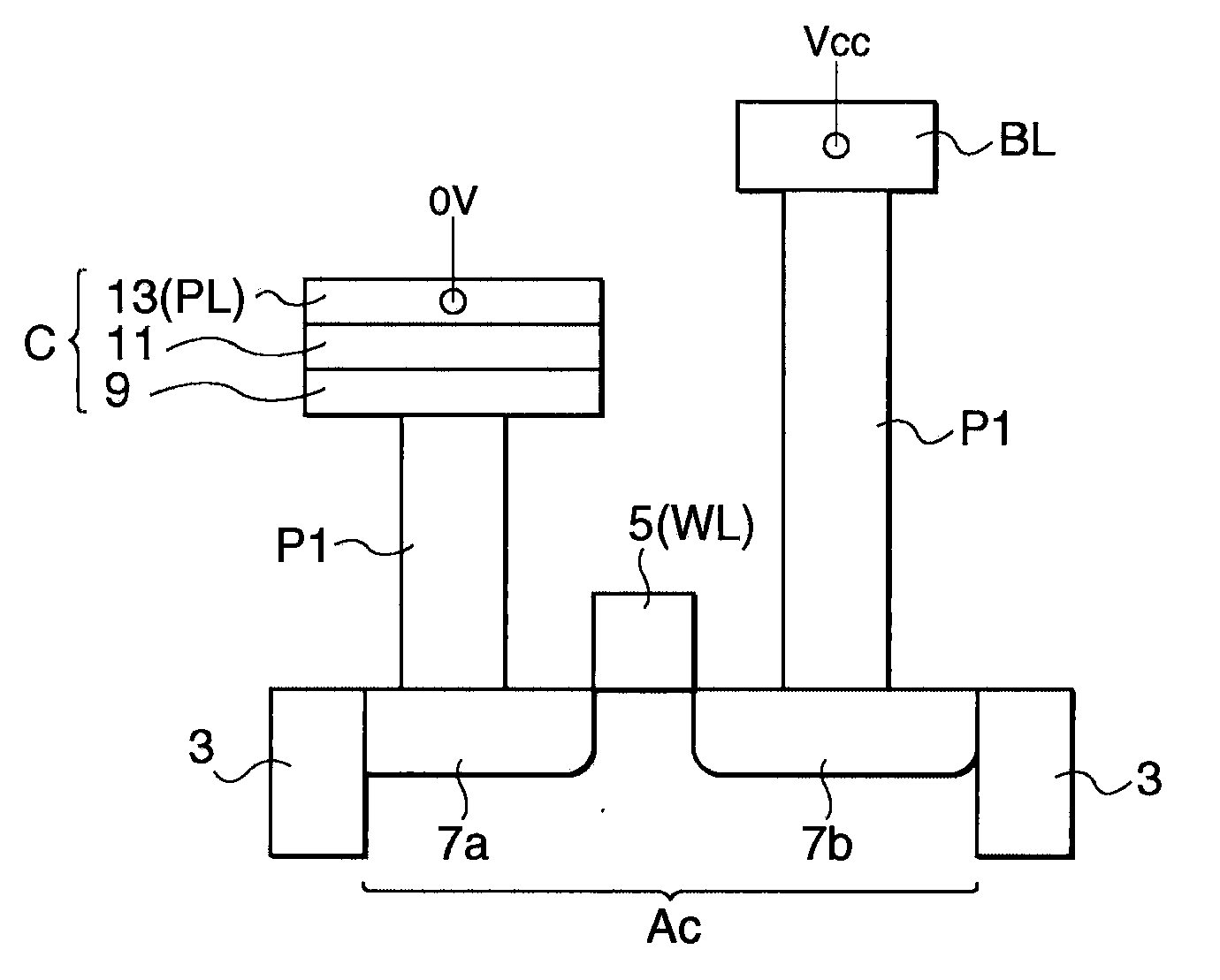

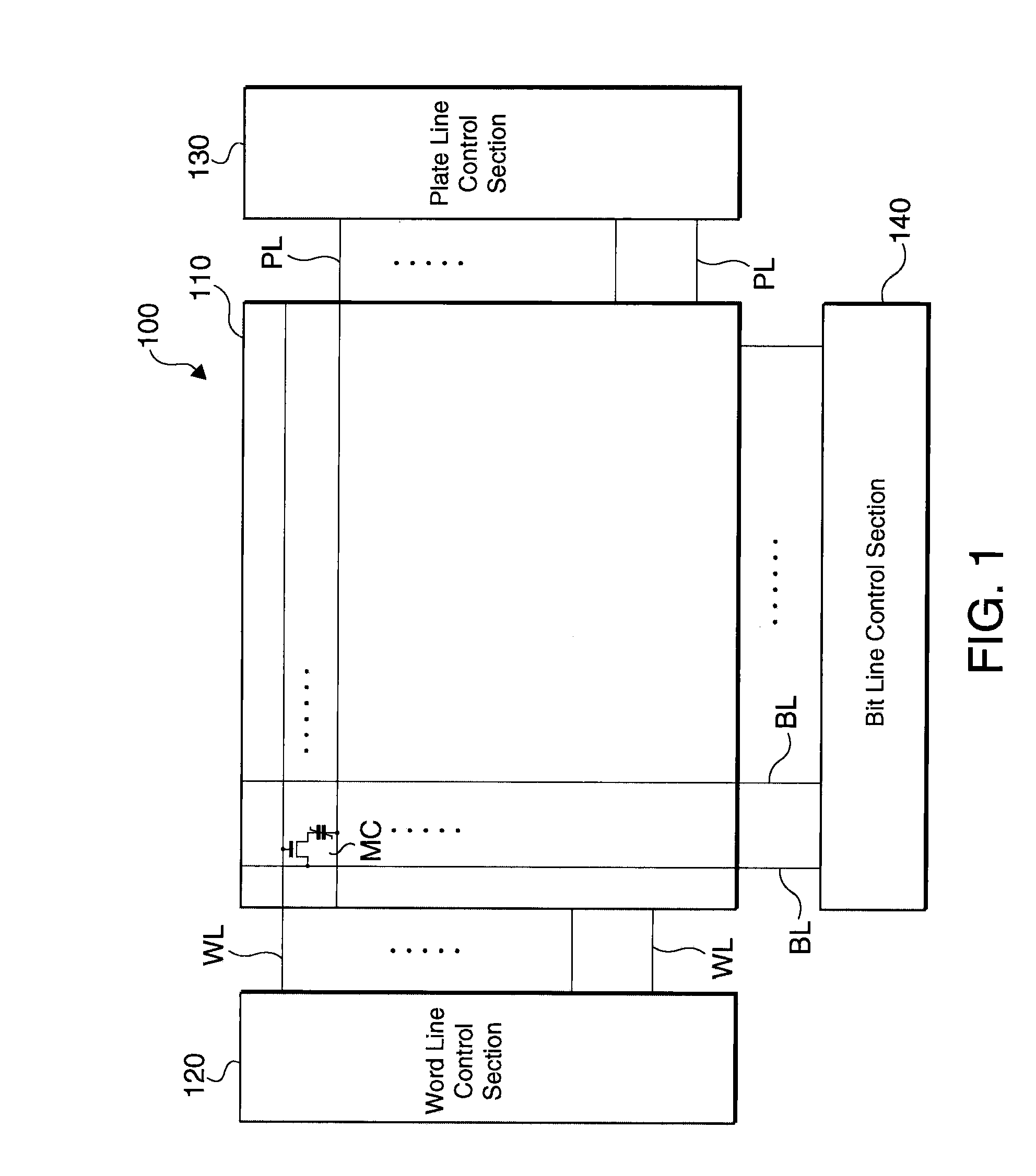

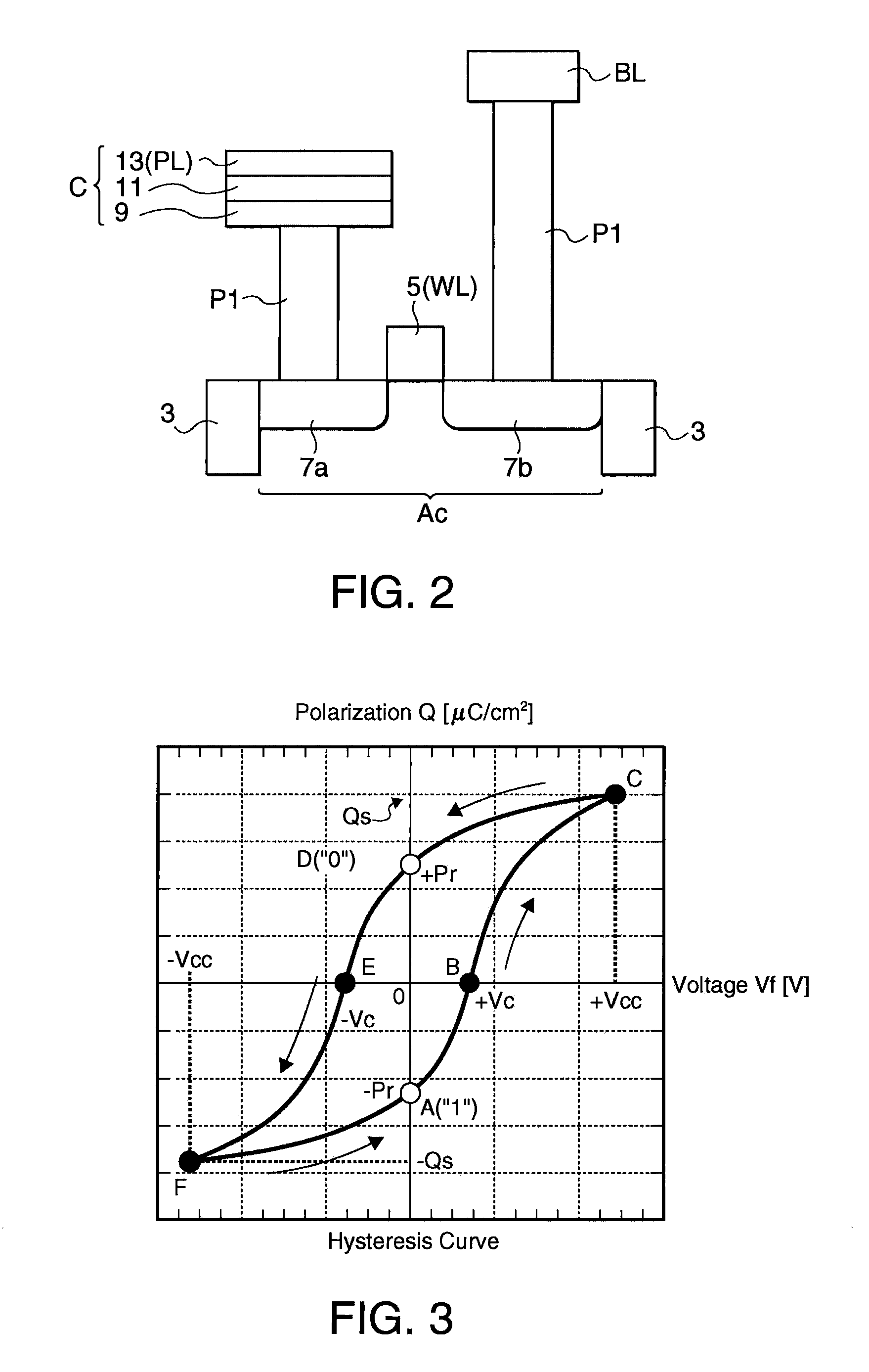

Method for initializing ferroelectric memory device, ferroelectric memory device, and electronic equipment

InactiveUS20100025747A1Reduce impactAvoid imprintsSolid-state devicesSemiconductor/solid-state device manufacturingComputer scienceElectron

A method for initializing a ferroelectric memory device is provided. The method includes the steps of: packaging a ferroelectric memory device having memory cells arranged in an array, each of the memory cells having a ferroelectric film disposed between a lower electrode and an upper electrode; applying a potential between the lower electrode and the upper electrode in an examination step; and after the examination step, applying a first potential to the upper electrode and applying a second voltage higher than the first potential to the lower electrode, and thereafter conducting a heat treatment at a first temperature higher than an operation guarantee temperature.

