Glass hot bending mold and glass hot bending forming method

A glass and mold technology, applied in the field of hot bending molds, can solve problems such as long polishing process, achieve the effects of reducing production costs, improving production efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0099] As an optional embodiment of the present invention, the preparation method of protective sheet (concave protective sheet and convex mold protective sheet) comprises the following steps:

[0100] (a) Material selection: Glass is used as the material of the protective sheet (such as Corning series, AGC series, and Schott series commonly used in the glass industry can be used), and its thickness ranges from 0.2mm to 1.3mm. According to the different materials of the glass to be bent, it is necessary to pay attention to the softening temperature of the protective sheet when selecting materials that are 30°C higher than the softening temperature of the glass to be bent;

[0101] (b) Cutting & CNC: Use cutting machine to cut the material, with approximate dimensions, dimensional accuracy tolerance ±0.2mm, and then use CNC machine and grinding wheel rod to refine the size and edge chamfering, and the dimensional accuracy after processing is high (± 0.02mm), the edge is chamfer...

Embodiment 1

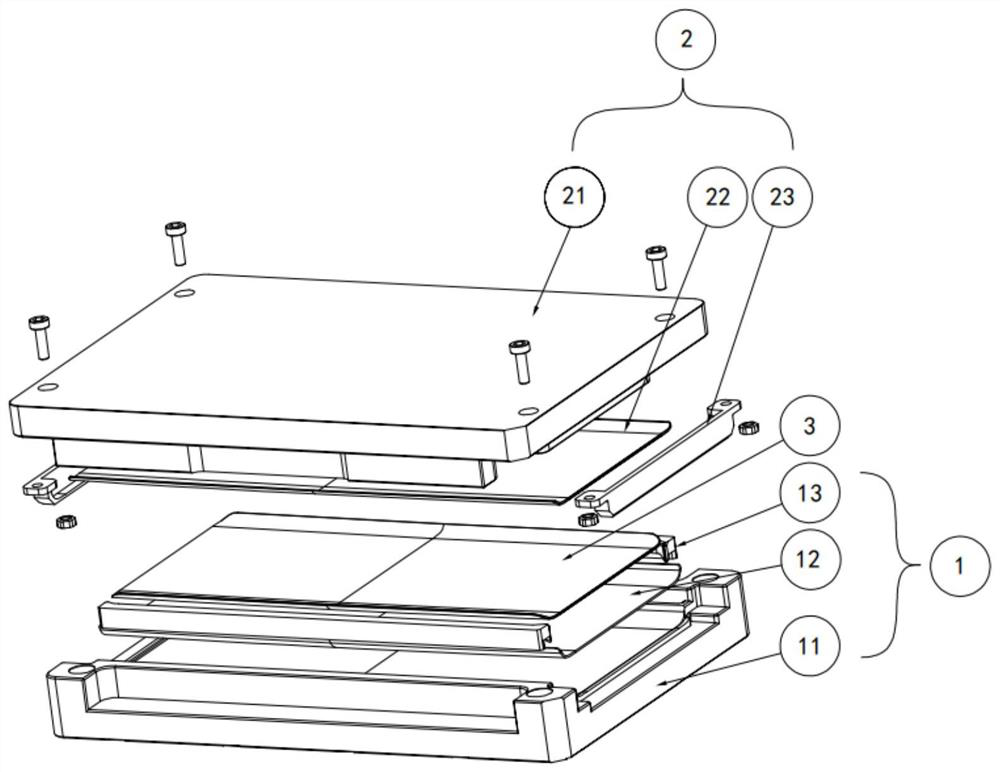

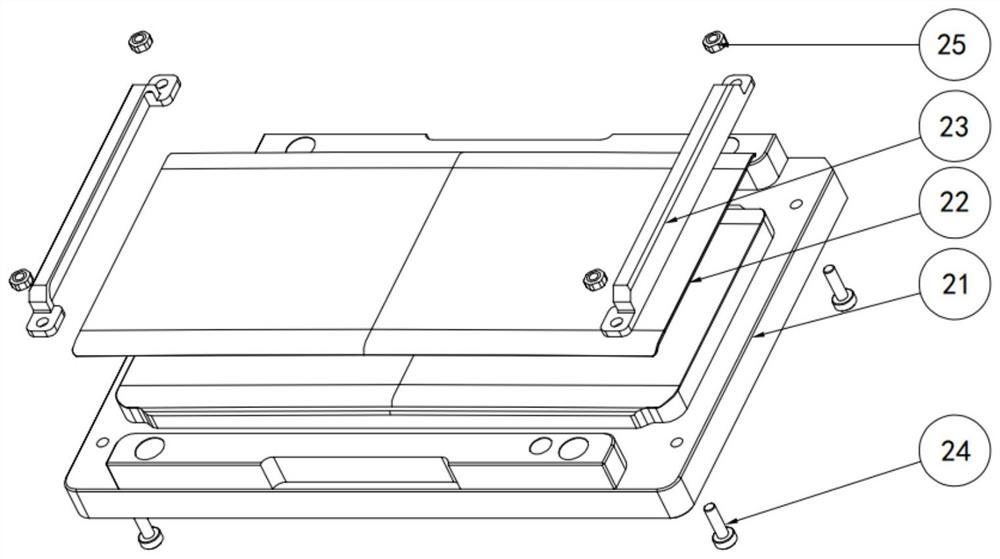

[0115] This embodiment provides a glass hot bending mold, including a die assembly and a punch assembly;

