Dryer for uniformly drying solid wood board raw materials

A solid wood board and dryer technology, used in dryers, wood drying, progressive dryers, etc., can solve the problems of deformation paint adhesion, high level of operation requirements, environmental pollution, etc., to reduce deformation and ensure uniformity. drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

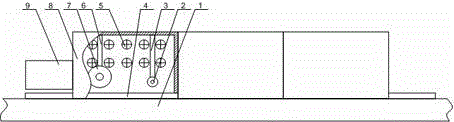

[0018] Such as figure 1 As shown, the present embodiment includes a bracket 1 and a conveyor belt 4 matched therewith. Above the conveyor belt 4, a plurality of drying cavities 8 arranged side by side and communicating with each other are fixed, and the two sides of the drying cavity 8 are provided with At the inlet end and the outlet end, two rows of magnetrons 5 parallel to each other are fixed on the inner wall of the drying cavity 8, and also include a small roller 2 and a large roller 7, and the small roller 2 and the large roller 7 pass through the connecting rod respectively. A3, the connecting rod B6 is fixed on the inlet end and the outlet end of the drying cavity 8, and the bottom ends of the small roller 2 and the big roller 7 are located on the same straight line; a radiator 9 is also included, and the radiator 9 is fixed on the drying chamber. On the side wall of the cavity 8 and facing the discharge port of the conveyor belt 4 .

[0019] When the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com