Owner:SEIKO EPSON CORP

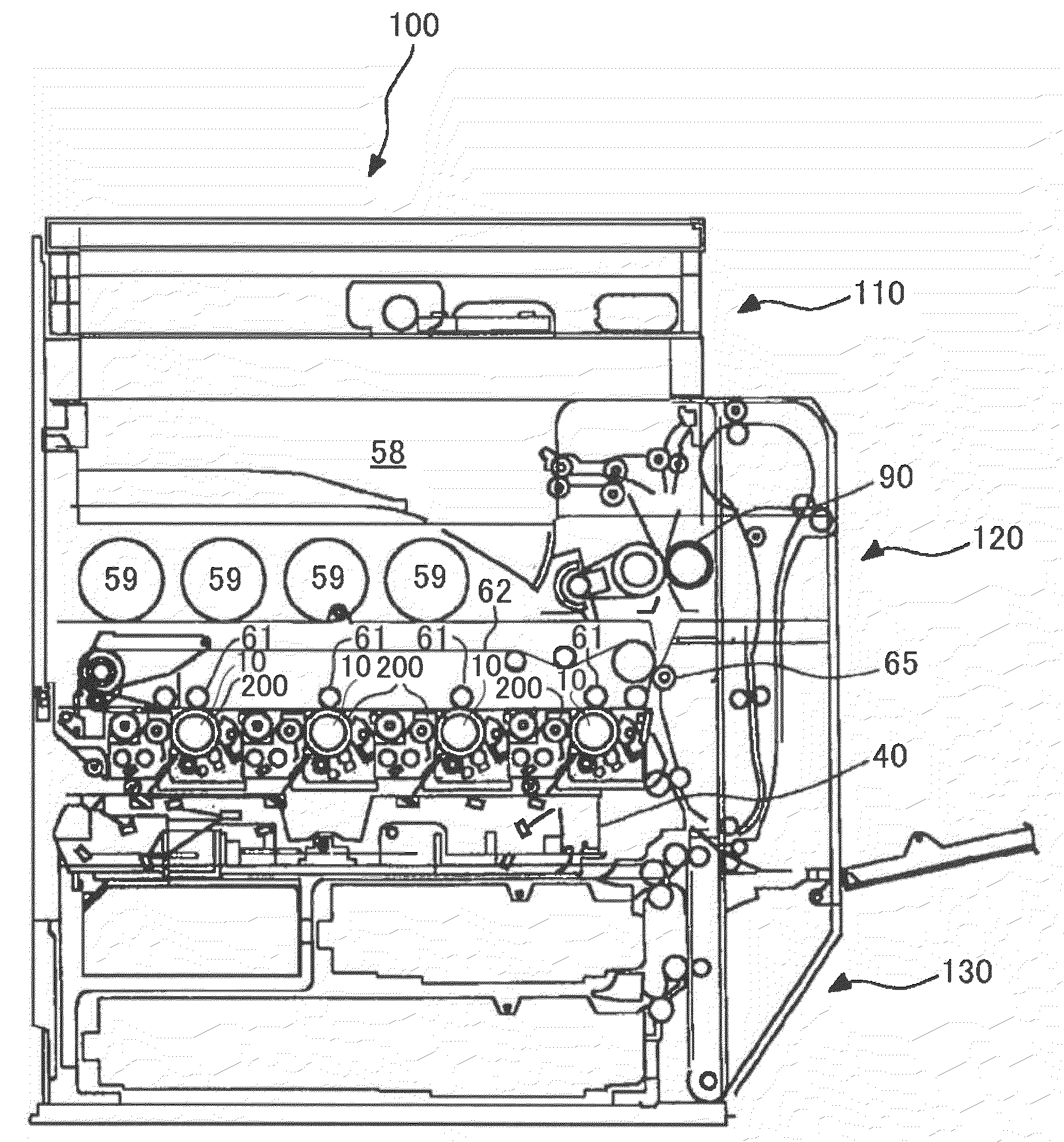

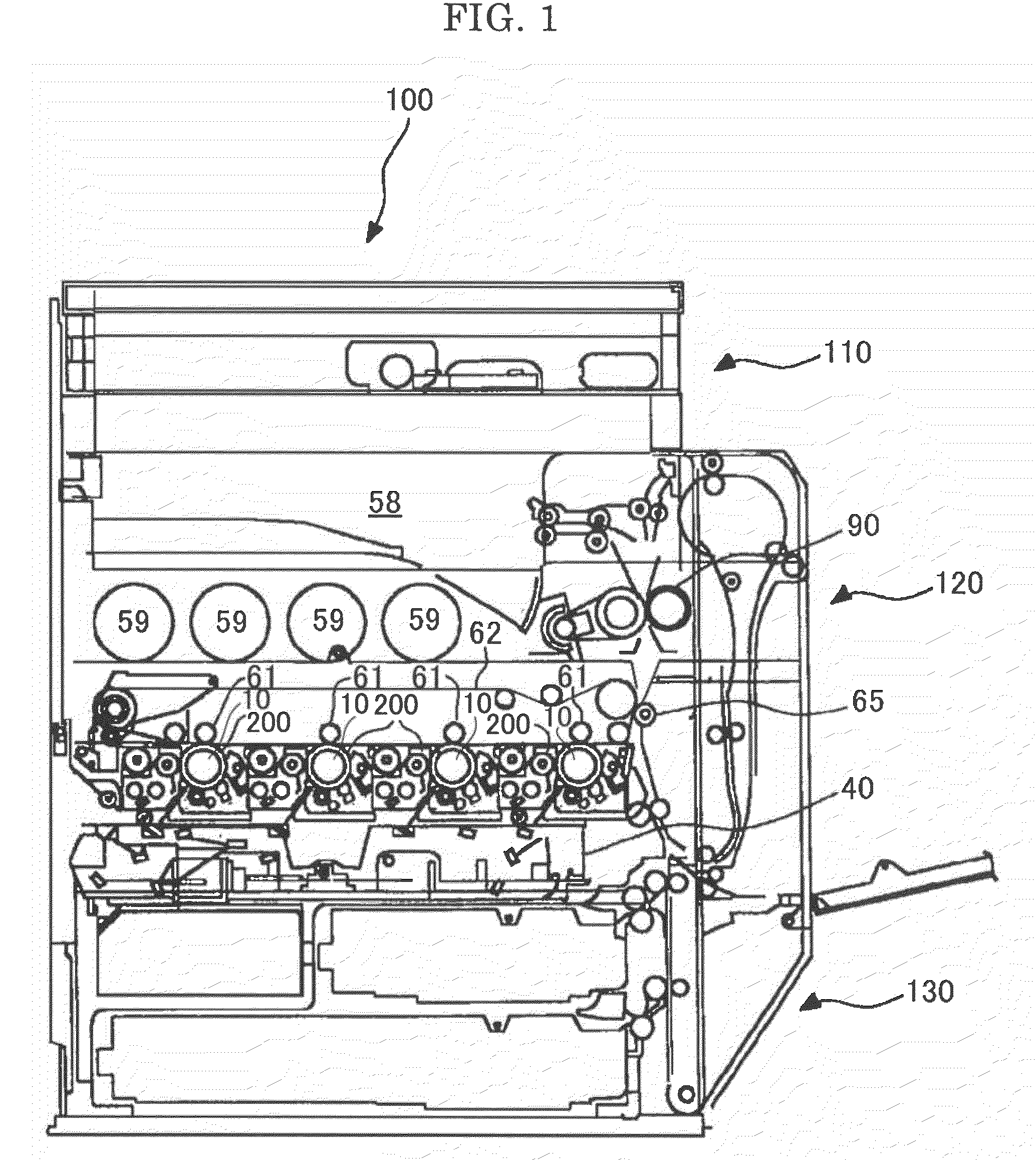

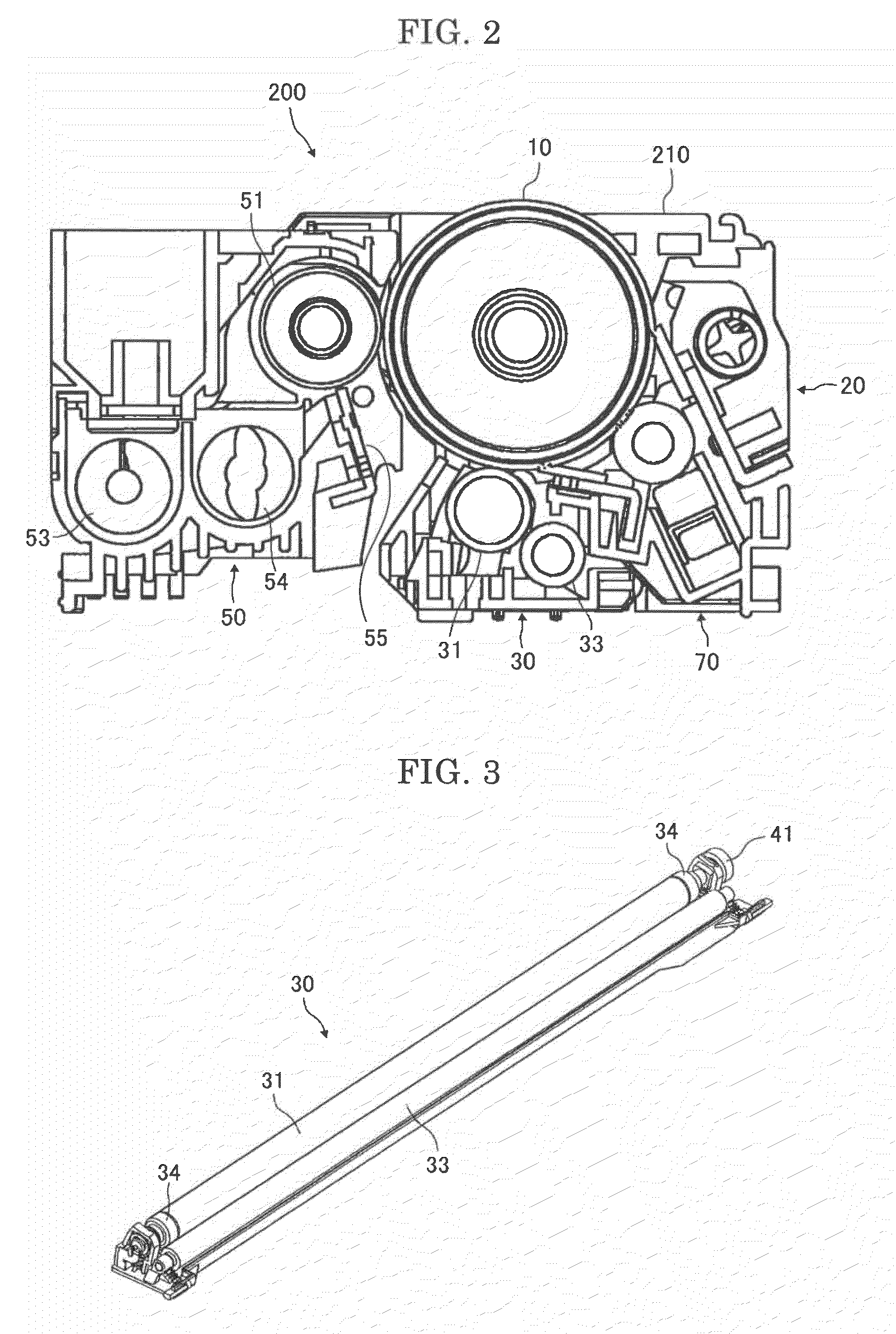

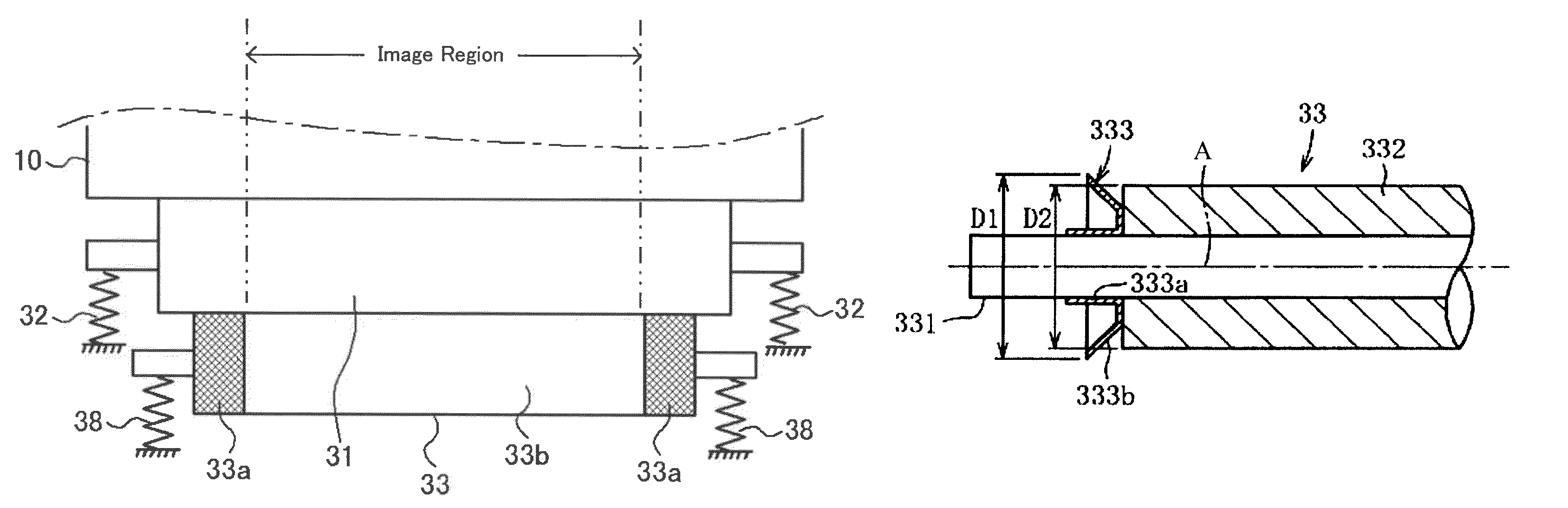

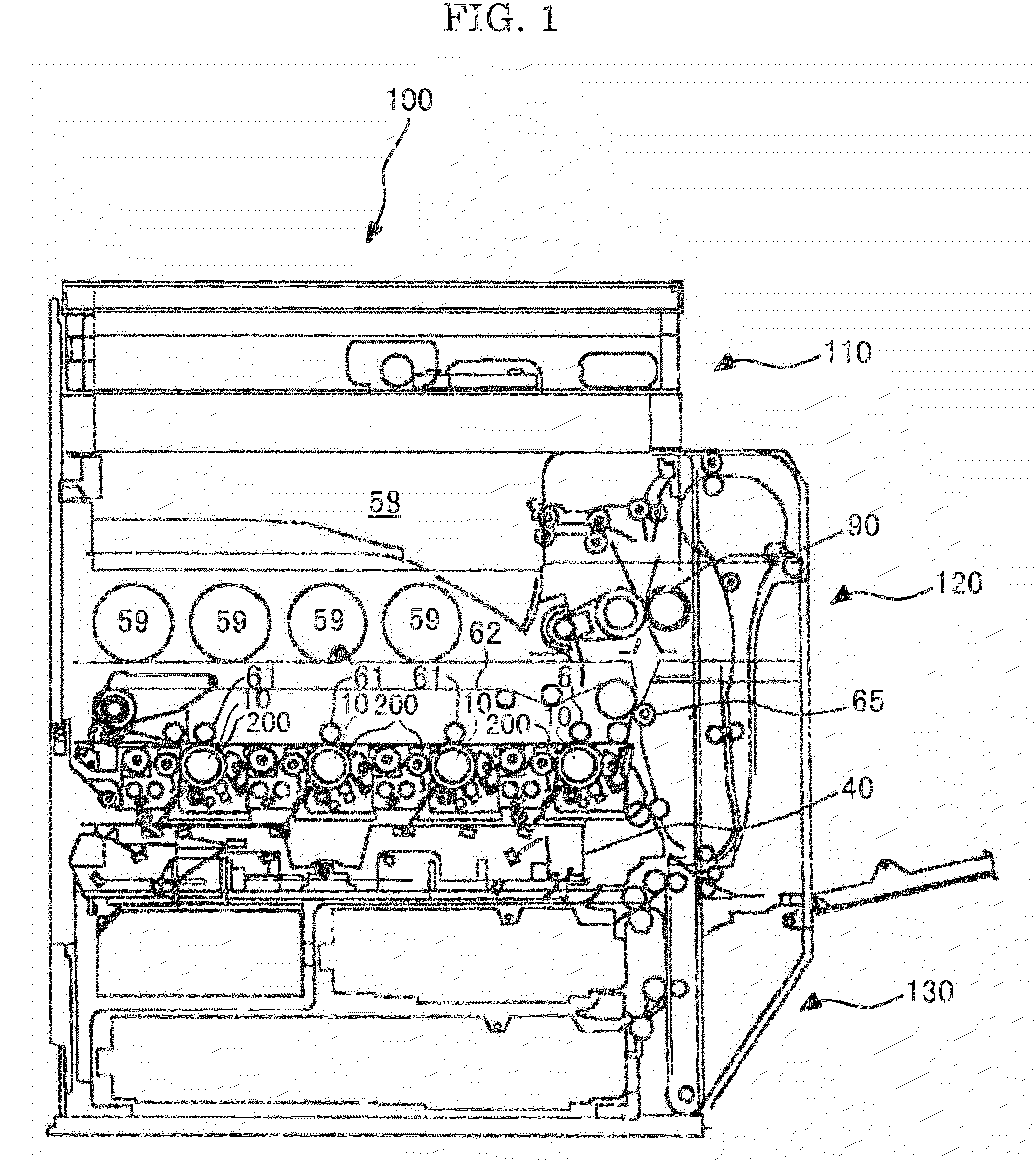

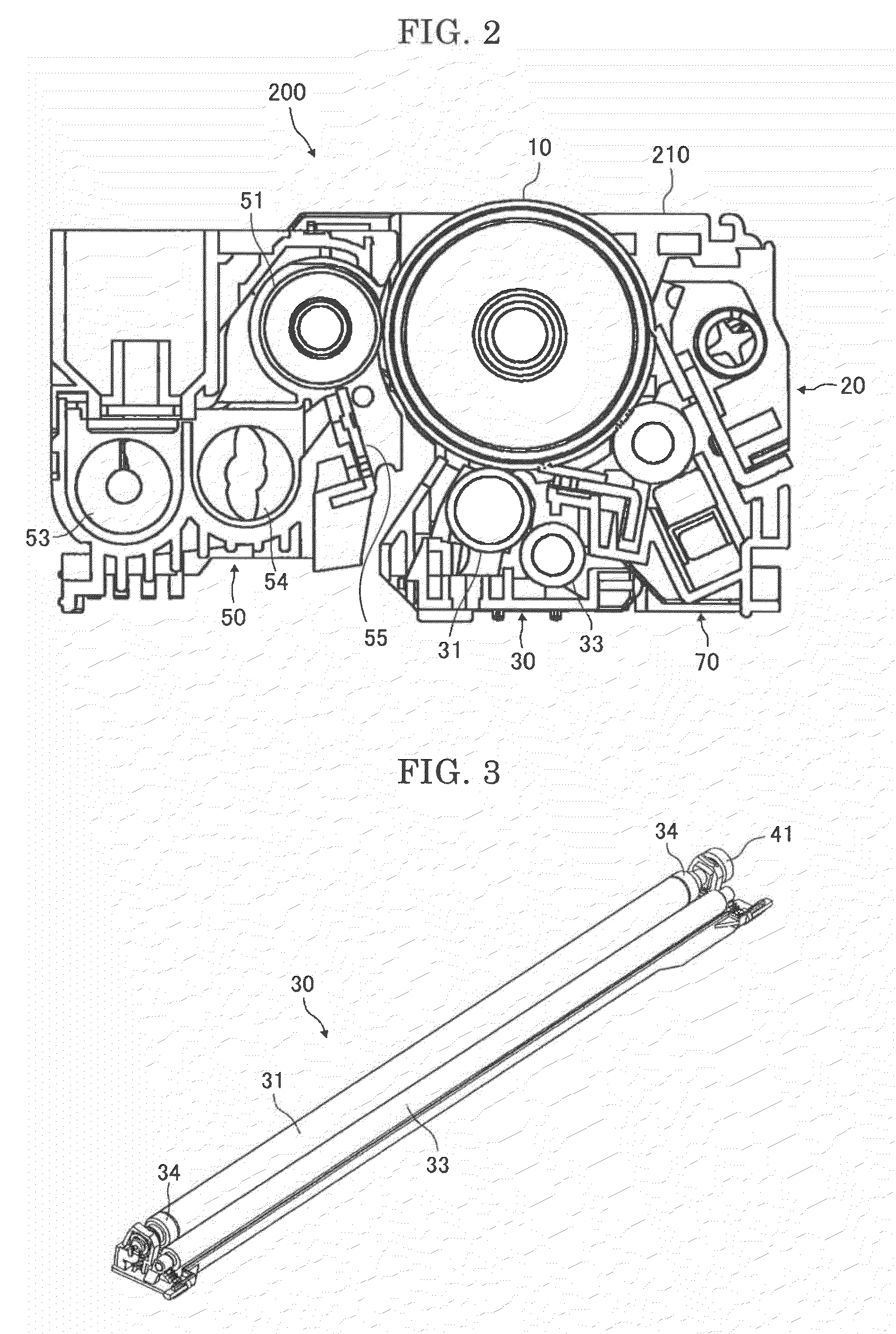

Cleaning member, charging device, process cartridge, and image forming apparatus

InactiveUS20090297206A1Good cleanabilityImage can be preventedBrushesWork treatment devicesEngineeringMechanical engineering

A cleaning member including a core bar, an elastic coating layer, and high-friction coefficient parts provided on both ends of the cleaning member, wherein the cleaning member is roller-shaped and configured to clean a surface of a roller member to be cleaned in contact therewith.

Owner:RICOH KK

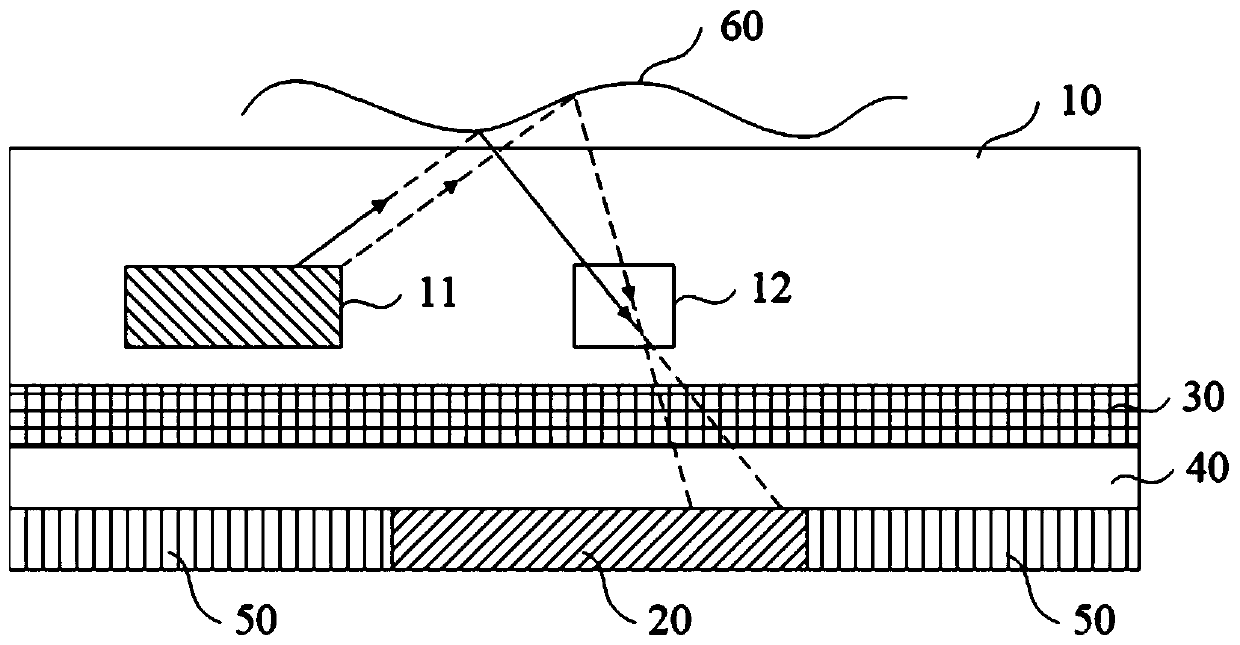

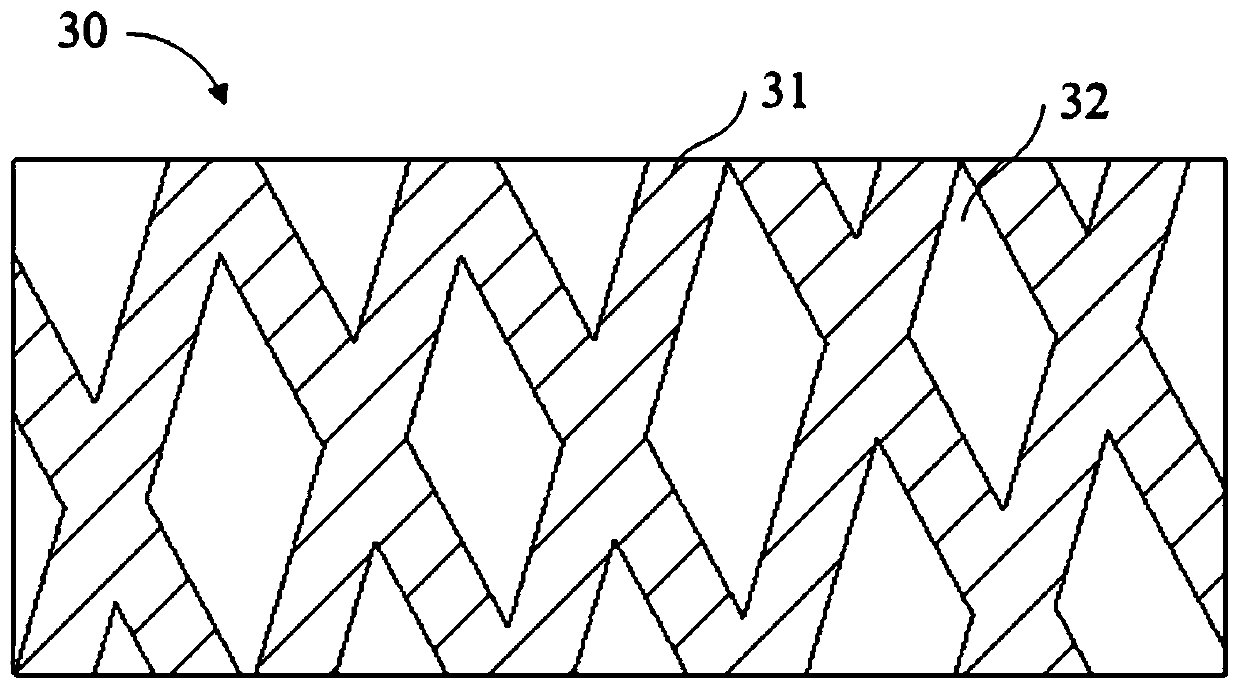

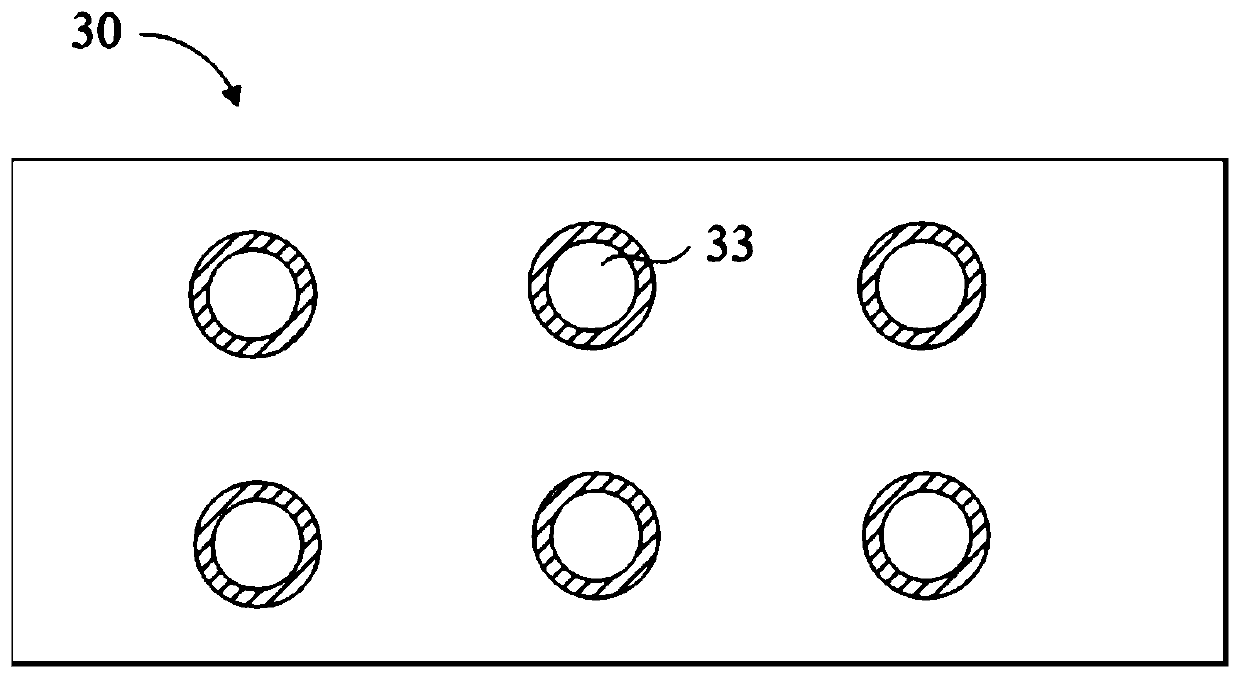

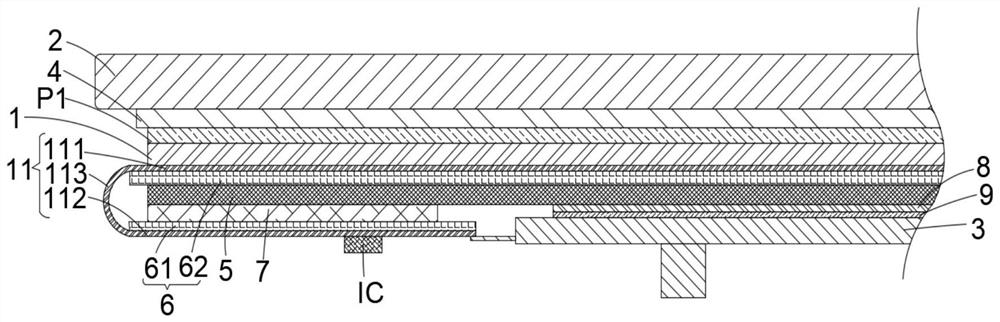

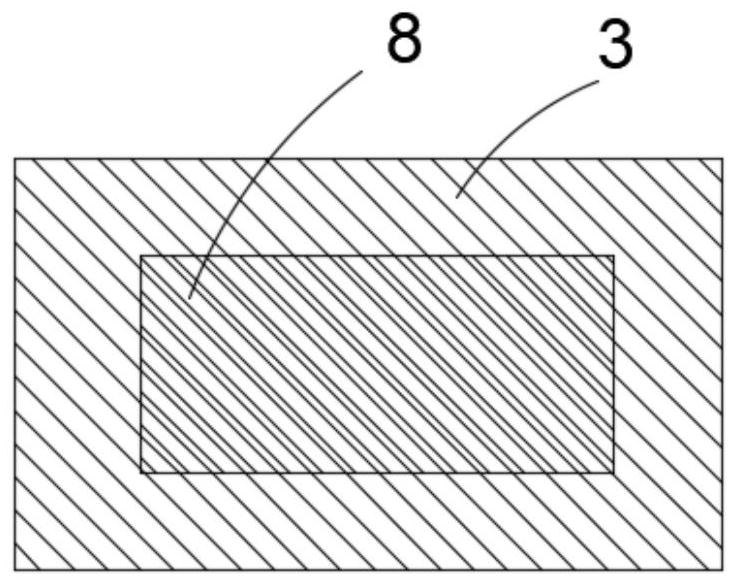

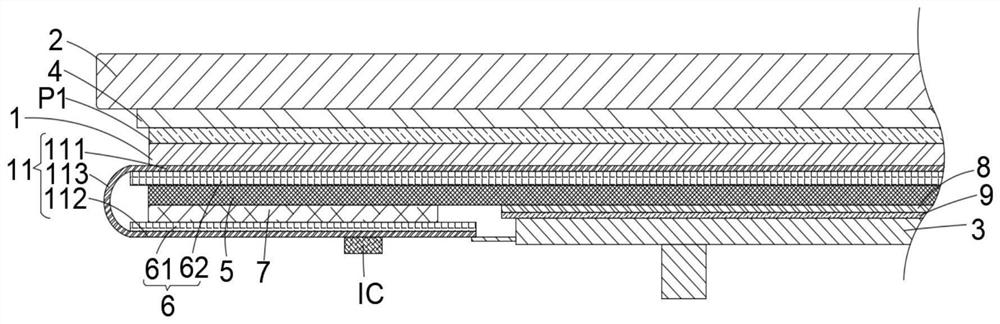

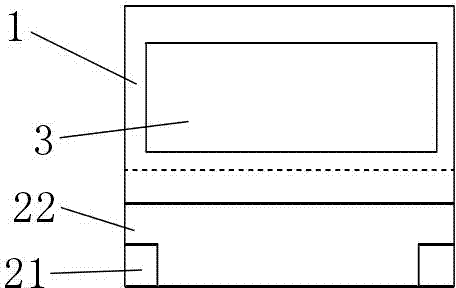

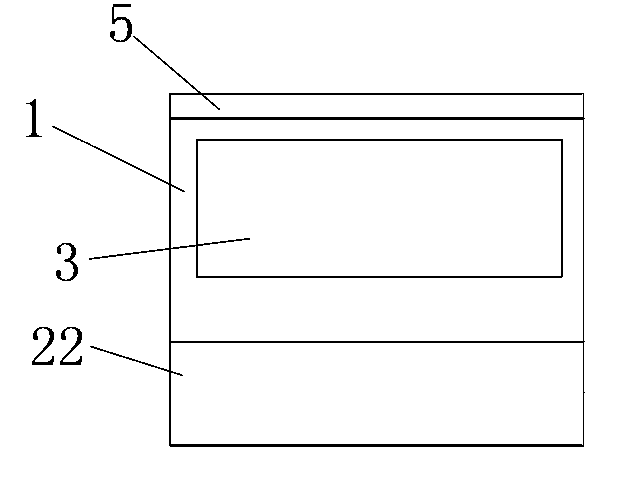

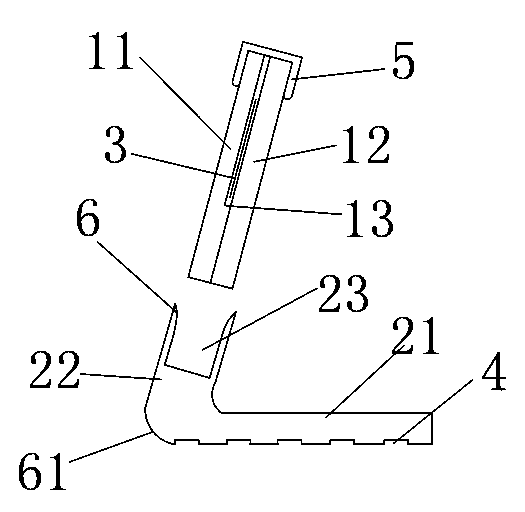

Display device for under-screen fingerprint identification

ActiveCN109712527AImprove flatnessImprove aestheticsCharacter and pattern recognitionIdentification meansDisplay deviceFingerprint

The invention provides a display device for under-screen fingerprint identification. The display device includes a display panel and a fingerprint module, a support layer is arranged between the display panel and the fingerprint module and extends along the joint face of the display panel and the fingerprint module, and at least part of the support player is located at the joint between the display panel and the edge of the fingerprint module. By adopting the display device for under-screen fingerprint identification, pressure generated when the display panel fits the fingerprint module can beeffectively relieved; the situations are avoided that fingerprint module profile impressions appear on the display panel, and the display panel deforms; the surface flatness and attractiveness of thedisplay panel are improved, the light inlet amount of the fingerprint module is increased, and the fingerprint identification accuracy is improved.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

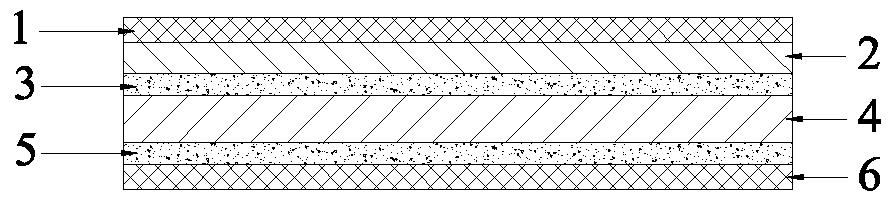

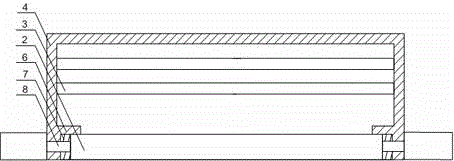

Modified BOPP composite film, and preparation method of composite film and optical glue

ActiveCN109249659AIngenious structural designReasonable structural designNon-macromolecular adhesive additivesSynthetic resin layered productsComposite filmLiquid-crystal display

The invention discloses a modified BOPP composite film, and a preparation method of the composite film and an optical glue. The modified BOPP composite film comprises an upper protective layer, an using layer, an upper optical glue layer, a BOPP composite film, a lower optical glue layer, and a lower protective layer which are overlapped successively from top to bottom. The modified BOPP compositefilm is skillful and reasonable in structure design; the light transmittance rate reaches 90 to 97%; the haze degree is low; the light transmittance adjustable performance is excellent; bending resistance and excellent flexibility are achieved; folding mark is not easily cause; the comprehensive performance is excellent; function requirements of different liquid crystal display screens are satisfied; it is beneficial for production of flexible fixing of curved display screens, flexible coiled display screens, flexible folding display screens, and whole flexible display screens; and the suitable range is wide.