[0116] Die assembly is mainly composed of graphite die, die protection sheet consistent with the contour of graphite die, and die fixing insert. Convex die assembly is mainly composed of graphite punch, punch with contour consistent with graphite punch Composed of protective sheet and punch fixing insert;

[0117] The graphite concave mold and the graphite convex mold cooperate with each other to form a mold cavity for processing the glass to be bent. The graphite concave mold is provided with a concave mold protection sheet on the side facing the mold cavity. The concave mold protection sheet can be fixed and inlaid The parts are fixed on the graphite die; the side of the graphite punch facing the mold cavity is provided with a punch protection sheet, and the punch protection sheet can be fixed on the graphite punch through the punch fixing insert;

[0118] The roughnes...

Embodiment 2

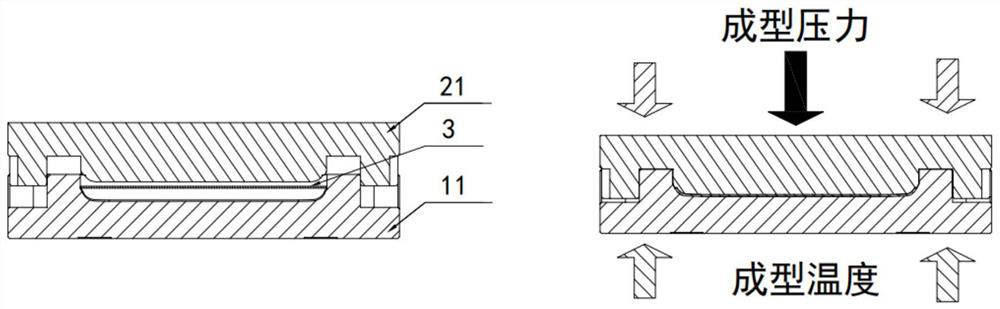

[0122] This embodiment provides a glass hot-bending forming method, using the glass hot-bending mold provided in Example 1 to perform hot-bending forming on the glass to be bent, including the following steps:

[0123] (a) graphite die, die protection sheet and die fixing insert are assembled into die assembly, and graphite punch, punch protection sheet and punch fixing insert are assembled into punch assembly;

[0124] (b) placing the glass to be bent in the die assembly, then placing the punch assembly on the glass to be bent, and closing the molds;

[0125] (c) Place the mold-closed glass hot-bending mold in a hot-bending machine for hot-bending forming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com