DC-driven mobile refrigeration equipment

A refrigeration equipment, direct current technology, applied in heating/cooling equipment, refrigerators, refrigeration components, etc., can solve the problems of high maintenance costs, consumption, large resources and costs, and achieve stable cooling capacity, simple design principles, and fuel savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

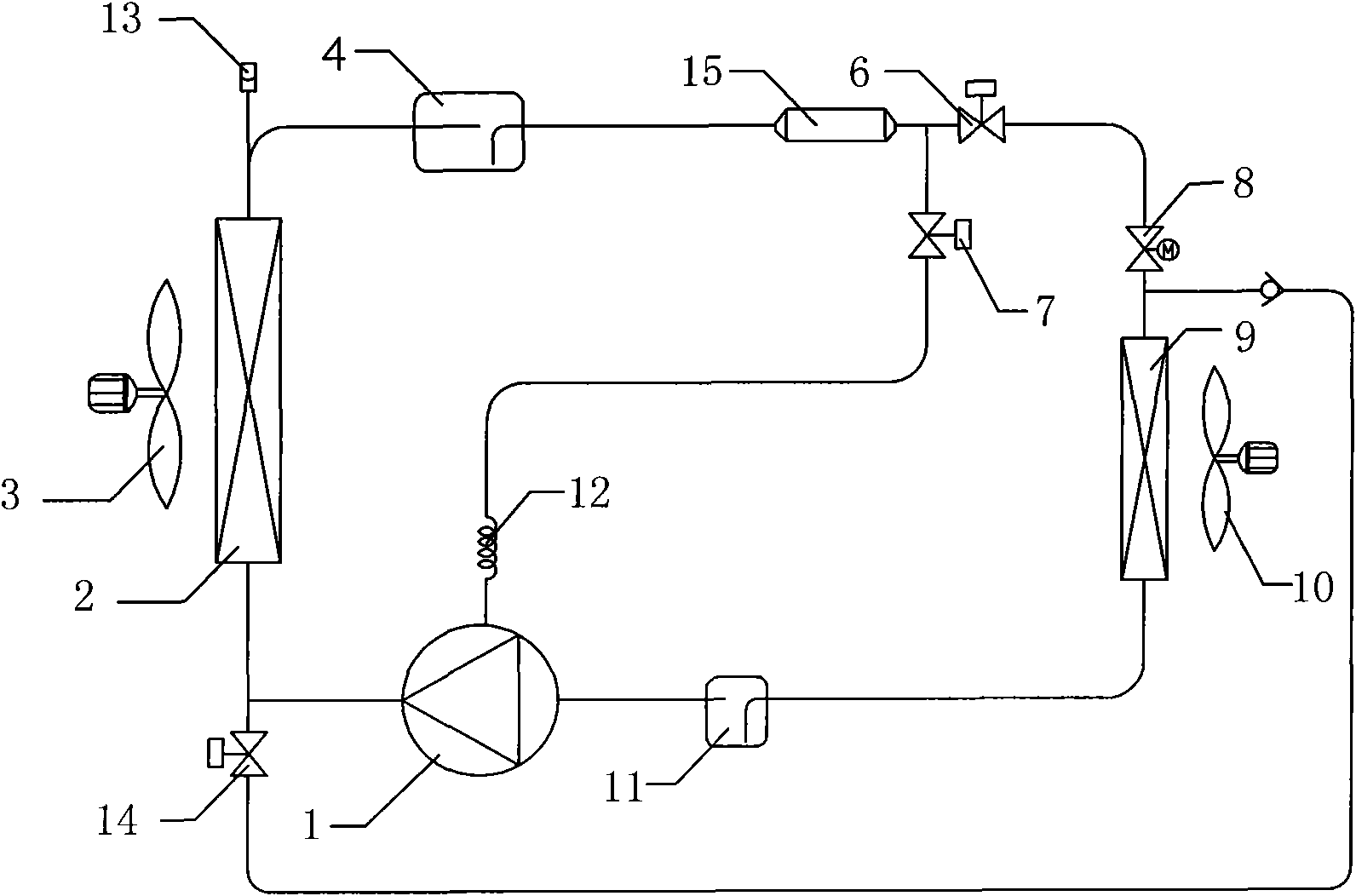

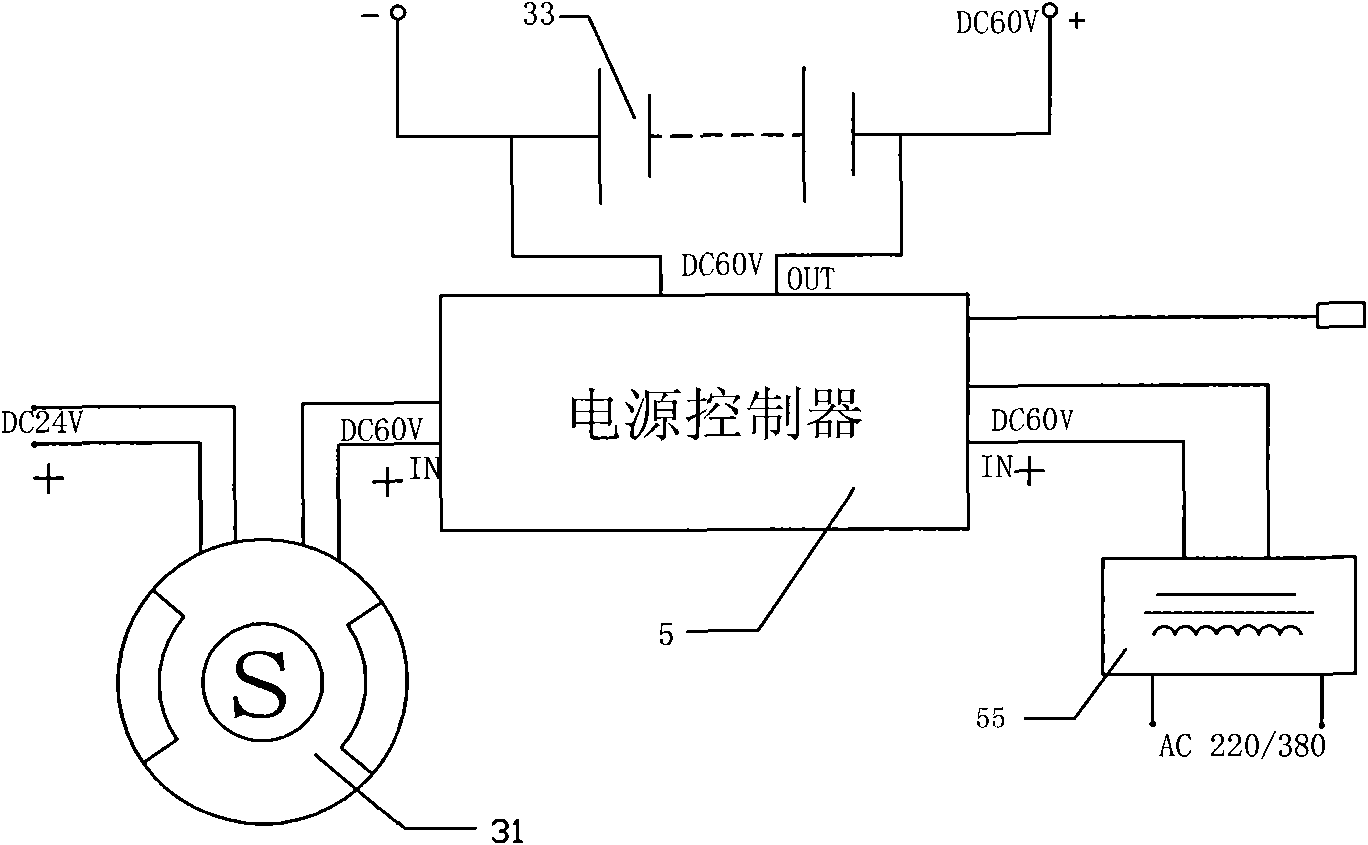

[0029] refer to Figure 1-8 : DC-driven mobile refrigeration equipment, including a built-in insulation storage body 16 of a refrigeration system, the refrigeration system includes a DC frequency conversion compressor 1, a condenser 2, a throttling device 8, and an evaporator 9 that are cycled in sequence; The DC inverter compressor 1 is a DC inverter compressor powered by DC60V; in this embodiment, the throttling device 8 is preferably an electronic expansion valve, of course, an ordinary balanced expansion valve can also be used. A power supply system is also provided in the thermal insulation storehouse body 16, and the power supply system includes a dual-power DC generator 31 capable of outputting a first DC voltage and a second DC voltage, and a storage battery 33 charged with a second DC voltage. The power supply DC generator 31 is powered by the vehicle engine, and its first DC voltage output terminal supplies power for the vehicle-mounted electrical equipment; the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com