Owner:DONGGUAN DINGLI FILM TECH

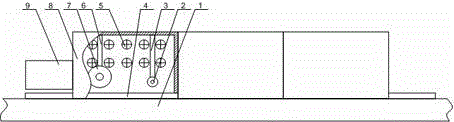

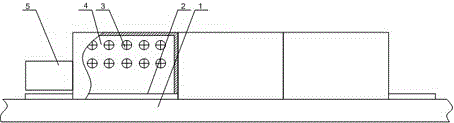

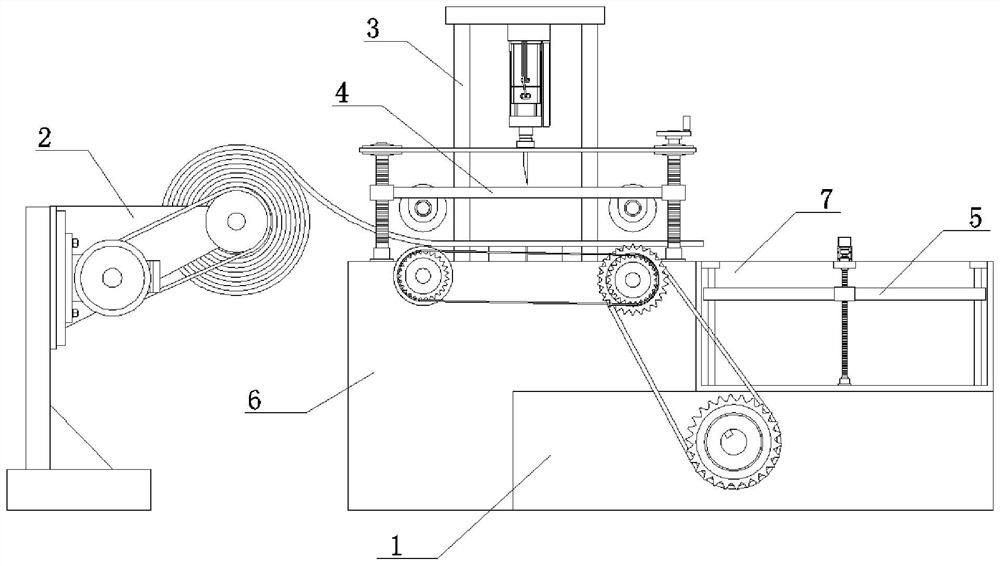

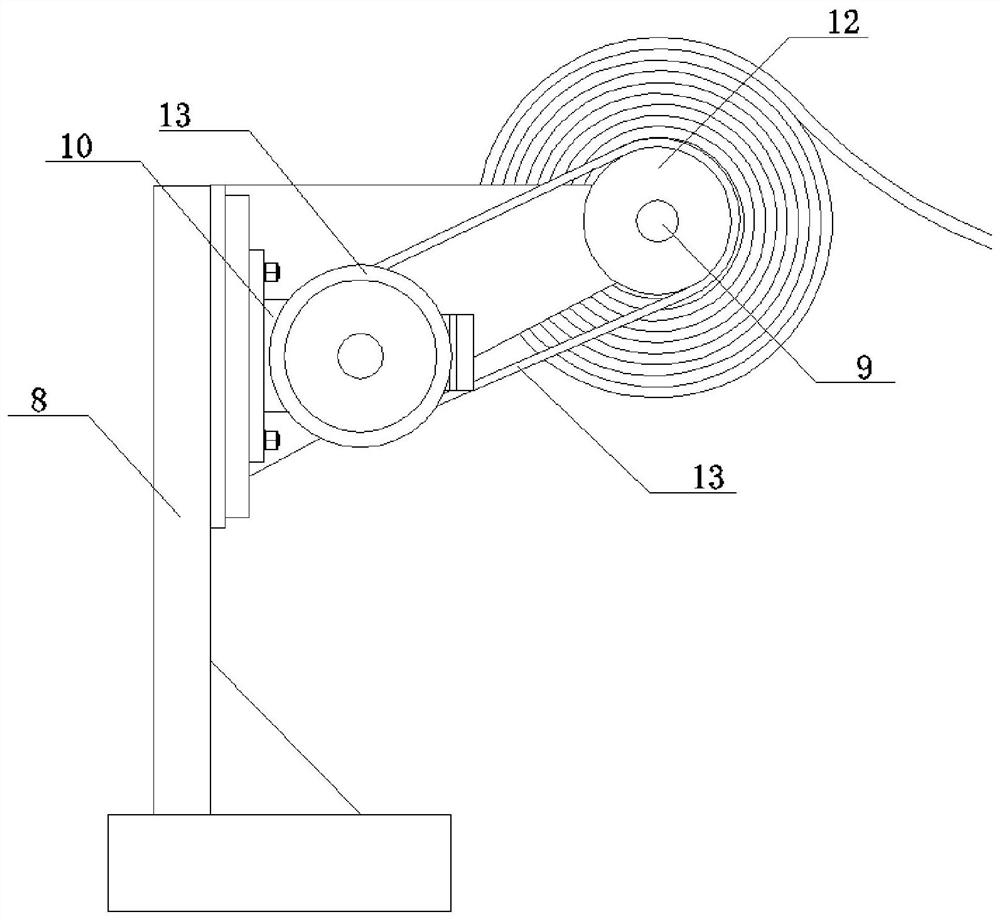

Dryer for uniformly drying solid wood board raw materials

InactiveCN104647491ADry evenlyWill not affect the running trackDrying machines with progressive movementsWood dampingSolid woodEngineering

The invention discloses a dryer for uniformly drying solid wood board raw materials. The dryer comprises a bracket and a conveying belt matched with the bracket, wherein a plurality of drying cavities which are arranged side by side and are communicated with one another are fixedly formed on the upper part of the conveying belt; inlet ends and outlet ends are formed at two sides of the drying cavities; upper and lower rows of magnetrons which are parallel with one another are fixedly arranged on the inner walls of the drying cavities; small rollers and big rollers are fixedly arranged at the inlet ends and the outlet ends of the drying cavities by virtue of connecting rods A and connecting rods B, and the bottom ends of the small rollers and the big rollers are located on a same linear line; after logs enter the drying cavities, the upper surfaces of the logs are directly contacted with the outer circumferences of the small rollers, and after the logs move by a distance, the upper surfaces of the logs are contacted with the outer circumferences of the big rollers; under the squeezing of the big and small rollers, the logs are dried and dewatered, and meanwhile the logs are prevented from becoming twisted or deforming integrally; and the moving track of the logs is not affected even if the conveying belt shakes or jumps with a certain degree during conveying, so that the uniform drying of the logs is guaranteed.

Owner:CHENGDU NONDO FURNITURE

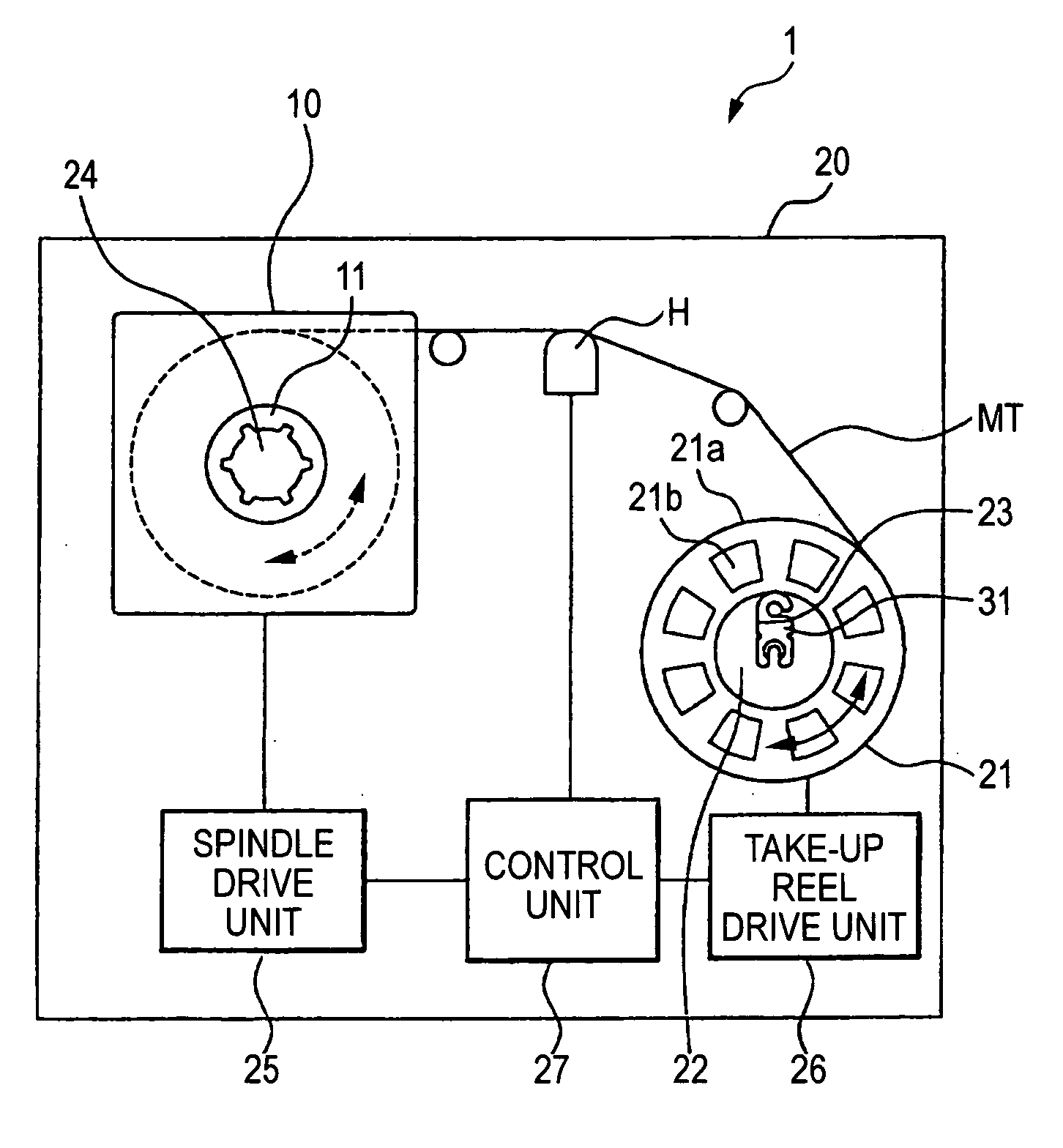

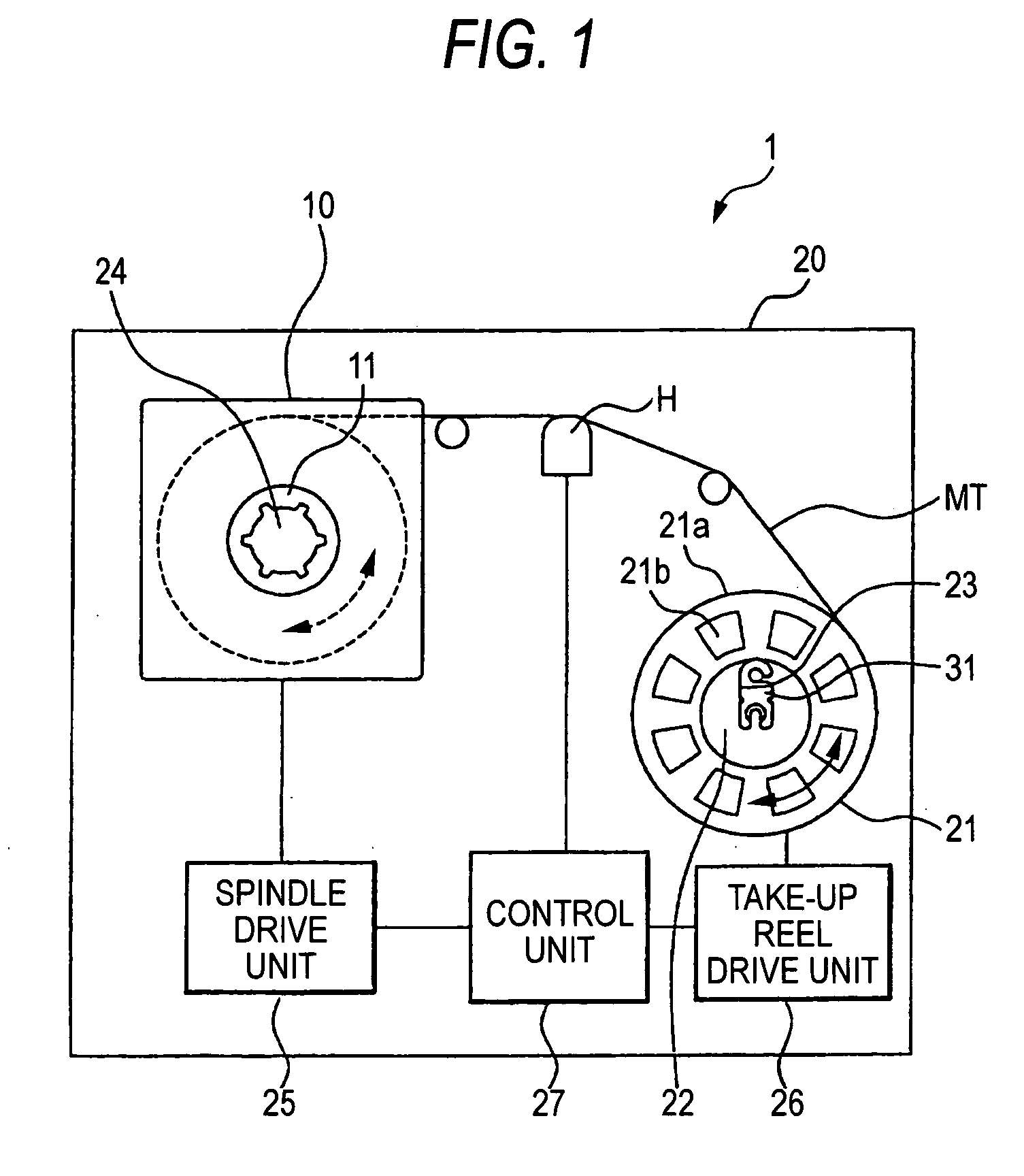

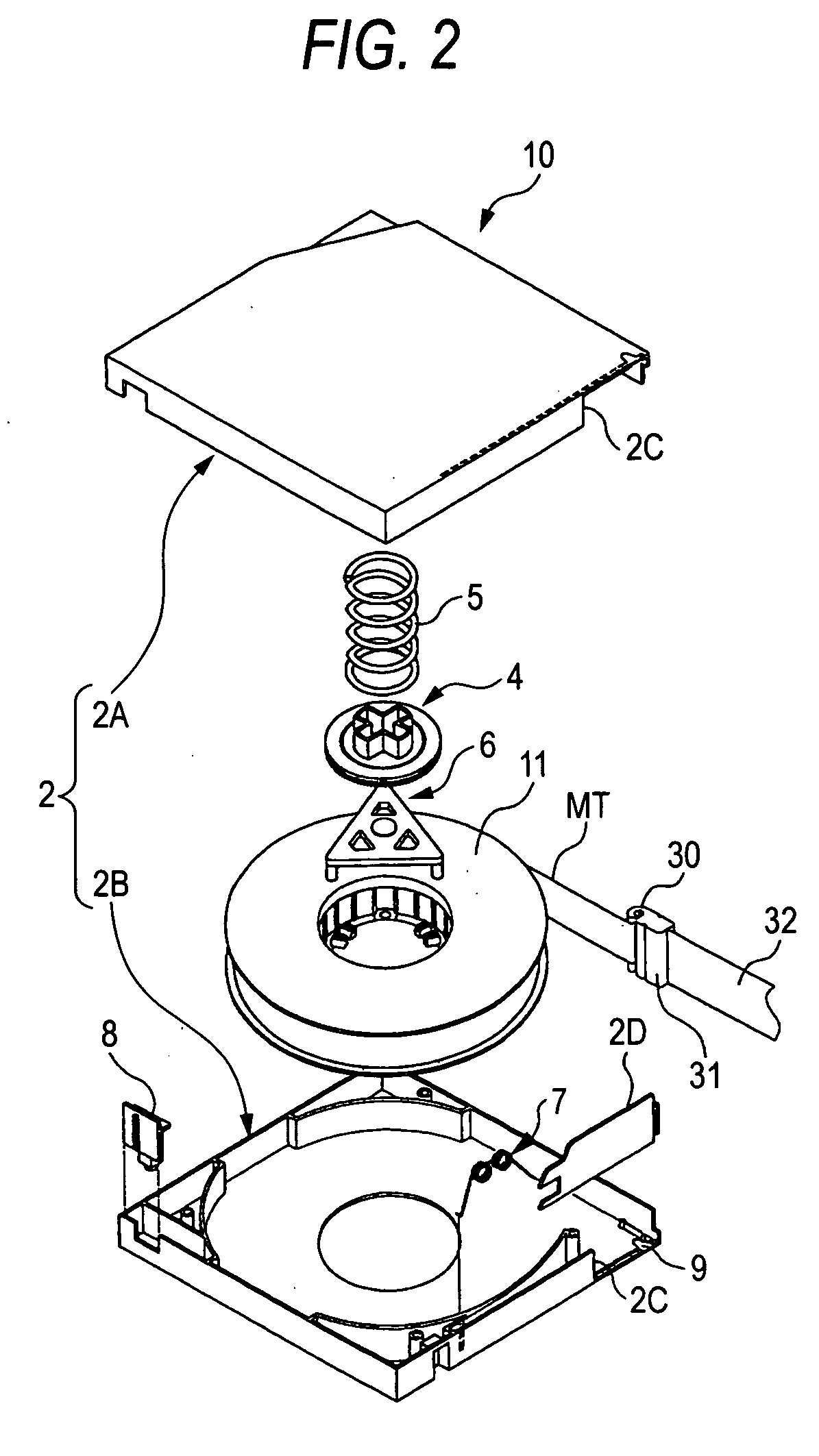

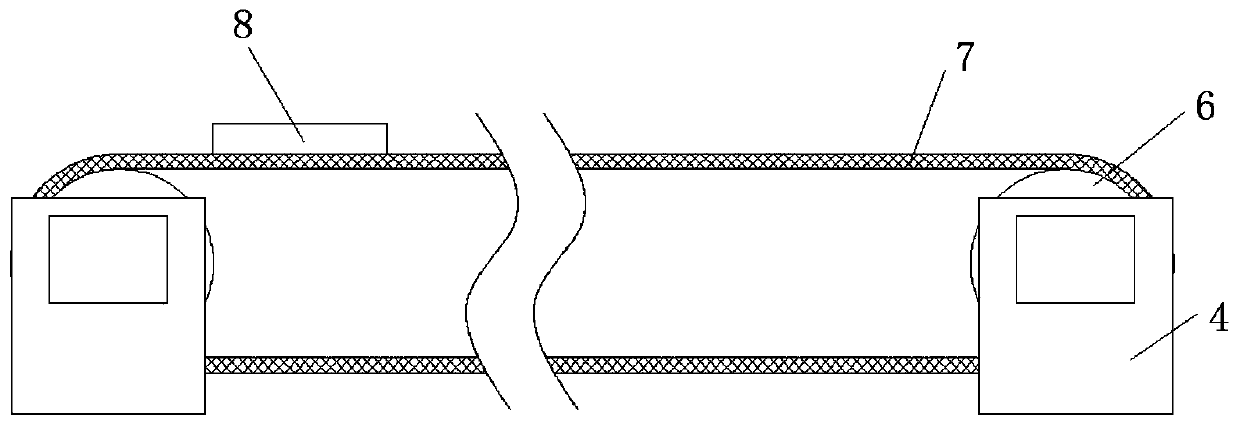

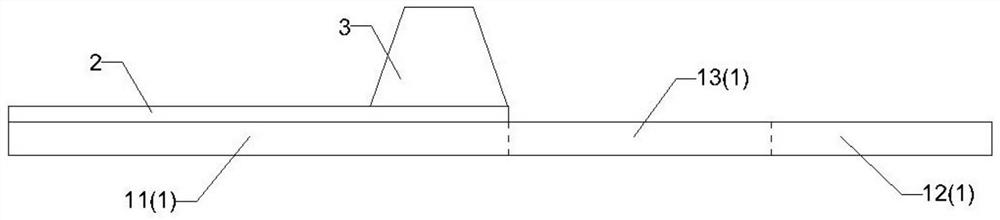

Leader Tape and Magnetic Tape Cartridge Using the Same

InactiveUS20080259495A1Reduce outputAvoid imprintsCarrier storage meansRecord information storageEngineeringCoating

An object is to provide a leader tape which suppresses the increase of dropout resulting from imprinting of the drive reel or leader block part due to storage for a long time or running at a high temperature and hardly causes the edge damage of a magnetic tape, and also provide a magnetic tape cartridge using the leader tape.1) A leader tape comprising a support having provided on at least one surface thereof a coating layer comprising a powder material and a binder, wherein the center line average roughness (Ra) on at least one surface of the leader tape is from 10 to 60 nm and the friction coefficient against an Al2O3 / TiC member is from 0.1 to 0.3; and 2) a magnetic tape cartridge including a cartridge case; and a single reel or a plurality of reels, each reel being rotatably housed in the cartridge case and having a magnetic tape wound therearound, in which the magnetic tape has a leader tape of 1), the leader tape being jointed to an leading end of the magnetic tape and drawn out into a magnetic recording and reproducing apparatus while leading the magnetic tape.

