Printing device for inflatable model production

A printing and inflatable technology, applied in printing, stamping and other directions, can solve the problems of complicated operation, complicated structure of printing equipment and complicated design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

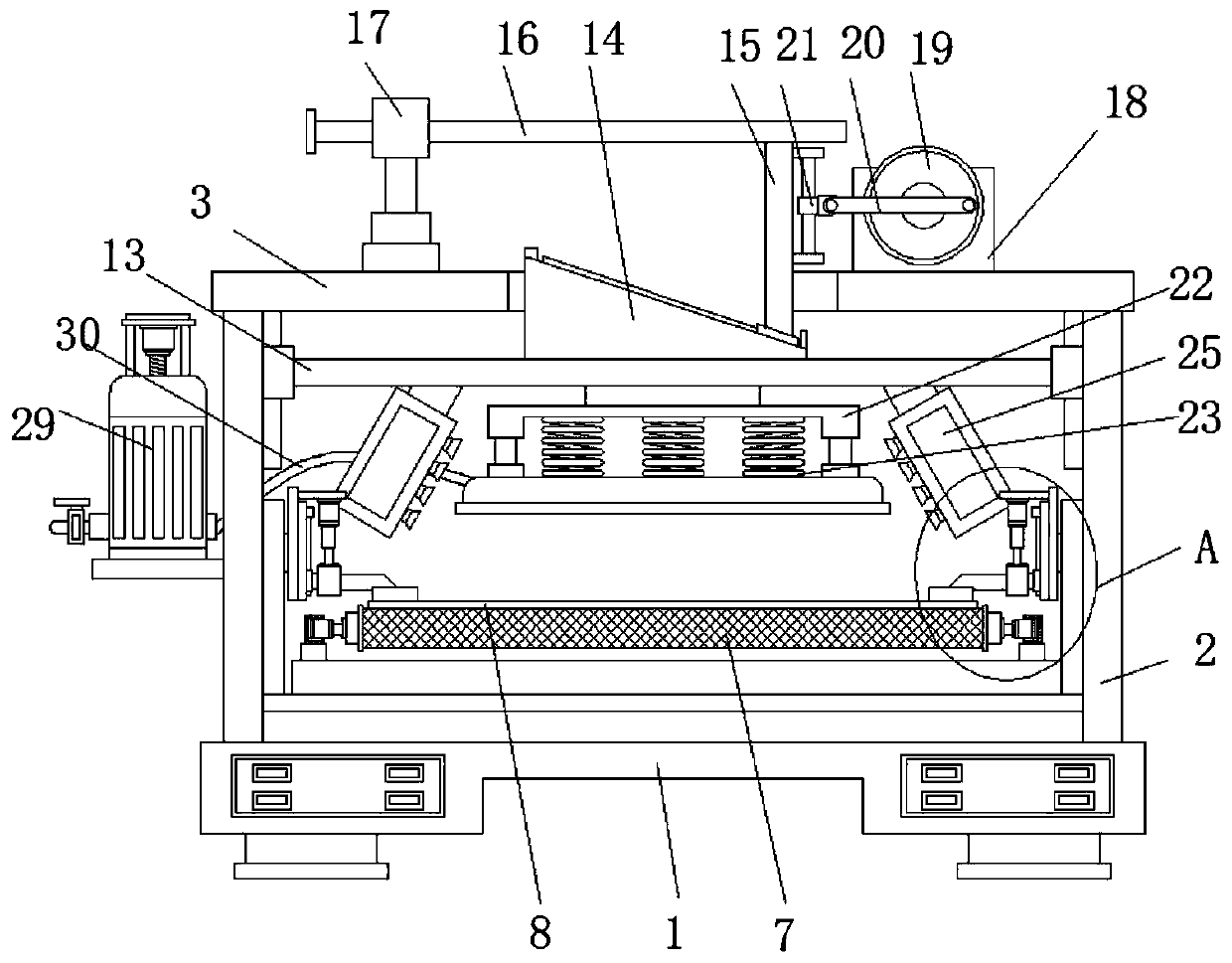

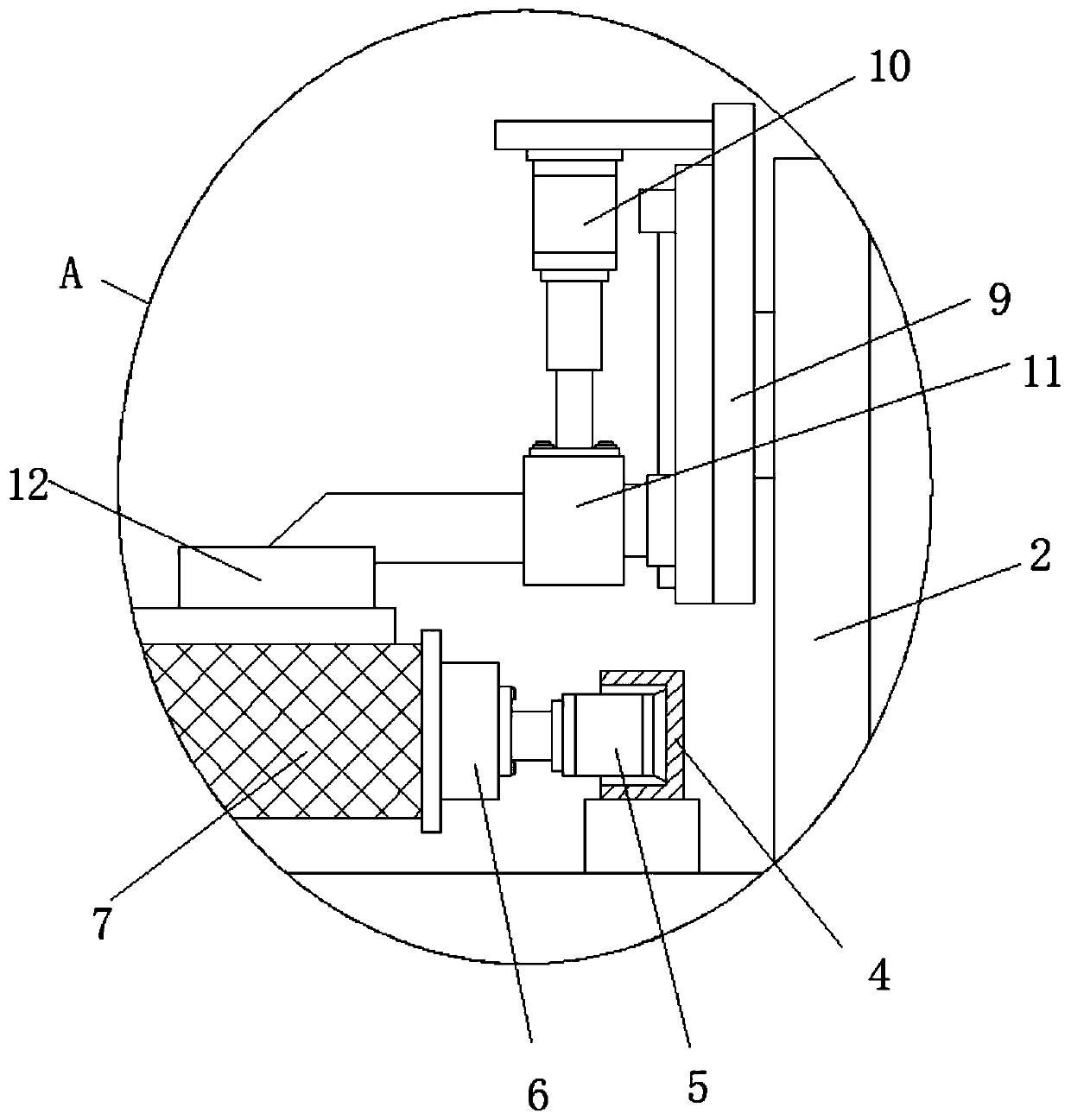

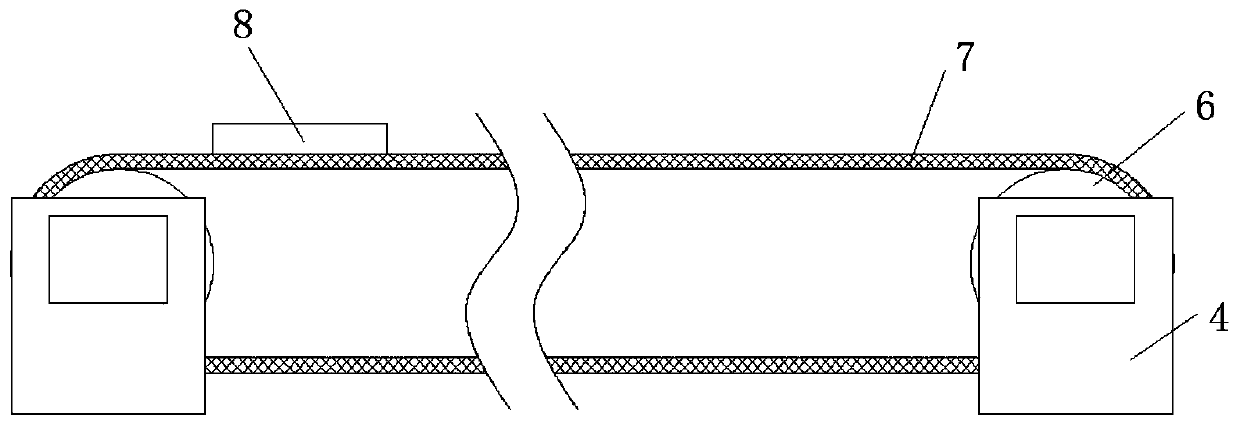

[0033] Such as Figure 1-7 As shown, a kind of printing equipment for inflatable mold production includes a console 1, two support frames 2 symmetrically arranged are fixedly installed on the top of the console 1, and the same top plate 3 is fixedly installed on the top of the two support frames 2, The top of the operating table 1 is provided with a transport assembly, and the air mold product 8 is placed on the transport assembly, and the pressing assembly for fixing the air mold product 8 is arranged on the operating table 1, and the sides of the two support frames 2 that are close to each other are slidingly connected There is the same limiting plate 13, the top of the limiting plate 13 is fixedly connected with a trapezoidal plate 14, the top slope of the trapezoidal plate 14 is slidably connected with a push rod 15, and the top of the push rod 15 is fixedly equipped with a slide bar 16, and the top of the top plate 3 The top is fixedly connected to the limit block 17, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com