Owner:FUJIFILM CORP

Cleaning member, charging device, process cartridge, and image forming apparatus

InactiveUS8218997B2Avoid imprintsGood cleanabilityBrushesWork treatment devicesMechanical engineeringCoating

A cleaning member includes a core bar, an elastic coating layer, and high-friction coefficient parts provided on both ends of the cleaning member. The high-friction coefficient parts include an elastic material. Outer peripheries of the high-friction coefficient parts are inclined with respect to an axial direction of the core bar. The cleaning member is roller-shaped and is configured to clean a surface of a roller member to be cleaned in contact therewith. A charging device and a process cartridge also include the cleaning member.

Owner:RICOH KK

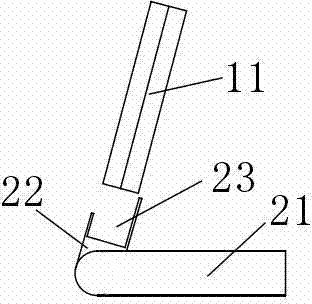

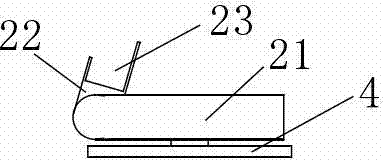

Display device and display device bonding method

ActiveCN112117319AAvoid imprintsAvoid local deformationSolid-state devicesIdentification meansFlexible circuitsDisplay device

The invention discloses a display device and a display device fitting method. The display device comprises: a display module which comprises a flexible display substrate; the flexible display substrate further comprises a first sub-part, a second sub-part and a bending part connecting the first sub-part and the second sub-part; the second sub-part is located on one side, deviating from the light emitting surface of the display module, of the first sub-part; a cover plate which is arranged on one side, deviating from the second sub-part, of the first sub-part, wherein a first adhesive layer isarranged between the cover plate and the first sub-part; a flexible circuit board which is arranged on one side, deviating from the cover plate, of the first sub-part and is connected with the secondsub-part; a rigid plate body which is arranged between the flexible circuit board and the first sub-part, wherein the rigid plate body and the flexible circuit board are at least partially overlappedin the direction perpendicular to the plane where the first sub-part is located. Due to the fact that the rigid plate body is arranged between the flexible circuit board and the first sub-part, the acting force of the pressing head acting on the flexible display panel can be transmitted to the rigid plate body, the acting force is evenly dispersed through the rigid plate body, and the problem thata display module of the display device has impressions is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

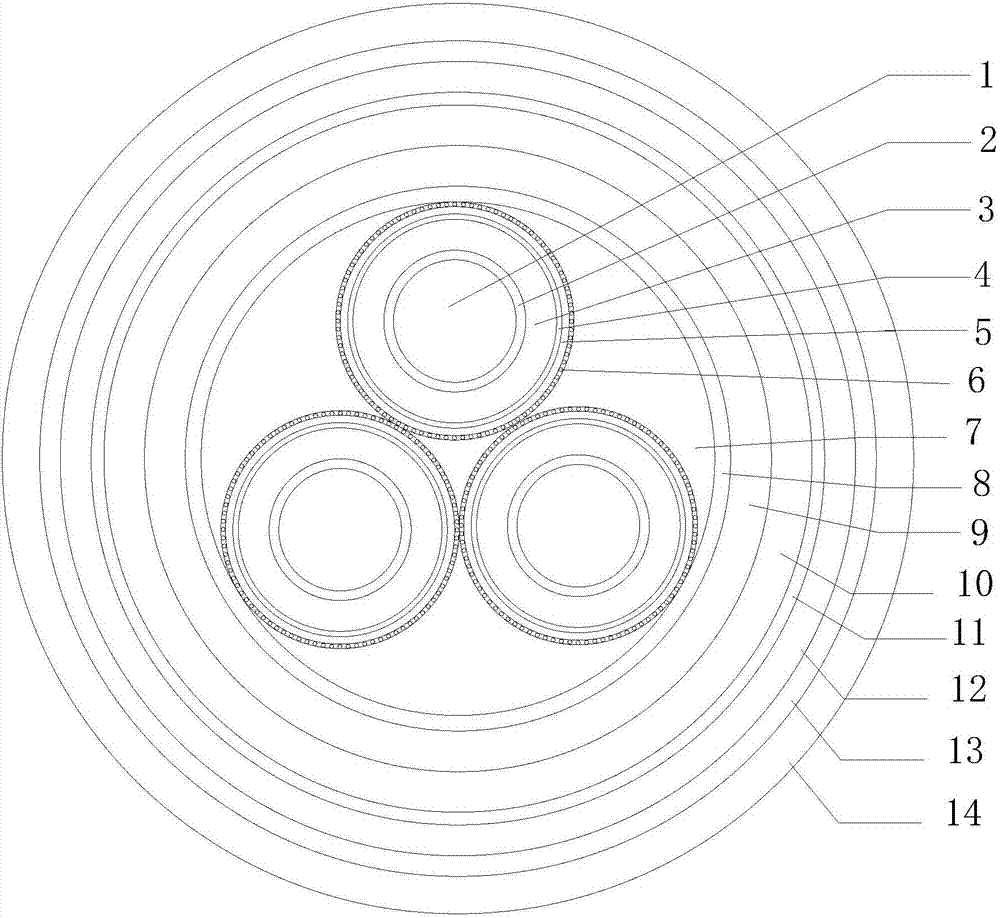

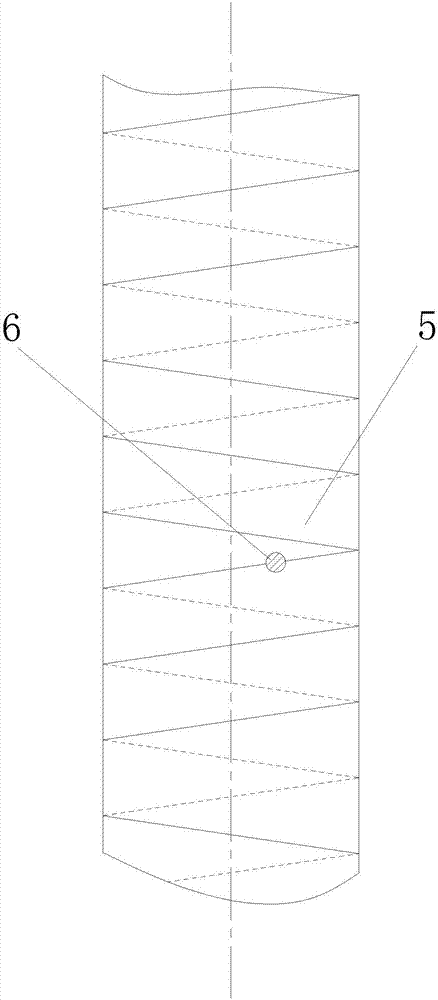

Fireproof medium-voltage multi-core cable

InactiveCN106935326AAvoid imprintsAvoid disadvantagesInsulated cablesInsulated conductorsGlass fiberMulticore cable

The invention relates to a fireproof medium-voltage multi-core cable. The fireproof medium-voltage multi-core cable comprises cable cores, a flame-retardant glass fiber wrapping belt wrapping the cable cores, and a first-layer fireproof and fire-resistant sheath wrapping the flame-retardant glass fiber wrapping belt; each cable core comprises a conductor as well as an inner screen, an insulating layer and an external screen which sequentially coat the conductor from inside to outside, wherein the external screen is wrapped with a buffer semi-conductive belt, wherein the buffer semi-conductive belt is wound with an SZ-type copper wire; the first-layer fireproof and fire-resistant sheath is wrapped with a second-layer fireproof and fire-resistant sheath; and the exterior of the second-layer fireproof and fire-resistant sheath is provided with a second flame-retardant glass fiber wrapping belt. The buffer semi-conductive belts of the fireproof medium-voltage multi-core cable are high-temperature buffer semi-conductive belts which can play a role of thermal expansion, buffering and heat insulation; the SZ-type copper wires are wound on the high-temperature buffer semi-conductive belts through special process so as to replace copper wires, so that the SZ-type copper wires can shrink freely with the expansion cooling of the materials of the inner layers when being heated, and therefore, the pressing marks of insulation wire cores can be prevented. With the fireproof medium-voltage multi-core cable of the invention adopted, the shortcomings of existing cable products can be greatly eliminated.

Owner:浙江万马股份有限公司

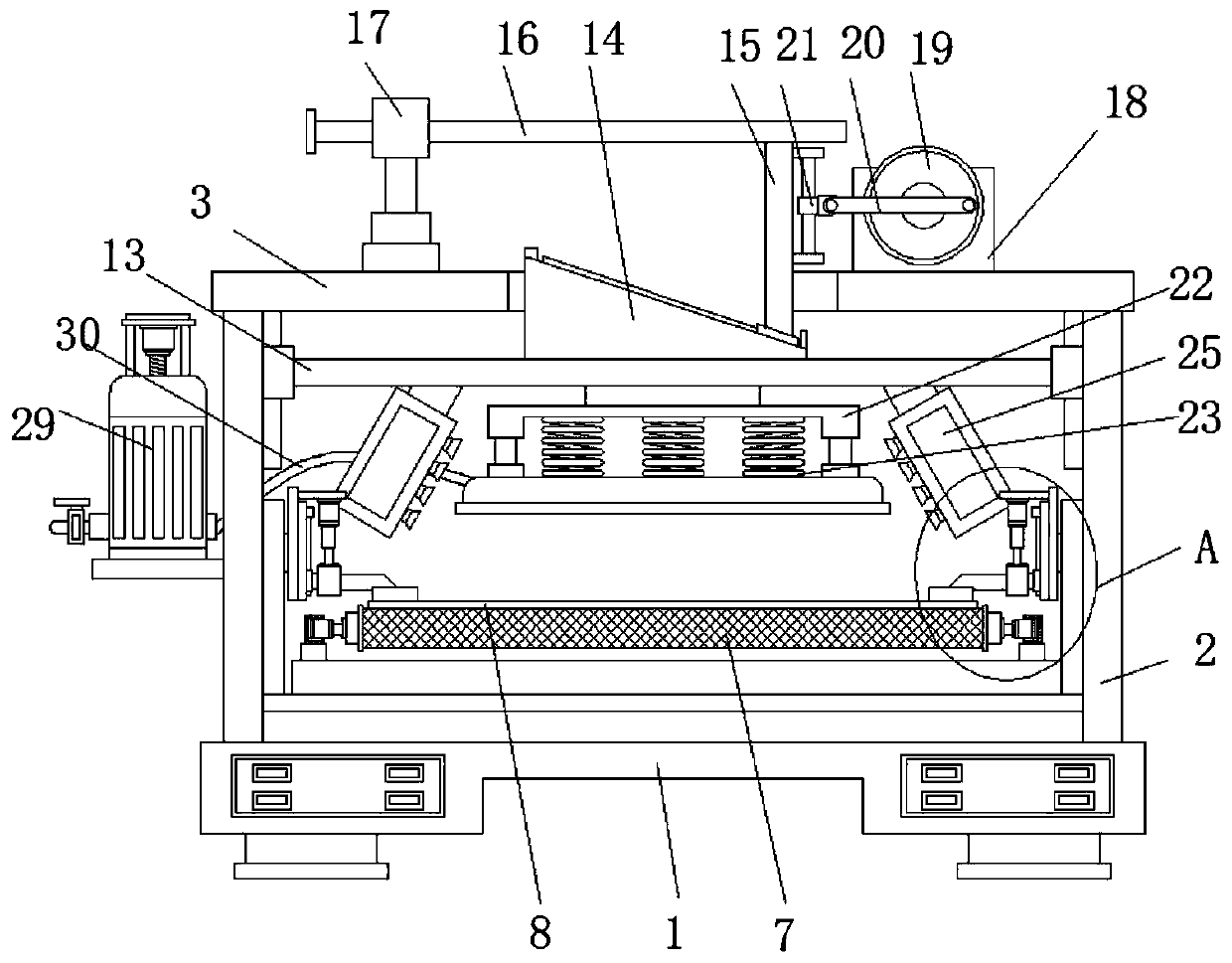

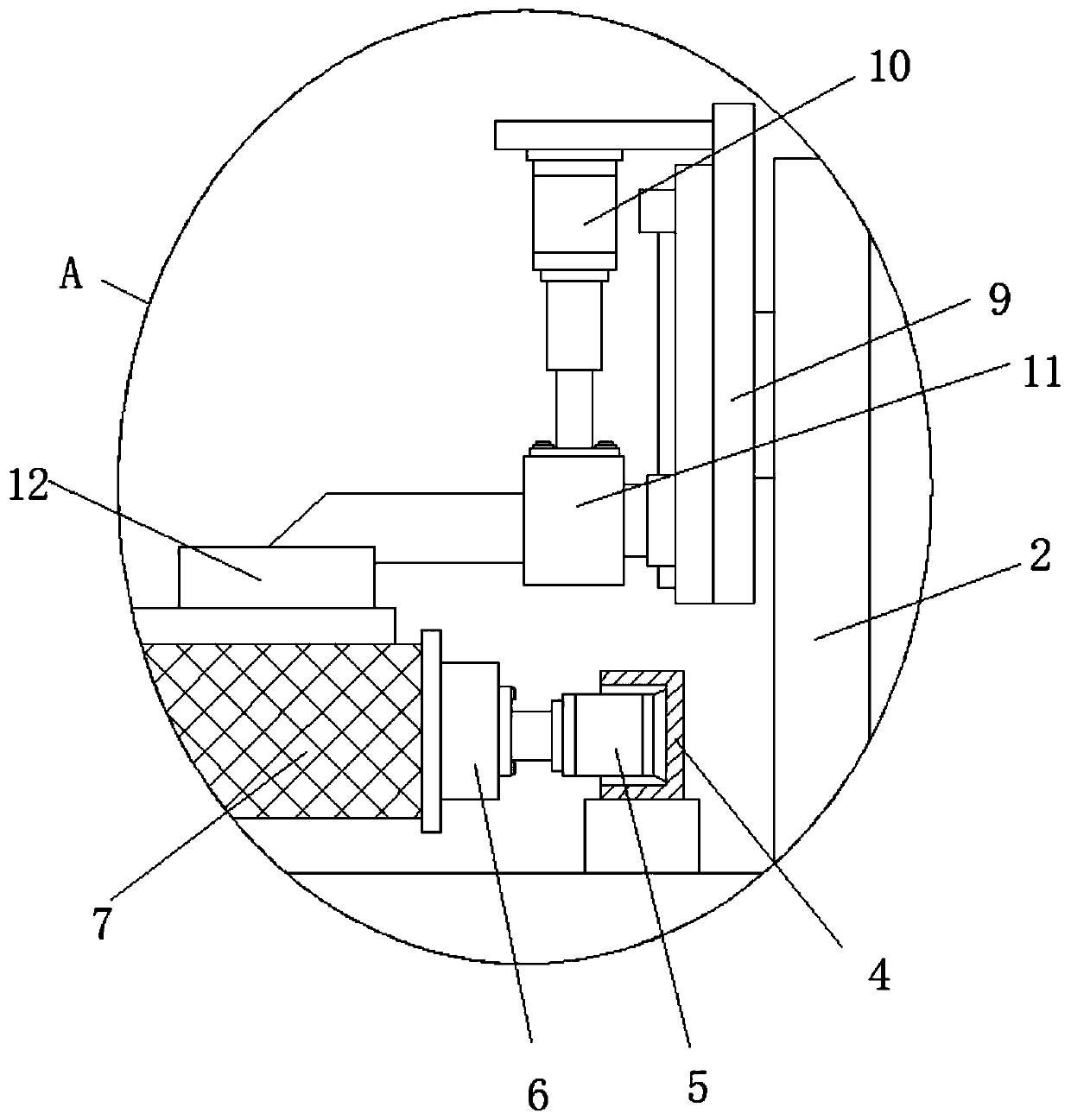

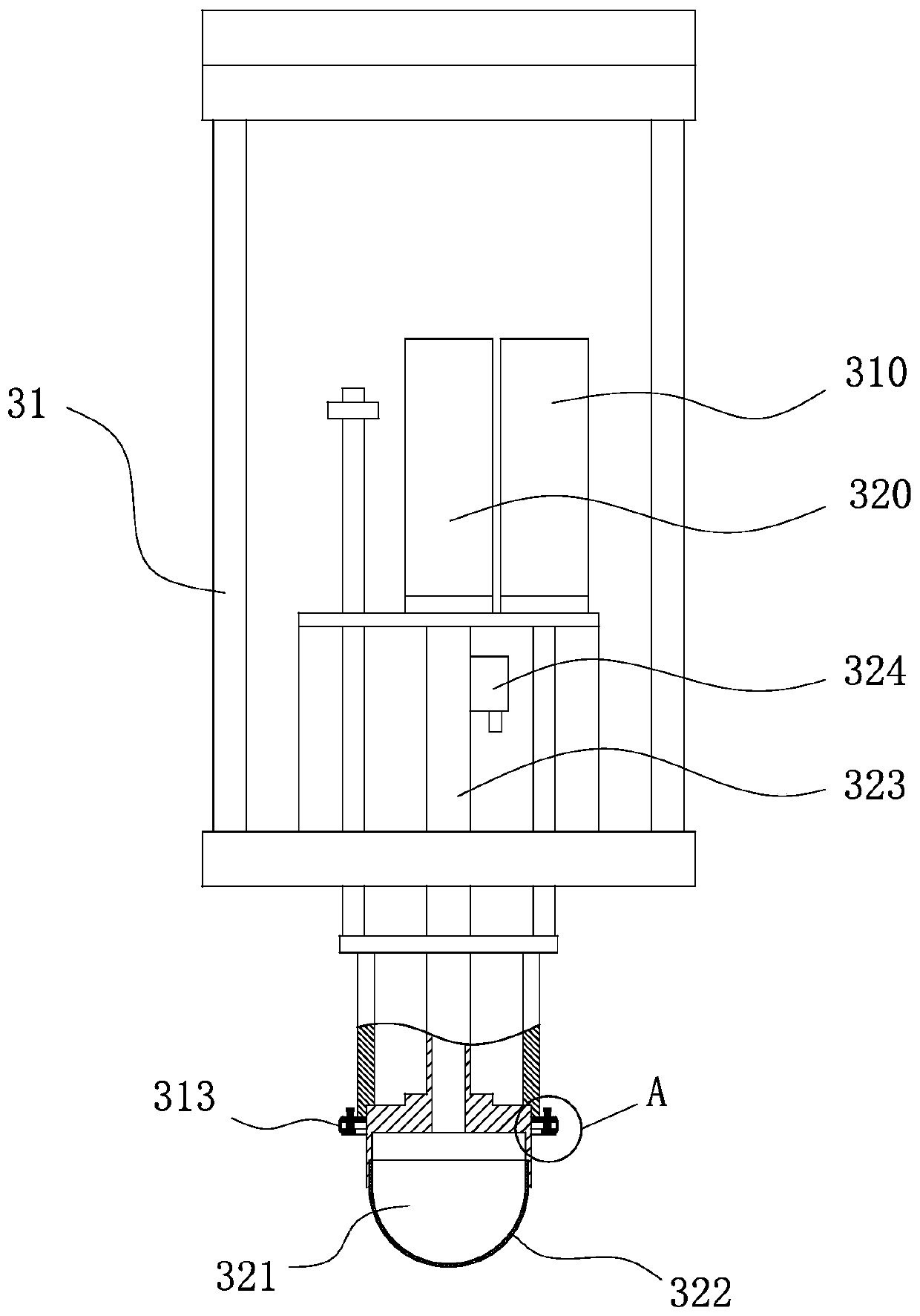

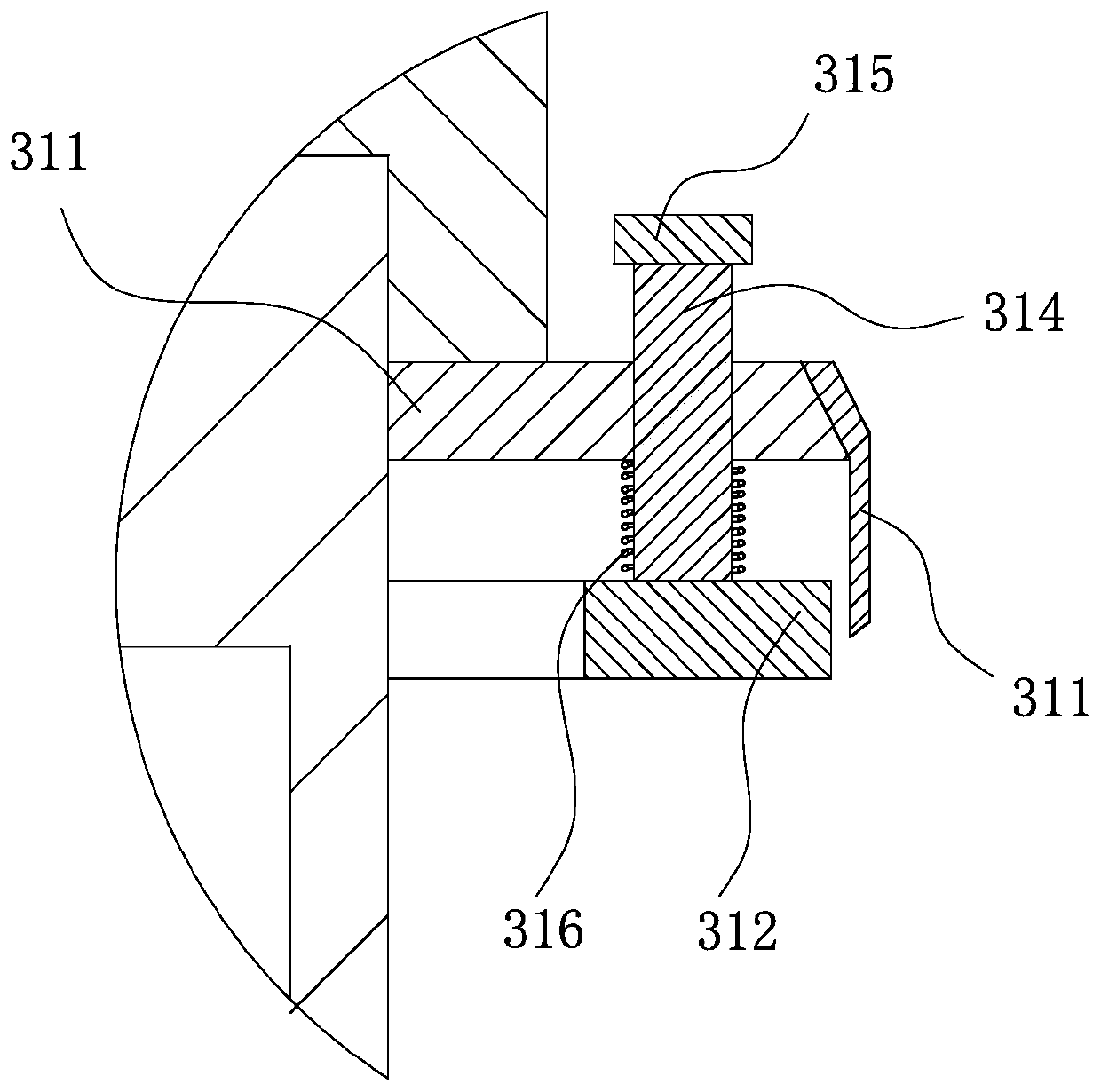

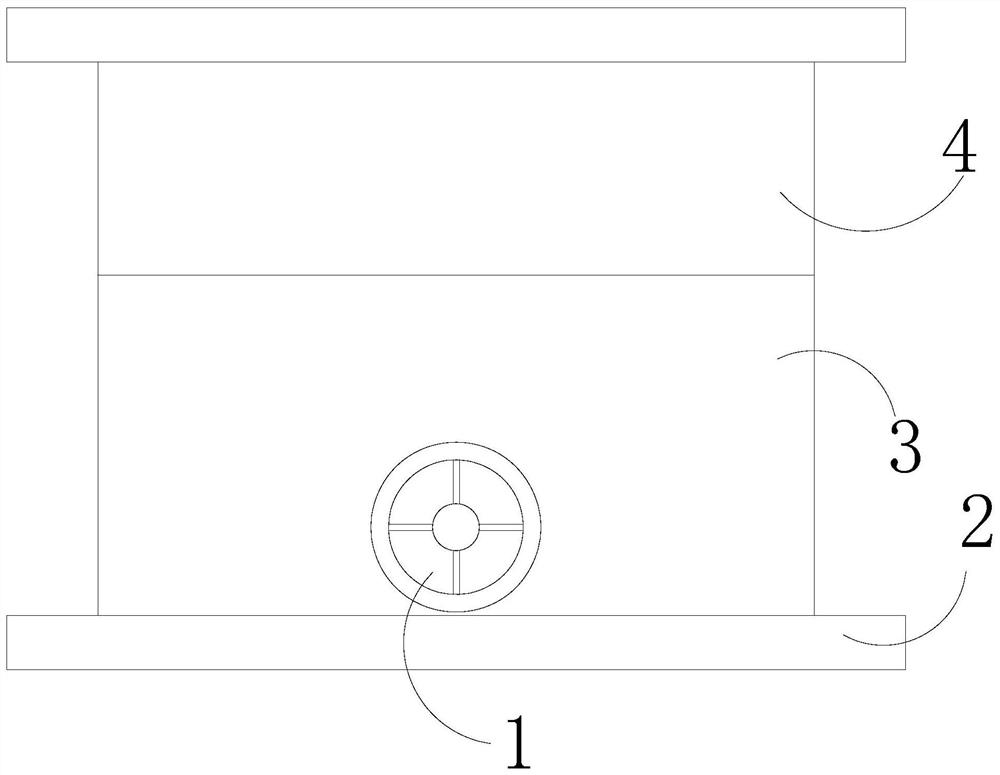

Printing device for inflatable model production

The invention relates to the technical field of inflatable model making, in particular to a printing device for inflatable model production. The printing device for inflatable model production comprises a control console. Two supporting frames which are symmetrically arranged are fixedly installed on the top of the control console. The same top plate is fixedly installed on the tops of the two supporting frames. A conveying assembly is arranged on the top of the control console. An inflatable model product is placed on the conveying assembly. A pressing assembly for fixing the inflatable modelproduct is arranged on the control console. The same limiting plate is in sliding connection with the side, close to the other one, of each supporting frame. A trapezoidal plate is fixedly connectedwith the top of the limiting plate. A push rod is in sliding connection with a top slope of the trapezoidal plate. A sliding rod is fixedly installed on the top of the push rod. The printing device for inflatable model production is simple in body structure, convenient to operate, low in manufacturing cost and high in structural linkage, can carry out quick printing operation on the inflatable model product, is high in mechanical automation degree, and has the broad market promotion prospects.

Owner:范武

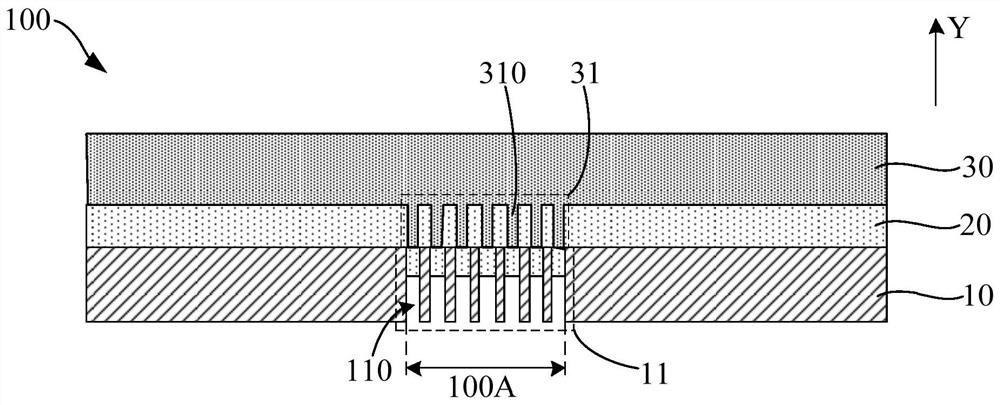

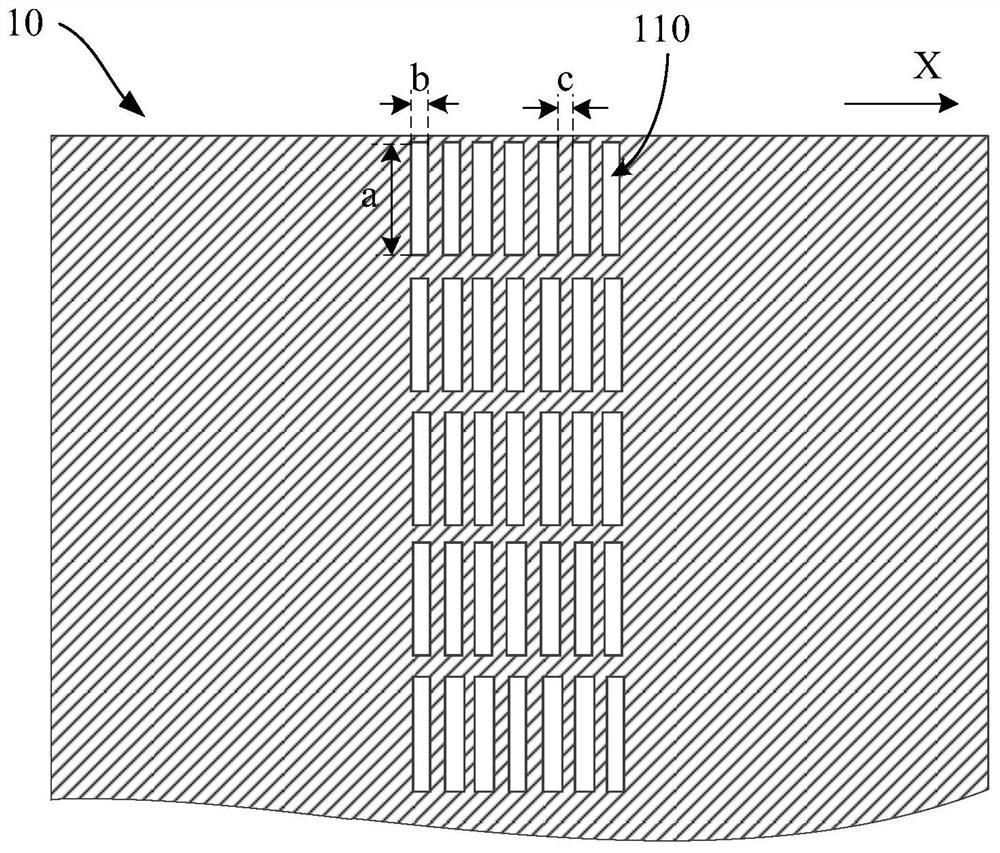

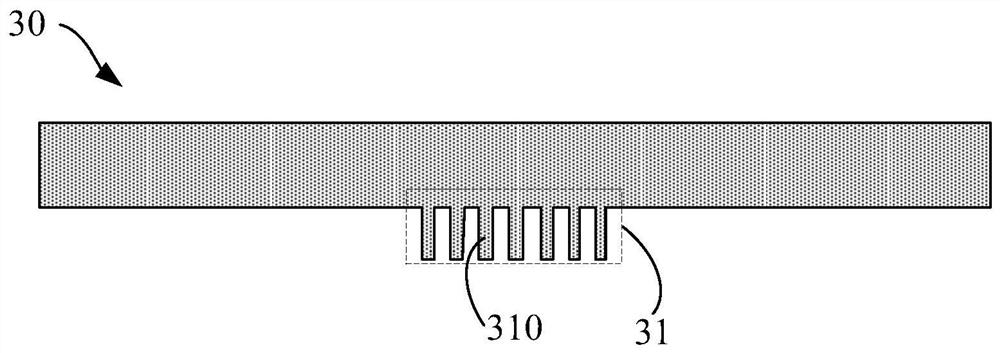

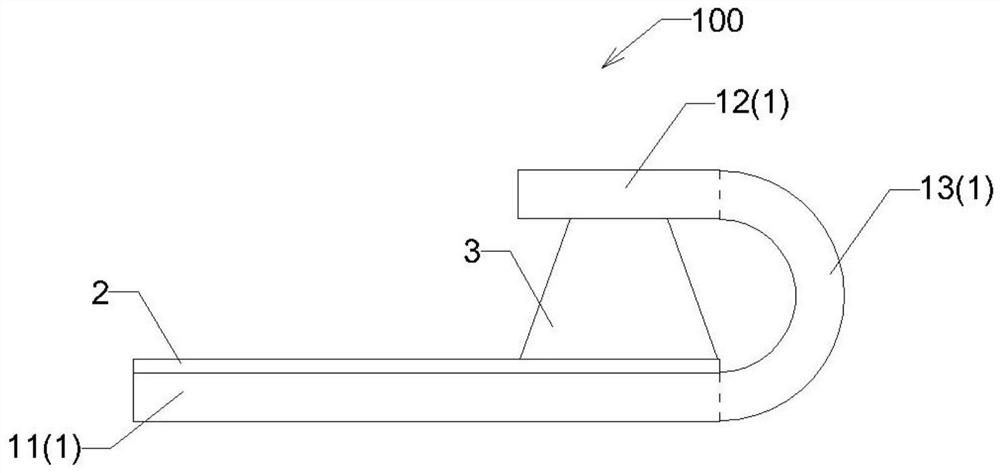

Supporting plate, manufacturing method thereof and flexible display device

ActiveCN113066362AAvoid imprintsGuaranteed flatnessPhotovoltaic energy generationIdentification meansEngineeringFlexible display

The embodiment of the invention discloses a supporting plate and a manufacturing method thereof and a flexible display device. The supporting plate comprises a hard substrate, an adhesive layer and a flexible layer. The hard substrate is provided with a groove structure, the adhesive layer is arranged on the hard substrate, the flexible layer is arranged on the side, away from the hard substrate, of the adhesive layer, the side, close to the hard substrate, of the flexible layer is provided with a protruding structure, and the protruding structure corresponds to the groove structure; and a part of the adhesive layer is located in the groove structure. According to the invention, the flatness of the flexible layer after being attached to the hard substrate can be ensured, and the side, far away from the hard substrate, of the flexible layer is prevented from being printed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

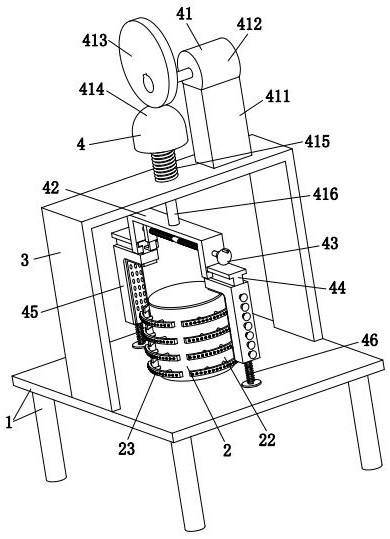

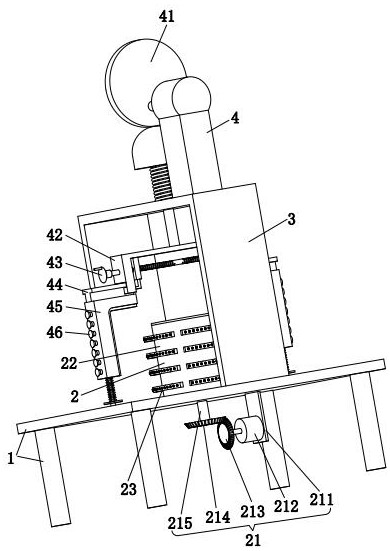

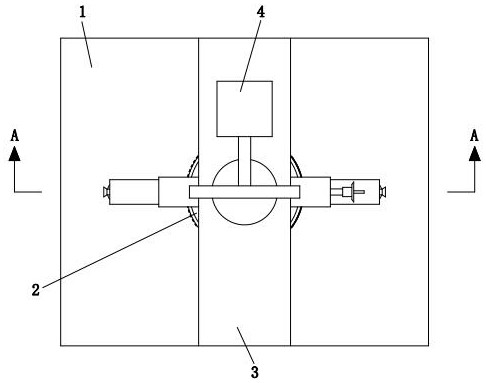

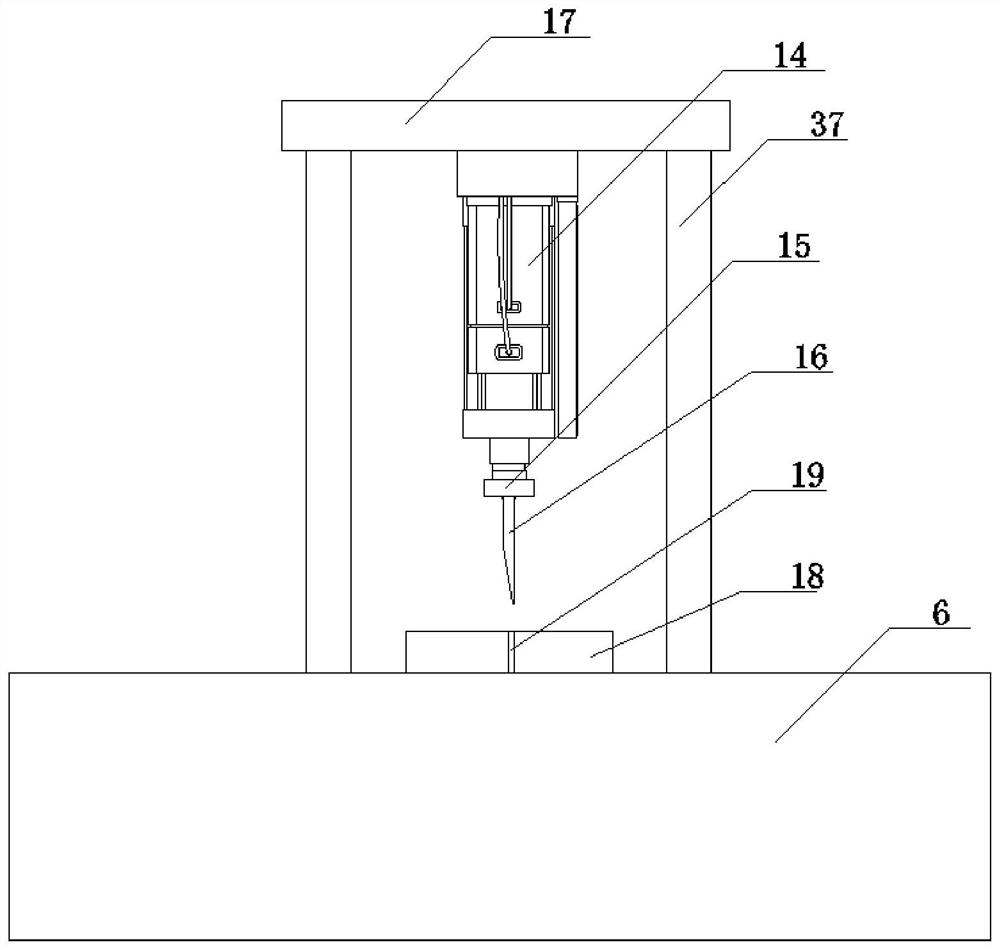

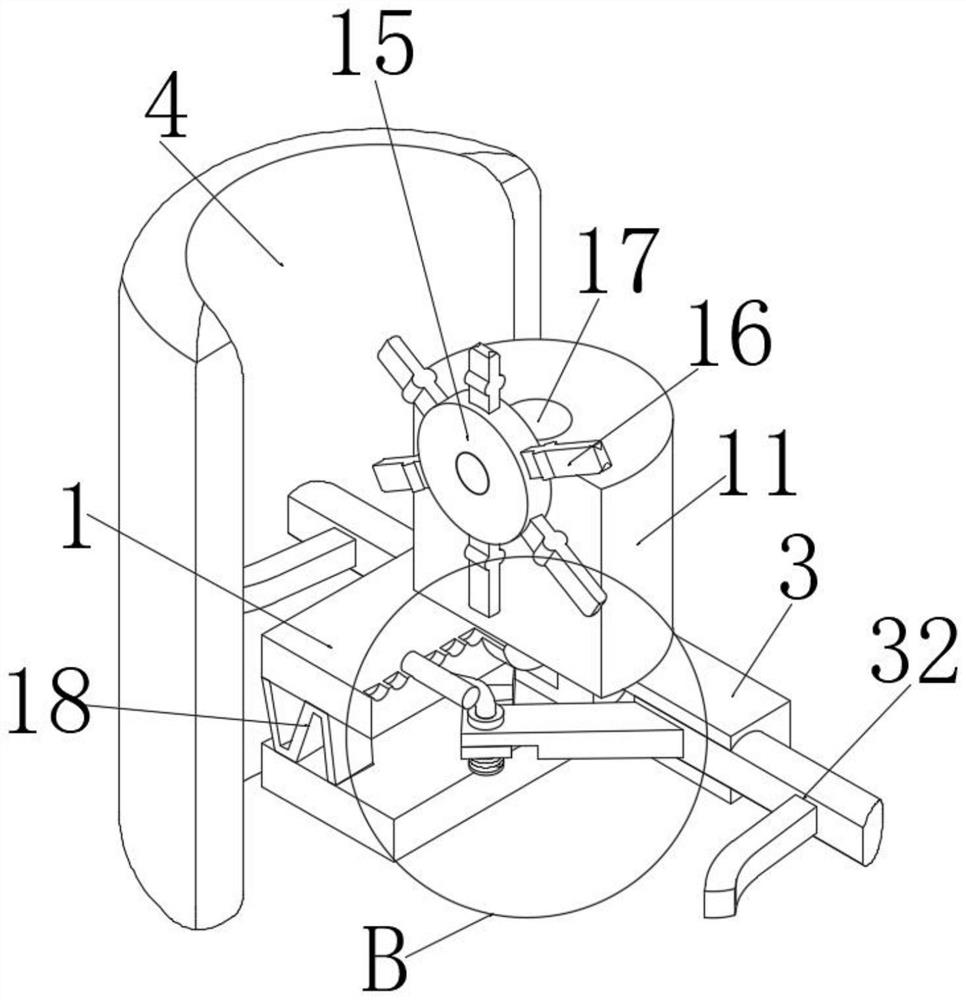

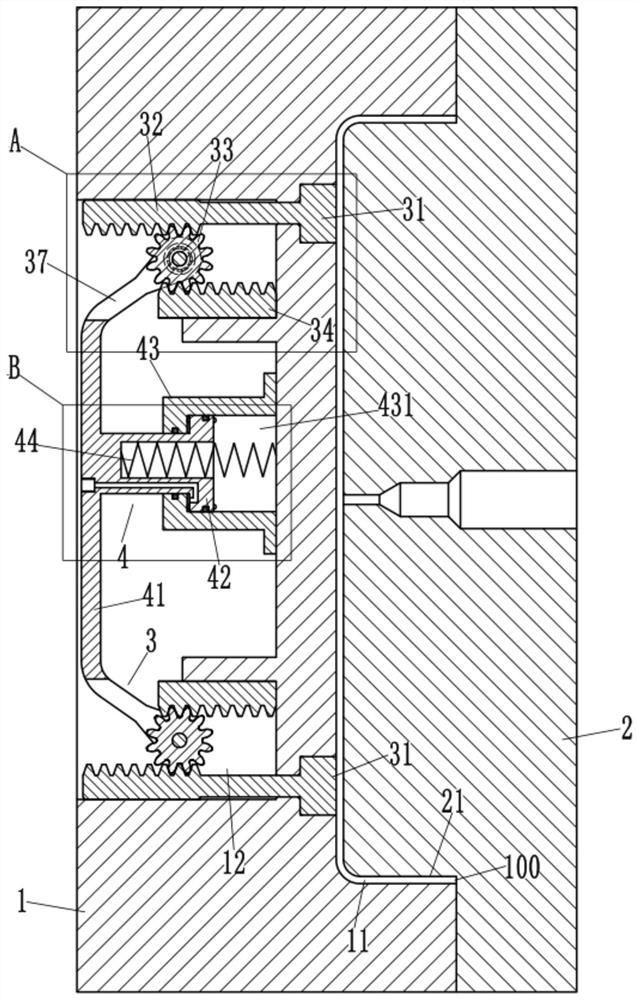

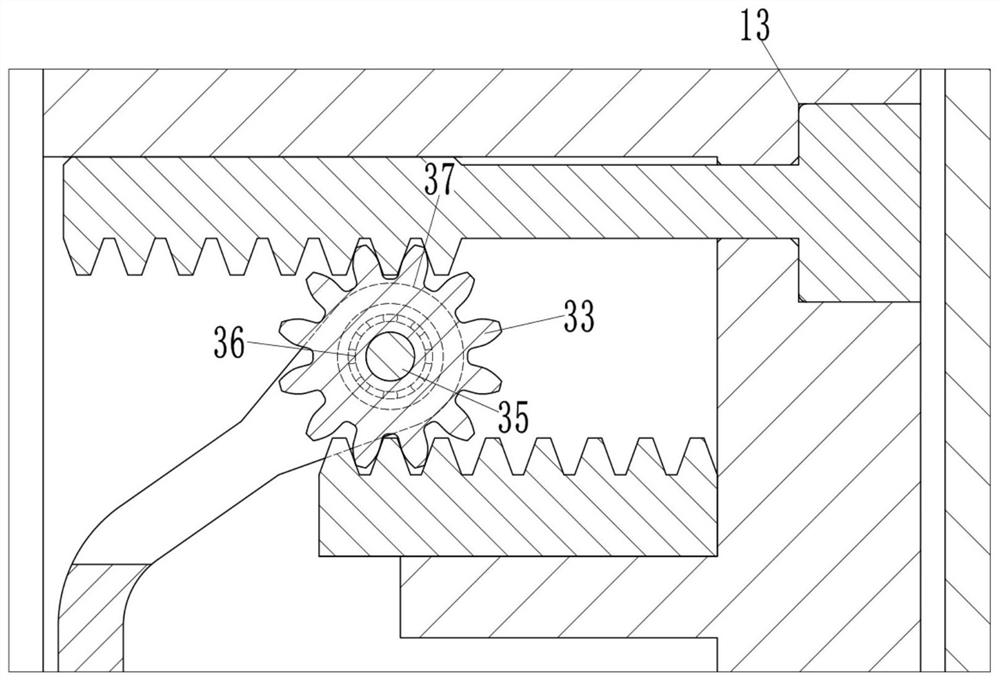

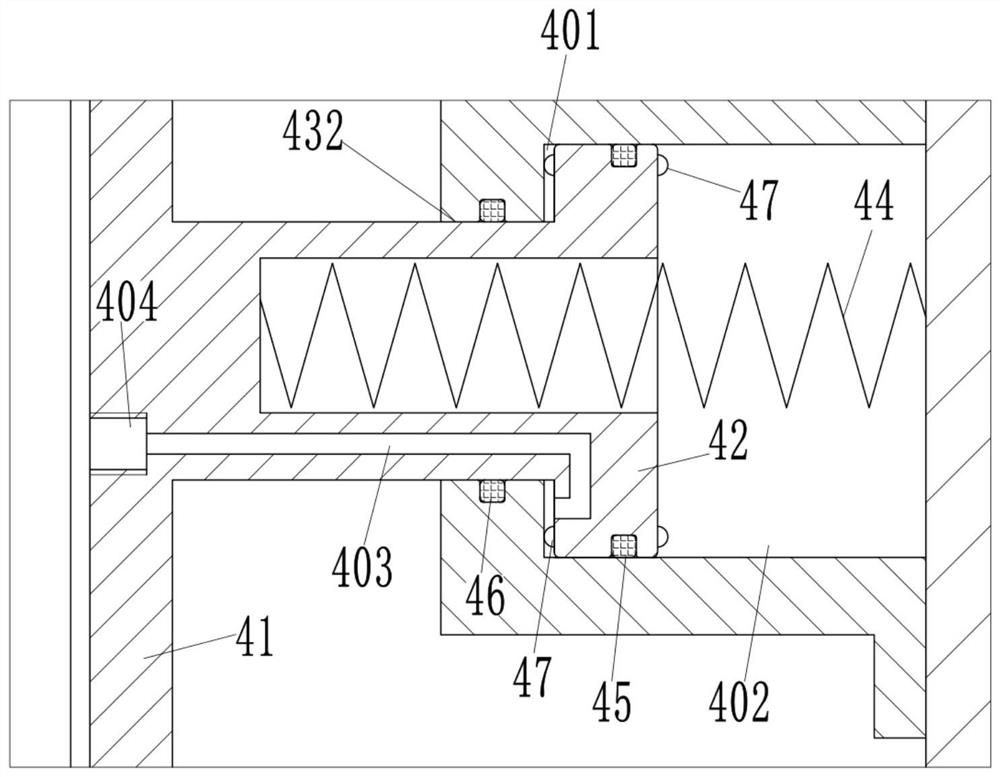

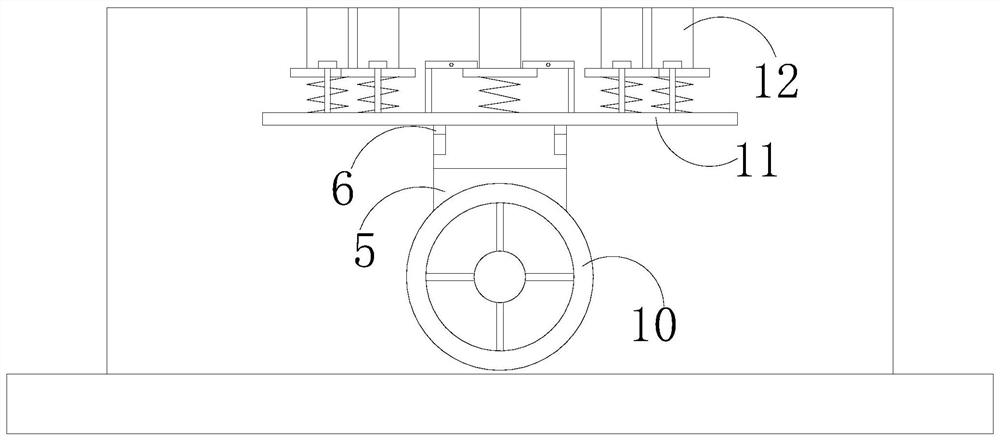

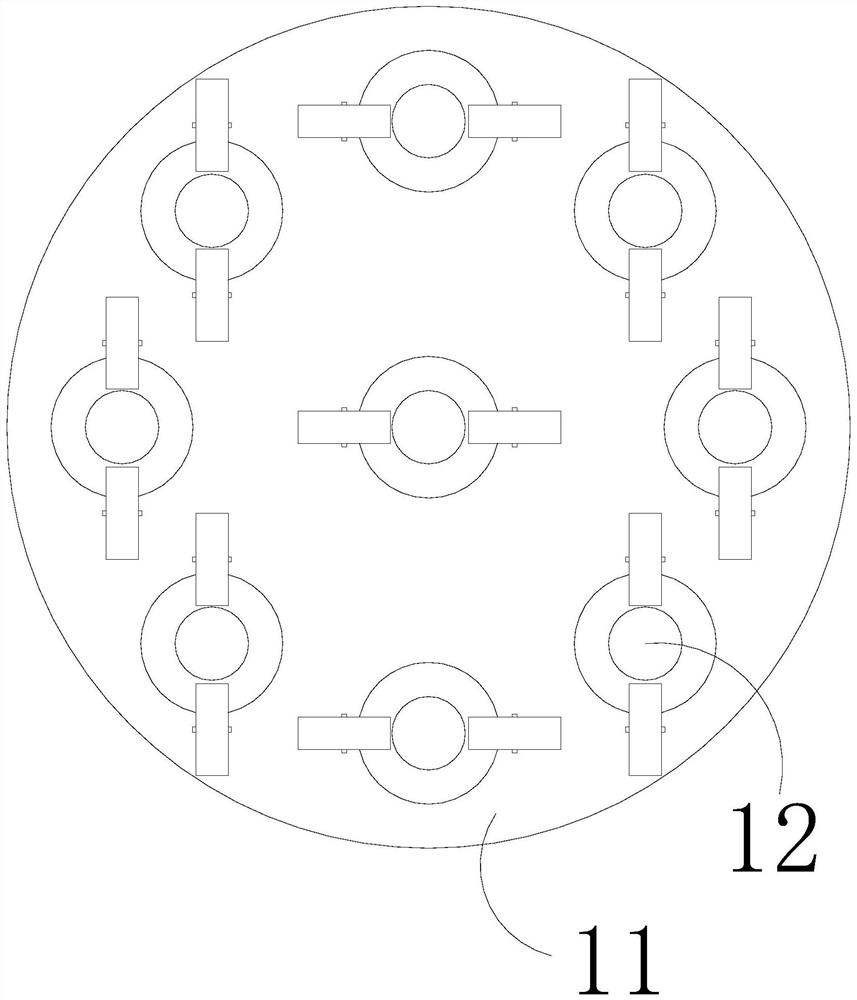

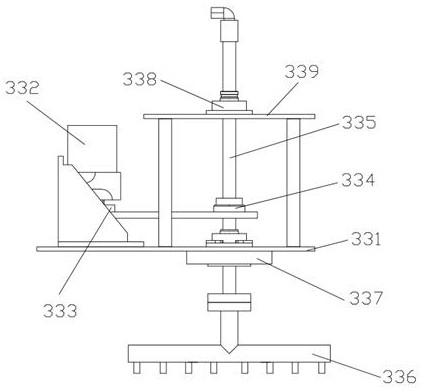

Intelligent LED lamp box structure manufacturing and processing machine

ActiveCN113732836AImprove the tightening and fixing effectAvoid imprintsRevolution surface grinding machinesGrinding drivesEngineeringLED lamp

The invention relates to the field of lamp box finishing, polishing and manufacturing, in particular to an intelligent LED lamp box structure manufacturing and processing machine which comprises a workbench, a tight supporting component, a C-shaped plate and a finishing component. The tight supporting component is arranged in the middle of the top of the workbench, the lower end of the C-shaped plate is fixedly connected to the workbench, and the finishing component is installed on the C-shaped plate. According to the intelligent LED lamp box structure manufacturing and processing machine, a cylindrical lamp box is tightly supported and fixed from the interior of the cylindrical lamp box through tight supporting branch chains, so that the outer side wall of the cylindrical lamp box can be comprehensively trimmed and polished through trimming branch chains, the trimming and polishing cost is saved, and the trimming and polishing effect is guaranteed; and secondly, the outer side wall of the cylindrical lamp box is trimmed and polished through a flexible L-shaped polishing layer instead of a rigid polishing plate, the problem that scratches are likely to be left on the outer side wall of the cylindrical lamp box in the polishing process is solved, meanwhile, generated chippings can be subjected to air blowing treatment in time in the polishing process through the trimming branch chains, the chippings are prevented from adhering to the surface of the cylindrical lamp box to affect the finishing and polishing effect, and the subsequent using effect of the cylindrical lamp box is improved.

Owner:江苏二五七特显科技集团有限公司

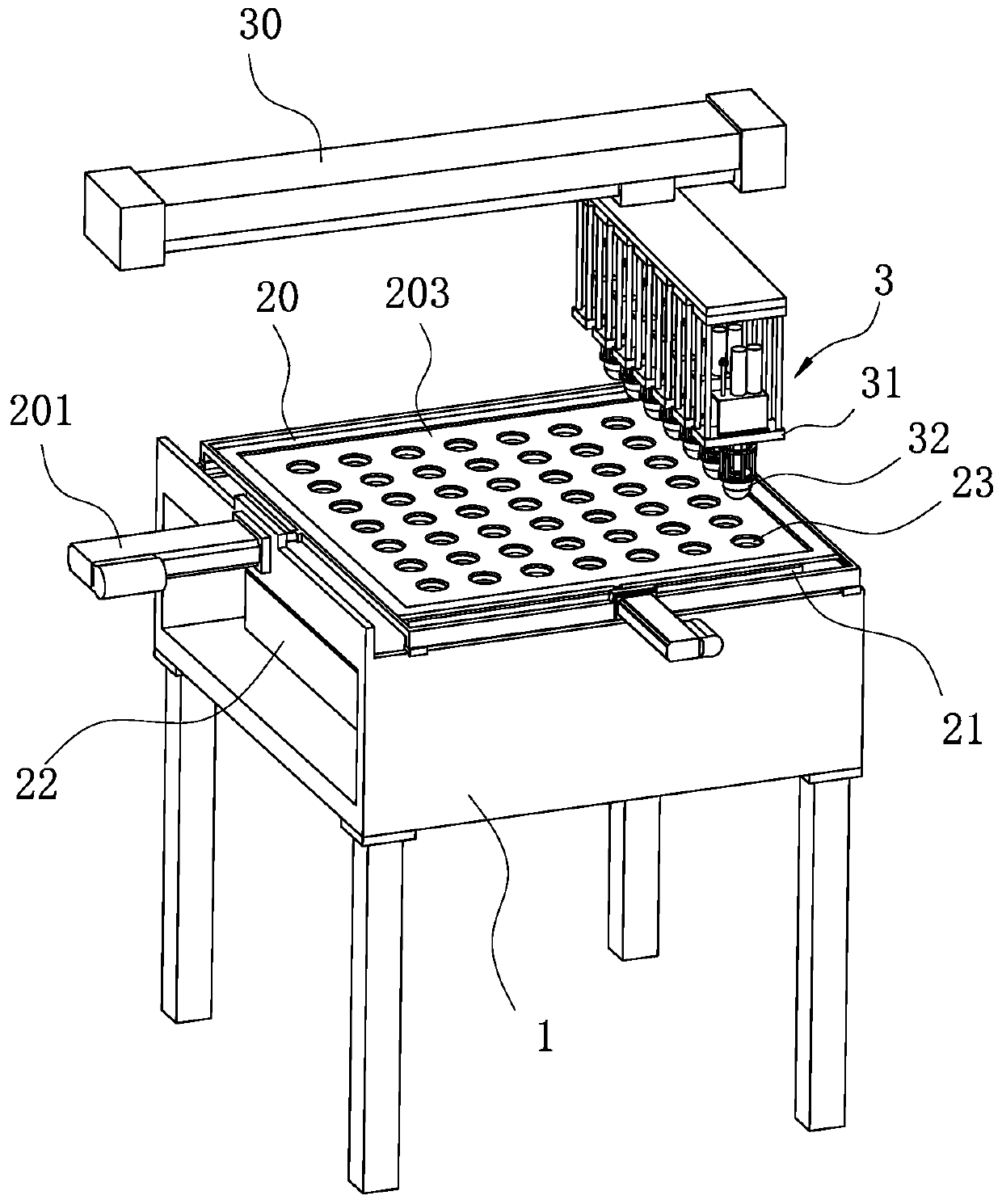

Steamed bun packaging machine and packaging method

PendingCN110294161ARealize one-piece packagingEasy to placeWrapper twisting/gatheringPackaging foodstuffsEngineeringPackaging machine

The invention discloses a steamed bun packaging machine and a packaging method, and relates to the technical field of steamed bun packaging. The steamed bun packaging machine comprises a support. A film forming assembly is mounted on the support, and film pressing assemblies driven by a first plane motion mechanism are arranged above the film forming assembly. Multiple forming cavities which are designed by simulating the shapes of steamed buns and completely contain the steamed buns are formed in the film forming assembly. Forming heads capable of moving up and down and annular cutting knivesare arranged on the film pressing assemblies. The forming heads are matched with the forming cavities, and the annular cutting knives surround the forming heads. The technical problem that the steamed bun packaging efficiency is low in the prior art is solved, steamed buns can be efficiently packed in batch, the packaging quality is high, damage to the shapes of the steamed buns is small, and integrity of the shapes of the steamed buns is guaranteed; and meanwhile the steamed bun packaging machine has the advantages of being convenient to use and reducing the labor amount.

Owner:潍坊佑晨工贸有限公司

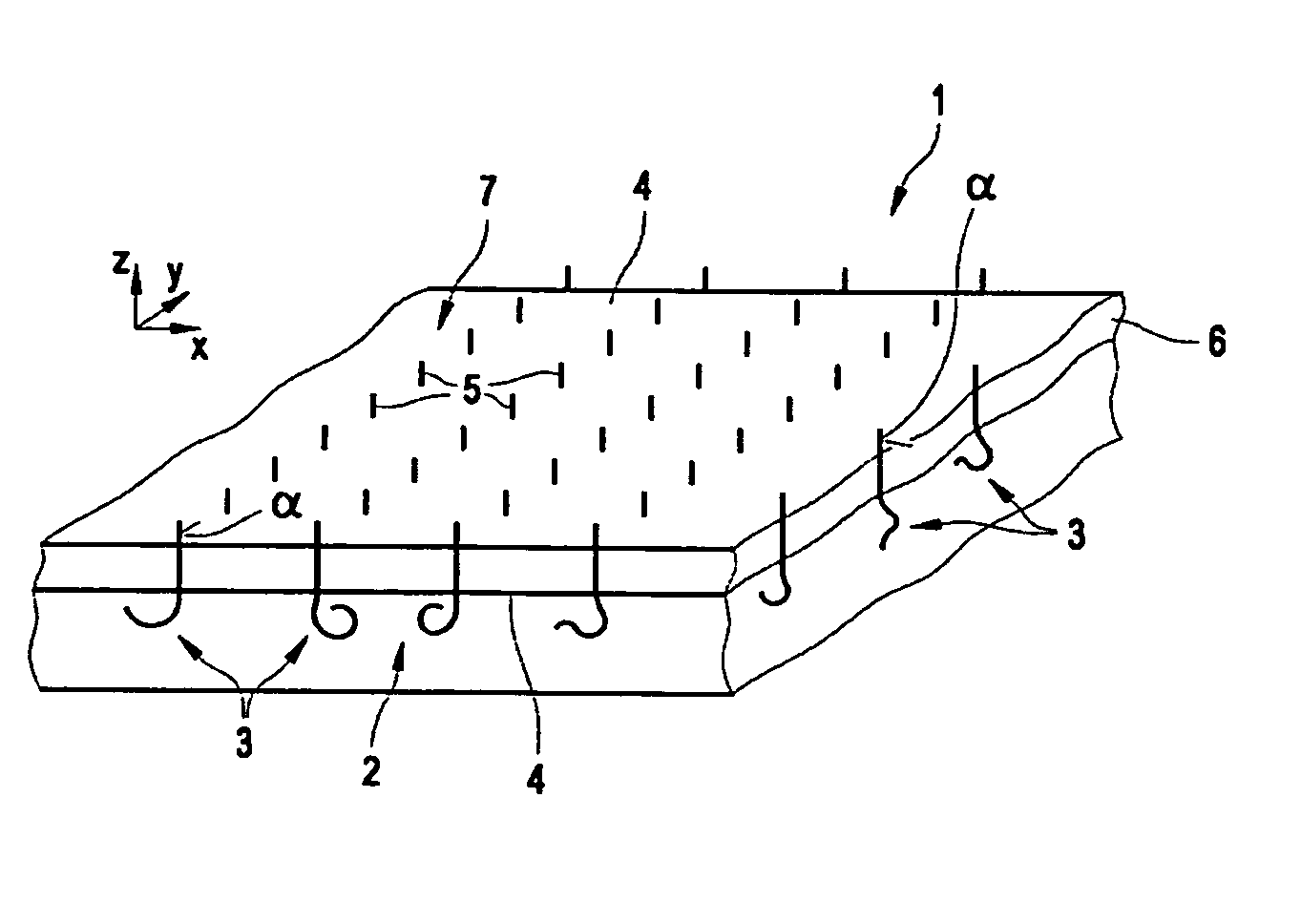

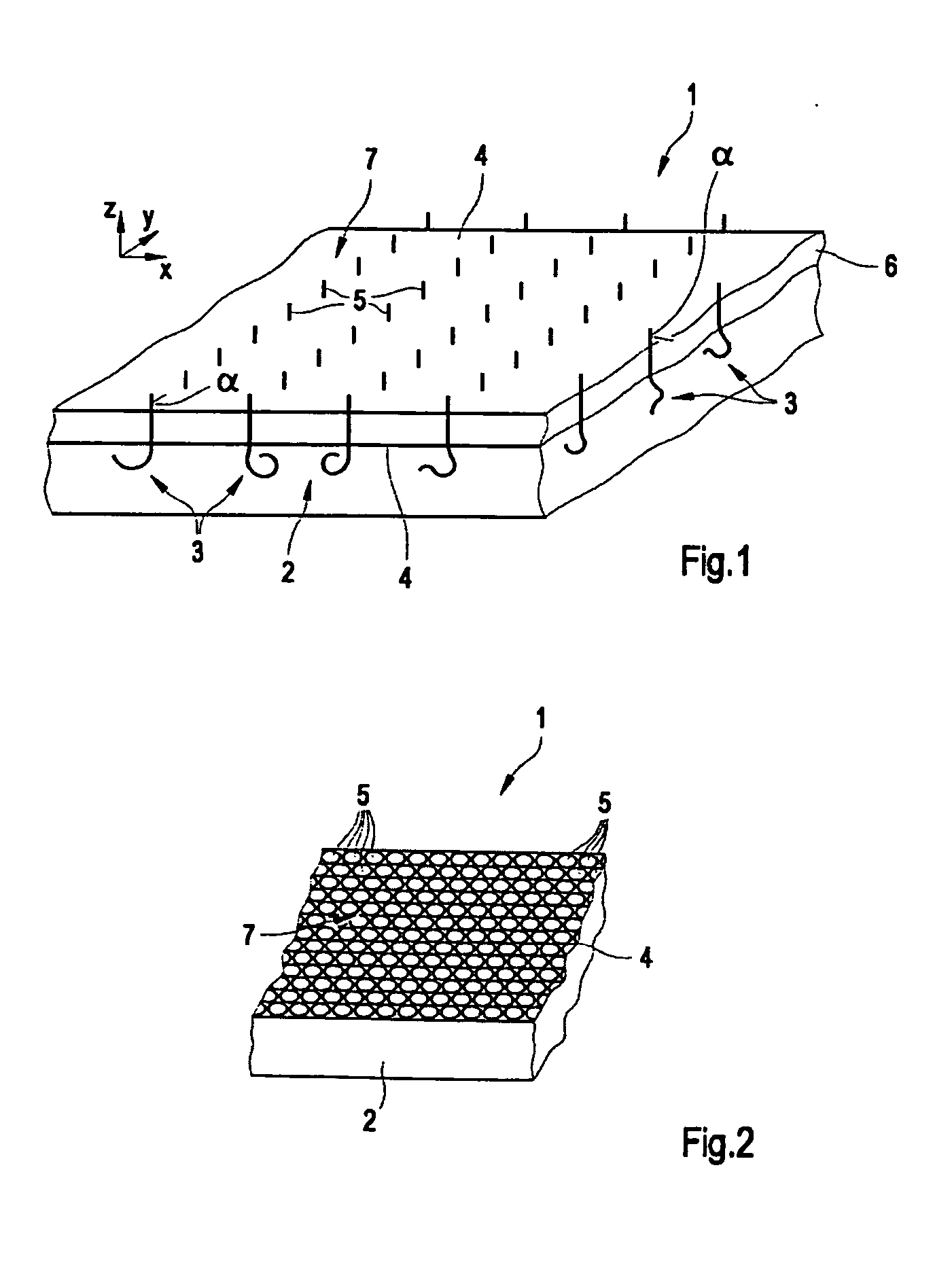

Papermachine fabric

InactiveUS20060180292A1Improved paper removal propertyQuality improvementPress sectionWoven fabricsFiberPaper machine

The invention relates to a papermachine fabric, in particular a press felt, having a carrier layer on which, at least in some sections, fibers with exposed fiber ends are arranged, the fibers forming a contact surface with which a paper web can be brought into contact, and wherein the contact surface is substantially formed by the exposed fiber ends.

Owner:VOITH PATENT GMBH

Seat sign

The invention belongs to the field of advertisements, in particular to a seat sign comprising a base frame and a face plate arranged on the base frame. The base frame comprises a base and a frame seat which are hinged to each other, the face plate is arranged on the frame seat, the lower surface of the base is a rough surface, the face plate comprises two transparent sheets, a card for displaying information is arranged between the sheets, a frame groove is formed in the frame seat, and the bottom of the face plate is inserted into the frame groove. When the card is mounted or replaced, the face plate is taken off, the card is clamped between the sheets, and then the two sheets are inserted into the frame groove; after the card is mounted, orientation of the face plate can be adjusted by means of rotating the frame seat according to requirements of an actual environment and occasion so as to achieve a better viewing angle and clearly display content on the card. The seat sign is stable in placement, the card is less prone to loss and damage, and the face plate can be adjusted to regulate to the optimal visual angle.

Owner:湖州二十一城文化传媒有限公司

Display panel, binding method thereof and display device

PendingCN112420792AIncrease contact areaReduce pressureSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

The invention provides a display panel, a binding method thereof and a display device. The display panel comprises a display layer, a heat dissipation layer and an adhesive layer. The display layer isprovided with a display area, a binding area and a bending area connected with the display area and the binding area. The heat dissipation layer is arranged on one surface of the display layer and corresponds to the display area. And the bonding layer is arranged between the heat dissipation layer and the binding area. The contact area between the bonding layer and the binding area is smaller than the contact area between the bonding layer and the heat dissipation layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

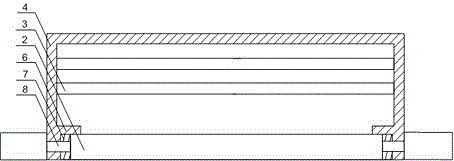

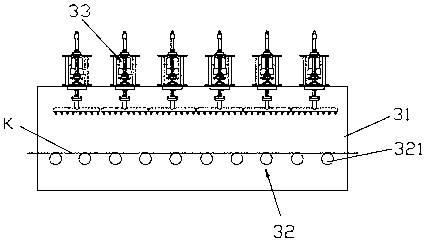

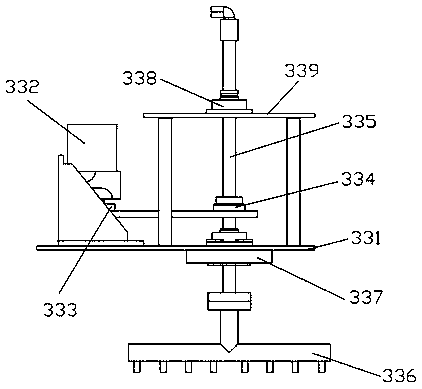

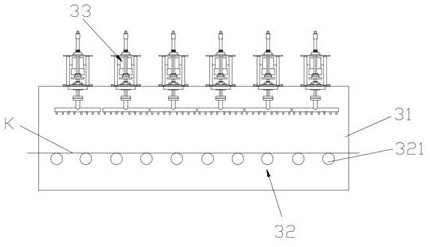

Sterilization and water removal device for thermal processing of solid wood board

ActiveCN104647492BAchieve left and right swingIncrease the areaWood treatment detailsWood dampingSolid woodMicrowave

The invention discloses a thermal processing, sterilizing and dewatering device of a solid wood panel. The thermal processing, sterilizing and dewatering device comprises a support and a conveying belt matched with the support, wherein a plurality of drying cavities which are arranged side by side and are communicated with one another are fixed above the conveying belt; upper and lower rows of parallel magnetic control pipes are fixed on the inner wall of each drying cavity; U-shaped grooves are fixedly formed in two sides of the conveying belt; two air cylinders are fixedly arranged in the support; the output ends of the two air cylinders are arranged in the U-shaped grooves in a sliding mode; the inner walls at two sides of each drying cavity are also provided with bulges which are in contact with the upper surfaces of two end parts of the conveying belt. The two air cylinders are fixed in the support, and the two ends of the conveying belt are provided with the U-shaped grooves; the output ends of the air cylinders are arranged in the U-shaped grooves in the sliding mode, so that the two air cylinder perform shrinkage stretching at opposite directions respectively, and the conveying belt can swing left and right; the contact frequency of the outer wall, in per unit of area, of a log with microwaves is increased; the drying effect of the log is improved.

Owner:创源智能家居(东莞)有限公司

Manufacturing method of shell, shell and mobile terminal

ActiveCN107877096AImprove molding qualityUniform stressTelephone set constructionsComputer terminalBiomedical engineering

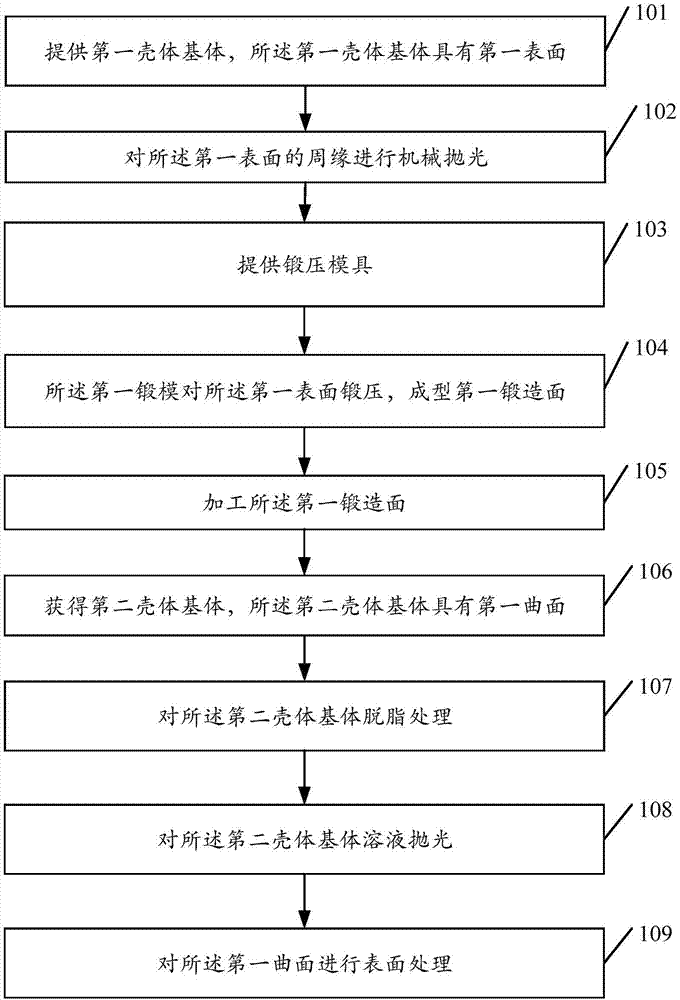

The invention provides a manufacturing method of a shell, the shell and a mobile terminal. The manufacturing method of the shell comprises the steps that a first shell base body is provided, and the first shell base body is provided with a first surface; mechanical polishing is conducted on the periphery of the first surface; a forging die is provided, and the forging die is provided with a firstforging die body, and the extrusion stress of the first forging die body on the periphery of the first surface is larger than that of the first forging die body on the non-peripheral position of the first surface; the first surface is forged through the first forging die body to form a first forged surface; and the first forged surface is processed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

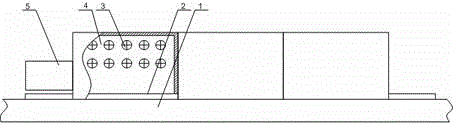

Thermal processing, sterilizing and dewatering device of solid wood panel

ActiveCN104647492AAchieve left and right swingIncrease the areaWood treatment detailsWood dampingSolid woodMicrowave

The invention discloses a thermal processing, sterilizing and dewatering device of a solid wood panel. The thermal processing, sterilizing and dewatering device comprises a support and a conveying belt matched with the support, wherein a plurality of drying cavities which are arranged side by side and are communicated with one another are fixed above the conveying belt; upper and lower rows of parallel magnetic control pipes are fixed on the inner wall of each drying cavity; U-shaped grooves are fixedly formed in two sides of the conveying belt; two air cylinders are fixedly arranged in the support; the output ends of the two air cylinders are arranged in the U-shaped grooves in a sliding mode; the inner walls at two sides of each drying cavity are also provided with bulges which are in contact with the upper surfaces of two end parts of the conveying belt. The two air cylinders are fixed in the support, and the two ends of the conveying belt are provided with the U-shaped grooves; the output ends of the air cylinders are arranged in the U-shaped grooves in the sliding mode, so that the two air cylinder perform shrinkage stretching at opposite directions respectively, and the conveying belt can swing left and right; the contact frequency of the outer wall, in per unit of area, of a log with microwaves is increased; the drying effect of the log is improved.

Owner:创源智能家居(东莞)有限公司

Novel seat board convenient to assemble and disassemble

The invention belongs to the field of advertising, and particularly relates to a novel seat board convenient to assemble and disassemble. The novel seat board comprises a base frame and a panel arranged on the base frame. The base frame comprises a horizontally-arranged base and a frame seat fixedly connected to one end of the base and aslant arranged. The panel is arranged on the frame seat. An anti-skid groove is formed in the lower surface of the base. The panel comprises a front transparent thin plate and a rear transparent thin plate, and a card displaying information is arranged between the two thin plates. A limiting step concaved inwards is arranged on the rear surface of the front thin plate or the front surface of the rear thin plate and is perpendicular to end surfaces of the two sides of the front thin plate, and the width of the limiting step ranges from 1.1mm to 1.8mm. A frame groove is formed in the frame seat. The bottom end of the panel is inserted into the frame groove. The top portion of the panel is sleeved with a clamping frame. The seat board is stably placed, simple in structure, easy to process, low in cost, capable of being repeatedly used and more environmentally friendly and saves more energy, and the card can not be lost or damaged. When the novel seat board is used, the base frame and the panel can be independently replaced when any of the base frame and the panel abrades, and cost is reduced.

Owner:湖州二十一城文化传媒有限公司

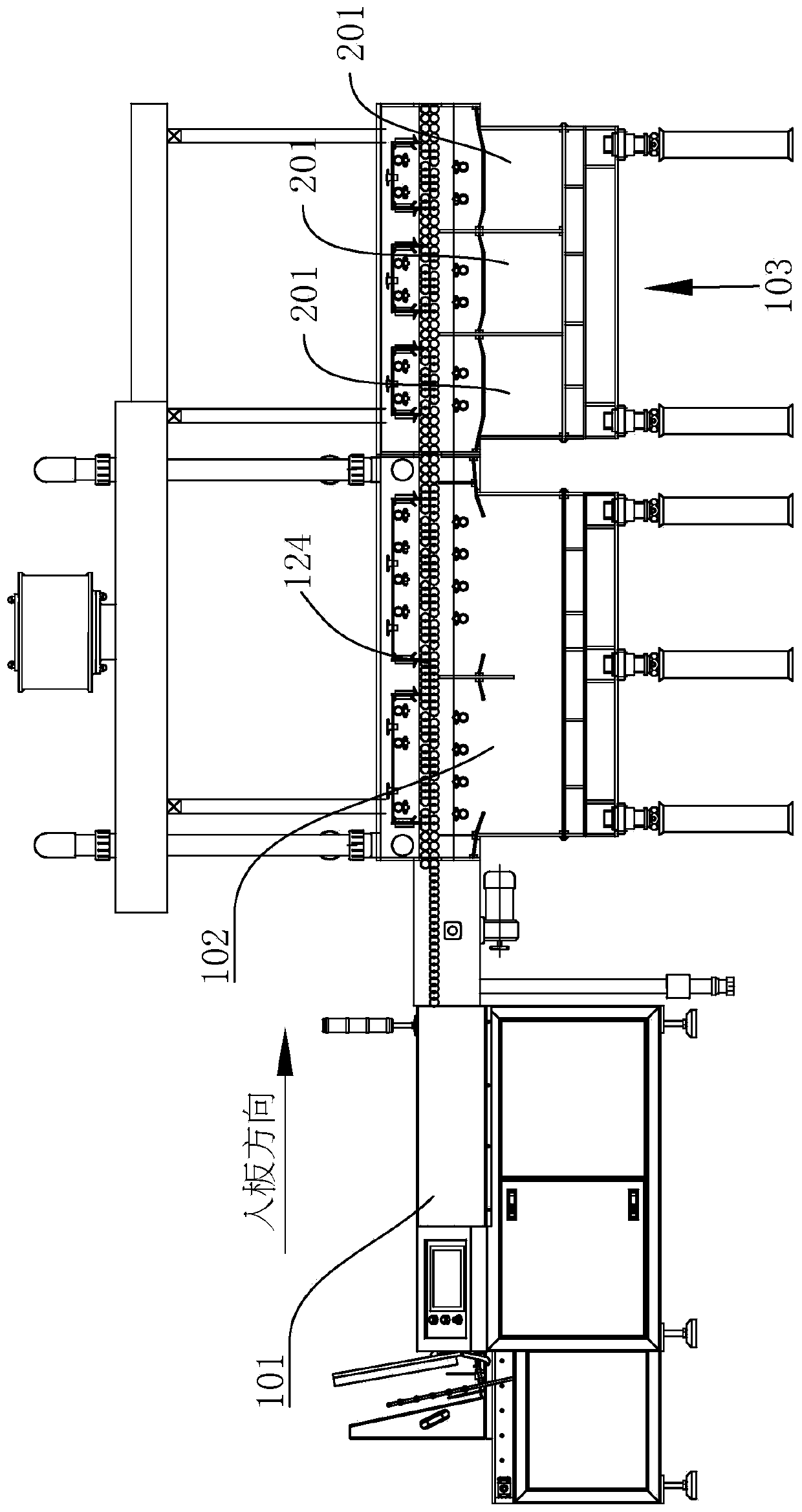

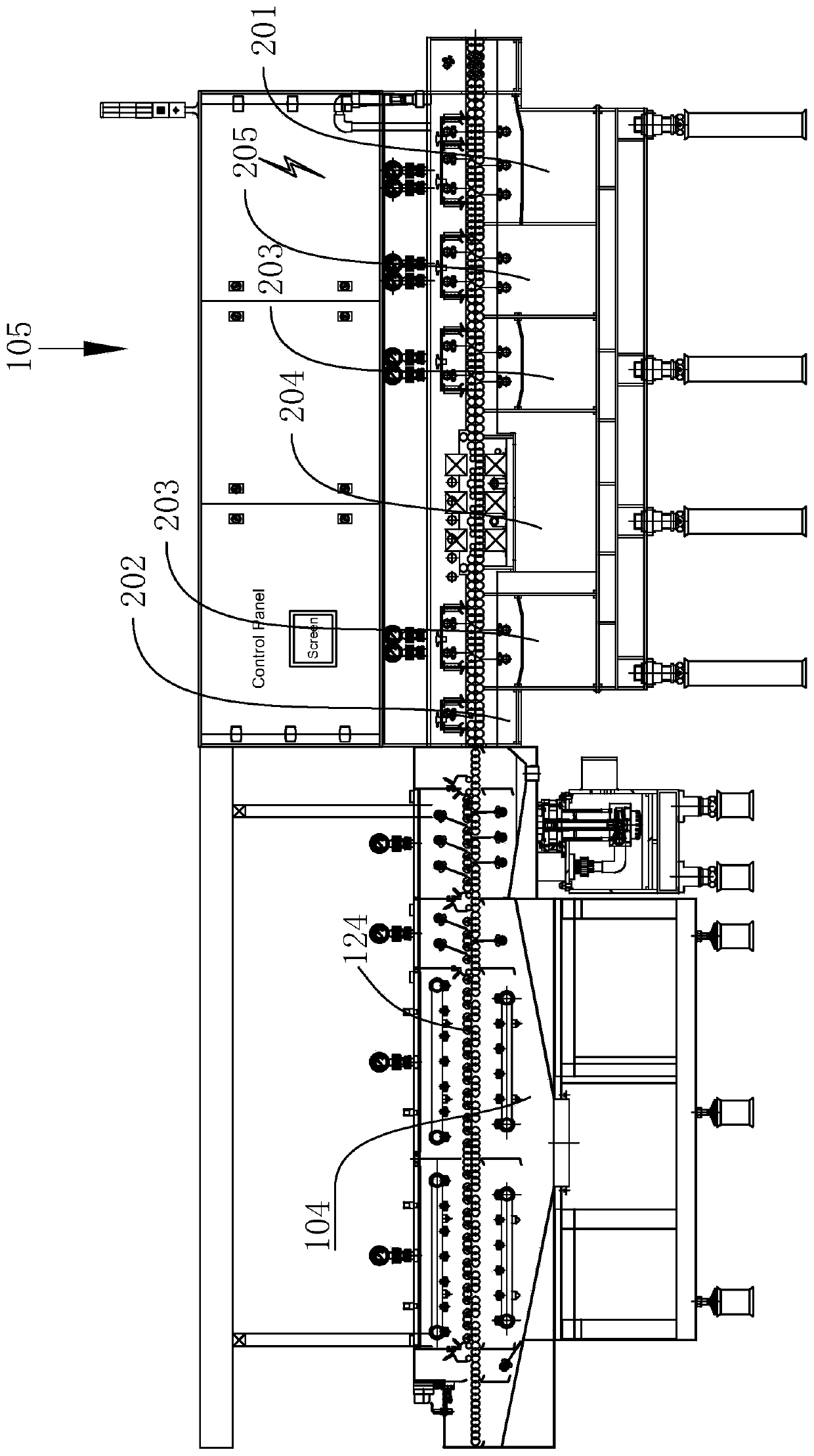

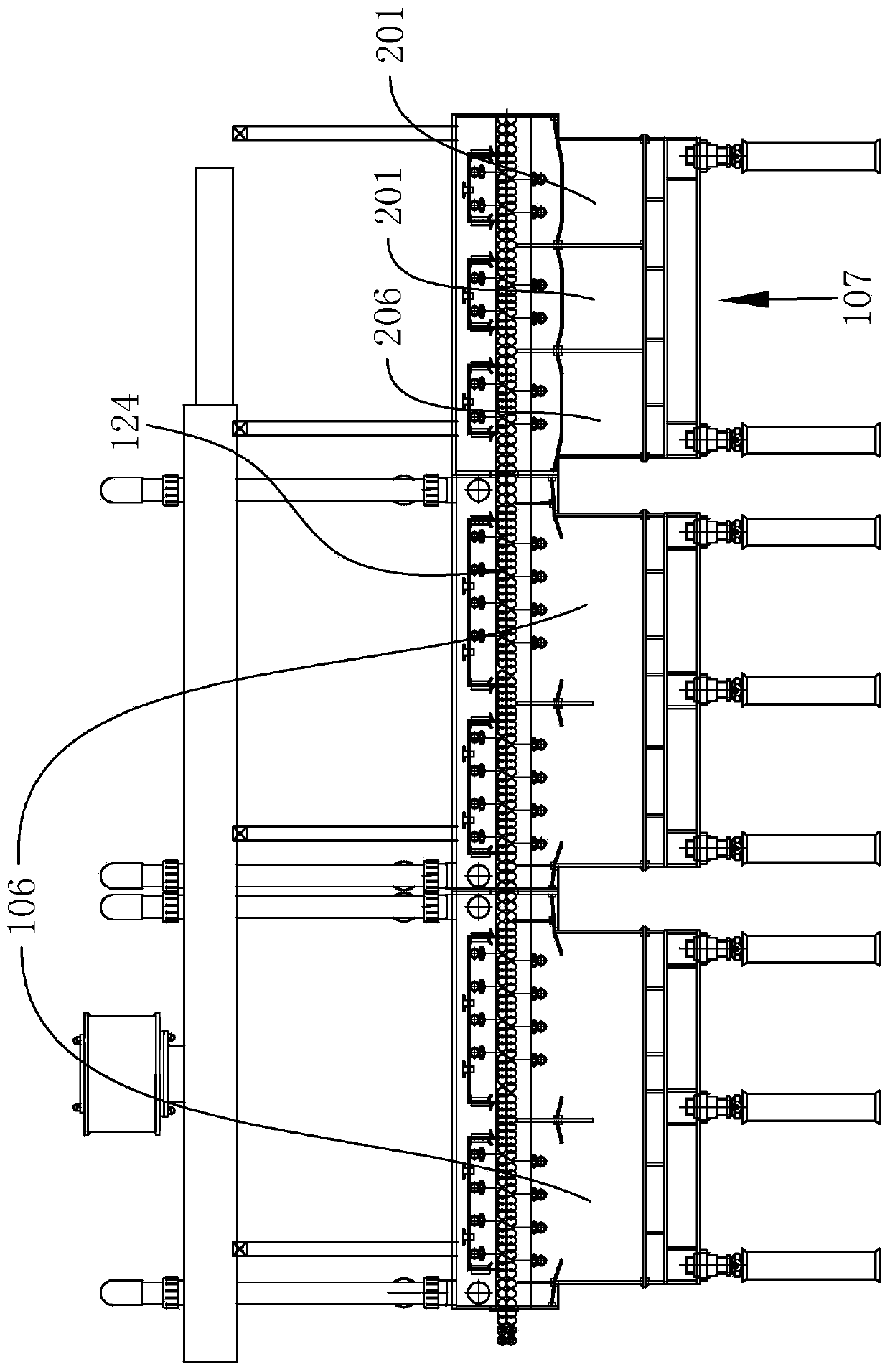

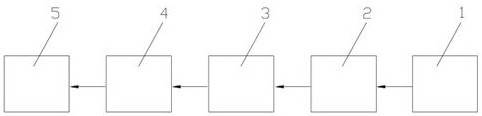

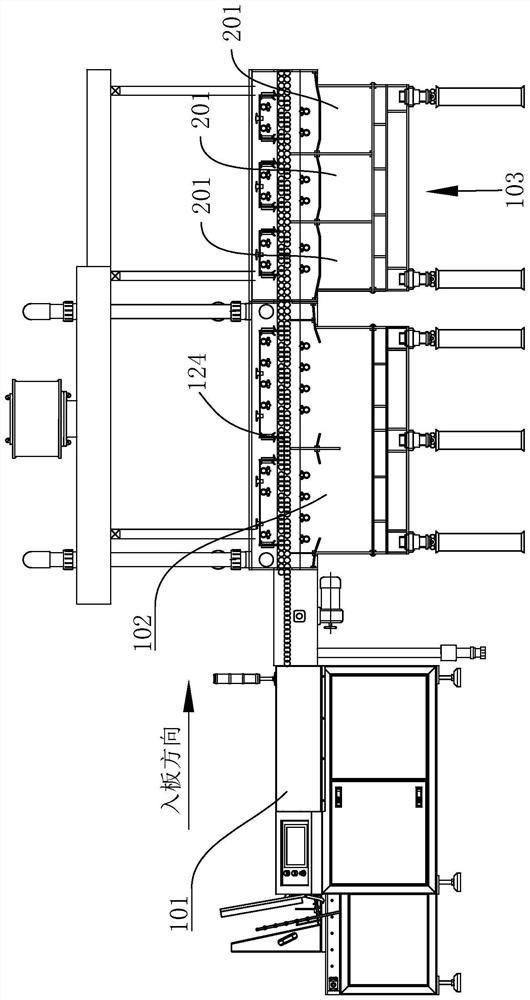

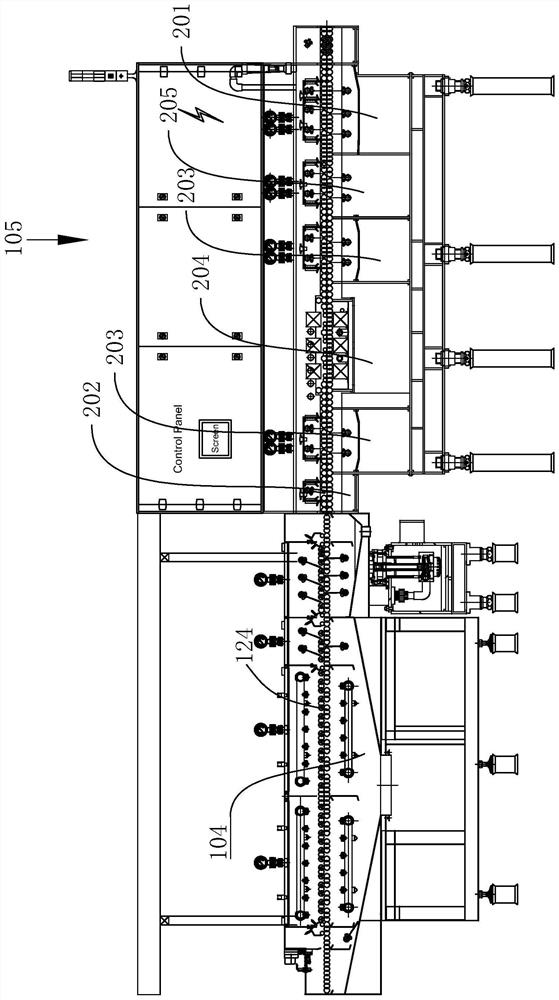

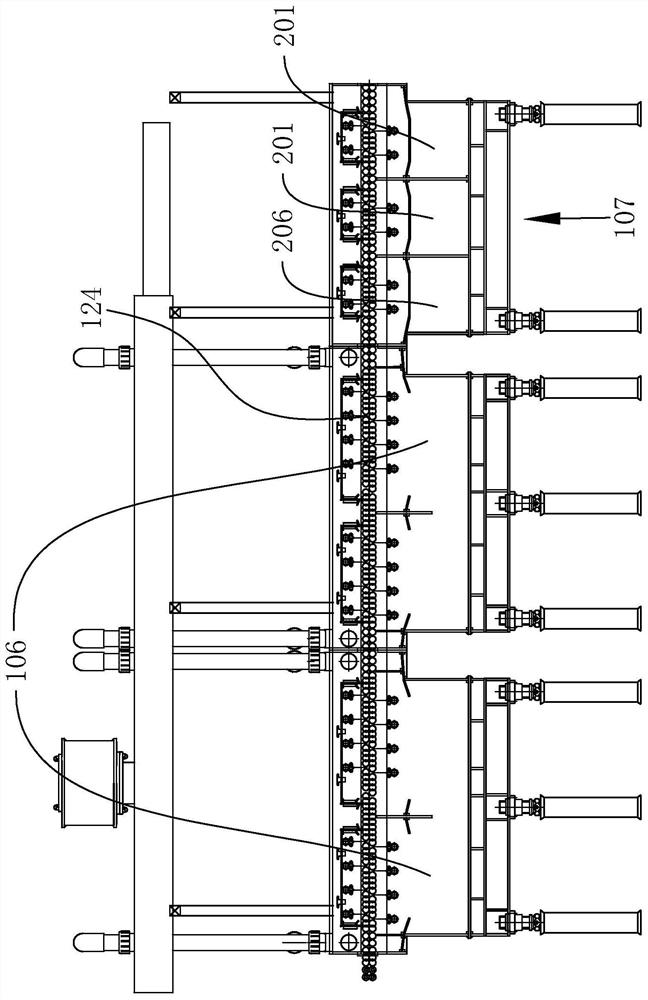

Horizontal electroless nickel/immersion gold assembly line and electroless nickel/immersion gold method

ActiveCN110318042AShorten the lengthImprove efficiencyLiquid/solution decomposition chemical coatingPrinted circuit manufactureElectroless nickelSand blasting

The invention relates to a horizontal electroless nickel / immersion gold assembly line and an electroless nickel / immersion gold method. The horizontal electroless nickel / immersion gold assembly line comprises an automatic plate placing machine, a first micro-etching bath, a first rinsing bath set, a sand blasting machine, a second rinsing bath set, an oil removing bath set, a third rinsing bath set, a second micro-etching bath, a fourth rinsing bath set, a pre-soaking bath, an activated bath set, a fifth rinsing bath set, a pickling bath, a sixth rinsing bath set, a first surface treatment system, a seventh rinsing bath set, a second surface treatment system, a gold recovery bath, an eighth rinsing bath set, an operation station, a ninth rinsing bath set, a blowing-drying bath set, an automatic plate collecting machine and a conveying mechanism which are sequentially arranged. The horizontal electroless nickel / immersion gold assembly line has the effects of being short, suitable for installation and use in general small factories, high in electroless nickel / immersion gold efficiency and high in electroless nickel / immersion gold quality.

Owner:SHENZHEN CYPRESS IND DEV CO LTD

Cut section storage device for tent cloth processing

ActiveCN111908243AAvoid overfeedingEasy to operateSevering textilesPile receiversElectric machineryEngineering

The invention discloses a cut section storage device for tent cloth processing. The cut section storage device comprises a base, a discharge mechanism, a cutting mechanism, a material guide mechanismand a storage mechanism, wherein the base is fixedly connected with a workbench and a storage groove, the cutting mechanism and the material guide mechanism are arranged at the upper end of the workbench, and the storage mechanism is arranged in the storage groove. According to the cut section storage device, the storage groove is formed to store a cloth cutting section; and meanwhile, the storagemechanism is arranged, so that the rotating speed of a storage motor can be adjusted according to the tent cloth cutting speed, a movable bottom plate is matched with the frequency of the cloth cutting section entering the storage groove, and the storage motor drives a second lead screw to rotate; and the second lead screw drives the movable bottom plate to continuously descend according to the feeding of the cloth cutting section, so that the fall of the cloth cutting section entering the storage groove is reduced, and the situations that because the cloth cutting section is curled after entering the storage groove, curled cloth is pressed to generate marks during storage, and the storage space is not sufficiently utilized are avoided.

Owner:安徽北极户外用品有限公司

Bumper strip manufacturing equipment

ActiveCN108527737AReduce contact areaReduce frictionDrying gas arrangementsCleaning using liquidsHigh pressure waterHigh pressure

The invention provides bumper strip manufacturing equipment. The bumper strip manufacturing equipment comprises an extruder, a salt bath device, a washing device, a blow-drying device and a drying device, wherein the washing device comprises a washing bin, a first conveying roller line and a plurality of rotary washing mechanisms, wherein the first conveying roller line penetrates through the washing bin; the first conveying roller line comprises a plurality of first conveying roller shafts which are arranged at intervals; each rotary washing mechanism comprises a motor and a rotating shaft pipe; one end of each rotating shaft pipe communicates with a high-pressure water source; the other end of each rotating shaft pipe communicates with a water spraying line after penetrating through thewashing bin; the length of each water spraying line is larger than the width of a bumper strip; and after rotating in the length direction of the first conveying roller line, the water spraying linesof the rotary washing mechanisms are straightly engaged in the length direction of the first conveying roller line. According to the bumper strip manufacturing equipment provided by the invention, thewater spray range of each rotary washing mechanism is relatively large, so the bumper strip can be washed and cleaned effectively; and by adopting the conveying roller line, the friction between thebumper strip and the conveying roller shafts can be reduced.

Owner:盐城市大丰区比齐密封系统有限公司

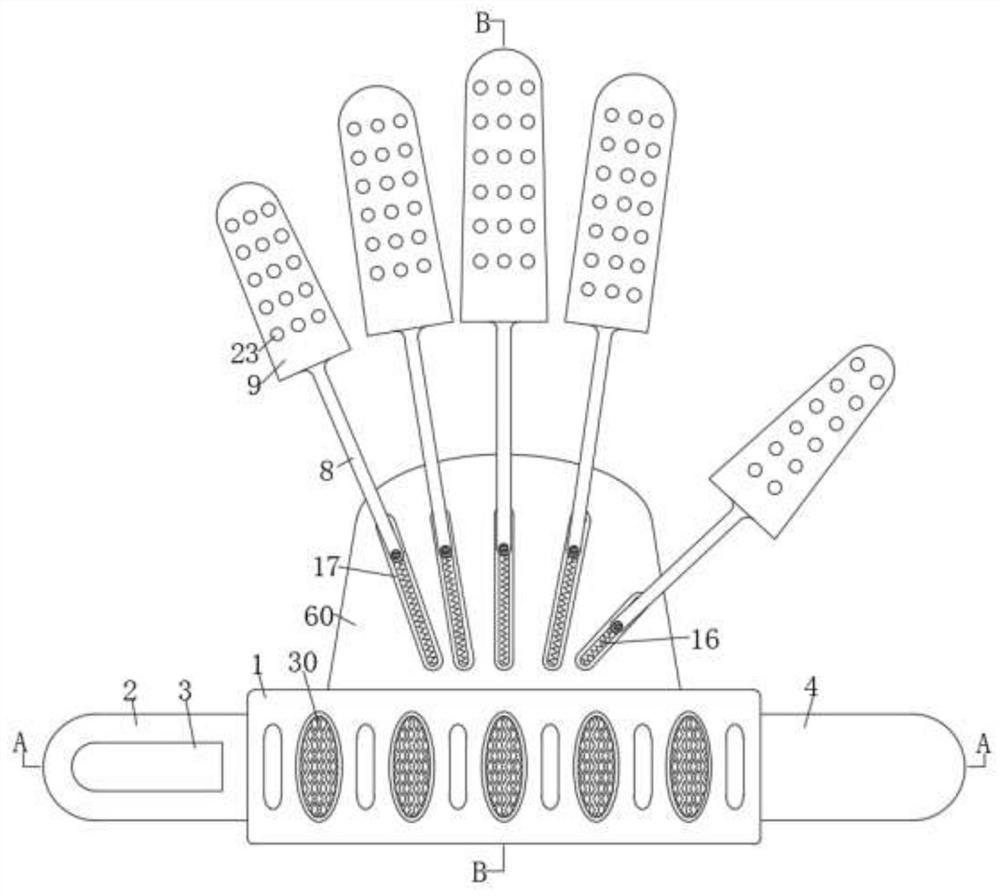

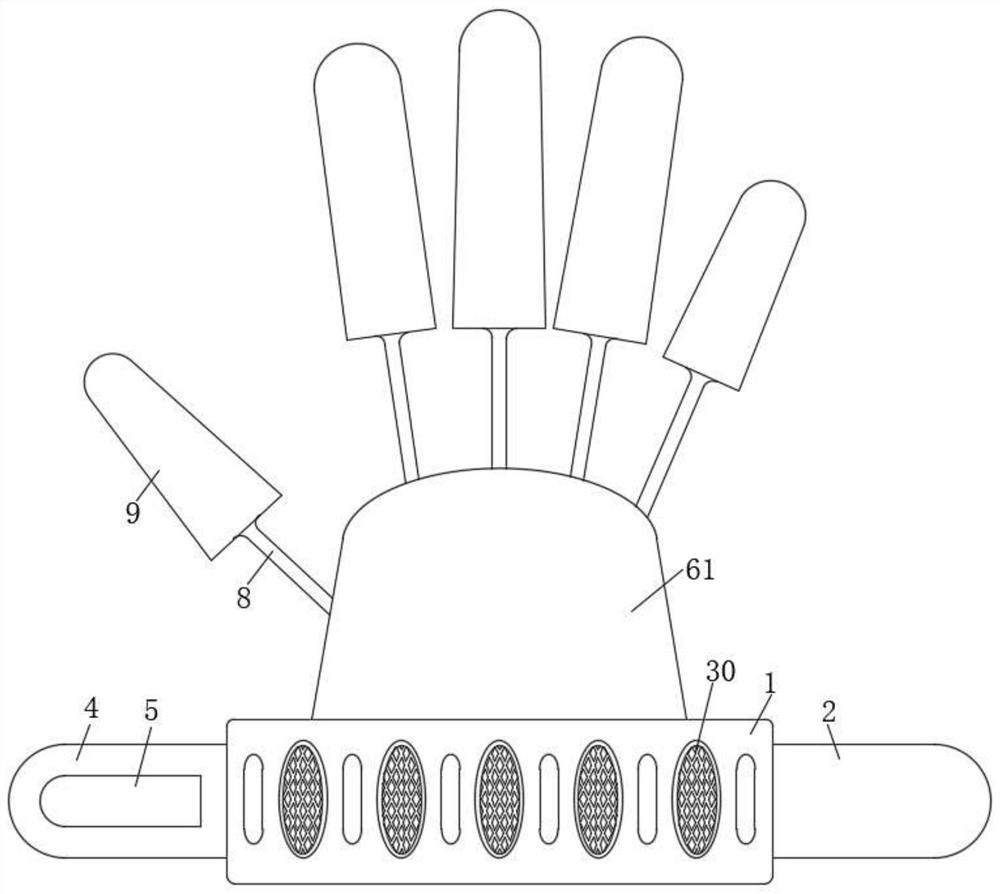

Printing protective fingerstall with ventilation function

PendingCN112617315AWith breathable functionWith cooling and exhaust functionGarment special featuresProtective garmentStructural engineeringMechanical engineering

The invention relates to the technical field of protective fingerstalls, in particular to a printed protective fingerstall with a ventilation function, which comprises a wrist strap, one end of the wrist strap is connected with a first binding strip, one side of the first binding strip is provided with a pile loop strip, and one end of the wrist strap far away from the first binding strip is connected with a second binding strip; a hook strip matched with the pile loop strip is arranged on one side of the second binding strip, a connecting cloth piece is arranged on the side, close to the fingers, of the wrist strap, five mounting columns are arranged on the side, away from the hand back, of the connecting cloth piece, and the outer sides of the five mounting columns are sleeved with first connecting strips; the ends, away from the mounting column, of the first connecting strips are connected with outer finger sleeves matched with the five fingers respectively, protective woven sleeves are arranged in the five outer finger sleeves respectively, arc-shaped supporting plates are evenly connected to insertion openings of the inner finger sleeves, and elastic connecting ropes are arranged between the adjacent arc-shaped supporting plates for fixed connection. By means of the finterstall, the fingers of an operator can be prevented from being scalded by printed products, and meanwhile, the protective fingerstalls facilitate heat dissipation and are not prone to sliding off.

Owner:卢发均

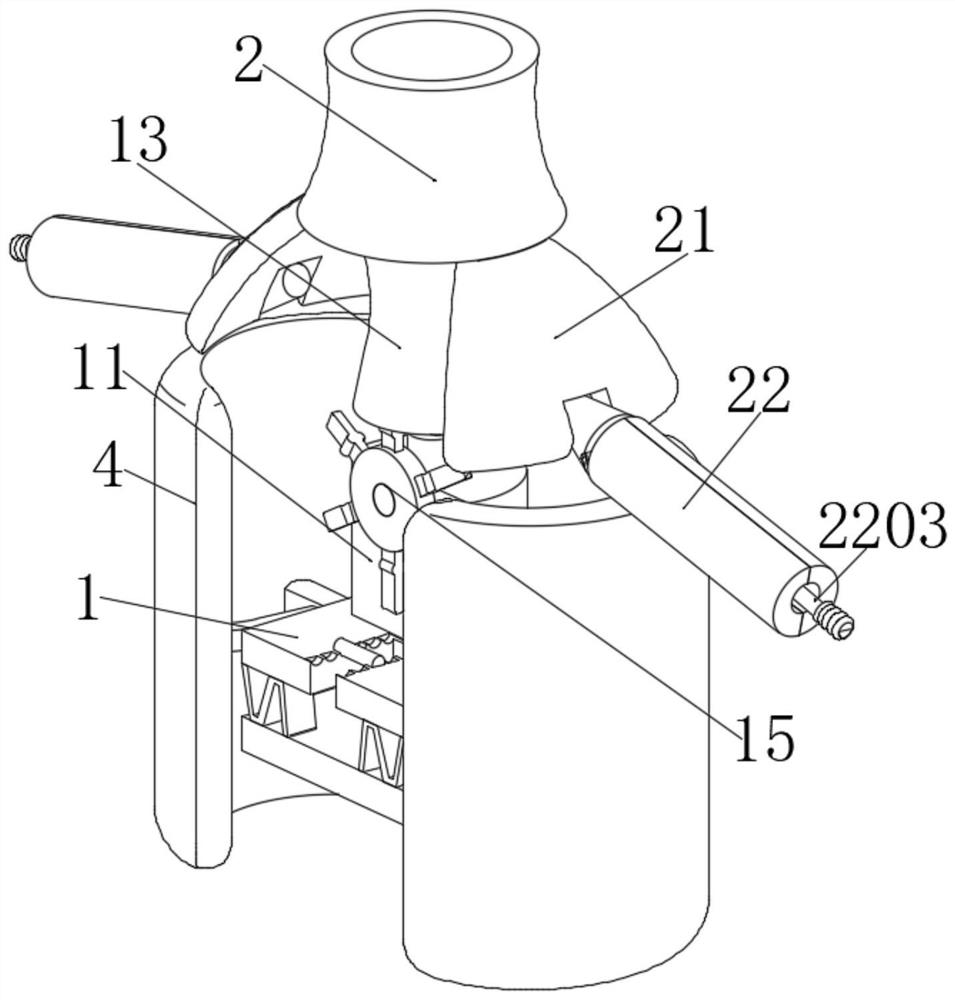

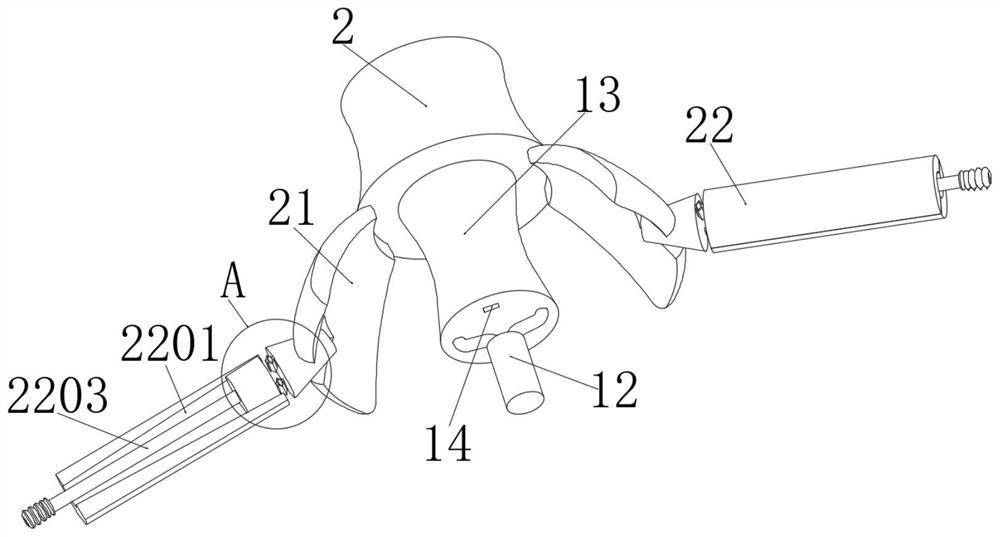

An ironing device for textile T-shirt processing

ActiveCN112921614BEasy to useEasy ironingIroning apparatusTextiles and paperProcess engineeringIndustrial engineering

The present invention relates to the technical field of ironing devices for textile T-shirt processing, in particular to an ironing device for textile T-shirt processing. An integrally formed upper support cylinder is arranged on the upper side of the U-shaped center plate. The improvement of the T-shirt auxiliary device can greatly increase the usability of the T-shirt, which is conducive to ironing T-shirts of different sizes, and can effectively avoid the problem of marks on the T-shirt after ironing, thereby ensuring T-shirt The quality of the T-shirt after ironing; the invention operates with the U-shaped center rod as the center, which allows the staff to quickly and appropriately adjust the size of the auxiliary device, thus effectively solving the problem of the staff laying the T-shirt flat, At the same time, the operation of the auxiliary device can save the staff time and effort.

Owner:江西嘉丰纺织有限公司

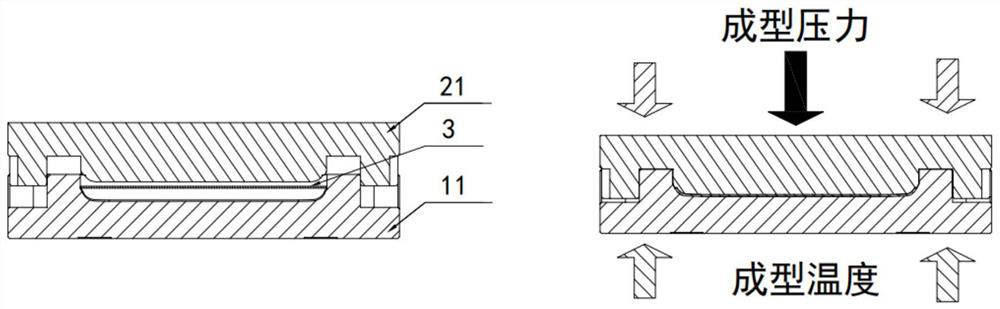

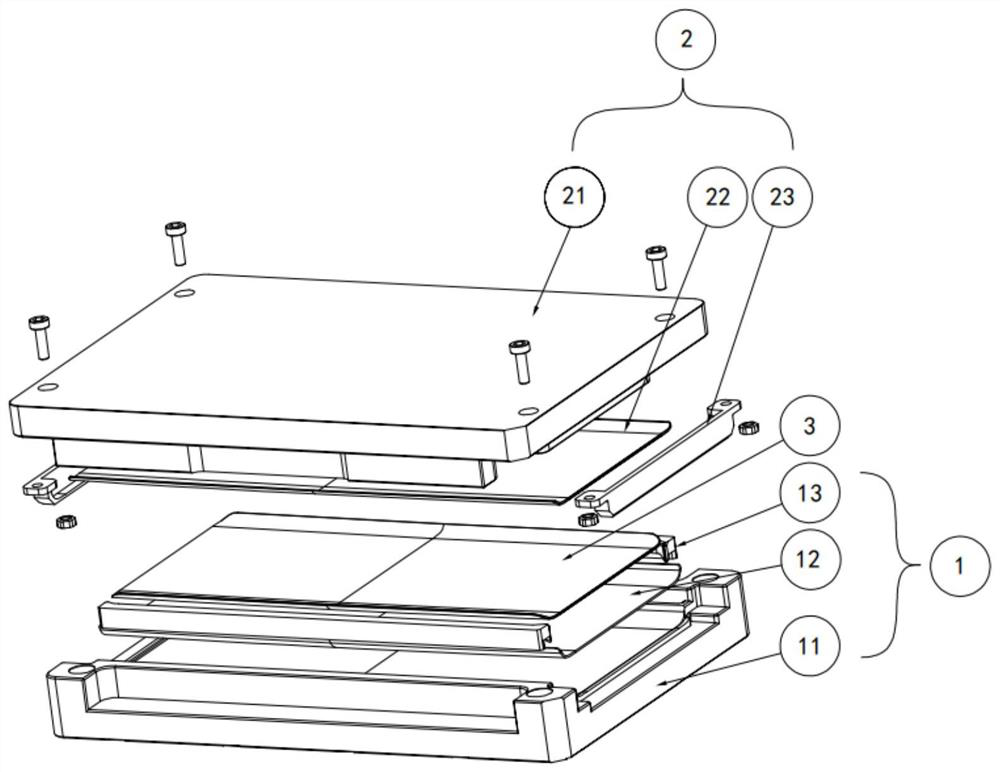

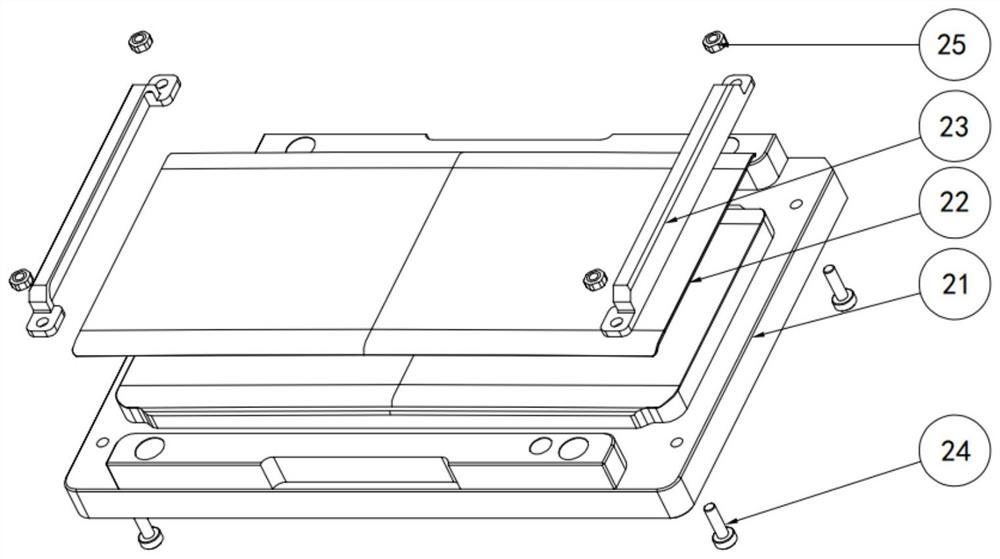

Glass hot bending mold and glass hot bending forming method

The invention provides a glass hot bending mold and a glass hot bending forming method, and relates to the technical field of hot bending molds. The glass hot bending die comprises a female die assembly and a male die assembly, the female die assembly is mainly composed of a graphite female die, a female die protection sheet consistent with the graphite female die in profile tolerance and a female die fixing insert, and the male die assembly is mainly composed of a graphite male die, a male die protection sheet consistent with the graphite male die in profile tolerance and a male die fixing insert; in the hot bending forming process, the female die protection sheet and the male die protection sheet replace a graphite female die and a graphite male die respectively to be in direct contact with the glass to be subjected to hot bending, and the contact surface of the female die protection sheet and the glass to be subjected to hot bending and the contact surface of the male die protection sheet and the glass to be subjected to hot bending are bright and have low roughness. The surface of the formed glass is still bright and has no bad die impressions, the die impressions generated on the surface of the glass by the die after hot bending are avoided, and the product polishing time after hot bending can be shortened, so that the production efficiency is improved, and the production cost is reduced.

Owner:LENS TECH

A new type of injection mold for the production of plastic products with mold opening and anti-marking

The invention discloses a mold opening impression prevention novel injection mold for plastic product production. The mold opening impression prevention novel injection mold for plastic product production structurally comprises a demolding assisting device, a base, a lower mold, an upper mold, an air flow main channel, limiting blocks and air flow branch channels. The four corners of the bottom surface of the upper mold are matched with locating holes at the four corners of the top surface of the lower mold through locating columns correspondingly. Compared with the prior art, the mold openingimpression prevention novel injection mold for plastic product production has the beneficial effects that air is compressed through the polarity repulsion and attraction principle; the area of the air flow channels is limited, air flow is concentrated and acts on a movable disk to expand the area of the air flow main channel, channel openings of air flow branch channel opening appearance and disappearance startup groups, and the air flow is guided out from the channel openings of the air flow branch channels to act on plastic products. Cooling on the plastic products is accelerated. Moreover,the plastic products can be ejected by the air flow to be subjected to rapid demolding. An ejector rod ejection method is abandoned. The plastic products are efficiency protected against impression.The attractiveness of the plastic products can be ensured. Manufacturing resources are saved. The manufacturing cost is lowered.

Owner:SHENZHEN JIANGNAN WEIYE MOLD PLASTIC

A kind of anti-collision strip preparation equipment

ActiveCN108527737BReduce contact areaReduce frictionDrying gas arrangementsCleaning using liquidsRotational axisElectric machinery

Owner:盐城市大丰区比齐密封系统有限公司

Horizontal nickel-gold assembly line and nickel-gold method

ActiveCN110318042BShorten the lengthImprove efficiencyLiquid/solution decomposition chemical coatingPrinted circuit manufactureElectroless nickelSand blasting

Owner:SHENZHEN CYPRESS IND DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com